SPANCO Jib Crane Brochure

SPANCO Jib Crane Brochure

SPANCO Jib Crane Brochure

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

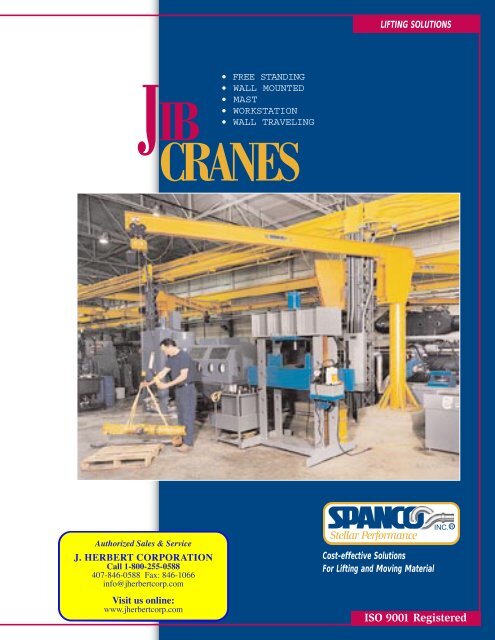

JIB CRANESTABLE OF CONTENTSWhy a <strong>Jib</strong> <strong>Crane</strong> 2How To Choose The Right <strong>Crane</strong> 2Free Standing <strong>Jib</strong> <strong>Crane</strong>s 3100 Series 4101 Series 4102 Series 5Mast <strong>Jib</strong> <strong>Crane</strong>s200 Series 6201 Series 6Wall Mounted <strong>Jib</strong> <strong>Crane</strong>s300 Series 7301 Series 8Enclosed Track Workstation <strong>Jib</strong> <strong>Crane</strong>sFree Standing 9Wall Mounted 10Special <strong>Jib</strong> <strong>Crane</strong> DesignsWall Traveling <strong>Jib</strong> <strong>Crane</strong>s 11Articulating <strong>Jib</strong> <strong>Crane</strong>s 12Retrofit Drives 13Control Panel 13Motorized <strong>Jib</strong> and Drive Systems 141

100 SERIESstandard capacities to 5 tons,special capacities to 15 tonsstandard spans to 20 ft.up to 60 ft. on requeststandardunder boomheights from8 to 20 ft.,up to 40 ft.on requestBase PlateMounted• Utilizes a hexagonal baseplate reinforced with sixknee braces equally spacedon the circumference of themast.• The base plate assemblyis secured by means ofanchor bolts to a prescribedreinforced concretefoundation, with the number of anchor boltsvarying with the capacity of the crane.• Six bolts are used for columns less than 16" indiameter and 12 bolts for columns 16" indiameter and greater.101 SERIESstandard spans to 20 ft.up to 60 ft. on requeststandardunder boomheights from8 to 20 ft.,up to 40 ft.on requeststandard capacities to 5 tons,special capacities to 15 tonsFoundationMounted• Utilizes a square steel platewhich is welded to thebottom of the column.• The plate positions andlevels the mast byanchoring it to a first-pourconcrete footing.• A second-pour foundationof reinforced concrete supports the mast. Makescomplete use of the work floor area and can beused in applications where a base plate couldhamper floor activity.4

FREE STANDING JIB CRANESFREE STANDINGJIB CRANESCost-effective SolutionsFor Lifting and MovingHeavy MaterialFREE STANDING SERIES JIB CRANECAPACITY SPAN HEIGHT MAST BOOM OVERALL BOLTTONS UNDER HEIGHT CIRCLEBOOMDIAMETER10'10'12''8" 10'-8"30"12'10'12"8" 10'-8"30"1/214'10'12" 10" 10'-10"30"16'10'12" 10" 10'-10"30"1810'12" 12" 11'-0"30"20'10'14" 12" 11'-0"36"102 SERIESstandard spans to 20 ft.up to 60 ft. on request123510'12'14'16'1820'10'12'14'16'1820'10'12'14'16'1820'10'12'14'16'1820'10'10'10'10'10'10'12'12'12'12'12'12'12'12'12'12'12'12'12'12'12'12'12'12'12"14"14"14"14"16"14"16"16"16"16"x18"16"16"x16"x18"18"24"18"20"20"24"24"24"10"10"12"12"15"15"12"12"15"18"18"18"15"15"18"20R20R24R18"18"20R24R24R25R10'-10"10'-10"11'-0"11'-0"11'-3"11'-3"13'-0"13'-0"13'-3"13'-6"13'-6"13'-6"13'-3"13'-3"13'-6"14'-6"14'-6"14'-6"13'-8"13'-8"14'-6"14'-6"14'-6"15'-0"30"36"36"36"36"42"36"42"42"42"42"48"42"42"42"48"48"60"48"54"54"60"60"60"standard capacities to 5 tons,special capacities to 15 tonsstandardunder boomheights from8 to 20 ft.,up to 40 ft.on requestSleeve InsertMounted• 360° rotation.• Utilizes a square steel platewhich is welded to thebottom of the sleeve.• Allows for relocation of themast.• The plate positions and levelsthe sleeve by anchoring it to afirst-pour concrete footing.• A second-pour foundation ofreinforced concrete supportsthe sleeve.• The mast is then placed into the sleeve where it is leveledby wedges and welded in place. 102 series can berelocated without damaging the mast.*• Makes complete use of the work floor area and can beused in applications wherea base plate couldhamper floor activity.360°ROTATION*New sleeve andfoundation wouldbe required.5

MAST JIB CRANES• <strong>SPANCO</strong> mast mounted jib cranes offer a lower cost alternative tofree standing jib cranes.• Full 360° rotation, without requiring a large mounting foundation(which can cost more than the crane).• Requires top and bottom support of the mast to building floorand overhead building steel.• Power rotation is available on all models.WARNING:<strong>Jib</strong> cranes should not be hung from any existing building structure without first consulting aqualified architect or engineer for the purpose of determining if the structure is adequate. Severebodily injury and property damage can result if this procedure is not followed.MASTJIB CRANESstandardheight to20 ft.200 SERIESstandard capacities to 5 tonsGreater spans, heights, andcapacities on requeststandard spans to 20 ft.Full Cantilever• Utilizes an I-beam for the boomand an H-beam for the column.• Two types of bearing arrangements:1. A self-aligning spherical bearing is used onthe top bearing assembly.2. A bronze bearing and bronze thrust washerare used on the bottom assembly.• Both bearing assemblies are provided withgrease fittings to provide lubrication and toaid rotation.• The boom is mounted at the top of the mastin order to provide maximum underboom clearance.MAST SERIES JIB CRANECAPACITY SPAN OVERALL MAST BOOMTONSHEIGHT201 SERIESstandard spans to 20 ft.1/210'16'20'10'10'-0"10'-0"10'-0"10'-0"10''14''14''14''8''10''12''10''116'10'-0"14''12''20'10'-0"16''15''10'12'-0"14''12''standardheight to20 ft.216'20'10'12'-0"12'-0"12'-0"18''21''16''18''20R15''standard capacities to 5 tonsGreater spans, heights, andcapacities on requestDropCantilever• Identical to the Series 200 with the addition of side-plateconnections which allow the boom to be mountedpermanently at any specified height on the mast.• Provides clearance for overhead obstructions above theboom, below the top of the mast.3516'20'10'16'20'12'-0"12'-0"14'-0"14'-0"14'-0"21''21''18''24''27''20R24R18''24R24R6

WALLMOUNTEDJIB CRANESCost-effective SolutionsFor Lifting and MovingHeavy MaterialWALL MOUNTED JIB CRANES300 SERIESstandard spans to 30 ft.(longer spans available)200°ROTATIONWALL CANTILEVER SERIES JIB CRANECAPACITY SPAN SUPPORT BEAM SUPPORTTONS BRACKET TO PIVOTCENTERSPOINT1/212310'16'20'10'16'20'10'16'20'10'16'20'4'-0"4'-0"4'-0"5'-0"6'-0"6'-0"4'-0"6'-0"6'-6"4'-0"6'-6"9'-6"8''10''12''10''12''15''12''18''20R15''18''24R3 1/2"3 1/2"3 1/2"3 1/2"3 1/2"3 1/2"4"4"4"4"4"4"standard capacitiesto 5 tons,higher capacitiesavailableWall Cantilever <strong>Jib</strong> <strong>Crane</strong>s• 200° rotation.• Offers greatest potential underboom clearance because itcan be installed more closely to the ceiling than otherwall mounted styles.• Two connection types:1. A welded connection is used in most capacity andboom spans.2. A bolted connection is used for larger spans andcapacities because of shipping considerations.Stiffeners are welded to the mast at the point wherethe wall brackets are connected to stiffen the web ofthe I-beam.• Powered rotation is available on all models.• Hardware for mounting to wall or column supplied byothers.510'16'6'-6"9'-6"18''24R6"6"20'9'-6"25R6"Wall Cantilever Kits (shown left)Customers can fabricate their own Wall Cantilever <strong>Jib</strong> <strong>Crane</strong> using the hingecomponents supplied by <strong>SPANCO</strong>. All hardware for bolting the hinges to thejib are supplied.7

WARNINGS FOR 300 AND 301 SERIES JIBSThis equipment is not, in any way, designed for the lifting, supporting, ortransporting humans. Failure to follow the specified load and mounting limitationscan result in serious bodily injury and/or property damage.<strong>Jib</strong> cranes should not be hung from any existing building structure without firstconsulting a qualified architect or engineer for the purpose of determining if thestructure is adequate. Severe bodily injury and property damage can result if thisprocedure is not followed.301 SERIES200°ROTATIONstandard capacities to 5 tonsWALL BRACKET KITSInclude all components except theI-beam, tie rod, and mountinghardware which if preferred, canbe purchased locally.standard spans to 30 ft.(longer spans available)Wall Bracket Tie Rod Supported <strong>Jib</strong> <strong>Crane</strong>s• 200° degree rotation.• Utilizes a standard I-beam boom, a tie rod threaded at bothends, a fabricated beam bracket, and two wall brackets; onefor the tie rod and one for the boom.• Allows maximum usage of the work area, including workclose to the existing structure, because there are no supportingcomponents under the boom.• This design is the most economical style of jib crane, providedoverhead clearance or building column strengthis not a limiting factor.• Hardware for mounting to wall or column supplied by others.CAPACITYTONS1/2Wall Bracket Connection• Top and bottom wall bracketsutilize a formed steel channel,with two bronze bushings,bronze thrust washers, andformed tie rod clevises.• All bolted connections are indouble shear.• All swivel connections utilizebronze bushings and greasefittings to ease rotation,promoting long life and lowmaintenance.1235WALL BRACKET SERIES JIB CRANEBRACKET SUPPORT BEAMSPAN CENTERS BRACKET BEAMTO BEAM END10'16'20'10'16'20'10'16'20'10'16'20'10'16'20'3'-0"5'-6"6'-6"3'-0"5'-6"6'-6"3'-0"5'-6"6'-6"3'-3"5'-6"7'-0"3'-3"5'-6"7'-0"1'-6"2'-0"2'-3"1'-6"2'-3"2'-6"1'-6"2'-3"2'-6"1'-6"2'-3"2'-6"1'-6"2'-6"3'-6"6"6"10"6"8"10"8"10"12"8"10"12"12"15"15"*SUPPORTTO PIVOT3 1/2"3 1/2"3 1/2"3 1/2"3 1/2"3 1/2"4"4"4"4"4"4"6"6"6"TIE RODDIAMETER1" DIA.1" DIA.1" DIA.1" DIA.1" DIA.1" DIA.1 1/2" DIA.1 1/2" DIA.1 1/2" DIA.1 1/2" DIA.1 1/2" DIA.1 1/2" DIA.2" DIA.2" DIA.2" DIA.8

ENCLOSED TRACK WORKSTATION JIB CRANESFREE STANDINGWORKSTATIONJIB CRANESCost-effective SolutionsFor Lifting and MovingHeavy MaterialFREESTANDING• <strong>SPANCO</strong> can custom design and manufacturejib cranes for any application.• <strong>SPANCO</strong> freestanding 360° rotationworkstation jib cranes are an ideal,lightweight ergonomic solution forsmaller capacity loads up to 1,000 lbs.,spans to 16 ft. Lightweight boomdesign makes the jib easier to rotateand position.360°ROTATIONMAXIMUMHEIGHTCSPANAMAST DIA.10"Counterweight BasesPortable counterweight bases are available forfreestanding workstation jibs, which allows thejib to be moved by fork lift anywhere in thefacility.• Available in capacities to 500 lbs.and spans to 16 ft., dependingon combination ofTRACKDEPTHHEIGHTUNDERBOOMspan and capacity.• Portable craneseliminate the needfor unnecessary hoisting equipment. One unit canservice multiple areas.• See form # MTJ-301BDEPTH OF FOUNDATION48"9

WALL MOUNTEDWORKSTATIONJIB CRANESWALL MOUNTED• <strong>SPANCO</strong>’swall mounted200° rotationenclosed trackworkstation jibcranes can be tie rodsupported for the lowest cost orcompression braced for maximumhead room.• Tie rod supported models can befabricated with trussed track forspans up to 34 ft.200°ROTATION7"10"C3"BDE3 1/2"2"11/16" DIA. 4 HOLES2" AWARNING:<strong>Jib</strong> cranes should not be hung from any existing building structure without first consulting aqualified architect or engineer for the purpose of determining if the structure is adequate. Severebodily injury and property damage can result if this procedure is not followed.10

WALLTRAVELINGJIB CRANESCost-effective SolutionsFor Lifting and MovingHeavy MaterialSPECIAL JIB CRANE DESIGNSWALL TRAVELING JIB CRANES• Wall traveling jib cranes are custom engineered as a perfectcomplement to an overhead crane system to perform tasksefficiently without tying up an overhead crane, also theycan be used to cover a series of workstations with little orno downtime waiting for an overhead crane.• Wall traveling jib crane end trucks use channel beam construction frames toresist twisting and are jig-fixtured and machined to maintain consistentmanufacturing tolerances. Bolt type connection to back frame for ease oferection and assembly. Top running end trucks utilize forged steel doubleflange crane wheels for long life.• <strong>Crane</strong> drive utilizes squirrel cage motor with double reduction spur gearreducer.• Standard single speed controls include mainline contactor, control transformer,inverter acceleration control and fuses in NEMA 3R, 4, 12 control enclosures.• Multi-speed units are equipped with variable frequency drives.• <strong>Jib</strong> boom is fabricated from standard “S” beam with vertical angle truss toreduce deflection. <strong>Jib</strong> boom and truss bolt to back frame for ease of erectionand assembly.• A professional architect or engineer should approve any wall traveling jibapplication since forces exerted on a building structure are severe.<strong>SPANCO</strong>manufacturers themost complete line ofcustom designed andstandard jib cranes inthe United States.11

ARTICULATING JIB CRANESFree StandingARTICULATINGJIB CRANES• Articulating jib cranes can move loads around cornersand columns, reach into machinery and containers andservice an area from close to the pivot point to the end ofthe boom for 360° of operation. Capacities from 150 to2,000 lbs., spans to 16 ft.• Articulating jibs can be floor, wall, ceiling, or bridgecrane mounted to best suit your application.• Free standing and ceiling mounted series offer360° rotation with options tointernally pipecompressed air,vacuum orelectrificationto any devicesupported on theend of the boom.360°ROTATIONBridge and Ceiling Mounted• <strong>SPANCO</strong>’s bridge mountedarticulating jib design offersmore headroom than those byother manufacturers.• Bridge mounted jibs cansupport nearly any type ofmanipulator, balancer,or hoist.12

OPTIONS FORJIB CRANESCost-effective SolutionsFor Lifting and MovingHeavy MaterialRETROFIT DRIVE• <strong>SPANCO</strong>’s retrofit drive will fit all free standing jib cranes with a box stylehead assembly. Our modular style bolts to the back of the head assembly.High efficiency electric motor and worm gear reducer power large steelrollers with polyurethane treads, insuring good traction. Drive rollers areeasily adjusted through spring tension insuring constant driving force.• Standard unit is single speed with mainline contactor, reversingcontactor, control transformer and fusing with a NEMA 3R control panel.Options include:• Multi-speed control, special controlenclosures, air drives and specialprotective coatings.• Retrofit drive kits are a costeffective method to upgrade anexisting freestandingjib crane or a lower costalternative to power rotatea new jib crane.CONTROL PANEL• <strong>SPANCO</strong> Standard Single Speed Control Panel - Includes mainlinecontactor, reversing magnetic contactors, thermal overload, 110Vfused control transformer, branch circuit fusing to crane motor andsolid state adjustable “soft start” control adjustable for time andtorque in a NEMA 3R enclosure.• <strong>SPANCO</strong> offers a variable frequency drive option, whicheliminates the need for reversing contactors, and allows formulti-speed operation of jib cranes. Variable frequency driveprovides infinitely variable speed options for maximum controland load positioning from micro speed to full speed, both inacceleration and deceleration phases.• Optional control panels meet requirements for NEMA 12 and 4environments for outdoor and indoor use.• Explosion-proof enclosures and wiring are available forhazardous environments.13

MOTORIZED JIBS AND DRIVE SYSTEMS• <strong>SPANCO</strong> motorized jibs are custom designed to fit yourrequirements.• Standard drive package is of chain and sprocket design,which provides positive traction, eliminating the slippagecommon to tractor-type drives or drives which power theroller assemblies and increases durability of the drive unitby not driving on load-bearing roller assemblies. Includesfield-adjustable torque limiter for drive protection, wormgear reducer in oil bath lubrication for long lasting reliableoperation and low maintenance. TEFC 30 minute ratedmotors are standard with thermal overload protection.Direct chain and sprocket drive allows for accurate andeasy positioning of loads.• Wall cantilever, wall bracket and mast type design utilizethe same basic drive as the freestanding jib crane,guaranteeing high performance and reliability.Options include:• Stainless steel wear rings for corrosive or spark resistantapplications, air drives for spark resistant applications,gear and pinion drive components for accurate positioningor high duty cycles, special control enclosures and wiringfor hazardous locations, multi-speed units for delicatehandling situations, and protective coatings: galvanizing,epoxy, Steelit, etc. just to name a few.• All <strong>SPANCO</strong> motorized jibs are designed, with thecustomer in mind, for ease of maintenance. All drive partsare easily accessible for lubrication and adjustment.As a leadingmanufacturer ofmotorized jib cranesin the U.S., <strong>SPANCO</strong>can design a crane tosolve your mostproblematic materialhandling need.14

ededStellar PerformanceLIFTING SOLUTIONSLIFTING SOLUTIONSStellar PerformanceISO 9001 RegisteredISO 9001 RegisterLIFTING SOLUTIONSStellar PerformanceISO 9001 RegisteredAluminumenclosed track linefrom Spanco:Alu-Track®Two track profilesCapacities to 3000 lb.Spans to 29 ft.1 CertifiedLIFTING SOLUTIONSStellar PerformanceISO 900Precision design, for precise lifting solutions.®LIFTING SOLUTIONSJIB CRANESCost-effective SolutionsFor Lifting and MovingHeavy MaterialWe have the solution for all your material handling needs.STAND ALONEWORKSTATIONBRIDGE CRANESStand AloneWorkstationBridge <strong>Crane</strong>sGANTRYCRANESGantry <strong>Crane</strong>sCost-effective SolutionsFor Lifting and Moving MaterialCost-effective SolutionsFor Lifting and Moving MaterialCEILING MOUNTEDWORKSTATIONBRIDGE CRANESCeiling MountedWork StationBridge <strong>Crane</strong>sAluminumWork StationBridge <strong>Crane</strong>sSmooth as Silk PerformanceCost-effective SolutionsFor Lifting and Moving MaterialsWORKSTATIONJIB CRANESWork Station<strong>Jib</strong> <strong>Crane</strong>sFall Arrest TrackCost-effective SolutionsFor Lifting and Moving MaterialStellar PerformanceMorgantown Business Park604 Hemlock RoadMorgantown, PA 19543 U.S.A.INC. RTo request the featured literature.,contact your authorized <strong>SPANCO</strong>distributor or call <strong>SPANCO</strong> at thenumbers listed below.Tel: (610) 286-7200 Fax: (610) 286-0085800-869-2080 Canada & U.S.A.95-800-270-1080 MexicoVisit <strong>SPANCO</strong>’s Web site: www.spanco.comForm # JC001 02/05