GM 300 Instruments - Guhring

GM 300 Instruments - Guhring

GM 300 Instruments - Guhring

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

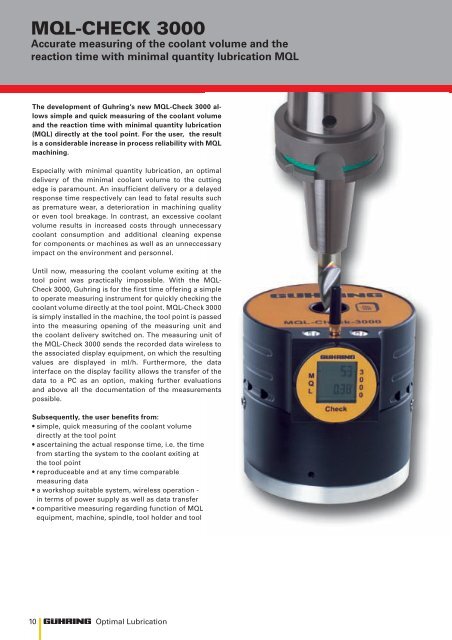

MQL-Check <strong>300</strong>0Accurate measuring of the coolant volume and thereaction time with minimal quantity lubrication MQLThe development of <strong>Guhring</strong>‘s new MQL-Check <strong>300</strong>0 allowssimple and quick measuring of the coolant volumeand the reaction time with minimal quantity lubrication(MQL) directly at the tool point. For the user, the resultis a considerable increase in process reliability with MQLmachining.Especially with minimal quantity lubrication, an optimaldelivery of the minimal coolant volume to the cuttingedge is paramount. An insufficient delivery or a delayedresponse time respectively can lead to fatal results suchas premature wear, a deterioration in machining qualityor even tool breakage. In contrast, an excessive coolantvolume results in increased costs through unnecessarycoolant consumption and additional cleaning expensefor components or machines as well as an unneccessaryimpact on the environment and personnel.Until now, measuring the coolant volume exiting at thetool point was practically impossible. With the MQL-Check <strong>300</strong>0, <strong>Guhring</strong> is for the first time offering a simpleto operate measuring instrument for quickly checking thecoolant volume directly at the tool point. MQL-Check <strong>300</strong>0is simply installed in the machine, the tool point is passedinto the measuring opening of the measuring unit andthe coolant delivery switched on. The measuring unit ofthe MQL-Check <strong>300</strong>0 sends the recorded data wireless tothe associated display equipment, on which the resultingvalues are displayed in ml/h. Furthermore, the datainterface on the display facility allows the transfer of thedata to a PC as an option, making further evaluationsand above all the documentation of the measurementspossible.Subsequently, the user benefits from:• simple, quick measuring of the coolant volumedirectly at the tool point• ascertaining the actual response time, i.e. the timefrom starting the system to the coolant exiting atthe tool point• reproduceable and at any time comparablemeasuring data• a workshop suitable system, wireless operation -in terms of power supply as well as data transfer• comparitive measuring regarding function of MQLequipment, machine, spindle, tool holder and tool10 Optimal Lubrication