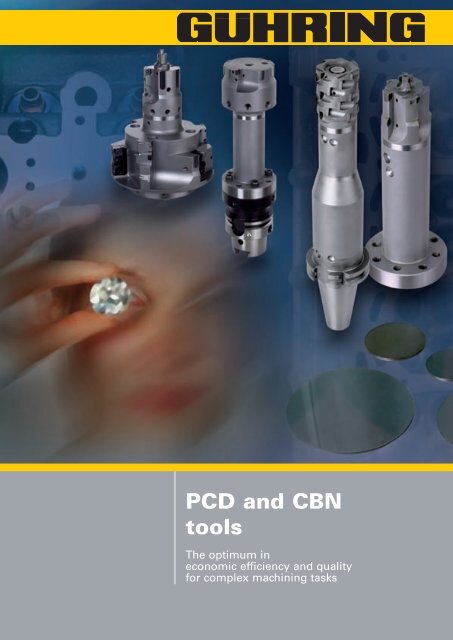

PCD and CBN tools - Guhring

PCD and CBN tools - Guhring

PCD and CBN tools - Guhring

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> from <strong>Guhring</strong> page 5<strong>Guhring</strong> is one of the leading suppliers of <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>with world-wide production <strong>and</strong> service facilities.From natural diamond to synthetic <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> page 6A natural diamond possesses numerous characteristics that makes it the ideal toolmaterial. However, the industry believes it is not perfect enough.This is the reason why synthetic tool materials such as <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> were developed.Advantages <strong>and</strong> application ranges page 8<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> are especially suitable for the machining of difficult-to-machine,highly abrasive materials offering highest quality <strong>and</strong> economic efficiency.Application examples: aviation <strong>and</strong> automotive page 10The automotive, aviation <strong>and</strong> aerospace industries apply <strong>Guhring</strong> <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>for especially dem<strong>and</strong>ing operations such as the machining of cylinder heads or theproduction of rivet holes in aeroplanes.Our tool program page 12A speciality of <strong>Guhring</strong>‘s <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> tool production are customer specific special <strong>tools</strong>for highly complex machining tasks.Process design for optimal results page 14The application of <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> is only the first step to success.Decisive for a highly efficient production is the design of the complete process.Here, <strong>Guhring</strong> gives customers the benefit of a long-st<strong>and</strong>ing know-how.Service for the entire tool life page 16<strong>Guhring</strong>‘s technical field service <strong>and</strong> service centres all over the worldensure a continuous <strong>and</strong> comprehensive support for our <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> customers.Contacts page 18Specialist technicians are available for further information in all matters of design<strong>and</strong> application of <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>.Production in the new plant II in AlbstadtComplete state-of-the-artGÜHRING PKD-Werkzeuge xx

The new plant II in Albstadt / GermanyChoongnam / KoreaBrookfield / USA4 GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>

<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> from <strong>Guhring</strong>Global know-howThe development <strong>and</strong> productionof <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> hasbeen one of <strong>Guhring</strong>‘s high-techsectors since the mid 80‘s. At threeproduction locations, Germany,Czech Republic <strong>and</strong> USA, innovative<strong>and</strong> complex <strong>tools</strong> are developedglobally for highly specialisedmachining tasks.New <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> productionCentre-piece of our <strong>PCD</strong> <strong>and</strong><strong>CBN</strong> production is our facility inAlbstadt, located in a purposebuilt,state-of-the-art building sinceearly 2004. Here, a workforce ofapproximately 200 develops <strong>and</strong>produces predominantly customerspecific special <strong>tools</strong> but alsost<strong>and</strong>ard <strong>tools</strong>. In addition, designguidelines with world-wide validityare also developed <strong>and</strong> stipulatedhere.Locations in USA, Korea <strong>and</strong>Pol<strong>and</strong><strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> have beenproduced in USA since 2001.Specifically trained field serviceengineers <strong>and</strong> an in-house designfacility offer our customers onthe American continent optimalsupport.In addition to the <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong>production in USA, <strong>Guhring</strong> openedindependent plants in Korea <strong>and</strong>Pol<strong>and</strong>. Service centres for regrinding<strong>and</strong> re-tipping of <strong>PCD</strong> <strong>and</strong><strong>CBN</strong> <strong>tools</strong> are established in China,Great Britain, Italy, Mexico <strong>and</strong> Indiato offer a real global development<strong>and</strong> production service for these<strong>tools</strong>.The application of the same type ofmachines at all locations ensuresan identical quality st<strong>and</strong>ard. Theorigin of the <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> isimmaterial, the customer alwaysreceives a consistently high quality.Equally, it doesn‘t matter which<strong>Guhring</strong> <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> plant thecustomer contacts, the selectedtool is available at every location.Competent personnelThe high dem<strong>and</strong>s for processknowledge <strong>and</strong> tool technologyrequires a competent workforce.Basic pre-requisite for the succcessof <strong>Guhring</strong>‘s <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong>production is therefore our highlyqualified technical personnel.Continuous training ensures thatall personnel are constantly up-todatewith the latest technologies<strong>and</strong> know-how.Tough <strong>and</strong> resistant:Tools with <strong>CBN</strong> cutting edgesfor hard steels <strong>and</strong> cast materialsStrong insertsCarbide interchangeable inserts with<strong>PCD</strong>- <strong>and</strong> <strong>CBN</strong>-tippedRegalHighly complex flexible <strong>tools</strong>are our specialityGUHRING <strong>PCD</strong> und <strong>CBN</strong> <strong>tools</strong> 5

… to synthetic <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong><strong>PCD</strong> – a super-hard tool materialBecause diamonds have alwaysbeen very valuable, mankindhas attempted to artificially recreatediamonds – by means of magic <strong>and</strong>alchemy of course without success.However, natural science hasincreasingly unearthed the secretof the diamond <strong>and</strong> opened thedoor for a synthetic production.20 tons per annumThe first synthetic diamond wascreated at General Electric, USA in1955. More or less simultaneously,ASEA in Sweden developed asimilar process. With this specialprocess, at a temperature between1500° C <strong>and</strong> 1800° C <strong>and</strong> a pressureof between 53,000 <strong>and</strong> 100,000bar, synthetic diamonds up to 1mm diameter are produced fromgraphite, marketed under the name<strong>PCD</strong> (polycrystalline diamond).Currently, the annual productionof <strong>PCD</strong> is approximately 20 tons,primarily applied for cutting <strong>tools</strong>,grinding powder <strong>and</strong> for theproduction of cutting wheels.The advantage of <strong>PCD</strong> is primarilyits consistent high quality – afundamental pre-requisite for thefurther machining of <strong>tools</strong> with thesame characteristic.<strong>CBN</strong> – a tough alternativeCubic boron nitride (<strong>CBN</strong>) is ahigh-performance tool materialfrom a polycrystalline mass, thatsimilar to <strong>PCD</strong> is produced in a hightemperature-pressure process.<strong>CBN</strong>, its hardness only surpassedby a diamond, is suitable forthe machining of materials thatcannot be machined with <strong>PCD</strong> ormonocrystalline diamond. Themain application range is ferrousmaterials possessing a hardnessfrom approximately 45 HRC as wellas grey cast iron, Cr-chilled cast iron<strong>and</strong> wear alloys on a cobalt, nickelor iron basis.In contrast to <strong>PCD</strong> <strong>and</strong> diamond,<strong>CBN</strong> does not react with thecarbide constituents existingin these materials. Also of noconsequence are the occurringmachining temperatures, because<strong>CBN</strong> only reacts with oxygen froma temperature of approximately1200° C <strong>and</strong> subsequently possessesan unequalled thermal hardness.Only in so-called super-alloys inthe aircraft or reactor industry witha distinctive austenitic phase <strong>and</strong>simultaneously high toughnessdo <strong>CBN</strong> <strong>tools</strong> generally reachtheir application limits. Typicalrepresentatives are high Ni-alloyedmaterials such as Inconel 718or Nimonic. For these materialsmachining trials are necessary toclarify the application possibility.Synthetically produced<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> circular blanksLike a puzzleThe segment separation is performedwith optical programsBear strength<strong>PCD</strong> or <strong>CBN</strong> equipped face milling cutterGUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 7

Advantages of <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>Powerful <strong>and</strong> economicalTools with <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> cuttingedges are the ideal solution fordifficult-to-machine, highly abrasivematerials. These <strong>tools</strong> achievehighest quality <strong>and</strong> economicefficiency. The result: Long tool life,highest surface quality, optimalprocess reliability <strong>and</strong> repeatability.CFK is probably the most suitablefuture material applied in the aircraftindustry thanks to its high rigidity<strong>and</strong> low weight. A consequenceof this development is the difficultmachining. The abrasive wear leadsto a visible rounding of carbidecutting edges within a short time(fig. 2). This results in the fibres nolonger being cut but squashed <strong>and</strong>then being ripped from the laminate(delamination).The range of application of our<strong>PCD</strong> <strong>tools</strong> begins with applicationsthat have the highest dem<strong>and</strong>s onsurface quality.However, in order to take fulladvantage of their performancepotential, the customer‘sproduction must fulfil certainminimum requirements. Thisincludes applying the <strong>tools</strong> on rigid<strong>and</strong> vibration-free machines as wellas highly accurate spindle bearingsor slide ways respectively.Figure 1: <strong>PCD</strong> toolConvincing, wear-resistant diamond cutting edge<strong>PCD</strong> <strong>tools</strong> do not display the typicalinitial wear (fig. 1), but guaranteeno delamination tendencies duringthe machining process thanks to theextremely resilient diamond cuttingedge.Figure 2: CarbideVisible rounding of cutting edge after short time8 GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>

Photograph: Airbus S.A.S.Assembly of the new Airbus A380Where the precision of<strong>Guhring</strong> <strong>tools</strong> counts.Photograph: Airbus S.A.S.ApplicationSatisfying highest dem<strong>and</strong>s<strong>PCD</strong> is especially suitable for thedrilling, milling <strong>and</strong> reamingof non-ferrous materials, light <strong>and</strong>heavy metals, fibre-reinforcedplastics, ceramics as well assynthetic glass.<strong>CBN</strong> is especially efficient for themachining of hardened steels <strong>and</strong>pearlitic cast materials.These materials are currentlyspecifically applied in theautomotive <strong>and</strong> aerospace industryas well as in the machine toolindustry.GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 9

Field of application - Aircraft industryHigh-tech <strong>and</strong> the dream of flyingThe increasing dem<strong>and</strong>s onaeroplanes, helicopters, rockets<strong>and</strong> satellites drives forward thecontinuous development of newmaterials, especially syntheticcomposite materials or specialalloys. The machining of thesematerials is, however, becomingincreasingly more difficult. Inaddition, the quality <strong>and</strong> precisionrequirements of the aerospaceindustry are constantly increasing.processes ensures that the <strong>tools</strong>developed by <strong>Guhring</strong> achieve therequired quality <strong>and</strong> economicalcutting parameters as well as toollife.The solution:<strong>Guhring</strong>‘s <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> know-howIn many cases it is the high hardness<strong>and</strong> the very sharp cutting edges of<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> that actuallymakes the machining of modernmaterials applied in the aerospaceindustry possible. In addition,<strong>Guhring</strong>‘s extensive know-how inthe <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> sector regardingthe design of <strong>tools</strong> <strong>and</strong> machiningPhotograph: EurocopterComplete trust in <strong>Guhring</strong>:Eurocopter, the market leaderAirbus application:<strong>Guhring</strong> <strong>tools</strong> with <strong>PCD</strong> cutting edges10 GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>Technology leader - Airbus:Composite materials require<strong>PCD</strong> or <strong>CBN</strong> <strong>tools</strong> respectively

Photograph: Volkswagen AG*Field of application - Automotive industryBetter performance - less fuel consumptionMulti-faceted application:Milling, drilling <strong>and</strong> reaming of atransmission housing.Lightweight construction forbetter performance <strong>and</strong> lessfuel consumption in the automotiveindustry is leading increasinglyto the application of specialmaterials such as aluminium<strong>and</strong> magnesium alloys in thisfield. Typical workpieces are, forexample, engine blocks, cylinderheads, crankshafts <strong>and</strong> camshaftsas well as transmission housings– ideal for the application of <strong>PCD</strong><strong>and</strong> <strong>CBN</strong> <strong>tools</strong>.Fine machining:Slide valve holes in a control plate.Photograph: Volkswagen AG*Complete machining:Motor mountings in a revolving machine*Publication with kind permission of Volkswagen AGDem<strong>and</strong>ing:Complete machining of cylinder headSafety components:Drilling <strong>and</strong> reaming a master brake cylinderGUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 11

The <strong>CBN</strong> tool programSt<strong>and</strong>ard <strong>and</strong> highly complex special <strong>tools</strong><strong>Guhring</strong>‘s <strong>CBN</strong> tool rangeincludes, dependent onthe range of application, drills,milling cutters, reamers <strong>and</strong>interchangeable inserts. These<strong>tools</strong> are applied in the automotive<strong>and</strong> medical industry as well asother specific applications. Forexample, <strong>CBN</strong> <strong>tools</strong> from <strong>Guhring</strong>are successfully <strong>and</strong> economicallyapplied in the production of wheels,pumps <strong>and</strong> shafts.A small selection from our<strong>CBN</strong> tool programGUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 13

Process design for optimal resultsThe machining process should be observed in its entiretyTo take full advantage of theefficiency of <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>,the complete machining processshould be looked at. This applies tothe application of complex specialsolutions combining severalmachining steps in one tool.From process design to theapplication of the tool in volumeproduction, <strong>Guhring</strong>‘s completeknow-how is available to thecustomer. World-wide, <strong>Guhring</strong>‘stechnical field service engineers for<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> provide adviceto customers on-site.State-of-the-art production processWorld-wide, a total workforce ofin excess of 200 is engaged in thedevelopment <strong>and</strong> production of<strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>.State-of-the-art CAD programs <strong>and</strong>computers provide support to personnelin their development workthat is carried out in close consultationwith the customer. Simulataneousengineering guaranteesa continuous interaction between<strong>Guhring</strong> <strong>and</strong> its customers – worldwidewithout complication thanksto three <strong>Guhring</strong> locations.1. Tool design <strong>and</strong>imperfection inspection.2. Design 3. Planning <strong>and</strong>co-ordination.14 GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>

Highest dem<strong>and</strong>sHighest production accuracy is dem<strong>and</strong>edfor the new high-performance engines inthe automotive industry.4. Acquisition <strong>and</strong>production.5. Assembly <strong>and</strong>pre-adjustment.6. Packing <strong>and</strong>despatch.GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 15

Die 1. ToolDienstleistungarrival,…Unser Service rund um‘s Werkzeug2. …incoming toolinspection,…3. …re-grinding<strong>and</strong>/or…After Sales ServiceFrom refurbishing, includingre-grinding, re-tipping <strong>and</strong> re-coating,to a complete Tool Management,you can rely on our know-how.16 GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>

4. …re-tippingof <strong>tools</strong>, …5. …final inspectionfollowed by…6. …the deliveryto the customer.Service - for the entire tool lifeFor the benefit of our customersNaturally, <strong>Guhring</strong>‘s servicecommitment doesn‘t endwhen the <strong>tools</strong> are delivered to ourcustomers. We continue to takecare of our products, including <strong>PCD</strong><strong>and</strong> <strong>CBN</strong> <strong>tools</strong>, for the duration oftheir application – world-wide. Thisincludes customer support on-siteby our technical field service aswell as a comprehensive serviceprogram.RefurbishmentFor the <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> sector ourservice includes the refurbishmentof worn but also the repair ofdamaged <strong>tools</strong>.Prior to the refurbishment we carryout a comprehensive inspection ofthe incoming tool <strong>and</strong> determinethe overall work required for therefurbishment. In accordance withthe result of the incoming toolinspection we choose the mostpractical <strong>and</strong> economical way toproceed in close co-operation withthe customer: to refurbish the toolor to supply a new tool.Our refurbishment service alsoincludes the re-tipping of heavilyworn <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> cutting edges,if there is only slight wear we canre-grind the cutting edge. A finalinspection <strong>and</strong> the return of the asnew tool follows.Tool ManagementNaturally, <strong>Guhring</strong> not only providesa re-tipping or re-grinding service foryour <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> cutting <strong>tools</strong> viaour <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> tool production.<strong>Guhring</strong>‘s service division providesa complete tool management – notonly for <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>, but forall your <strong>tools</strong>!GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 17

USA<strong>Guhring</strong>, Inc.1445 Commerce Ave.WI 53045 BrookfieldPhone +1 26 27 84 67 30Fax +1 26 27 84 90 96sales@guhring.comGreat Britan<strong>PCD</strong> Service Centres forRe-tipping <strong>and</strong> Re-grinding<strong>Guhring</strong> Ltd.Castle Bromwich Business ParkTameside DriveBirmingham B35 7AGPhone +44 121 776 80 10Fax +44 121 747 79 64info@guhring.co.ukGermanyGühring oHGSigmaringer S72458 AlbstadPhone +49 74Fax +49 74 31info@guehrinMexico<strong>PCD</strong> Service Centres forRe-tipping <strong>and</strong> Re-grinding<strong>Guhring</strong> Mexicana S.A. de C.V.Av. Del Marqués No. 62Parque Ind. Bernardo QuintanaEl Marqués76246 QuerétaroPhone +52 44 22 21 61 92Fax +52 44 22 21 61 94guhring.mexicana@guehring.deItaly<strong>PCD</strong> Service Centres forRe-tipping <strong>and</strong> Re-grindingGühring s.r.l. unipersonaleVia 1o Maggio, 1523873 Missaglia (LC)Phone +39 0 39 59 31 51Fax +39 03 99 24 16 03Our technical field serviceCompetent support provided by qualified personnelspecifically trained <strong>and</strong>A qualified technical field serviceteam provides global support in allmatters regarding the applicationof <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>. <strong>Guhring</strong><strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> technicians analyseeach specific machining processon-site with the customer. Thetechnicians then work out theoptimal tool solution in closeco-operation with the customer <strong>and</strong>with support provided by the tooldesign department <strong>and</strong> production.Furthermore, they provide on-sitesupport for the initial trial run <strong>and</strong>of course for the duration of theentire production run.18 GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong>

tr. 160t31 17-017-2 79g.dePol<strong>and</strong>Gühring Katowice sp. z.o.o.ul.Tworzen 16241308 Dabrowa GorniczaPhone +48 3 22 62 80 69Fax +48 3 22 61 57 58biuro@guehring.plKoreaGühring Korea Co. Ltd.895 Munbong-riMyunchunmyun-MyonDangjingun343-880 ChoongnamPhone +82 26 89 85 42Fax +82 26 89 97 32guhring@unitel.co.krCzech RepublicGühring s.r.o.Na Perkách33021 Line-SulkovPhone +42 03 77 91 10 16Fax +42 01 97 91 10 18infomace@guehring.czIndia<strong>PCD</strong> Service Centres forRe-tipping <strong>and</strong> Re-grinding<strong>Guhring</strong> (India) Pvt. Ltd.No. 129, Bommas<strong>and</strong>ra Ind. Area4th PhaseBangalore - 560 099Phone +91 0 80 22 89 25 00Fax +91 0 80 22 89 25 10China<strong>PCD</strong> Service Centres forRe-tipping <strong>and</strong> Re-grinding<strong>Guhring</strong> (Changzhou)Cutting Tools Co., Ltd.No. 19, E Mei Shan RoadXin Bei District213022 ChangzhouPhone +86 5 19 8 51 09 71 31 00Fax +86 5 19 8 51 04 83 2info@guhringchina.comWorld-wide networkIn addition to a specialised <strong>PCD</strong><strong>and</strong> <strong>CBN</strong> field service, <strong>Guhring</strong>provides a comprehensive supportnetwork for its customers onevery continent. This includes aworld-wide technical field servicewith in excess of 130 applicationtechnicians <strong>and</strong> technical fieldservice engineers, 26 productioncentres, 36 service centres for regrinding<strong>and</strong> re-coating as well assubsidiaries in 43 countries <strong>and</strong>marketing partners all over theworld.GUHRING <strong>PCD</strong> <strong>and</strong> <strong>CBN</strong> <strong>tools</strong> 19

Gühring oHGHerderstraße 50 - 5472458 AlbstadtTel. +49 74 31 17-0Fax +49 74 31 17-2 79www.guehring.de078 579/0998-XI-22 • Printed in Germany