SUPRATON® High Shear In-line Mixers for Polymer Modified Bitumen

SUPRATON® High Shear In-line Mixers for Polymer Modified Bitumen

SUPRATON® High Shear In-line Mixers for Polymer Modified Bitumen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BWS Technologie GmbH<br />

Nordstrasse 41<br />

41515 Grevenbroich, Germany<br />

Phone: +49(21 81)60 20<br />

Fax: +49(21 81)60 23 42<br />

E-Mail: bws@bws-technologie.de<br />

Buckau-Wolf<br />

SUPRATON<br />

<strong>SUPRATON®</strong><br />

www.bws-technology.com<br />

BWS<br />

Technologie GmbH<br />

SUPRATON ® <strong>High</strong> <strong>Shear</strong> <strong>In</strong>-<strong>line</strong> <strong>Mixers</strong><br />

<strong>for</strong> <strong>Polymer</strong> <strong>Modified</strong> <strong>Bitumen</strong><br />

<strong>SUPRATON®</strong> <strong>High</strong> <strong>Shear</strong> <strong>In</strong>-<strong>line</strong> <strong>Mixers</strong> have been successfully in use in the production of polymer<br />

modified bitumen <strong>for</strong> more than 15 years.<br />

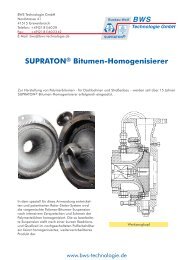

For this application a special patented rotor/<br />

stator system has been developed. This system<br />

homogenizes the premixed polymer suspension<br />

by intensive squeezing and shearing of the<br />

polymer particles. After a short reaction and<br />

swelling time such polymer suspension is an<br />

excellent homogeneous bitumen product.<br />

Cross Section Drawing

The <strong>SUPRATON®</strong> Mixer is characterized by an enormous lifetime of tooling and a minimum of maintenance.<br />

Together with the unique hydraulic working gap adjustment you get the most reliable, efficient<br />

and trouble free operating mill.<br />

Technical Data<br />

Type 349-5.03 449-5.03 549-5.03<br />

Tool Set Progressively-turned, wedge-shaped shear gap and<br />

toothed ring rotor-stator system<br />

Product Wetted Parts SS 316Ti, special carbon steel hardened<br />

Bearings Cylindric roller-/angular ball bearings with oil lubrication<br />

Speed 4,800 rpm 3,000 rpm (3,600 rpm 2,000 rpm (1,800 rpm)<br />

Power Transmission V-belt drive Torsionally flexible<br />

coupling<br />

www.bws-technology.com<br />

V-belt drive<br />

(coupling)<br />

Drive 45–75 kW 90 – 160 kW 160 – 300 kW<br />

Capacity – 15 m 3/h (– 60 gpm) – 30 m 3/h (– 120 gpm) – 60 m 3/h (– 240 gpm)<br />

<strong>Polymer</strong> Content 3 – 20 mass %<br />

Pumping Effect 10 m L.C.<br />

Heating Jacket Heatable up to 240 °C (465 °F)<br />

Working Gap Hydraulically-actuated axial shaft movement<br />

Gap Setting Standard: open - closed<br />

Optional: stepless hydraulic setting available