WIDIA-Hanita / WIDIA-Rubig Catalog - Tyson Tool Company Limited

WIDIA-Hanita / WIDIA-Rubig Catalog - Tyson Tool Company Limited

WIDIA-Hanita / WIDIA-Rubig Catalog - Tyson Tool Company Limited

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

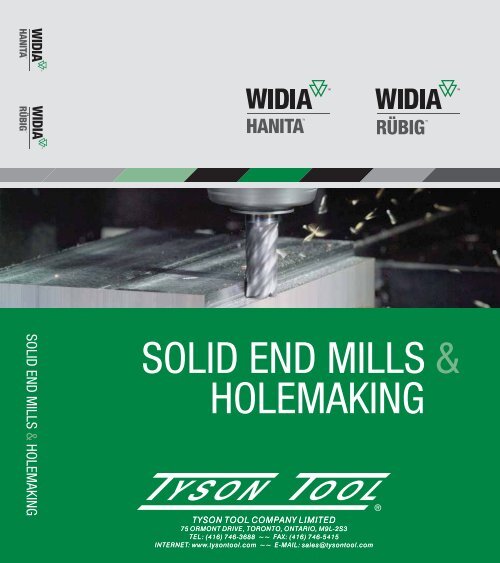

SOLID END MILLS & HOLEMAKINGSOLID END MILLS &HOLEMAKING

<strong>WIDIA</strong>-<strong>Hanita</strong> and <strong>WIDIA</strong>-Rübig Mean Complete QualityAs an innovator for more than 80 years, the <strong>WIDIA</strong> Products Group hasbeen designing and manufacturing metalcutting products that makecustomer machining processes more efficient and effective.With thousands of products in our portfolio, including well-respected brandssuch as <strong>WIDIA</strong>-<strong>Hanita</strong> and <strong>WIDIA</strong>-Rübig, the <strong>WIDIA</strong> Products Group offerscompetitive advantages that will enhance your productivity and bolsteryour profitability.To learn more, contact your Authorized <strong>WIDIA</strong>-<strong>Hanita</strong> or <strong>WIDIA</strong>-RübigDistributor or visit www.widia.com.SOLID END MILLS &HOLEMAKINGtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

Solid End Mills & HolemakingSolid End Mills & HolemakingIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii–viiSolid End Mills • Inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1–A190Solid End Mills • Metric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B1–B315Holemaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C1–C165Custom Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D1–D10Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E1–E7Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F1–F63Index by Order Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G2–G34Index by <strong>Catalog</strong> Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G35–G67Global Metalworking Sales Offices/Authorized <strong>WIDIA</strong> Distributors . . . . . . . . . . . . . . . . . . .H2–H3tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

<strong>WIDIA</strong>-<strong>Hanita</strong> • <strong>WIDIA</strong>-Rübig mean complete qualityWhen you buy products from the <strong>WIDIA</strong> family of brands, you’re not just buying speed, power,and precision — you’re buying complete quality.As an industry-leading manufacturer of cutting tools, <strong>WIDIA</strong> brands offer the most complete portfolio of precision-engineeredproducts and custom solution services available today. With thousands of products in our portfolio and a skilled networkof Authorized Distributor partners, you’ll find everything you need.80 Years of Quality1925Application to register“<strong>WIDIA</strong>” as a trademark1952Ernst RübigPrecision<strong>Tool</strong> wasfounded1962First patent grantedfor coated carbideinserts1972New Rübigfactoryopens inNabburg2000QS 9000 TESand VDA 6.4certification forthe <strong>WIDIA</strong>operationsin Essen andLichtenau2006<strong>WIDIA</strong>celebrates80 years2008Launch of the newTurning InsertsTN5105 andTN51201926Tungsten carbideproduction begins1955<strong>Hanita</strong> wasestablished1968Launch of firstglobal coatedgrade1999WavCut islaunched globally2002<strong>Hanita</strong> launchesVariMill I program2009<strong>WIDIA</strong>-<strong>Hanita</strong> •<strong>WIDIA</strong>-<strong>Rubig</strong> brands join the<strong>WIDIA</strong> family2007Acquisition ofManchesterCutting <strong>Tool</strong>sand Clapp-DiCO;<strong>WIDIA</strong>-Manchesterand <strong>WIDIA</strong>-Clapp-DiCObrands are borniitel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

Custom Solutions forSolid End Mills and HolemakingWe are dedicated to designing and developing special milling and holemaking solutions for demanding operations and focusedmanufacturing. Our factory engineers, production experts, and field application engineers are available to work with you to designsolutions to provide maximum productivity and throughput.Unique advantages such as in-house PVD high-quality coating facilities (TiN, TiCN, TiAIN, AlTiN, and Z-coat), a wide range of rawmaterials (HSS, HSS-E, HSS-Powder; Solid Carbide, Brazed Carbide), and capabilities for a wide range of diameters 0,25mm to 75mm(0.010" to 3.000"), position <strong>WIDIA</strong>-<strong>Hanita</strong> • <strong>WIDIA</strong>-Rübigas the preferred brands for high-quality, application-specific tools.We specialize in designing and manufacturing blueprint specials in the following tool styles:• End Mills• Arbor Style Milling Cutters• Carbide Drills (straight and step)• Routers• Reamers• Counterbores• Tapered <strong>Tool</strong>s• Thread Milling Cuttersvitel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

Environmental ResponsibilityWe are deeply committed to offering environmentally responsible products that deliver high performance and proven value. With decades of experiencein tooling and manufacturing combined with the synergies of superior engineering, we offer customers some of the most effective opportunities forsustainable manufacturing in the industry.Sustainable EngineeringLeading the way with innovation, engineering, and service in standard and custom tooling.A proven methodology and partnership.Successful project engineering requires planning, teamwork, and disciplined execution. Through our extensive experience in developing andimplementing new project engineering strategies, <strong>WIDIA</strong>-<strong>Hanita</strong> • <strong>WIDIA</strong>-Rübig have pioneered a proven methodology to help you manufacturenew products and bring them to market quickly. Service deliverables are carefully outlined and jointly agreed to before the project begins. Weformally evaluate progress and results with you throughout the project through our stage-gate management systems.With our best-in-class process, you’ll experience accelerated time to market, lower overall costs, and reduced risks to implement new technologies.Vendor of ChoiceWe serve every major industrial market throughout the world and are a brand of choice in the most demanding industries, including Aerospace,Die and Mold, Automotive, Heavy Equipment, Medical, and General Engineering. Throughout our 80+ year history, we have achieved a reputationfor providing our customers with a constant flow of new and unique products and services, specially designed for maximum efficiency andperformance. We have enabled customers to become more competitive and more profitable in their own industries, producing parts in lesstime, with fewer tool changes and longer tool life.We are committed to providing you with tools and services that deliver the ultimate in customer satisfaction, and we are pleased to feature someof our latest breakthroughs in this catalog. For more information about how these products can impact your bottom line, please contact your localAuthorized <strong>WIDIA</strong>-<strong>Hanita</strong> or <strong>WIDIA</strong>-Rübig Distributor today.viitel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

Solid End Mills • InchHow to Choose the Correct End Mill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2Recommended Series for Highest Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A3<strong>Tool</strong> Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A4–A11High-Performance Solid Carbide End Mills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A13–A103VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A13–A37Hard Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A39–A50Aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A53–A82Finishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A85–A94Roughing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A97–A103High-Performance High-Speed Steel (HSS-E/PM) End Mills . . . . . . . . . . . . . . . . . . . . . . . . .A105–A136Finishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A105–A117Roughing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A119–A136General Purpose+ Solid Carbide End Mills • Roughing/Finishing . . . . . . . . . . . . . . . . . . . . . .A139–A155General Purpose+ High-Speed Steel (HSS-E) End Mills • Roughing/Finishing . . . . . . . . . . . .A157–A190WWW.<strong>WIDIA</strong>.COMA1tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

Recommended Series for Highest PerformanceSolid Carbide End Mills • Solid HSS-E/PM End MillsWorkpiece Material GroupPMKS1–S3S4NHSolid Carbide End MillsType of CutRoughingSemi-FinishingFinishingLong Axial Depth of Cut3D (Z-Axis Milling)Steelsand AlloyedSteelsStainlessSteels(not PH)Cast Iron4M0RSee p. A100VariMill II 5V0SSee p. A224S07See p. A88VariMiIl I 4V05See p. A14VariMill I 4V00See p. A24High-TempAlloys andPH MaterialsRecommended SeriesTitaniumVariMill II 5V0TSee p. A28VariMill I 4V0TSee p. A26Aluminum4A0RSee p. A74AluSurf 5A03See p. A55ArCut 4K03See p. A634AO1, 4AN1Seepp. A72, A73HardMaterials(> 40 HRC)Vision Plus 7S7RSee p. A44Vision Plus7S05See p. A40Vision Plus X-Feed See p. A42Recommended Series for Highest PerformanceWorkpiece Material GroupPMKS1–S3S4NHSteelsand AlloyedSteelsStainlessSteels(not PH)Cast IronHigh-TempAlloys andPH MaterialsTitaniumAluminumHardMaterials(> 40 HRC)Solid HSS-E/PM End MillsType of CutRecommended SeriesRoughing6K06See p. A1306K08See p. A1286K06See p. A1306T0RSee p. A1266A0RSee p. A124Semi-Finishing1K05See p. A113WavCut II See p. A122FinishingLong Axial Depth of Cut1K07See p. A1133407See p. A1103003See p. A106See Inside Back Cover for legend of specific workpiece materials.WWW.<strong>WIDIA</strong>.COMA3tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

<strong>Tool</strong> Reference Guide • SEM • Inch<strong>Tool</strong> Reference Guide • InchGoodBetterBestSeriesHigh-Performance Solid Carbide End Mills • VariMill Range of DiameterØ min–Ø maxinchNumberof FlutesCuttingCenterUncoatedTiCNTiAINAlTiN4V05 1/8"–1-1/4" 4 Yes X X4VN5 1/4"–1" 4 Yes X4VP5 1/4"–1" 4 Yes X5V0S 3/16"–1" 5 No X5VNS 1/4"–1" 5 No X4V00 1/8"–1-1/4" 4 Yes X4VP0 1/4"–1" 4 Yes X4V0T 1/2"–1-1/4" 4 Yes X4VPT 1/2"–1" 4 Yes X5V0T 1/4"–1" 5 No XHigh-Performance Solid Carbide End Mills • Hard Materials7S05 1/4"–1" 4/5/6 Yes X7S5F 1/8"–3/4" 4 Yes X7FN6 1/4"–3/4" 6 No X7FN7 1/4"–3/4" 6 No X7S7R 5/32"–1" 3/4/6 Yes XA4WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

<strong>Tool</strong> Reference Guide • SEM • InchPM KNS1 2 3 4 5 6 1 2 3 1 2 1 2 3 4 5 6 1 2 3 4H1 2 3 4Steel

<strong>Tool</strong> Reference Guide • SEM • Inch<strong>Tool</strong> Reference Guide • InchGoodBetterBestSeriesHigh-Performance Solid Carbide End Mills • AluminumRange of DiameterØ min–Ø maxinchNumberof FlutesCuttingCenter5A02 1/4"–1" 2 Yes X5A03 1/4"–1" 3 Yes X5AN2 1/8"–1" 2 Yes X5AN3 1/8"–1" 3 Yes XUncoatedTiCNTiAIN4K02 1/8"–1" 2 Yes X X4K03 1/4"–1" 3 Yes X X4AN2 1/8"–1" 2 Yes X X4AN3 3/8"–1" 3 Yes X X4AP2 1/8"–1" 2 Yes X4AP3 3/8"–1" 3 Yes X4B02 1/4"–1" 2 Yes X4A01 1/8"–1" 2 Yes X X4AN1 1/4"–1" 2 Yes X4A0R 1/4"–1" 3 Yes X X4A0B 1/4"–3/4" 3 Yes XHigh-Performance Solid Carbide End Mills • Finishing4C03 1/8"–1" 3 Yes X X X4C05 1/8"–1" 5 Yes X X X4S05/4S07 3/16"–1" 4/6 Yes X X4S0F 1/4"–1" 6/8/10 Yes XA6WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

<strong>Tool</strong> Reference Guide • SEM • InchPM KNS1 2 3 4 5 6 1 2 3 1 2 1 2 3 4 5 6 1 2 3 4H1 2 3 4Steel

<strong>Tool</strong> Reference Guide • SEM • Inch<strong>Tool</strong> Reference Guide • InchGoodBetterBestSeriesHigh-Performance Solid Carbide End Mills • RoughingHigh-Performance HSS-E/PM End Mills • FinishingRange of DiameterØ min–Ø maxinchNumberof FlutesCuttingCenterUncoatedTiCNTiAINAlTiN4Q03/4Q05 3/16"–1" 3/4 Yes X4QN3 1/4"–3/4" 3 Yes X4M0R 1/4"–1" 3/4/6 Yes X3K03 3/8"–2" 3 Yes X X3405/3407 3/8"–2" 4/6 Yes X X3K05/3K07 1/2"–2" 4/6 Yes X X1K05/1K07 1/4"–1-1/4" 4/6 Yes X X300A 1/2"–1-1/4" 3 Yes X3003 1/4"–2" 3 Yes X XHigh-Performance HSS-E/PM End Mills • Roughing620W 3/4"–2" 4/6 Yes X620V 3/4"–2" 4/6/8 Yes X X6A0R 1/2"–1-1/4" 3 Yes X X6ANR 1/2"–1-1/4" 3 Yes X6T0R 1/2"–1-1/2" 4/5/6 Yes X6TNR 5/8"–1-1/4" 4/5/6 Yes X6K08 1/4"–1-1/4" 4/5/6 Yes X X X6K07 1-1/2"–2" 6/8 No X X6K06 3/8"–1-1/4" 4/5/6 Yes X X X6K04 1/4"–1-1/4" 4/5/6 Yes X X XA8WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

<strong>Tool</strong> Reference Guide • SEM • InchPM KNS1 2 3 4 5 6 1 2 3 1 2 1 2 3 4 5 6 1 2 3 4H1 2 3 4Steel

<strong>Tool</strong> Reference Guide • SEM • Inch<strong>Tool</strong> Reference Guide • InchGoodBetterBestRange of DiameterØ min–Ø maxSeriesinchGeneral Purpose+ Solid Carbide End Mills • Roughing/FinishingNumberof FlutesCuttingCenterUncoatedTiCNTiAIN4202 1/32"–1" 2 Yes X X X4201 1/16"–3/4" 2 Yes X X X4203 1/16"–1" 3 Yes X X4205 3/64"–1" 4 Yes X X X4200 1/16"–1" 4 Yes X X X4207 1/4"–1" 6 Yes X4S0B 1/4"–1" 3/4 Yes X4S0R 1/4"–1" 3/4/5 Yes X XGeneral Purpose+ HSS-E End Mills • Roughing/Finishing3002 1/4"–2" 2 Yes X3001 1/2"–1-1/4" 2 Yes X1202 1/8"–2" 2 Yes X X1402 1/8"–3/4" 2 Yes X X1201 1/4"–1-1/4" 2 Yes X X1203K 1/4"–3/4" 3 Yes X1205/1207 1/8"–2" 4/6 Yes X X X1405 1/8"–3/4" 4 Yes X X1200 1/4"–1-1/4" 4/6 Yes X X6209 1/4"–2" 3 Yes X X6206 3/16"–2" 4/5/6 Yes X X X6205 5/8"–2" 4/5/6/8 No X X X6208 5/32"–2" 4/5/6 Yes X X X6207 5/8"–2" 4/5/6/8 No X X X6306 3/8"–2" 4/5/6 Yes X X X6308 3/8"–1-1/4" 4/5/6 Yes X X XA10WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

<strong>Tool</strong> Reference Guide • SEM • InchPM KNS1 2 3 4 5 6 1 2 3 1 2 1 2 3 4 5 6 1 2 3 4H1 2 3 4Steel

°e°VariMill II Solid Carbide End MillsThe next generation high-performance end mill, VariMill II dramaticallyimproves metal removal rates without reducing tool life.• Best suited for applications in the Aerospace, Medical,Die and Mold, Automotive, and General Engineering markets.• Outstanding performance in Stainless Steel, Titanium,INCONEL ® , and other High-Temperature Alloys and Steels.• Increased metal removal rates in roughing and finishing operations.• Excellent performance in both slotting and profiling operations.a°c°d°NOTE: Unequal flute spacing.Featured Application: Slotting an Engine RingOperation:Customer:Workpiece:Material:Solution:Results:SlottingAerospace ManufacturerEngine RingSST nickel-based alloy EZ3NCT25(25% nickel, 13% chromium) at 245 HBVariMill II 5-Flute with AlTiN coating90% increase in metal removal rateCOMPETITORVariMill IIcoating: TiAlN AlTiNend mill:4-flute 12mm5-flute 12mm1mm radius1mm radiusmaterial: SST nickel-based alloy SST nickel-based alloydepth of cut (ap): 11,15mm (.44") 11,15mm (.44")width of cut (ae): 12mm (.472") 12mm (.472")speed (Vc): 30 m/min (100 SFM) 40 m/min (132 SFM)RPM (N): 800 RPM 1,060 RPMfeed rate (Vf): 112mm/min (4.41 IPM) 212mm/min (8.3 IPM)chip load pertooth (Fz):0,035mm/th (0.0014 in/th) 0,04mm/th (0.0016 in/th)metalremoval rate:15 cm 3 /min (0.91 in 3 /min) 28 cm 3 /min (1.73 in 3 /min)metal removal rate90% Productivity Increase!35302520151050Competitor VariMill IIA12tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill High-Performance Solid Carbide • VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A13–A37Series 4V05 • VariMill • Lists 4V05 4V154V25 4V45 4V65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A14–A18Series 4VN5 • VariMill • With Neck . . . . . . . . . . . . . . . . .A20Series 4VP5 • VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21Series 5V0S • VariMill II . . . . . . . . . . . . . . . . . . . . . . . .A22–A23Series 5VNS • VariMill II . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A23Series 4V00 • VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24Series 4VP0 • VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A25Series 4V0T • VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26Series 4VPT • VariMill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A27Series 5V0T for Titanium • VariMill II . . . . . . . . . . .A28–A29Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30–A31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A37A13tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V05 • VariMill • Lists 4V05 4V15 4V25 4V45 4V65High-Performance Solid Carbide End Mills• Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions, see page A90.• For information about Reconditioning Services, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A30–31.length of cut lengthD1 D Ap1 max L Rε BCH TiAlN - LT AlTiN - MT TiAlN - LW AlTiN - MW1/8 1/8 1/4 1 1/2 — .010 TF4V4503001 — — —1/8 1/8 1/4 1 1/2 — — TF4V4503001S — — —1/8 1/8 1/2 2 .015 — TF4V0503001A — — —1/8 1/8 1/2 2 — .010 TF4V0503001 — — —1/8 1/8 1/2 2 — — TF4V0503001S — — —3/16 3/16 5/16 1 1/2 — .010 TF4V4505000 — — —3/16 3/16 5/16 1 1/2 — — TF4V4505000S — — —3/16 3/16 5/8 2 1/4 .015 — TF4V0505000A — — —3/16 3/16 5/8 2 1/4 .030 — TF4V0505000B — — —3/16 3/16 5/8 2 1/4 — .010 TF4V0505000 — — —3/16 3/16 5/8 2 1/4 — — TF4V0505000S — — —1/4 1/4 3/8 2 .030 — TF4V4507002B — — —1/4 1/4 3/8 2 — .016 TF4V4507002 TM4V4507002 — —1/4 1/4 3/8 2 — — TF4V4507002S TM4V4507002S — —1/4 1/4 3/4 2 1/2 .015 — TF4V0507002A — — —1/4 1/4 3/4 2 1/2 .030 — TF4V0507002B — — —1/4 1/4 3/4 2 1/2 .060 — TF4V0507002C — — —1/4 1/4 3/4 2 1/2 — .016 TF4V0507002 TM4V0507002 — —1/4 1/4 3/4 2 1/2 — — TF4V0507002S TM4V0507002S — —1/4 1/4 1 1/4 3 1/4 .015 — TF4V1507002A — — —1/4 1/4 1 1/4 3 1/4 .030 — TF4V1507002B — — —1/4 1/4 1 1/4 3 1/4 — — TF4V1507002S — — —1/4 1/4 1 3/4 4 .015 — TF4V2507002A — — —1/4 1/4 1 3/4 4 .030 — TF4V2507002B — — —(continued)A14WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V05 • VariMill • Lists 4V05 4V15 4V25 4V45 4V65(continued)P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see pages A30–31.length of cut lengthD1 D Ap1 max L Rε BCH TiAlN - LT AlTiN - MT TiAlN - LW AlTiN - MW1/4 1/4 1 3/4 4 — — TF4V2507002S — — —5/16 5/16 1/2 2 .030 — TF4V4508003B — — —5/16 5/16 1/2 2 — .016 TF4V4508003 — — —5/16 5/16 1/2 2 — — TF4V4508003S — — —5/16 5/16 3/4 2 1/2 .015 — TF4V0508003A — — —5/16 5/16 3/4 2 1/2 .030 — TF4V0508003B — — —5/16 5/16 3/4 2 1/2 .060 — TF4V0508003C — — —5/16 5/16 3/4 2 1/2 — .016 TF4V0508003 — — —5/16 5/16 3/4 2 1/2 — — TF4V0508003S — — —5/16 5/16 1 1/4 3 1/4 .030 — TF4V1508003B — — —5/16 5/16 1 1/4 3 1/4 — — TF4V1508003S — — —5/16 5/16 1 5/8 4 — — TF4V2508003S — — —3/8 3/8 1/2 2 .030 — TF4V4510004B — — —3/8 3/8 1/2 2 — .020 TF4V4510004 TM4V4510004 — —3/8 3/8 1/2 2 — — TF4V4510004S TM4V4510004S — —3/8 3/8 7/8 2 1/2 .015 — TF4V0510004A — — —3/8 3/8 7/8 2 1/2 .030 — TF4V0510004B TM4V0510004B — —3/8 3/8 7/8 2 1/2 .060 — TF4V0510004C — — —3/8 3/8 7/8 2 1/2 .090 — TF4V0510004D — — —3/8 3/8 7/8 2 1/2 — .020 TF4V0510004 TM4V0510004 — —3/8 3/8 7/8 2 1/2 — — TF4V0510004S TM4V0510004S — —3/8 3/8 1 1/2 4 .030 — TF4V1510004B — — —3/8 3/8 1 1/2 4 .060 — TF4V1510004C — — —3/8 3/8 1 1/2 4 — — TF4V1510004S TM4V1510004S — —3/8 3/8 2 1/2 4 .030 — TF4V2510004B — — —3/8 3/8 2 1/2 4 .060 — TF4V2510004C — — —3/8 3/8 2 1/2 4 — — TF4V2510004S — — —7/16 7/16 5/8 2 1/2 — .020 TF4V451101A — — —7/16 7/16 5/8 2 1/2 — — TF4V451101AS — — —7/16 7/16 7/8 2 1/2 — .020 TF4V051101A — — —7/16 7/16 7/8 2 1/2 — — TF4V051101AS — — —7/16 7/16 2 4 — — TF4V151100AS — — —7/16 7/16 3 5 — — TF4V251100AS — — —1/2 1/2 5/8 2 1/2 .030 — — — TF4V4513005B —1/2 1/2 5/8 2 1/2 .060 — — — TF4V4513005C —1/2 1/2 5/8 2 1/2 — .020 — — TF4V4513005 TM4V45130051/2 1/2 5/8 2 1/2 — — — — TF4V4513005S TM4V4513005S1/2 1/2 1 3 — .020 — — TF4V0513005 TM4V05130051/2 1/2 1 3 — — — — TF4V0513005S TM4V0513005S1/2 1/2 1 1/4 3 .015 — — — TF4V0513015A —(continued)High-Performance Solid Carbide End MillsWWW.<strong>WIDIA</strong>.COMA15tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V05 • VariMill • Lists 4V05 4V15 4V25 4V45 4V65(continued) P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN High-Performance Solid Carbide End MillsP - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A30–31.length of cut lengthD1 D Ap1 max L Rε BCH TiAlN - LT AlTiN - MT TiAlN - LW AlTiN - MW1/2 1/2 1 1/4 3 .030 — — — TF4V0513015B TM4V0513015B1/2 1/2 1 1/4 3 .060 — — — TF4V0513015C —1/2 1/2 1 1/4 3 .090 — — — TF4V0513015D —1/2 1/2 1 1/4 3 .120 — — — TF4V0513015E —1/2 1/2 1 1/4 3 — .020 — — TF4V0513015 TM4V05130151/2 1/2 1 1/4 3 — — — — TF4V0513015S TM4V0513015S1/2 1/2 1 1/2 4 .030 — — — TF4V6513015B —1/2 1/2 1 1/2 4 .060 — — — TF4V6513015C TM4V6513015S1/2 1/2 1 1/2 4 — .020 — — TF4V6513015 TM4V65130151/2 1/2 1 1/2 4 — — — — TF4V6513015S —1/2 1/2 2 4 .030 — — — TF4V1513005B —1/2 1/2 2 4 .060 — — — TF4V1513005C —1/2 1/2 2 4 — — — — TF4V1513005S TM4V1513005S1/2 1/2 2 1/2 4 1/2 .030 — — — TF4V6513025B —1/2 1/2 2 1/2 4 1/2 .060 — — — TF4V6513025C —1/2 1/2 2 1/2 4 1/2 — — — — TF4V6513025S —1/2 1/2 3 5 .030 — — — TF4V2513005B —1/2 1/2 3 5 .060 — — — TF4V2513005C —1/2 1/2 3 5 — — — — TF4V2513005S —5/8 5/8 3/4 3 .060 — — — TF4V4516006C —5/8 5/8 3/4 3 .120 — — — TF4V4516006E —5/8 5/8 3/4 3 — .020 — — TF4V4516006 —5/8 5/8 3/4 3 — — — — TF4V4516006S —5/8 5/8 1 1/4 3 1/2 .030 — — — TF4V0516006B TM4V0516006B5/8 5/8 1 1/4 3 1/2 .060 — — — TF4V0516006C —5/8 5/8 1 1/4 3 1/2 .090 — — — TF4V0516006D —5/8 5/8 1 1/4 3 1/2 .120 — — — TF4V0516006E —5/8 5/8 1 1/4 3 1/2 — .020 — — TF4V0516006 TM4V05160065/8 5/8 1 1/4 3 1/2 — — — — TF4V0516006S —5/8 5/8 1 5/8 4 1/8 .060 — — — TF4V6516016C —5/8 5/8 1 5/8 4 1/8 — .020 — — TF4V6516016 —5/8 5/8 1 5/8 4 1/8 — — — — TF4V6516016S —5/8 5/8 2 1/4 5 .060 — — — TF4V1516006C —5/8 5/8 2 1/4 5 — — — — TF4V1516006S —5/8 5/8 3 5 1/4 — — — — TF4V2516006S —3/4 3/4 7/8 3 1/2 .030 — — — TF4V4519007B —3/4 3/4 7/8 3 1/2 .060 — — — TF4V4519007C —3/4 3/4 7/8 3 1/2 .120 — — — TF4V4519007E —3/4 3/4 7/8 3 1/2 — .020 — — TF4V4519007 TM4V45190073/4 3/4 7/8 3 1/2 — — — — TF4V4519007S TM4V4519007S3/4 3/4 1 1/2 4 .030 — — — TF4V0519007B TM4V0519007B3/4 3/4 1 1/2 4 .060 — — — TF4V0519007C TM4V0519007C3/4 3/4 1 1/2 4 .090 — — — TF4V0519007D TM4V0519007D3/4 3/4 1 1/2 4 .120 — — — TF4V0519007E TM4V0519007E(continued)A16WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V05 • VariMill • Lists 4V05 4V15 4V25 4V45 4V65(continued)P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A30–31.length of cut lengthD1 D Ap1 max L Rε BCH TiAlN - LT AlTiN - MT TiAlN - LW AlTiN - MW3/4 3/4 1 1/2 4 — .020 — — TF4V0519007 TM4V05190073/4 3/4 1 1/2 4 — — — — TF4V0519007S TM4V0519007S3/4 3/4 1 5/8 4 — .020 — — TF4V6519017 —3/4 3/4 1 5/8 4 — — — — TF4V6519017S —3/4 3/4 2 1/4 5 .030 — — — TF4V1519007B —3/4 3/4 2 1/4 5 .060 — — — TF4V1519007C —3/4 3/4 2 1/4 5 — .020 — — TF4V1519007 TM4V15190073/4 3/4 2 1/4 5 — — — — TF4V1519007S TM4V1519007S3/4 3/4 3 6 .030 — — — TF4V6519007B —3/4 3/4 3 6 .060 — — — TF4V6519007C —3/4 3/4 3 6 — .020 — — TF4V6519007 —3/4 3/4 3 6 — — — — TF4V6519007S TM4V6519007S3/4 3/4 4 6 1/4 .030 — — — TF4V2519007B —3/4 3/4 4 6 1/4 .060 — — — TF4V2519007C —3/4 3/4 4 6 1/4 — — — — TF4V2519007S —1 1 1 1/2 4 .030 — — — TF4V0525008B TM4V0525008B1 1 1 1/2 4 .060 — — — TF4V0525008C TM4V0525008C1 1 1 1/2 4 .090 — — — TF4V0525008D TM4V0525008D1 1 1 1/2 4 .120 — — — TF4V0525008E TM4V0525008E1 1 1 1/2 4 .250 — — — TF4V0525008F —1 1 1 1/2 4 — .020 — — TF4V0525008 TM4V05250081 1 1 1/2 4 — — — — TF4V0525008S TM4V0525008S1 1 2 5 — .020 — — TF4V6525018 —1 1 2 5 — — — — TF4V6525018S —1 1 2 1/4 5 .030 — — — TF4V1525008B —1 1 2 1/4 5 .060 — — — TF4V1525008C —1 1 2 1/4 5 — .020 — — TF4V1525008 —1 1 2 1/4 5 — — — — TF4V1525008S TM4V1525008S1 1 3 6 .030 — — — TF4V2525008B —1 1 3 6 .060 — — — TF4V2525008C —1 1 3 6 — .020 — — TF4V2525008 —1 1 3 6 — — — — TF4V2525008S —1 1 4 7 .030 — — — TF4V6525028B —1 1 4 7 .060 — — — TF4V6525028C —1 1 4 7 — .020 — — TF4V6525028 —1 1 4 7 — — — — TF4V6525028S TM4V6525028S1 1/4 1 1/4 2 1/4 5 .030 — — — TF4V0532009B —1 1/4 1 1/4 2 1/4 5 .120 — — — TF4V0532009E —1 1/4 1 1/4 2 1/4 5 — .020 — — TF4V0532009 —1 1/4 1 1/4 2 1/4 5 — — — — TF4V0532009S —(continued)High-Performance Solid Carbide End MillsWWW.<strong>WIDIA</strong>.COMA17tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V05 • VariMill • Lists 4V05 4V15 4V25 4V45 4V65(continued)P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN High-Performance Solid Carbide End MillsP - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A30–31.length of cut lengthD1 D Ap1 max L Rε BCH TiAlN - LT AlTiN - MT TiAlN - LW AlTiN - MW1 1 4 7 — — — — TF4V6525028S TM4V6525028S1 1/4 1 1/4 2 1/4 5 .030 — — — TF4V0532009B —1 1/4 1 1/4 2 1/4 5 .120 — — — TF4V0532009E —1 1/4 1 1/4 2 1/4 5 — .020 — — TF4V0532009 —1 1/4 1 1/4 2 1/4 5 — — — — TF4V0532009S —A18WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

VariMill : The <strong>Tool</strong> of Choice for All Ferrous ApplicationsVariMill carbide end mills are the proven leader in the field of high-performance, chatter-free machining and the most universal andconsistent performer for use in a wide range of workpiece materials and types of operations. Utilizing an innovative and patenteddesign with unequal flute spacing, VariMill carbide end mills provide users with the most versatile technology available, capable ofoutperforming most other high-performance tools.Outstanding performance in:• Stainless Steels• Steels and Alloyed Steels• Cast Iron• High-Temperature Alloys• Low Carbon Steels

High-Performance Solid Carbide End Mills • VariMill Series 4VN5 • VariMill • With NeckHigh-Performance Solid Carbide End Mills• Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A35.length of cutlengthD1 D Ap1 max L3 L Rε BCH D3 TiAlN - LT TiAlN - LW1/4 1/4 3/8 1 1/4 4 .015 — .235 TF4VN507012A —1/4 1/4 3/8 1 1/4 4 .030 — .235 TF4VN507012B —1/4 1/4 3/8 1 1/4 4 — .016 .235 TF4VN507012 —3/8 3/8 1/2 1 7/8 4 .030 — .353 TF4VN510014B —3/8 3/8 1/2 1 7/8 4 .060 — .353 TF4VN510014C —3/8 3/8 1/2 1 7/8 4 — .020 .353 TF4VN510014 —1/2 1/2 5/8 2 1/4 4 .030 — .470 — TF4VN513005B1/2 1/2 5/8 2 1/4 4 .060 — .470 — TF4VN513005C1/2 1/2 5/8 2 1/4 4 .120 — .470 — TF4VN513005E1/2 1/2 5/8 2 1/4 4 — .020 .470 — TF4VN5130055/8 5/8 3/4 2 1/4 4 1/8 .060 — .588 — TF4VN516006C5/8 5/8 3/4 2 1/4 4 1/8 .120 — .588 — TF4VN516006E5/8 5/8 3/4 2 1/4 4 1/8 — .020 .588 — TF4VN5160065/8 5/8 3/4 3 1/8 5 — .020 .588 — TF4VN5160163/4 3/4 1 2 1/4 4 1/4 — .020 .705 — TF4VN5190073/4 3/4 1 3 1/4 5 1/4 .030 — .705 — TF4VN519017B3/4 3/4 1 3 1/4 5 1/4 .060 — .705 — TF4VN519017C3/4 3/4 1 3 1/4 5 1/4 .120 — .705 — TF4VN519017E3/4 3/4 1 3 1/4 5 1/4 — .020 .705 — TF4VN5190171 1 1 1/8 2 1/4 4 1/2 — .020 .940 — TF4VN5250081 1 1 1/8 3 1/4 5 1/2 .030 — .940 — TF4VN525018B1 1 1 1/8 3 1/4 5 1/2 .060 — .940 — TF4VN525018C1 1 1 1/8 3 1/4 5 1/2 .120 — .940 — TF4VN525018E1 1 1 1/8 3 1/4 5 1/2 — .020 .940 — TF4VN5250181 1 1 1/8 4 1/4 6 1/2 — .020 .940 — TF4VN525028A20WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4VP5 • VariMill • Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A32.High-Performance Solid Carbide End Millslength of cutlengthD1 D Ap1 max L BCH TiAlN - LT1/4 1/4 3/8 4 — TF4VP507012S1/4 1/4 3/8 4 .016 TF4VP5070123/8 3/8 1/2 4 — TF4VP510014S3/8 3/8 1/2 4 .020 TF4VP5100141/2 1/2 5/8 5 — TF4VP513005S1/2 1/2 5/8 5 .020 TF4VP5130051/2 1/2 5/8 6 — TF4VP513015S1/2 1/2 5/8 6 .020 TF4VP5130155/8 5/8 3/4 5 — TF4VP516006S5/8 5/8 3/4 5 .020 TF4VP5160065/8 5/8 3/4 6 — TF4VP516016S5/8 5/8 3/4 6 .020 TF4VP5160165/8 5/8 3/4 7 — TF4VP516026S5/8 5/8 3/4 7 .020 TF4VP5160263/4 3/4 1 5 — TF4VP519007S3/4 3/4 1 5 .020 TF4VP5190073/4 3/4 1 6 — TF4VP519017S3/4 3/4 1 6 .020 TF4VP5190173/4 3/4 1 7 — TF4VP519027S3/4 3/4 1 7 .020 TF4VP5190271 1 1 1/8 5 — TF4VP525008S1 1 1 1/8 5 .020 TF4VP5250081 1 1 1/8 6 — TF4VP525018S1 1 1 1/8 6 .020 TF4VP5250181 1 1 1/8 7 — TF4VP525028S1 1 1 1/8 7 .020 TF4VP525028WWW.<strong>WIDIA</strong>.COMA21tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 5V0S • VariMill II High-Performance Solid Carbide End Mills• Unequal flute spacing.• Non-center cutting.• Maximum ramp angle = 3°.• For information about Custom Solutions, see page A90.• For information about Reconditioning Services, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A33.length of cut lengthD1 D Ap1 max L Rε AlTiN - MT AlTiN - MW3/16 3/16 5/8 2 1/4 .015 TM5V0S05000A —3/16 3/16 5/8 2 1/4 .030 TM5V0S05000B —3/16 3/16 5/8 2 1/4 — TM5V0S05000S —1/4 1/4 3/4 2 1/2 .015 TM5V0S07002A —1/4 1/4 3/4 2 1/2 .030 TM5V0S07002B —1/4 1/4 3/4 2 1/2 .060 TM5V0S07002C —1/4 1/4 3/4 2 1/2 — TM5V0S07002S —5/16 5/16 3/4 2 1/2 .015 TM5V0S08003A —5/16 5/16 3/4 2 1/2 .030 TM5V0S08003B —5/16 5/16 3/4 2 1/2 .060 TM5V0S08003C —5/16 5/16 3/4 2 1/2 — TM5V0S08003S —3/8 3/8 7/8 2 1/2 .015 TM5V0S10004A —3/8 3/8 7/8 2 1/2 .030 TM5V0S10004B —3/8 3/8 7/8 2 1/2 .060 TM5V0S10004C —3/8 3/8 7/8 2 1/2 — TM5V0S10004S —1/2 1/2 1 1/4 3 .015 TM5V0S13015A TM5V0S13015AW1/2 1/2 1 1/4 3 .030 TM5V0S13015B TM5V0S13015BW1/2 1/2 1 1/4 3 .060 TM5V0S13015C TM5V0S13015CW1/2 1/2 1 1/4 3 .090 TM5V0S13015D TM5V0S13015DW1/2 1/2 1 1/4 3 .120 TM5V0S13015E TM5V0S13015EW1/2 1/2 1 1/4 3 — TM5V0S13015S TM5V0S13015SW5/8 5/8 1 1/4 3 1/2 .030 TM5V0S16006B TM5V0S16006BW5/8 5/8 1 1/4 3 1/2 .060 TM5V0S16006C TM5V0S16006CW5/8 5/8 1 1/4 3 1/2 .090 TM5V0S16006D TM5V0S16006DW(continued)A22WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 5V0S • Series 5VNS • VariMill II (continued) P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A33.length of cut lengthD1 D Ap1 max L Rε AlTiN - MT AlTiN - MW5/8 5/8 1 1/4 3 1/2 — TM5V0S16006S TM5V0S16006SW3/4 3/4 1 1/2 4 .030 TM5V0S19007B TM5V0S19007BW3/4 3/4 1 1/2 4 .060 TM5V0S19007C TM5V0S19007CW3/4 3/4 1 1/2 4 .090 TM5V0S19007D TM5V0S19007DW3/4 3/4 1 1/2 4 .120 TM5V0S19007E TM5V0S19007EW3/4 3/4 1 1/2 4 — TM5V0S19007S TM5V0S19007SW1 1 1 3/4 4 1/2 .030 TM5V0S25008B TM5V0S25008BW1 1 1 3/4 4 1/2 .060 TM5V0S25008C TM5V0S25008CW1 1 1 3/4 4 1/2 .090 TM5V0S25008D TM5V0S25008DW1 1 1 3/4 4 1/2 .120 TM5V0S25008E TM5V0S25008EW1 1 1 3/4 4 1/2 — TM5V0S25008S TM5V0S25008SWHigh-Performance Solid Carbide End Mills• Unequal flute spacing.• Non-center cutting.• Standard items listed. Additional styles and coatings made to order.• For information about Custom Solutions, see page A90.• For information about Reconditioning Services, see page A95.length of cutlengthD1 D Ap1 max L3 L Rε D3 AlTiN - MT AlTiN - MW1/4 1/4 1/2 1 1/4 4 .015 .235 TM5VNS07012A —3/8 3/8 7/8 1 7/8 4 .015 .353 TM5VNS10014A —1/2 1/2 1 1/4 2 1/4 4 .030 .470 TM5VNS13005B TM5VNS13005BW5/8 5/8 1 1/4 2 1/4 4 .030 .590 TM5VNS16006B TM5VNS16006BW3/4 3/4 1 1/2 3 1/4 5 1/2 .030 .705 TM5VNS19017B TM5VNS19017BW1 1 1 3/4 3 1/4 5 1/2 .030 .940 TM5VNS25018B TM5VNS25018BWWWW.<strong>WIDIA</strong>.COMA23tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V00 • VariMill High-Performance Solid Carbide End Mills• Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A35.length of cutlengthD1 D Ap1 max L TiAlN - LT TiAlN - LW1/8 1/8 1/2 2 TF4V0003001 —3/16 3/16 5/8 2 1/4 TF4V0005000 —1/4 1/4 3/4 2 1/2 TF4V0007002 —5/16 5/16 3/4 2 1/2 TF4V0008003 —3/8 3/8 7/8 2 1/2 TF4V0010004 —7/16 7/16 7/8 2 1/2 TF4V001101A —1/2 1/2 1 3 — TF4V00130051/2 1/2 1 1/4 3 — TF4V00130155/8 5/8 1 1/4 3 1/2 — TF4V00160063/4 3/4 1 1/2 4 — TF4V00190071 1 1 1/2 4 — TF4V00250081 1/4 1 1/4 2 1/4 5 — TF4V0032009A24WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4VP0 • VariMill • Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P M K S H1 2 3 4 5 6 1 2 3 1 2 3 1 2 3 4 1TiAlN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A36.High-Performance Solid Carbide End Millslength of cutlengthD1 D Ap1 max L TiAlN - LT1/4 1/4 3/8 4 TF4VP0070123/8 3/8 1/2 4 TF4VP0100141/2 1/2 5/8 5 TF4VP0130055/8 5/8 3/4 6 TF4VP0160163/4 3/4 1 6 TF4VP0190171 1 1 1/8 6 TF4VP025018WWW.<strong>WIDIA</strong>.COMA25tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4V0T • VariMill High-Performance Solid Carbide End Mills• Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P S5 6 2 3 4AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A37.length of cutlengthD1 D Ap1 max L BCH AlTiN - MW1/2 1/2 5/8 2 1/2 .020 TM4V4T130051/2 1/2 5/8 2 1/2 — TM4V4T13005S1/2 1/2 1 1/4 3 .020 TM4V0T130151/2 1/2 1 1/4 3 — TM4V0T13015S5/8 5/8 3/4 3 .020 TM4V4T160065/8 5/8 3/4 3 — TM4V4T16006S5/8 5/8 1 1/4 3 1/2 .020 TM4V0T160065/8 5/8 1 1/4 3 1/2 — TM4V0T16006S3/4 3/4 7/8 3 1/2 .020 TM4V4T190073/4 3/4 7/8 3 1/2 — TM4V4T19007S3/4 3/4 1 1/2 4 .020 TM4V0T190073/4 3/4 1 1/2 4 — TM4V0T19007S1 1 1 1/2 4 .020 TM4V0T250081 1 1 1/2 4 — TM4V0T25008S1 1/4 1 1/4 2 1/4 5 .020 TM4V0T320091 1/4 1 1/4 2 1/4 5 — TM4V0T32009SA26WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 4VPT • VariMill • Unequal flute spacing.• Center cutting.• Standard items listed. Additionalstyles and coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P S5 6 2 3 4AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A37.High-Performance Solid Carbide End Millslength of cutlengthD1 D Ap1 max L BCH AlTiN - MT1/2 1/2 5/8 5 .020 TM4VPT130051/2 1/2 5/8 5 — TM4VPT13005S1/2 1/2 5/8 6 .020 TM4VPT130151/2 1/2 5/8 6 — TM4VPT13015S5/8 5/8 3/4 5 .020 TM4VPT160065/8 5/8 3/4 5 — TM4VPT16006S5/8 5/8 3/4 6 .020 TM4VPT160165/8 5/8 3/4 6 — TM4VPT16016S5/8 5/8 3/4 7 .020 TM4VPT160265/8 5/8 3/4 7 — TM4VPT16026S3/4 3/4 1 5 .020 TM4VPT190073/4 3/4 1 5 — TM4VPT19007S3/4 3/4 1 6 .020 TM4VPT190173/4 3/4 1 6 — TM4VPT19017S3/4 3/4 1 7 .020 TM4VPT190273/4 3/4 1 7 — TM4VPT19027S1 1 1 1/8 5 .020 TM4VPT250081 1 1 1/8 5 — TM4VPT25008S1 1 1 1/8 6 .020 TM4VPT250181 1 1 1/8 6 — TM4VPT25018S1 1 1 1/8 7 .020 TM4VPT250281 1 1 1/8 7 — TM4VPT25028SWWW.<strong>WIDIA</strong>.COMA27tel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

High-Performance Solid Carbide End Mills • VariMill Series 5V0T for Titanium • VariMill II High-Performance Solid Carbide End Mills• Unequal flute spacing.• Non-center cutting.• Maximum ramp angle = 3°.• For information about Custom Solutions, see page A90.• For information about Reconditioning Services, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P S5 6 2 3 4AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A37.length of cutlengthD1 D Ap1 max L Rε AlTiN - MT AlTiN - MW1/4 1/4 3/4 2 1/2 .015 TM5V0T07002A —1/4 1/4 3/4 2 1/2 .030 TM5V0T07002B —1/4 1/4 3/4 2 1/2 .060 TM5V0T07002C —1/4 1/4 3/4 2 1/2 — TM5V0T07002S —5/16 5/16 3/4 2 1/2 .015 TM5V0T08003A —5/16 5/16 3/4 2 1/2 .030 TM5V0T08003B —5/16 5/16 3/4 2 1/2 .060 TM5V0T08003C —5/16 5/16 3/4 2 1/2 — TM5V0T08003S —3/8 3/8 7/8 2 1/2 .015 TM5V0T10004A —3/8 3/8 7/8 2 1/2 .030 TM5V0T10004B —3/8 3/8 7/8 2 1/2 .060 TM5V0T10004C —3/8 3/8 7/8 2 1/2 — TM5V0T10004S —1/2 1/2 1 1/4 3 .015 TM5V0T13015A TM5V0T13015AW1/2 1/2 1 1/4 3 .030 TM5V0T13015B TM5V0T13015BW1/2 1/2 1 1/4 3 .060 TM5V0T13015C TM5V0T13015CW1/2 1/2 1 1/4 3 .090 TM5V0T13015D TM5V0T13015DW1/2 1/2 1 1/4 3 .120 TM5V0T13015E TM5V0T13015EW1/2 1/2 1 1/4 3 — TM5V0T13015S TM5V0T13015SW(continued)A28WWW.<strong>WIDIA</strong>.COMtel: (416) 746-3688 <strong>Tyson</strong> <strong>Tool</strong> <strong>Company</strong> <strong>Limited</strong> www.tysontool.com

(continued) P S5 6 2 3 4AlTiN High-Performance Solid Carbide End Mills • VariMill Series 5V0T for Titanium • VariMill II P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A37.length of cutlengthD1 D Ap1 max L Rε AlTiN - MT AlTiN - MW5/8 5/8 1 1/4 3 1/2 .030 TM5V0T16006B TM5V0T16006BW5/8 5/8 1 1/4 3 1/2 .060 TM5V0T16006C TM5V0T16006CW5/8 5/8 1 1/4 3 1/2 .090 TM5V0T16006D TM5V0T16006DW5/8 5/8 1 1/4 3 1/2 — TM5V0T16006S TM5V0T16006SW3/4 3/4 1 1/2 4 .030 TM5V0T19007B TM5V0T19007BW3/4 3/4 1 1/2 4 .060 TM5V0T19007C TM5V0T19007CW3/4 3/4 1 1/2 4 .090 TM5V0T19007D TM5V0T19007DW3/4 3/4 1 1/2 4 .120 TM5V0T19007E TM5V0T19007EW3/4 3/4 1 1/2 4 — TM5V0T19007S TM5V0T19007SW1 1 1 3/4 4 .030 TM5V0T25008B TM5V0T25008BW1 1 1 3/4 4 .060 TM5V0T25008C TM5V0T25008CW1 1 1 3/4 4 .090 TM5V0T25008D TM5V0T25008DW1 1 1 3/4 4 .120 TM5V0T25008E TM5V0T25008EW1 1 1 3/4 4 — TM5V0T25008S TM5V0T25008SWHigh-Performance Solid Carbide End MillsWWW.<strong>WIDIA</strong>.COMA29

High-Performance Solid Carbide End Mills • VariMill Application Data • Series 4V05 • Lists 4V05 4V45 4V15 4V25 4V65 • VariMill Series 4V05 - Lists 4V05 4V45High-Performance Solid Carbide End MillsTiAlNAlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc Cutting Speed Vc D1 - DiameterSFM SFM frac. 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 1 1/4Group ap ae ap Min Max Min Max dec. .1250 .1880 .2500 .3130 .3750 .4380 .5000 .6250 .7500 1.000 1.250P1 1.25 x D 0.5 x D 1 x D 490 - 660 490 - 660 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P2 1.25 x D 0.5 x D 1 x D 460 - 620 460 - 620 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P3 1.25 x D 0.5 x D 1 x D 390 - 520 390 - 520 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057P4 1.25 x D 0.5 x D 0.75 x D 300 - 490 300 - 490 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049P5 1.25 x D 0.5 x D 1 x D 200 - 330 200 - 330 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046P6 1.25 x D 0.5 x D 0.75 x D 160 - 250 160 - 250 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036M1 1.25 x D 0.5 x D 1 x D 260 - 330 260 - 330 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057M2 1.25 x D 0.5 x D 1 x D 200 - 260 200 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046M3 1.25 x D 0.5 x D 1 x D 200 - 260 200 - 260 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036K1 1.25 x D 0.5 x D 1 x D 390 - 520 390 - 520 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062K2 1.25 x D 0.5 x D 1 x D 360 - 460 360 - 460 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057K3 1.25 x D 0.5 x D 1 x D 330 - 430 330 - 430 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S1 1.0 x D 0.3 x D 0.3 x D 160 - 300 160 - 300 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057S2 1.0 x D 0.3 x D 0.3 x D 70 - 130 70 - 130 Fz .0004 .0006 .0008 .0010 .0012 .0014 .0016 .0018 .0020 .0025 .0031S3 1.25 x D 0.5 x D 1 x D 160 - 260 160 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S4 1.25 x D 0.5 x D 1 x D 150 - 210 150 - 210 Fz .0005 .0008 .0011 .0014 .0017 .0019 .0022 .0025 .0028 .0033 .0042H1 1.25 x D 0.5 x D 0.75 x D 260 - 460 260 - 460 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".Series 4V05 - Lists 4V15 4V65TiAlNAlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc Cutting Speed Vc D1 - DiameterSFM SFM frac. 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 1 1/4Group ap ae ap Min Max Min Max dec. .1250 .1880 .2500 .3130 .3750 .4380 .5000 .6250 .7500 1.000 1.250P1 2 x D 0.25 x D 0.5 x D 490 - 660 490 - 660 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P2 2 x D 0.25 x D 0.5 x D 460 - 620 460 - 620 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P3 2 x D 0.25 x D 0.5 x D 390 - 520 390 - 520 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057P4 2 x D 0.25 x D 0.4 x D 300 - 490 300 - 490 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049P5 2 x D 0.25 x D 0.5 x D 200 - 330 200 - 330 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046P6 2 x D 0.25 x D 0.4 x D 160 - 250 160 - 250 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036M1 2 x D 0.25 x D 0.5 x D 260 - 330 260 - 330 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057M2 2 x D 0.25 x D 0.5 x D 200 - 260 200 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046M3 2 x D 0.25 x D 0.5 x D 200 - 260 200 - 260 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036K1 2 x D 0.25 x D 0.5 x D 390 - 520 390 - 520 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062K2 2 x D 0.25 x D 0.5 x D 360 - 460 360 - 460 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057K3 2 x D 0.25 x D 0.5 x D 330 - 430 330 - 430 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S1 2 x D 0.15 x D 0.2 x D 160 - 300 160 - 300 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057S2 2 x D 0.15 x D 0.2 x D 70 - 130 70 - 130 Fz .0004 .0006 .0008 .0010 .0012 .0014 .0016 .0018 .0020 .0025 .0031S3 2 x D 0.25 x D 0.5 x D 160 - 260 160 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S4 2 x D 0.25 x D 0.5 x D 150 - 210 150 - 210 Fz .0005 .0008 .0011 .0014 .0017 .0019 .0022 .0025 .0028 .0033 .0042H1 2 x D 0.25 x D 0.4 x D 260 - 460 260 - 460 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parametersaccordingly on diameters greater than 1/2".A30WWW.<strong>WIDIA</strong>.COM

High-Performance Solid Carbide End Mills • VariMill Application Data • Series 4V05 • Lists 4V05 4V45 4V15 4V25 4V65 • VariMill Series 4V05 - Lists 4V25 4V65TiAlN AlTiN Recommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).A Cutting Speed Vc Cutting Speed Vc D1 - DiameterSFMSFMinch -frac1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 1 1/4Group ap ae Min Max Min Maxinch -dec.1250 .1880 .2500 .3130 .3750 .4380 .5000 .6250 .7500 1.000 1.250P1 2.5 x D 0.1 x D 490 - 660 490 - 660 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P2 2.5 x D 0.1 x D 460 - 620 460 - 620 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P3 2.5 x D 0.1 x D 390 - 520 390 - 520 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057P4 2.5 x D 0.1 x D 300 - 490 300 - 490 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049P5 2.5 x D 0.1 x D 200 - 330 200 - 330 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046P6 2.5 x D 0.1 x D 160 - 250 160 - 250 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036M1 2.5 x D 0.1 x D 260 - 330 260 - 330 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057M2 2.5 x D 0.1 x D 200 - 260 200 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046M3 2.5 x D 0.1 x D 200 - 260 200 - 260 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036K1 2.5 x D 0.1 x D 390 - 520 390 - 520 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062K2 2.5 x D 0.1 x D 360 - 460 360 - 460 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057K3 2.5 x D 0.1 x D 330 - 430 330 - 430 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S1 2.5 x D 0.06 x D 160 - 300 160 - 300 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057S2 2.5 x D 0.06 x D 70 - 130 70 - 130 Fz .0004 .0006 .0008 .0010 .0012 .0014 .0016 .0018 .0020 .0025 .0031S3 2.5 x D 0.1 x D 160 - 260 160 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S4 2.5 x D 0.1 x D 150 - 210 150 - 210 Fz .0005 .0008 .0011 .0014 .0017 .0019 .0022 .0025 .0028 .0033 .0042H1 2.5 x D 0.1 x D 260 - 460 260 - 460 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parametersaccordingly on diameters greater than 1/2".High-Performance Solid Carbide End MillsWWW.<strong>WIDIA</strong>.COMA31

High-Performance Solid Carbide End Mills • VariMill Application Data • Series 4VN5 4VP5 • VariMill Series 4VN5 4VP5High-Performance Solid Carbide End MillsTiAlNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/4 3/8 1/2 5/8 3/4 1Group ap ae ap Min Max dec. .2500 .3750 .5000 .6250 .7500 1.000P1 0.75 x D 0.5 x D 0.75 x D 500 - 650 Fz .0018 .0027 .0035 .0039 .0043 .0050P2 0.75 x D 0.5 x D 0.75 x D 450 - 625 Fz .0018 .0027 .0035 .0039 .0043 .0050P3 0.75 x D 0.5 x D 0.75 x D 400 - 525 Fz .0015 .0023 .0029 .0034 .0038 .0046P4 0.75 x D 0.5 x D 0.5 x D 300 - 475 Fz .0014 .0020 .0026 .0030 .0033 .0039P5 0.75 x D 0.5 x D 0.75 x D 200 - 325 Fz .0012 .0018 .0023 .0027 .0030 .0036P6 0.75 x D 0.5 x D 0.5 x D 150 - 225 Fz .0010 .0015 .0019 .0022 .0024 .0028M1 0.75 x D 0.5 x D 0.75 x D 260 - 330 Fz .0015 .0023 .0029 .0034 .0038 .0046M2 0.75 x D 0.5 x D 0.75 x D 200 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036M3 0.75 x D 0.5 x D 0.75 x D 200 - 260 Fz .0010 .0015 .0019 .0022 .0024 .0028K1 0.75 x D 0.5 x D 0.75 x D 390 - 520 Fz .0018 .0027 .0035 .0039 .0043 .0050K2 0.75 x D 0.5 x D 0.75 x D 360 - 460 Fz .0015 .0023 .0029 .0034 .0038 .0046K3 0.75 x D 0.5 x D 0.75 x D 330 - 430 Fz .0012 .0018 .0023 .0027 .0030 .0036S1 0.75 x D 0.3 x D 0.3 x D 150 - 275 Fz .0015 .0023 .0029 .0034 .0038 .0046S2 0.75 x D 0.3 x D 0.3 x D 70 - 130 Fz .0008 .0012 .0016 .0018 .0020 .0025S3 0.75 x D 0.5 x D 0.75 x D 160 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036S4 0.75 x D 0.5 x D 0.75 x D 150 - 210 Fz .0011 .0017 .0022 .0025 .0028 .0033H1 0.75 x D 0.5 x D 0.5 x D 260 - 450 Fz .0014 .0020 .0026 .0030 .0033 .0039Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Reach from 2 x D up to 3 x D - in slotting applications ap=0.5 x D.Reach longer than 3 x D - side milling only ae up to 0.25 x D.A32WWW.<strong>WIDIA</strong>.COM

High-Performance Solid Carbide End Mills • VariMill Series 5V0SApplication Data • Series 5V0S • VariMill II AlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1Group ap ae ap Min Max dec. .1880 .2500 .3130 .3750 .4380 .5000 .6250 .7500 1.000P1 1.25 x D 0.5 x D 1 x D 490 - 660 Fz .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050P2 1.25 x D 0.5 x D 1 x D 460 - 620 Fz .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050P3 1.25 x D 0.5 x D 1 x D 390 - 520 Fz .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046P4 1.25 x D 0.5 x D 0.75 x D 300 - 490 Fz .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039P5 1.25 x D 0.5 x D 1 x D 200 - 330 Fz .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036P6 1.25 x D 0.5 x D 0.75 x D 160 - 250 Fz .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028M1 1.25 x D 0.5 x D 1 x D 260 - 330 Fz .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046M2 1.25 x D 0.5 x D 1 x D 200 - 260 Fz .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036M3 1.25 x D 0.5 x D 1 x D 200 - 260 Fz .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028K1 1.25 x D 0.5 x D 1 x D 390 - 520 Fz .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050K2 1.25 x D 0.5 x D 1 x D 360 - 460 Fz .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046K3 1.25 x D 0.5 x D 1 x D 330 - 430 Fz .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036S1 1.0 x D 0.3 x D 0.3 x D 160 - 300 Fz .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046S2 1.0 x D 0.3 x D 0.3 x D 70 - 130 Fz .0006 .0008 .0010 .0012 .0014 .0016 .0018 .0020 .0025S3 1.25 x D 0.5 x D 1 x D 160 - 260 Fz .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036S4 1.25 x D 0.5 x D 1 x D 150 - 210 Fz .0008 .0011 .0014 .0017 .0019 .0022 .0025 .0028 .0033H1 1.25 x D 0.5 x D 0.75 x D 260 - 460 Fz .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parametersaccordingly on diameters greater than 1/2".High-Performance Solid Carbide End MillsWWW.<strong>WIDIA</strong>.COMA33

High-Performance Solid Carbide End Mills • VariMill Application Data • Series 5VNS • VariMill II Series 5VNSHigh-Performance Solid Carbide End MillsAlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/4 3/8 1/2 5/8 3/4 1Group ap ae ap Min Max dec. .2500 .3750 .5000 .6250 .7500 1.000P1 0.75 x D 0.5 x D 0.75 x D 490 - 660 Fz .0018 .0027 .0035 .0039 .0043 .0050P2 0.75 x D 0.5 x D 0.75 x D 460 - 620 Fz .0018 .0027 .0035 .0039 .0043 .0050P3 0.75 x D 0.5 x D 0.75 x D 390 - 520 Fz .0015 .0023 .0029 .0034 .0038 .0046P4 0.75 x D 0.5 x D 0.5 x D 300 - 490 Fz .0014 .0020 .0026 .0030 .0033 .0039P5 0.75 x D 0.5 x D 0.75 x D 200 - 330 Fz .0012 .0018 .0023 .0027 .0030 .0036P6 0.75 x D 0.5 x D 0.5 x D 160 - 250 Fz .0010 .0015 .0019 .0022 .0024 .0028M1 0.75 x D 0.5 x D 0.75 x D 260 - 330 Fz .0015 .0023 .0029 .0034 .0038 .0046M2 0.75 x D 0.5 x D 0.75 x D 200 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036M3 0.75 x D 0.5 x D 0.75 x D 200 - 260 Fz .0010 .0015 .0019 .0022 .0024 .0028K1 0.75 x D 0.5 x D 0.75 x D 390 - 520 Fz .0018 .0027 .0035 .0039 .0043 .0050K2 0.75 x D 0.5 x D 0.75 x D 360 - 460 Fz .0015 .0023 .0029 .0034 .0038 .0046K3 0.75 x D 0.5 x D 0.75 x D 330 - 430 Fz .0012 .0018 .0023 .0027 .0030 .0036S1 0.75 x D 0.3 x D 0.3 x D 160 - 300 Fz .0015 .0023 .0029 .0034 .0038 .0046S2 0.75 x D 0.3 x D 0.3 x D 70 - 130 Fz .0008 .0012 .0016 .0018 .0020 .0025S3 0.75 x D 0.5 x D 0.75 x D 160 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036S4 0.75 x D 0.5 x D 0.75 x D 150 - 210 Fz .0011 .0017 .0022 .0025 .0028 .0033H1 0.75 x D 0.5 x D 0.5 x D 260 - 460 Fz .0014 .0020 .0026 .0030 .0033 .0039Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".A34WWW.<strong>WIDIA</strong>.COM

High-Performance Solid Carbide End Mills • VariMill Series 4V00Application Data • Series 4V00 • VariMill TiAlNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 1 1/4Group ap ae ap Min Max dec. .1250 .1880 .2500 .3130 .3750 .4380 .5000 .6250 .7500 1.000 1.250P1 1.25 x D 0.5 x D 1 x D 490 - 660 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P2 1.25 x D 0.5 x D 1 x D 460 - 620 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062P3 1.25 x D 0.5 x D 1 x D 390 - 520 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057P4 1.25 x D 0.5 x D 0.75 x D 300 - 490 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049P5 1.25 x D 0.5 x D 1 x D 200 - 330 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046P6 1.25 x D 0.5 x D 0.75 x D 160 - 250 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036M1 1.25 x D 0.5 x D 1 x D 260 - 330 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057M2 1.25 x D 0.5 x D 1 x D 200 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046M3 1.25 x D 0.5 x D 1 x D 200 - 260 Fz .0005 .0008 .0010 .0013 .0015 .0017 .0019 .0022 .0024 .0028 .0036K1 1.25 x D 0.5 x D 1 x D 390 - 520 Fz .0009 .0014 .0018 .0023 .0027 .0031 .0035 .0039 .0043 .0050 .0062K2 1.25 x D 0.5 x D 1 x D 360 - 460 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057K3 1.25 x D 0.5 x D 1 x D 330 - 430 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S1 1.0 x D 0.3 x D 0.3 x D 160 - 300 Fz .0007 .0011 .0015 .0020 .0023 .0026 .0029 .0034 .0038 .0046 .0057S2 1.0 x D 0.3 x D 0.3 x D 70 - 130 Fz .0004 .0006 .0008 .0010 .0012 .0014 .0016 .0018 .0020 .0025 .0031S3 1.25 x D 0.5 x D 1 x D 160 - 260 Fz .0006 .0009 .0012 .0016 .0018 .0021 .0023 .0027 .0030 .0036 .0046S4 1.25 x D 0.5 x D 1 x D 150 - 210 Fz .0005 .0008 .0011 .0014 .0017 .0019 .0022 .0025 .0028 .0033 .0042H1 1.25 x D 0.5 x D 0.75 x D 260 - 460 Fz .0007 .0010 .0014 .0018 .0020 .0023 .0026 .0030 .0033 .0039 .0049Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".High-Performance Solid Carbide End MillsWWW.<strong>WIDIA</strong>.COMA35

High-Performance Solid Carbide End Mills • VariMill Application Data • Series 4VP0 • VariMill Series 4VP0High-Performance Solid Carbide End MillsTiAlNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/4 3/8 1/2 5/8 3/4 1Group ap ae ap Min Max dec. .2500 .3750 .5000 .6250 .7500 1.000P1 0.75 x D 0.5 x D 0.75 x D 490 - 660 Fz .0018 .0027 .0035 .0039 .0043 .0050P2 0.75 x D 0.5 x D 0.75 x D 460 - 620 Fz .0018 .0027 .0035 .0039 .0043 .0050P3 0.75 x D 0.5 x D 0.75 x D 390 - 520 Fz .0015 .0023 .0029 .0034 .0038 .0046P4 0.75 x D 0.5 x D 0.5 x D 300 - 490 Fz .0014 .0020 .0026 .0030 .0033 .0039P5 0.75 x D 0.5 x D 0.75 x D 200 - 330 Fz .0012 .0018 .0023 .0027 .0030 .0036P6 0.75 x D 0.5 x D 0.5 x D 160 - 250 Fz .0010 .0015 .0019 .0022 .0024 .0028M1 0.75 x D 0.5 x D 0.75 x D 260 - 330 Fz .0015 .0023 .0029 .0034 .0038 .0046M2 0.75 x D 0.5 x D 0.75 x D 200 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036M3 0.75 x D 0.5 x D 0.75 x D 200 - 260 Fz .0010 .0015 .0019 .0022 .0024 .0028K1 0.75 x D 0.5 x D 0.75 x D 390 - 520 Fz .0018 .0027 .0035 .0039 .0043 .0050K2 0.75 x D 0.5 x D 0.75 x D 360 - 460 Fz .0015 .0023 .0029 .0034 .0038 .0046K3 0.75 x D 0.5 x D 0.75 x D 330 - 430 Fz .0012 .0018 .0023 .0027 .0030 .0036S1 0.75 x D 0.3 x D 0.3 x D 160 - 300 Fz .0015 .0023 .0029 .0034 .0038 .0046S2 0.75 x D 0.3 x D 0.3 x D 70 - 130 Fz .0008 .0012 .0016 .0018 .0020 .0025S3 0.75 x D 0.5 x D 0.75 x D 160 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036S4 0.75 x D 0.5 x D 0.75 x D 150 - 210 Fz .0011 .0017 .0022 .0025 .0028 .0033H1 0.75 x D 0.5 x D 0.5 x D 260 - 460 Fz .0014 .0020 .0026 .0030 .0033 .0039Side milling applications - For longest reach (L3) tools, reduce ae by 30%.Slot milling applications - For longest reach (L3) tools, reduce ap by 30%.Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".A36WWW.<strong>WIDIA</strong>.COM

High-Performance Solid Carbide End Mills • VariMill Application Data • Series 4V0T • Series 4VPT • VariMill • Series 5V0T • VariMill II Series 4V0TAlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/2 5/8 3/4 1 1 1/4Group ap ae ap Min Max dec. .5000 .6250 .7500 1.000 1.250P5 1.25 x D 0.5 x D 1 x D 200 - 330 Fz .0023 .0027 .0030 .0036 .0046P6 1.25 x D 0.5 x D 0.75 x D 160 - 250 Fz .0019 .0022 .0024 .0028 .0036S2 1.0 x D 0.3 x D 0.3 x D 70 - 130 Fz .0016 .0018 .0020 .0025 .0031S3 1.25 x D 0.5 x D 1 x D 160 - 260 Fz .0023 .0027 .0030 .0036 .0046S4 1.25 x D 0.5 x D 1 x D 150 - 210 Fz .0022 .0025 .0028 .0033 .0042Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".Series 4VPTAlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/2 5/8 3/4 1Group ap ae ap Min Max dec. .5000 .6250 .7500 1.000P5 0.75 x D 0.5 x D 0.75 x D 200 - 325 Fz .0023 .0027 .0030 .0036P6 0.75 x D 0.5 x D 0.5 x D 150 - 225 Fz .0019 .0022 .0024 .0028S2 0.75 x D 0.3 x D 0.3 x D 70 - 130 Fz .0016 .0018 .0020 .0025S3 0.75 x D 0.5 x D 0.75 x D 160 - 260 Fz .0023 .0027 .0030 .0036S4 0.75 x D 0.5 x D 0.75 x D 150 - 210 Fz .0022 .0025 .0028 .0033Side milling applications - For longest reach (L3) tools, reduce ae by 30%.Slot milling applications - For longest reach (L3) tools, reduce ap by 30%.Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".High-Performance Solid Carbide End MillsSeries 5V0TAlTiNRecommended Feed Per Tooth (Fz=inch/th) for Side Milling (A).For Slotting (B), reduce Fz by 20%.A B Cutting Speed Vc D1 - DiameterSFM frac. 1/4 3/8 1/2 5/8 3/4 1Group ap ae ap Min Max dec. .2500 .3750 .5000 .6250 .7500 1.000P5 1.25 x D 0.5 x D 1 x D 200 - 325 Fz .0012 .0018 .0023 .0027 .0030 .0036P6 1.25 x D 0.5 x D 0.75 x D 150 - 225 Fz .0010 .0015 .0019 .0022 .0024 .0028S2 1.0 x D 0.3 x D 0.3 x D 70 - 130 Fz .0008 .0012 .0016 .0018 .0020 .0025S3 1.25 x D 0.5 x D 1 x D 160 - 260 Fz .0012 .0018 .0023 .0027 .0030 .0036S4 1.25 x D 0.5 x D 1 x D 150 - 210 Fz .0011 .0017 .0022 .0025 .0028 .0033Lower value of cutting speed is used for high-stock removal applications or for higher hardness (machinability) within group.Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group.Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordinglyon diameters greater than 1/2".WWW.<strong>WIDIA</strong>.COMA37

X-Feed End Mills for High-Feed MillingSpecifically engineered to machine hardened steel up to 67 HRCat extreme speeds and feeds.• Unique tool with new 6-flute style for high productivity.• Necked shanks provide extended reach in deep cavities.• High-feed rates, up to 0,6mm (.024"), per tooth on a 20mm (3/4") tool.• Machine hardened materials at 2x to 3x the metal removal rate of competitive end mills.• Wide range of cutting diameters: down to 6mm (.250") for small and medium pocket work.• Innovative new geometry maximizes metal removal rates.• High metal removal rates lower manufacturing costs.Featured Application: Milling a MoldOperation:Customer:Material:Workpiece:Results:Pocket MillingDie & Mold ManufacturerAISI 4340 hardened steel (52 HRC)Mold• 3x better metal removal rate than competitive tool!• Machined at more than 3x faster feed!700Increased MetalRemoval Rate by 191%COMPETITOR<strong>WIDIA</strong>-<strong>Hanita</strong>tool: 4-flute H/P for die & mold 70N612005MTmaterial:medium-hardened steel medium-hardened steel(52 HRC) (52 HRC)surface speed: 120m/min (400 SFM) 160m/min (530 SFM)feed per tooth:0,34mm0,34mm(.013") (.013")depth of cut: 0,8mm (.031") 0,6mm (.023")table feed:4,331mm/min15,287mm/min(170 in/min) (600 in/min)metal removal rate:22,8 cm 3 60,5 cm 3(1.4 in 3 ) (3.7 in 3 )metal removal rate(cm3/min)600500400300200100Best Competitor<strong>WIDIA</strong>-<strong>Hanita</strong>A38WWW.<strong>WIDIA</strong>.COM

High-Performance Solid Carbide End Mills • Hard MaterialsHigh-Performance Solid Carbide • Hard Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A39–A50Series 7S05 • Lists 7S057S15 7S25 • Vision Plus . . . . . . . . . . . . . . . . . . . . . . . . . .A40Series 7S5F • Vision Plus . . . . . . . . . . . . . . . . . . . . . . . . . . .A41Series 7FN6 • 37–52 HRC •Vision Plus X-Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A42Series 7FN7 • >52 HRC •Vision Plus X-Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A43Series 7S7R • Vision Plus . . . . . . . . . . . . . . . . . . . . . . . . . . .A44Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A47Speed Calculation • Ball Nose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A48WWW.<strong>WIDIA</strong>.COMA39

High-Performance Solid Carbide End Mills • Hard MaterialsSeries 7S05 • Lists 7S05 7S15 7S25 • Vision Plus High-Performance Solid Carbide End Mills• Center cutting.• Standard items listed. Additional stylesand coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P H3 4 1 2 3 4AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A46.length of cutlengthD1 D Ap1 max L Z U AlTiN - MT1/4 1/4 3/8 3 4 TM7S05070021/4 1/4 5/8 3 4 TM7S15070021/4 1/4 7/8 3 4 TM7S25070025/16 5/16 1/2 4 4 TM7S05080005/16 5/16 3/4 4 4 TM7S15080005/16 5/16 1 1/8 4 4 TM7S25080003/8 3/8 9/16 4 4 TM7S05100043/8 3/8 15/16 4 5 TM7S15100043/8 3/8 1 5/16 4 5 TM7S25100041/2 1/2 3/4 5 4 TM7S05130051/2 1/2 1 1/4 5 6 TM7S15130051/2 1/2 1 3/4 5 6 TM7S25130055/8 5/8 1 5/16 5 4 TM7S05160065/8 5/8 1 9/16 5 6 TM7S15160065/8 5/8 2 3/16 5 6 TM7S25160063/4 3/4 1 1/8 6 4 TM7S05190073/4 3/4 1 7/8 6 6 TM7S15190073/4 3/4 2 5/8 6 6 TM7S25190071 1 1 1/2 6 5 TM7S05250081 1 2 1/2 6 6 TM7S15250081 1 3 1/2 6 6 TM7S2525008A40WWW.<strong>WIDIA</strong>.COM

High-Performance Solid Carbide End Mills • Hard MaterialsSeries 7S5F • Vision Plus • Center cutting.• Standard items listed. Additional stylesand coatings made to order.• For information about Custom Solutions,see page A90.• For information about ReconditioningServices, see page A95.High-Performance Solid Carbide End MillsEnd Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 ≤ 1/8" 0 / .00024> 1/8" to 1/4" 0 / .00031> 1/4" to 3/8" 0 / .00035> 3/8" to 23/32" 0 / .00043> 23/32" to 1 3/16" 0 / .00051P H3 4 1 2 3 4AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A46.length of cutlengthD1 D Ap1 max L3 L BETA D3 AlTiN - MT1/8 1/4 1/8 — 3 2.5 — TM7S5F030025/32 1/4 5/32 — 3 2.5 — TM7S5F040023/16 1/4 3/16 — 3 2.5 — TM7S5F050021/4 3/8 1/4 — 4 2.5 — TM7S5F070045/16 3/8 5/16 — 4 2.5 — TM7S5F080043/8 1/2 3/8 — 5 2.5 — TM7S5F100051/2 5/8 1/2 1.95 5 — .47 TM7S5F130065/8 5/8 5/8 1.89 5 — .59 TM7S5F160063/4 3/4 3/4 2.27 6 — .71 TM7S5F19007WWW.<strong>WIDIA</strong>.COMA41

High-Performance Solid Carbide End Mills • Hard MaterialsSeries 7FN6 • 37–52 HRC • Vision Plus X-Feed High-Performance Solid Carbide End Mills• Non-center cutting.• Hi-Feed.• Standard items listed. Additional styles and coatingsmade to order.• For information about Custom Solutions, see page A90.• For information about Reconditioning Services, see page A95.End Mill TolerancesD1 Tolerance D Tolerance h6+ / -All +.000 / - .002 < 1/8" 0 / .000241/8" to 7/32" 0 / .000311/4" to 3/8" 0 / .0003513/32" to 11/16" 0 / .0004323/32" to 1 3/16" 0 / .00051P H4 1 2AlTiN P - Steels K - Cast Iron S - High-Temp AlloysM - Stainless Steels N - Non-Ferrous H - Hard MaterialsFor material descriptions, see Inside Back Cover.For application data, see page A50.length of cutlengthD1 D Ap1 max L3 L Rt D3 AlTiN - MT1/4 1/4 .013 .750 2 1/2 .027 .21 TM7FN6070025/16 5/16 .017 1.000 3 .034 .27 TM7FN6080033/8 3/8 .020 1.250 3 1/2 .040 .34 TM7FN6100041/2 1/2 .027 1.500 4 .054 .46 TM7FN6130055/8 5/8 .033 2.000 4 1/2 .067 .59 TM7FN6160063/4 3/4 .040 2.500 5 .080 .71 TM7FN619007Geometrical ParametersRamping Guide for Circular and Linear RampingCircular InterpolationLinear RampingOptimal Range of Circle Diameter for a Single PassCalculated Length per Ramp AngleD1 Ap1 max R Rε YRC RCN Smallest Largest 1 deg. 2 deg. 3 deg. 4 deg. 5 deg.1/4 0.0133 0.250 0.0160 0.0313 0.0525 0.355 0.500 0.762 0.381 0.254 0.190 0.1525/16 0.0166 0.313 0.0200 0.0391 0.0656 0.444 0.625 0.953 0.476 0.317 0.238 0.1903/8 0.0200 0.375 0.0235 0.0469 0.0788 0.533 0.750 1.143 0.572 0.381 0.285 0.2281/2 0.0266 0.500 0.0320 0.0625 0.1050 0.710 1.000 1.525 0.762 0.508 0.381 0.3045/8 0.0333 0.625 0.0400 0.0781 0.1313 0.888 1.250 1.906 0.953 0.635 0.476 0.3803/4 0.0399 0.750 0.0470 0.0938 0.1575 1.065 1.500 2.287 1.143 0.762 0.571 0.456Recommended % of programmed feed rate to use while ramping. 100% 70% 50% 30% 10%YRC = distance from center line to the crown of the R radius.RCN = distance from center line to the start of the cutting edge. This dimension can also help determine the minimum circle size when helical ramping.R = the head radius size.Rε = the shoulder radius or radius at the corner of the cutter.A42WWW.<strong>WIDIA</strong>.COM