Windscale Review 2005/06 - Research Sites Restoration Ltd

Windscale Review 2005/06 - Research Sites Restoration Ltd

Windscale Review 2005/06 - Research Sites Restoration Ltd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong>

Introduction by Peter Mann, Head of SiteAt <strong>Windscale</strong>, reactor decommissioning forms the core of the siterestoration programme with the <strong>Windscale</strong> Advanced Gas-cooled Reactor(WAGR), Pile 1 and Pile 2 all currently being decommissioned.Maintaining and accelerating the progress already made isthe basis of our current plans. Overall, the strategy is forthe restoration of the <strong>Windscale</strong> site to allow its reuse in asafe, environmentally friendly, progressive and cost-effectivemanner, making best use of available waste routes.This report covers the work UKAEA is doing at<strong>Windscale</strong> and our progress in the period from April<strong>2005</strong> to March 20<strong>06</strong>.Where we are todaySignificant progress has already been made towards siterestoration at <strong>Windscale</strong>. The WAGR core has alreadybeen completely removed and packaged for interimstorage. Phase one decommissioning of both Pile 1 andPile 2 has been completed with all fuel, isotopes anddebris removed from around the reactor cores and modernventilation and monitoring systems installed to supportongoing decommissioning works.The breakdown of our expenditure reflects our focus ondecommissioning work.Vision for the futureThe vision for <strong>Windscale</strong> is to reduce all significant hazardsand restore the site to brownfield status as safely andquickly as possible. Removing accessible fuel and isotopesfrom the Piles and demolishing redundant facilities willleave the majority of the site in a quiescent state. Later, thePiles and remaining facilities will be demolished andenvironmental remediation undertaken. On current plans,the work will be completed in 2<strong>06</strong>5 assuming a nationalintermediate level waste repository will not be availablebefore 2040. We are challenging this programme to enablefinal decommissioning to be accelerated further.A number of major project achievements havebeen delivered during the year, including:• The first intrusive survey of the Pile 1 core foilholes since the 1957 fire.• Remote decontamination of WAGR fuel handlingfacility.• Decommissioning of the Mortuary Cave.• Successful hydrogen venting of Piles wastedrums and subsequent re-location to thepurpose-built store.• Site demolition and clearance of a number ofbuildings – B25, B56, F213, B13 Sump House.• Significant additional works in support of theadjacent site licence holder including buildingdemolition and office relocation.Overall, the main themes of our baseline are to:• Maintain and improve our track record of safety andrespect for the environment.• Maximise early hazard reduction.• Be innovative in finding cost-effective solutions.• More sharply focus site resources on safe, efficient,accelerated hazard reduction.• Move more aggressively into the physical work ofdecommissioning.• Continue to reshape our UKAEA workforce into a worldclass team.• Continue to consult and inform our stakeholders.• Support operations in a tenanted facility which isstrategically important for the nuclear industry.For 20<strong>06</strong>/07 we intend to undertake a number ofimportant work areas that include:• Retrieving the remaining isotopes in Pile 2.• Delivering the Piles acceleration plan for NuclearDecommissioning Authority (NDA) consideration.• Demolishing ancillary building.• Clearing out more caves in the post-irradiationexamination facility.• Carrying out the characterisation of the WAGR transfertube.2 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> | Introduction

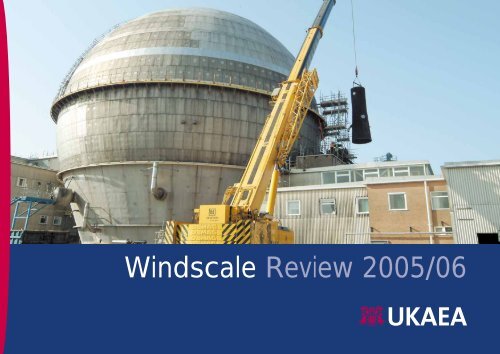

Message from Mark Dixon,NDA Regional Director• Starting decommissioning of a redundant materialsexamination facility with the clear out of redundantequipment and areas.We aim to deliver our plans for the site in a safe andenvironmentally friendly way, recognising that thesupport of our stakeholders is essential to theachievement of our goals.Breakdown of expenditure at <strong>Windscale</strong>for <strong>2005</strong>/<strong>06</strong>The Nuclear Decommissioning Authority (NDA) is a new organisation set up to deliver cost-effective clean-up of thenation’s civil nuclear legacy. Since April <strong>2005</strong> we have provided oversight management of the <strong>Windscale</strong> site andhave worked with our principal contractor, United Kingdom Atomic Energy Authority (UKAEA), to ensure that thedecommissioning of the <strong>Windscale</strong> site continues in a way that meets our core values of safety, security andenvironmental responsibility whilst providing value for money for the UK taxpayer.The past year has been a time of change as UKAEA has had to adapt to the requirements of the NDA as its customer andthe rigour of working to a contract. I am pleased with the increased responsiveness of Peter Mann and his team to theneeds of the NDA with introduction of new processes and procedures to manage the clean up work.Notable successes have been the acceleration of decommissioning activities within the WAGR fuel handling facility andcompletion of an intrusive survey of the Pile 1 core.With effect from 1 April 20<strong>06</strong>, we asked <strong>Windscale</strong> to take over full control of projects for:Waste & nuclearmaterialsmanagement£0.5M<strong>Sites</strong>upport£2MSupportservices£3MStakeholdersupport£0.5MCommercialoperations£2M• Implementation of safety and engineering improvements in the post-irradiation examination facility in support of ongoingcommercial operations.• Removal of the WAGR pressure vessel.I look forward to working with the site over the coming year as they progress work in these areas and continue to advancework associated with hazard reduction of the <strong>Windscale</strong> Piles.I encourage Peter and his team to continue to accelerate the clean-up of <strong>Windscale</strong> in a way that meets all of ourdemands to protect the safety of the workforce and those around the site, that meets the needs of national security andthat demonstrates our commitment to protect the environment.Decommissioning & termination £14MFront cover picture:Stack removal at <strong>Windscale</strong> post-irradiation examination facility.Introduction | <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> 3

Safety, security and the environmentThe foundationfor our successUKAEA aspires to best in classstandards of safety, security andenvironmental management in itsactivities at <strong>Windscale</strong>. Through thecommitment of everyone in thecompany we work hard to protectourselves, our colleagues, ourneighbours and the environment,and to continually introduceinnovations and initiatives that willimprove our performance.SafetyThe total number of safety events reported during theperiod was down on last year. To generate a longer termimprovement we have started to build in culturalenhancement through continuing awareness workshops,audits and promotions.External assessmentsUKAEA’s management system as a whole was re-certifiedwith both ISO 9001:2000 and ISO 14001:2004 qualitystandards. The site applies a loss control philosophy andhas a Level 7 International Safety Rating System (ISRS)award out of a maximum of 10 from the independentcertification authority Det Norske Veritas (DNV), anexcellent outcome.Key improvementsDuring the year a number of safety improvements wereintroduced.• An Employee Assistance Programme for staff, designedto provide confidential advice and support for work andpersonal related concerns.• To meet the requirements of the new Work at HeightRegulations, new access equipment has beenintroduced, together with a programme of training forUKAEA risk assessors.• A programme of PPE (personal protective equipment)modernisation has been completed, including aselection tool identifying suitable PPE for work activities.UKAEA’s achievements in this area have been featuredin both the Safety & Health Practitioner and the SafetyManagement Journal.Safety performanceThe overall number of events reported reduced to fourcompared with six during the previous year. We believe thisimprovement resulted from more effective managementand a programme of safety awareness initiatives, includinga successful campaign to increase the reporting of issues.a) Non-injury eventsTwo events occurred during the year; neither caused harmto employees or the environment.• A package of three liners was sent from <strong>Windscale</strong> tothe adjacent BNG Sellafield site. On arrival, monitoringrevealed higher than expected radiation dose rates. Thesources of the dose were identified and cleaned up withno significant dose to workers.• Internal shield doors were operated in a cave withoutcorrect arrangements in place.Top: Working in protective clothing at a controlled area in Pile 1.4 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> |Safety, security and the environment

Improvements in safetyperformance resulted fromeffective management and aprogramme of awareness-raisingcampaigns.Concerns over the safety management control of tenantoperations in one facility on the site led to the NII issuing anImprovement Notice on both UKAEA and the tenant. Thisrequired a review of the safety management arrangementsin place between UKAEA and the tenant for this facility.b) Lost Time AccidentsTwo Lost Time Accidents were reported during the year,compared with four the previous period. Both werereported as events. Our Accident Frequency Rate of 410/100,000 people compares favourably with values of 1,210for all industries and 1,980 for construction industries.Safety awareness initiativesProjects during the year have included:• Distribution of safety and environment newsletters.• A talk by a lecturer on acoustics from NottinghamUniversity as part of the site’s Health and Safety Weekfocus on noise.• A behavioural safety joint exercise between UKAEA andNexia Solutions <strong>Ltd</strong> in the tenanted ShieldedExamination Facility.• Training to re-focus staff on construction-style issuesassociated with decommissioning and demolition.Right: Safety briefing at the WAGR waste store.Safety, security and the environment | <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> 5

Safety, security and the environment<strong>Windscale</strong> maintained a highlevel of security awarenessand preparednessthroughout the year.Emergency planningSecuritySite instructions and procedures for emergency exerciseshave been updated to meet the changing arrangements ofthe decommissioning programmes. A high level ofcommand and control training has been completed byincident controllers to ensure a professional response toany facility or site incident.Emergency exercisesThe <strong>Windscale</strong> Level 1 annual site emergency exercise washeld in June <strong>2005</strong>. The exercise was a success and the NIIwere satisfied that it was an adequate demonstration of Environmental managementemergency arrangements. Additionally, seven nuclearfacilities on the <strong>Windscale</strong> site have completed localemergency exercises designed to test area-specificresponses during the year.Safety indicators: <strong>2005</strong>/<strong>06</strong>Lost Time Accidents 2 (UKAEA 0; Contractors/tenants 2)Safety events 4Accident Frequency Rate 0.22 per 100,000 hours workedAverage annual radiation0.8mSv (30% of averagedose to workersdose received by the public)Maximum annual radiation dose3.55mSvto workers(18% of dose limit)International Nuclear Event ScaleOne event atincidents Level 1International Safety Rating System Level 7 retained6 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> | Safety, security and the environmentUKAEA <strong>Windscale</strong> has maintained a high state of securityawareness and preparedness throughout the year inresponse to prevailing terrorist threats. There have been nobreaches of security involving nuclear material either instorage on the UKAEA site or in transit. The annual sitecounter-terrorism exercise was held in November <strong>2005</strong>.This exercise was successful and met with regulatoryapproval.<strong>Windscale</strong>’s site strategy to decommission the site upholdsthe UKAEA mission statement of ‘restoring ourenvironment’.Decommissioning work packages on site have achievedmajor environmental improvements, such as safe removal,treatment and storage of radioactive waste. The safemanagement of non-radioactive wastes which arehazardous and, where appropriate, inert wastes have beenrecycled. For example, non-active concrete waste hasbeen used as part of the site restoration, reducing theneed to bring material onto the site.Key achievementsSince <strong>Windscale</strong> achieved ISO 14001 accreditation for itsEnvironmental Management System (EMS), many of theimprovements identified in the site review have led toenhanced environmental performance. <strong>Windscale</strong> achievedall of the year’s environmental objectives and targets.Working with the Environment Agency, UKAEA has had newmultimedia discharge authorisation since January 20<strong>06</strong>.Environmental monitoringAs part of our EMS we have ensured that suitablemonitoring is in place for decommissioning and demolitionof major structures on the site.We monitor and report all discharges and transfers ofradioactive waste from the site in accordance with ourCertificate of Authorisation under the RadioactiveSubstances Act to the Environment Agency.Reportable eventsDuring the period there were no reportable environmentalevents on site and no enforcement actions taken.Top: Police dog training exercise near the <strong>Windscale</strong> site.

EcologyThe <strong>Windscale</strong> site is predominantly an industrial site,although it is set in the backdrop of the Lake DistrictNational Park and there are a number of <strong>Sites</strong> of SpecialScientific Interest close to site. Through our EMS weensure measures are in place to protect these areas.Environmental indicators: <strong>2005</strong>/<strong>06</strong>Energy consumptionWater usageElectricity - 6,348 MWHrSteam - 7,750 tonnes23,000 cubic metresRadiological discharges calendar year <strong>2005</strong>:Alpha Beta TritiumGaseous(Rolling twelve month 5.40% 2.49% 49.20%figure as a % ofAuthorisation)Liquid(Rolling twelve month 0.04% 0.09% 0figure as a % ofAuthorisation)Solid transfer(Total amount for year) 2.2 GBq 622 GBq

Environmental restorationProgress onmajor challengesThe key phases for <strong>Windscale</strong>’sLifetime Plan (LTP) reflect thecurrent strategy for restoring thesite. Programmes for removingsignificant radioactive hazards willbe followed by others for care andmaintenance, final decommissioningand site remediation.Early work involves decommissioning WAGR, removing fueland isotopes from the Piles and demolishing all redundantbuildings, whilst managing the site safely, securely andenvironmentally responsibly. When completed, the Pileswill be inherently safe and site services will be reducedappropriately. When the national intermediate level wasterepository opens, <strong>Windscale</strong>’s plan will culminate in theachievement of the final end state for the site - demolitionof all buildings, final site clearance and environmentalremediation to achieve a brownfield site.DecommissioningGood progress was achieved in a number of areas of the<strong>Windscale</strong> site as part of the decommissioning andrestoration plan during this year. In addition to our plannedprogramme of work at the start of the year an additional£1.7M of additional or accelerated work was added to theplan during the year.Key project achievements included:Western AreaThe WAGR thimble flask was removed from the facility andthe flask packed in to a transport container for direct disposalto the low level waste facility at Drigg. In the adjacent facility,intermediate level wastes (ILW) from the cave facilities wereconditioned and transferred to the long term storage facilityand the mortuary cave was decommissioned.Characterisation of the massive concrete biological shieldof WAGR was completed to support the most effectiveapproach to the final demolition of the structure. Surveysof the Transfer Tube were completed, to identify theapproach for its final dismantling and removal.In the latter part of the year the WAGR core and pressurevessel removal project transferred to direct UKAEAmanagement, with the WAGR agreement close-out lettersigned on 31st March. This opens up exciting possibilitiesfor accelerating further work within the Western Area in thecoming years.Top: Removing the WAGR thimble flask.8 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> |Environmental restoration

Good progress was achieved ina number of areas of the site aspart of the decommissioningand restoration plan.Pile reactorsWithin the Piles facilities significant enabling work has beencarried out to support the decommissioning plans. InPile 2, 15 flasks have been successfully de-lidded andinternal samples taken to determine the disposal strategyand arrangements. In Pile 1 an intrusive survey of the foilholes within the core was carried out – the first since the1957 fire – a significant step forward in confirming thecurrent state of the core. Supporting work included thesuccessful venting of the Piles waste drums and theirinterim storage in one purpose-built location while finalprocessing plans are being drawn up.In the latter part of the year work was initiated to developproposals for the accelerated decommissioning of thePiles, for review and agreement with the NDA in 20<strong>06</strong>.Other projects• Four facilities - B25, B56, F213 and B13 Sump Househave been cleared and demolished to floor slab level.Part of the demolition work was to support the LiquidSludge Treatment Plant enabling works by BritishNuclear Group on the neighbouring Sellafield site.• In a redundant materials examination facility, work toremove miscellaneous equipment was started this year.Right: Inside the Pile 1 building, showing the top of the foil holes.Environmental restoration | <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> 9

Environmental restorationSafe storage and disposal ofwaste and nuclear materials willremain a priority throughout the<strong>Windscale</strong> programme.Waste managementSafe storage and disposal of waste and nuclear materialswill remain a priority throughout the plan for the<strong>Windscale</strong> site.Integrated Waste Strategy<strong>Windscale</strong> is implementing a fully developed IntegratedWaste Strategy (IWS) for the site. The year has seen thegeneration of the full IWS following the development andanalysis of suitable options together with an externalstakeholder workshop to present and review the preferredapproaches to managing the wastes on the <strong>Windscale</strong>site. The IWS has been developed to allow the site toidentify and manage its current and future waste arisingsusing acceptable methods, techniques and disposalroutes. The intent is to replace the current Interim IWSfollowing completion of the stakeholder consultation periodin the coming year, 20<strong>06</strong>.Waste retrieval, storage and disposalWaste management activities across the site in this yearfocussed on the ongoing generation of wastes from thedecommissioning projects, notably WAGR and postirradiationexamination facility. As part of this programmethe WAGR ILW store overpack trials were completed tosupport the waste management arrangements for thefacility.Land remediationEnvironmental restoration activities across site will initiallybe to characterise the site conditions and then to developand implement a plan for restoration/remediation andcontrol, as required. Contaminated land and waterremediation will be carried out to achieve the End Stateconditions whilst complying with stakeholder,environmental and nuclear site licence requirements. This iscurrently assumed to be a radiological/industrial brownfield,based on site specific risk assessments and BestPracticable Environmental Option studies.Left: Remote-controlled decommissioning in the WAGR control room.10 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> |Environmental restoration

Land characterisationThis year saw the completion of land characterisation deskstudies in order to improve the existing information on landand water contamination. The next stage of theprogramme was also completed - the development of thedesign for characterisation systems.Decommissioning and waste management: <strong>2005</strong>/<strong>06</strong>No. of buildings demolished 4Volume of low level waste consigned toDrigg LLW repository following treatment 282.81m 3Decommissioning and termination expenditureWaste and nuclear materials expenditure£14.5M£4.5MTop: Digging a trial pit during <strong>Windscale</strong> land characterisation work.Right: Documentation from the land characterisation desktop study.Environmental restoration |<strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> 11

Working with our stakeholdersBuilding partnerships<strong>Windscale</strong> puts great emphasis onworking in partnership with localstakeholders to provide full andaccessible information on our plans.This will ensure that they have a sayin how we undertake ourprogrammes and properly protectthe environment.Local Stakeholder GroupUKAEA supports the Nuclear Decommissioning Authority’sinitiative to establish Local Stakeholder Groups to provideopen two-way communication channels between siteoperators, the NDA and local stakeholders. We have beenclosely involved in setting up the <strong>Windscale</strong> sub-committeeof the West Cumbria <strong>Sites</strong> Stakeholder Group under anindependent chairman and with meetings held in public.Membership includes local councillors, council officers,members of regulatory bodies, the NDA, emergencyservices and British Nuclear Group.UKAEA is engaging with the <strong>Windscale</strong> sub-committee onissues that are particularly important to the localcommunity. Following the inaugural meeting of the subcommittee in September <strong>2005</strong>, members of the subcommitteemet at <strong>Windscale</strong> in December <strong>2005</strong> to get afamiliarisation tour of the site’s facilities and to identifyfuture agenda items for the committee meetings. Thesecond formal meeting was held in March 20<strong>06</strong>.Stakeholder participationAt present the focus of attention is on the options fordecommissioning the Pile 1 reactor. A Best PracticableEnvironmental Option (BPEO) consultation meeting on Pile1 decommissioning was held in March <strong>2005</strong> and the reportpublished in June <strong>2005</strong>.Consultation is currently underway to identify the bestpracticable option for the Integrated Waste Strategy for the<strong>Windscale</strong> site. A consultation workshop was held inMarch 20<strong>06</strong>.International co-operationThe WAGR project manager was a guest speaker at theOECD (Organisation for Economic Development and Cooperationand Development) Technical Advisory Committeemeeting held in Japan. The international group includesrepresentatives from OECD countries and meets regularly toreview progress and exchange technical information. TheWAGR decommissioning project is a member project.VisitsWe welcomed many visitors to the <strong>Windscale</strong> site duringthe year. Among them:• Dr Ian Roxburgh, Chief Executive, NDA.• Representatives from the Shareholder Executive and theregulators.• Local community representatives.• Graduates from Birmingham and Liverpool Universities.Left: Talking to stakeholders at an NDA/West Cumbria DevelopmentAgency event at Westlakes.Top: <strong>Windscale</strong> Communications Manager Fee Wilson giving apresentation to local stakeholders at Salterbeck.12 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> |Working with our stakeholders

Supporting the communityWorking with the communityUKAEA has forged firm andpositive links with the localcommunity in West Cumbria, with astrong communications team at<strong>Windscale</strong>.SponsorshipOn behalf of the NDA, <strong>Windscale</strong> has supported a numberof projects over the past year - from support for localsports clubs to the GENII apprentice awards for studentswho have completed their first year of training.Events supported include the Whitehaven MaritimeFestival, which takes place every two years and is one ofthe highlights of the West Cumbrian calendar.Local conservation projectsFor the past four years, <strong>Windscale</strong> staff have been workingwith the British Trust for Conservation Volunteers (BTCV)on local environmental projects. In October <strong>2005</strong>, stafffrom <strong>Windscale</strong> joined BTCV volunteers to help clear scrubat Clints Quarry, Egremont, a local beauty spot as well asundertaking work at Christcliffe Nature Reserve in Eskdale.FundraisingCommunity-minded <strong>Windscale</strong> staff have collected moneyand raised funds for a wide range of good causes duringthe year, including Children in Need, Macmillan Nurses,Jeans for Genes and <strong>Research</strong> into Breast Cancer. Theyalso took part in ‘Uppies and Downies’, a Cumbrian eventwhich raises funds for local causes.Left: <strong>Windscale</strong> volunteers helping out with conservation work atClints Quarry.Above: Whitehaven Maritime Festival was among eventssupported during the year. (Photo courtesy of The Whitehaven News)Supporting the community | <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> 13

Site Performance-Based Incentives <strong>2005</strong>/<strong>06</strong>Continuing to raise standardsThe performance of the site management and operationscontractor is measured by delivery of a series ofPerformance-Based Incentives (PBIs) agreed with theNDA. Fee is dependent upon successful completion ofPBIs. This table summarises the PBIs for <strong>Windscale</strong>.a) Safety, security and environment:PBIEnhancement of site Environmental, Health, Safety,and Security (EHS&S) cultureOutcomeAchievedSubmittal and acceptance by the Authority of the AchievedSite Information Technology and Systems forSeparation Plan99% achievement of scheduled compliance dates Achievedfor key safety related (KSRE) maintenance tasks.90% achievement of scheduled compliance dates Achievedfor safety related (SRE) maintenance tasks70% achievement of scheduled compliance dates Achievedfor all maintenance tasksRegular Meetings with NIIAchievedRegular Meetings with EAAchievedSuccessful regulatory action closeoutAchievedb) Pile 1 decommissioning:PBIComplete scheme design for Pile 1 removable fueland isotopesSuccessful completion of Office of GovernmentCommerce Gateway 3 <strong>Review</strong>Completion of non-fire affected zone intrusivesurveyc) <strong>Windscale</strong> Advanced Gas-cooled Reactordecommissioning:PBIPlace contract for Remote Dismantling Machinesteelwork modificationsComplete Remote Dismantling Machine steelworkmodificationsComplete mortuary tube characterisationCompletion of dismantling and removal of otheritems of significant activityComplete building characterisationOutcomeAchievedAchievedAchievedOutcomeAchievedAchievedAchievedAchievedAchievedd) Pile 2 decommissioning:PBICharacterisation Safety Case endorsed by<strong>Windscale</strong> Safety Working PartyComplete specification for detailed design ofisotope removal equipmentIsotope waste route establishedContract placed for design studies for facilityisolatione) Post-irradiation examination facilitydecommissioning:PBIComplete remote decontamination ofDecontamination Cave 1 (DC1)Transfer soft waste to WAGR box, encapsulateand storeComplete specification for design, manufactureand implementation of waste transfer equipmentfor transfer of waste (ILW Waste Route)Completion of decommissioning Safety CaseCompletion of demolition of secondaryventilation filter housingOutcomeAchievedAchievedAchievedAchievedOutcomeAchievedAchievedAchievedAchievedAchieved14 <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> |Site Performance-Based Incentives <strong>2005</strong>/<strong>06</strong>

f) Piles asset care:PBICompletion of Pile 1 roof refurbishmentInstallation of emergency exits and staircasesOutcomeAchievedNot Achievedg) Shielded examination facility decommissioning:PBIOutcomeInterim Operational Safety Case – Peer <strong>Review</strong> Achievedacceptance of engineering substantiation reportsand Independent Technical AssessmentInterim Operational Safety Case – PeerNot Achieved<strong>Review</strong> acceptance of completion ofengineering substantiation reconciliationInterim Operational Safety Case endorsed by Achieved<strong>Windscale</strong> Safety Working Party (Includesindependent members)Initial characterisation – Completion of radiological Achievedsurvey of internals or redundant cells.Initial characterisation – Completion of assessmentof radiological surveyAchievedh) Liquid Sludge Treatment Plant enabling works:PBIOffice accommodation vacated by27 September <strong>2005</strong>Accommodation works complete andequipment/personnel relocatedi) General:PBIPrepare specification for the study and obtainNDA approvalSubmission of the options report to the NDAAcceptance of the report by the NDAIssue Lifecycle Baseline 3 by 30 June <strong>2005</strong>Issue Near Term Work Plan 3 by 15 March 20<strong>06</strong>Conduct timely and comprehensive performancereviewsProvide timely and accurate performance reports inaccordance with NDA requirements.Participate in Site Stakeholder GroupDevelop Socio-economic Development PlanSupport conservation projects in local communitythrough partnership with BTCV (British Trust forConservation Volunteers)Provide support to local organisations according toestablished UKAEA criteria and within budgetOutcomeAchievedAchievedOutcomeAchievedAchievedAchievedAchievedAchievedAchievedAchievedAchievedAchievedAchievedAchievedRight: Drum venting operations at the Pile reactors.Site Performance-Based Incentives <strong>2005</strong>/<strong>06</strong> | <strong>Windscale</strong> <strong>Review</strong> <strong>2005</strong>/<strong>06</strong> 15

For further informationvisit us at www.ukaea.org.ukor telephone 019467 28888UKAEA <strong>Windscale</strong> Seascale Cumbria CA20 1PFPaper used in this document is 80% post-consumer recycled fibre and the remaining 20% is produced from totally chlorine free pulp.Design and artwork by CM Design (01235 210269)