WORKSHOP INSPECTION CHECKLIST - Staff

WORKSHOP INSPECTION CHECKLIST - Staff

WORKSHOP INSPECTION CHECKLIST - Staff

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

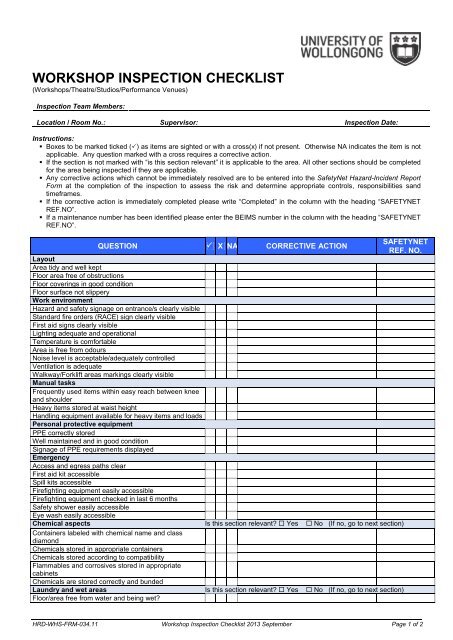

<strong>WORKSHOP</strong> <strong>INSPECTION</strong> <strong>CHECKLIST</strong>(Workshops/Theatre/Studios/Performance Venues)Inspection Team Members:Location / Room No.: Supervisor: Inspection Date:Instructions:• Boxes to be marked ticked () as items are sighted or with a cross(x) if not present. Otherwise NA indicates the item is notapplicable. Any question marked with a cross requires a corrective action.• If the section is not marked with “is this section relevant” it is applicable to the area. All other sections should be completedfor the area being inspected if they are applicable.• Any corrective actions which cannot be immediately resolved are to be entered into the SafetyNet Hazard-Incident ReportForm at the completion of the inspection to assess the risk and determine appropriate controls, responsibilities sandtimeframes.• If the corrective action is immediately completed please write “Completed” in the column with the heading “SAFETYNETREF.NO”.• If a maintenance number has been identified please enter the BEIMS number in the column with the heading “SAFETYNETREF.NO”.QUESTION X NA CORRECTIVE ACTIONSAFETYNETREF. NO.LayoutArea tidy and well keptFloor area free of obstructionsFloor coverings in good conditionFloor surface not slipperyWork environmentHazard and safety signage on entrance/s clearly visibleStandard fire orders (RACE) sign clearly visibleFirst aid signs clearly visibleLighting adequate and operationalTemperature is comfortableArea is free from odoursNoise level is acceptable/adequately controlledVentilation is adequateWalkway/Forklift areas markings clearly visibleManual tasksFrequently used items within easy reach between kneeand shoulderHeavy items stored at waist heightHandling equipment available for heavy items and loadsPersonal protective equipmentPPE correctly storedWell maintained and in good conditionSignage of PPE requirements displayedEmergencyAccess and egress paths clearFirst aid kit accessibleSpill kits accessibleFirefighting equipment easily accessibleFirefighting equipment checked in last 6 monthsSafety shower easily accessibleEye wash easily accessibleChemical aspects Is this section relevant? Yes No (If no, go to next section)Containers labeled with chemical name and classdiamondChemicals stored in appropriate containersChemicals stored according to compatibilityFlammables and corrosives stored in appropriatecabinetsChemicals are stored correctly and bundedLaundry and wet areas Is this section relevant? Yes No (If no, go to next section)Floor/area free from water and being wet?HRD-WHS-FRM-034.11 Workshop Inspection Checklist 2013 September Page 1 of 2

Dryer filter clean?QUESTION X NA CORRECTIVE ACTIONDrains (floors and sink ) clear and free flowingTaps free from dripsPlant and equipment Is this section relevant? Yes No (If no, go to next section)Area around plant cleanPlant and equipment maintained and in good conditionPlant cannot be operated/accessed when leftunattendedEmergency stops are workingPlant guarding in placeLog book maintained for useWarning labels/procedures on equipmentWelding screens maintained and in good conditionElectrical equipment tested, tagged and in datePower leads in good conditionPower boards used (not double adaptors)Compressed gases Is this section relevant? Yes No (If no, go to next section)Cylinder contents are identifiedCylinders are securedCylinders stored according to dangerous goods classGas lines are free of leaks, kinks, wear & tearTheatre and studio Is this section relevant? Yes No (If no, go to next section)Seating correctly set up and lockedCentre plates for seating correct and lockedHandrails in seating areas correct and lockedAudio SPL checks complete, maximum levels set?Safety lights operatingBarn doors in the stage area secureShutters and/or lighting frames secureProps secure, correct positionFloor leads gaffedSilicon leads used in the lighting gridLantern power cables free from binding and/or chafingThree phases balanced on the dimmer rackDimmer channels loaded maximum 20 AmpsDMX cables secured/coveredLanterns and/or droppers secured using scaffold and/orG-clampsLanterns and/or droppers have a secondary restraintLanterns operating in the correct planeGobo/gobo holders properly secureLighting poles removed from lanterns and secureGel holders stored correctly and secured with a chainLadders stored correctly and secured with a chainSAFETYNETREF. NO.Other Comments :HRD-WHS-FRM-034.11 Workshop Inspection Checklist 2013 September Page 2 of 2