FIBOX EX ATEX - Comdes

FIBOX EX ATEX - Comdes

FIBOX EX ATEX - Comdes

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

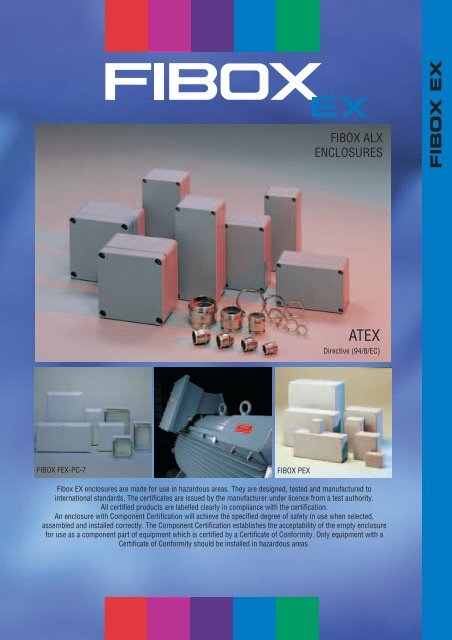

71<strong>FIBOX</strong> ALXENCLOSURES<strong>FIBOX</strong> <strong>EX</strong>AT<strong>EX</strong>Directive (94/8/EC)<strong>FIBOX</strong> F<strong>EX</strong>-PC-7<strong>FIBOX</strong> P<strong>EX</strong>Fibox <strong>EX</strong> enclosures are made for use in hazardous areas. They are designed, tested and manufactured tointernational standards. The certificates are issued by the manufacturer under licence from a test authority.All certified products are labelled clearly in compliance with the certification.An enclosure with Component Certification will achieve the specified degree of safety in use when selected,assembled and installed correctly. The Component Certification establishes the acceptability of the empty enclosurefor use as a component part of equipment which is certified by a Certificate of Conformity. Only equipment with aCertificate of Conformity should be installed in hazardous areas.

72<strong>FIBOX</strong> ALX<strong>FIBOX</strong> ALXALUMINIUM ENCLOSUREAt least IP 54, IK 08<strong>FIBOX</strong> ALX aluminium enclosuresfor housing terminal blocks,electronic devices and otherindustrial components. Theseenclosures are made from highquality, non corrosive aluminium.AT<strong>EX</strong>VTT 03 AT<strong>EX</strong> Q 002VTT 03 AT<strong>EX</strong> 044U (II 2 G, EEx e II)VTT 03 AT<strong>EX</strong> 137U (II 3 D)Supplement 1 to VTT 03 AT<strong>EX</strong> 044Uand VTT 03 AT<strong>EX</strong> 137UYmm506010015282127177252125222362163263Xmm4566666577818181124125125162162Including: Enclosure base, cover, cover screws, mounting screws, earth screws and earth terminal.ORDER SYMBOLGrey coverALX 050503ALX 060605ALX 061005ALX 061505ALX 080806ALX 081306ALX 081806ALX 082506ALX 121208ALX 122208ALX 123608ALX 161609ALX 162609Zmm32464646575757578181819191Cmm20353535454545456464747474ACCESSORIESOrder symbolMounting plateAM 0808AM 0813AM 0818AM 0825AM 1212AM 1222AM 1236AM 1616AM 1626AM 1636AM 1656AM 2320AM 2328AM 2333AM 2340AM 2360AM 3140AM 3160Mounting rail DIN 15ARM 0610 15 x 88ARM 0615 15 x 140ARM 0808 15 x 65ARM 0813 15 x 115ARM 0818 15 x 165ARM 0825 15 x 240Mounting rail DIN 35ARH 12ARH 22ARH 36ARH 16ARH 26ARH 1636ARH 1656ARH 2320ARH 2328ARH 2333ARH 40ARH 60Wall mounting lugsMRS 28540MRS 28541Size mm69 x 6469 x 11469 x 16469 x 240107 x 110107 x 207107 x 347146 x 146146 x 244146 x 346146 x 545215 x 184215 x 264215 x 315215 x 385215 x 586294 x 387293 x 58535 x 10535 x 20335 x 34335 x 14035 x 24035 x 34035 x 54035 x 18035 x 26035 x 31035 x 38335 x 580TECHNICAL INFORMATIONMore accessories and dimensions;see page 28.PROPERTY AlSi CAST ALUMINIUM CONFORMITY TO STANDARDSIngress Protection At least IP 54(EN 60529)IP66/IP67Impact Resistance7J(EN 50014)ALX 050503 to ALX 082506Temperature Range Celsius -50°. . .140°C(short term) Fahrenheit -60°. . .285°FTemperature Range Celsius -10°. . .80°C(continuous) Fahrenheit 14°. . .175°FGasketSiliconeALX 121208 to ALX 162609Temperature Range Celsius -50°. . .140°C(short term) Fahrenheit -60°. . .285°FTemperature Range Celsius -25°. . .80°C(continuous) Fahrenheit -13°. . .175°FGasketPURUSA Enclosures for Electrical EquipmentNEMA 1, 4, 4X, 6 12 and 13 (50/508)Europe Electrical apparatus for potentially explosive atmospheresEN 50014: 1997 + A1.....A5, Genreral requirementsEN 50019: 1997 + A1.....A5, Increased safety "e"Polyester Powder Paint ColourCover ScrewsChemical Resistance *RAL 7001 greyStainless SteelGoodData subject to change without notice. *Consult separate raw material data for more detailed information.ExternalheightYExternalwidthXExternaldepthZFree internalmounting heightCAlso bigger Ex sizes available.

74<strong>FIBOX</strong> F<strong>EX</strong> P<strong>EX</strong><strong>FIBOX</strong> P<strong>EX</strong>POLYESTER ENCLOSUREAt least IP 54The <strong>FIBOX</strong> P<strong>EX</strong> product family issuitable for enclosing terminalsand other electrical equipment inthe most demanding environmentssuch as mining orchemical industries.Xmm75757575120120160160160250250405Ymm80110160190122220160260360255400400Including: Enclosure base, cover, cover screws, and mounting screws.ORDER SYMBOLGrey coverP<strong>EX</strong> 080806P<strong>EX</strong> 081106P<strong>EX</strong> 081606P<strong>EX</strong> 081906P<strong>EX</strong> 121209P<strong>EX</strong> 122209P<strong>EX</strong> 161609P<strong>EX</strong> 162609P<strong>EX</strong> 163609P<strong>EX</strong> 252612P<strong>EX</strong> 254012P<strong>EX</strong> 404012Zmm555555559090909090120120120Cmm474747477575757575105105105ACCESSORIESOrder symbolMounting platePM 0808PM 0811PM 0816PM 0819PM 1616PM 1626PM 2526PM 2540PM 4040Mounting railDIN 15PRM 0811PRM 0816PRM 0819Mounting railDIN 35PRH 2526Size mm64 x 6964 x 9964 x 14964 x 179146 x 146146 x 244231 x 240231 x 383390 x 38515 x 9915 x 14915 x 17935 x 238Hinge kit1 pair includes screwsAH A/BPH ACERTIFICATES:- PTB: EEx e IIMountingfoot kitMRS 28540MRS 2854111x4215x50More accessories and dimensions;see page 28.TECHNICAL INFORMATIONPROPERTY POLYESTER CONFORMITY TO STANDARDSIngress Protection IP 65 USA Enclosures for Electrical Equipment(EN 60529) At least IP 54 NEMA 1, 4, 4X, 6 12 and 13Impact Resistance 7J UL 746 C 5 in. vertical flame test(EN 50014)IEC 695-2-1, Self-extinguishingTemperature Range Celsius -40°. . .120°C(short term) Fahrenheit -40°. . .250°FTemperature Range Celsius -10°. . .80°C(continuous) Fahrenheit 14°. . .175°FElectrical InsulationTotally insulationEnclosure Flammability Rating UL94-5V UL 746 C 5 in. vertical flame testGlow Wire Test 960°C IEC 695-2-1, Self-extinguishingCover screwsStainless SteelGasketEPDMChemical Resistance *GoodData subject to change without notice. *Consult separate raw material data for more detailed informationExternalheightYExternalwidthXExternaldepthZFree internalmounting heightC

75<strong>EX</strong> CERTIFICATION OF ENCLOSURESFibox <strong>EX</strong> enclosures are made for use in hazardous areas. Theyare designed, tested and manufactured to internationalstandards. The certificates are issued by the manufacturer underlicence from a test authority. All certified products are labelledclearly in compliance with the certification.An enclosure with Component Certification will achievethe specified degree of safety in use when selected, assembledand installed correctly. The Component Certification establishesthe acceptability of the empty enclosure for use as a componentpart of equipment which is certified by a Certificate of Conformity.Only equipment with a Certificate of Conformity should beinstalled in hazardous areas.Hazardous areas are referred to as they areclassified under CENELEC European Norms:<strong>EX</strong>PLANATION OF CERTIFICATE SYMBOLSThe following tables can be used as practical quick guides. For moredetailed information please contact your local Fibox representative.The different <strong>EX</strong> protection types specified are:Protection typ Symbol Test StandardIncreased safety e EN 50019Non-sparking n -Flameproof d EN 50018Intrinsically safe i EN 50020Special protection s -Encapsulation m EN 50028Oil immersion o EN 50015Pressurisation p EN 50016Sand or powder filled q EN 50017Classification of gas groups to IEC standards:Gas GroupIII AII BII CRepresentative GasMethaneProphaneEthyleneAcetylene and Hydrogen<strong>FIBOX</strong> <strong>EX</strong>Zone 0 = Zone in which an explosive gas/air mixture iscontinuously present or present for long periods.Zone 1 = Zone in which an explosive gas/air mixture islikely to occur in normal operation.Zone 2 = Zone in which an explosive gas/air mixture isnot likely to occur in normal operation and ifarises, will only last for a short period.Temperature classification to EN standards of the maximum surfacetemperature allowed for any part of an apparatus:TemperatureClassMax. SurfaceTemperatureT1 450 °CT2 300 °CT3 200 °CT4 135 °CT5 100 °CT6 85 °CThese temperature classifications are applicable only to mounted enclosureswhich have a Certificate of Conformity.CIRCUIT BOARD BRACKETPrinted circuit boards and mounting plates often need special mountingsupports that offer flexibility in positioning the boards across theenclosure body. Mounting supports also raise the board above theenclosure bottom, especially effective when using two sided boards. Thiscircuit board bracket has a standard E1 (IEC 297-3, DIN 41494) Eurocardscrew mounting distance of 89 mm (3.5") accepting M2,5 to M4 screws.The bracket can also be used for nonstandard boards by separating theends of the bracket (a) from the connector bridge (b).If the bracket is not needed, the adapter parts for each individualmounting pod size can be used only for raisingthe board above the enclosure base level.b)a) MB 28086Ø 0.4mmØ 0.3CIRCUIT BOARD BRACKETØ 0.3ORDER SYMBOLStandard Mounting Distancemm inchesRemarksMB 2808689 3.5Adapter for EURONORD,PICCOLO, MINI. Directmount to EK, SOLID, EKI,ALX, PC-7, P<strong>EX</strong>.a)b)a)CUSTOMISATIONEnclosures can be machined, painted, screen printedand preassembled to meet your customisationrequirements. Fibox's service center offers completeCNC machining, hinge mounting, screen printing,assembly and much more. Ourwide selection of enclosures andaccessories can be customised tocreate a unique enclosure meetingyour application requirements.