Manual Production Systems Brochure - Tectra Automation

Manual Production Systems Brochure - Tectra Automation

Manual Production Systems Brochure - Tectra Automation

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

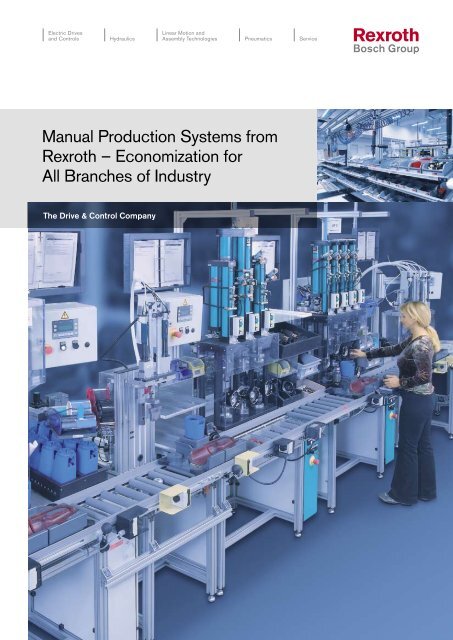

Electric Drivesand ControlsHydraulicsLinear Motion andAssembly TechnologiesPneumaticsService<strong>Manual</strong> <strong>Production</strong> <strong>Systems</strong> fromRexroth – Economization forAll Branches of IndustryThe Drive & Control Company

Increase in efficiency thanks to<strong>Manual</strong> <strong>Production</strong> <strong>Systems</strong> from RexrothTerms such as lean production, JIT, Kanban, etc., whichare used in modern organization models, can be foundmore and more in industrial production. Unfortunately,they are often only used in theory and in a limited scope.Implementation in production and assembly processesrequires production systems that make it possible toconsistently implement lean and efficient processes.The new “<strong>Manual</strong> <strong>Production</strong> <strong>Systems</strong> (MPS)” fromRexroth, which have been developed in strict keepingwith the aspects of lean production, make it unbelievablyeasy to quickly plan and implement such productioninstallations.Supermarket shelves with stock information, using colored Kanbanroller conveyors.Nowadays, change is the only constant in production and assemblyprocesses. The causes of this include quick innovationcycles and uncertain product service lives with a simultaneousincrease in variants. Lot sizes and the overall number ofunits are almost impossible to predict and thus make automationmeasures more difficult. Often, automation is onlyused in areas with so-called non-variable parts, althougheverything variant-specific here also has to be fed in or completedby hand. Before this backdrop, manual production systemsform the basis for modern, industrial production with ahigh level of flexibility.The quality of such systems is not reflected solely by characteristicssuch as versatility, assembly effort, or even thenumber of components. More emphasis is placed on thepossibilities to increase efficiency in production processes ora focus on added value. Many companies attempt to attain“lean production” using modern organization models, suchas Kanban for just-in-time production, production accordingto customer cycles, the pull principle, one-piece flow andmany others. With the new modules for <strong>Manual</strong> <strong>Production</strong><strong>Systems</strong> (MPS) and the MPScalc software from Rexroth,workstations, and even entire production and assembly lines,can be quickly adapted to the work contents and efficientlydesigned by avoiding waste, making the system more “lean”.Avoiding waste is the central factor for lean production, i.e.to reduce everything that does not add value. This coverswaiting times, inefficient processes, faults or unnecessarymovements, as well as overproduction, high levels of stocksor unnecessary transport. Work processes are comprised ofactivities that add value, as well as those that contain obviousor hidden waste. The objective of production planning is tocreate a lean production system by continually minimizinginefficient processes and converting them into value-addedprocesses. A typical example of this is the ergonomic designof workstations, whose layout directly influences all grabmovements and walking distances. Standard solutions fromthe catalog are universally applicable, but almost always requirea certain degree of compromise. This, in turn, leads tolonger routes or more complicated movements than are reallynecessary. The same applies to all of the equipment usedfor work, be it shelves, grab containers, material shuttles, orlinking components. However, the standard has been completelyredefined with MPS from Rexroth. These new <strong>Manual</strong><strong>Production</strong> <strong>Systems</strong> allow each user to create his or her ownstandards by exactly configuring the size, form, construction,and arrangement of all the system components to the respectivework contents and the needs of the employee.The standard has been redefined.MPS is based on the aluminum modular profile system fromRexroth. Development was carried out in accordance withstrict ergonomic and logistical factors and included decadesof experience attained at more than 200 Bosch plants worldwide.In comparison to the previous modular assembly sys-

The components for the <strong>Manual</strong> <strong>Production</strong> <strong>Systems</strong> cover materialsupply, workstations, and workstation equipment, as well as linkingelements. Users can easily configure a lean production systemthemselves and get everything from a single source.tems, MPS is not comprised of individual components, butcomplete function modules with plug and play capabilities.Characteristics such as dimensions, material, or constructionare defined in parameters and each function module containsall the individual components that correspond to the parametersin size, form, and quantity. For example, to configure awork table, all you have to do is enter the dimensions andselect functions, such as material shelves or ESD capability,and you will immediately get a work table that is best-suitedfor your own, individual production.Extended product portfolio for complete lines.MPS not only includes workstations with accessories, butalso modules for material supply (flow rack systems, materialshuttles, or grab containers), as well as components for materialflow and linking. In addition to variable dimensions, thenew Basic (Lean) flow rack system offers a wide selection ofdifferent conveyor media, for a flexible material supply design.It can be used as a supermarket shelf and also to supplycontainers directly at the workstation. The central idea hereis the Kanban principle to avoid having too much material inthe production flow. Multi-colored rollers (red, yellow, green)are also used with the conveyor tracks, so that information onthe material stock is immediately visible throughout the entireprocess with traffic light colors. The Economic (XLean)system is an alternative to this and consists of a steel profileand rollers with or without roller flanges. The flow of materialbetween the workstations, as well as in the warehouseand consignment areas can be implemented using EcoFlowcomponents. A basic profile is all that is needed to constructa range of track widths. Curves and points make it possible toadapt the conveyor sections to the arrangement of the workstationsand flow of materials. Using the workstations, versatileflow rack system, EcoFlow components, and the extensiverange of MPS accessories, complete production and assemblylines can be constructed according to your own standardsand the principles for lean production.A surprisingly simple custom configuration.Lean production with MPS can be implemented early onwith the MPScalc software for planning manufacturingequipment for manual production. It runs on any Windowscomputer, does not require any CAD software or knowledgeand helps you to configure individually designed worksta-tions or material supply systems simply by entering a few specifiedparameters. Design efforts that used to take hours oreven days are done within just a few minutes. The configuredobjects are displayed on the screen in 3-D and immediatelyupdated with each entered parameter. Reconfigurations onlyrequire additional entries or modifications to the appropriateparameters. Thus, professional designs and constructions,including an automatic price calculation and drawinggeneration, can be efficiently implemented for the <strong>Manual</strong><strong>Production</strong> <strong>Systems</strong>. A press of a button is all you need togenerate the corresponding ordering documents. Plus, toplan entire production lines, there is also an option to transfer3-D drawings and part lists into practically any commonCAD system.Above all, MPScalc enables a reduction in inefficient processesand planning and design efforts, but also helps you toavoid errors, as the software automatically selects and adaptsthe appropriate function modules and all the associatedcomponents in accordance with the entered parameters. Thisunique planning instrument is a fundamental part of theMPS system and makes an essential contribution to loweringthe total cost of ownership. It provides the user with a levelof flexibility that was previously unheard of. Developmenttimes from the initial idea to implementation are significantlyshortened, and modifications to existing lines or step-by-stepinvestments, such as those necessary for expansions to quantities,can be carried out quickly and easily. Even simultaneousengineering as early as the product development phase issimplified.MPScalc is available free-of-charge with the product catalog.The online version of the software can also be found in theInternet at www.boschrexroth.com/mps. As new functionmodules, such as material shelves, additional flow rack systems,or complete shuttles, are continually added, you canfind software updates online that are virtually up to theminute.

Bosch Rexroth AGLinear Motion andAssembly TechnologiesPostfach 30 02 0770442 Stuttgart, GermanyTel. +49 711 811-30698Fax +49 711 811-30364www.boschrexroth.com/mpsAustraliaBosch Rexroth Pty. Ltd.3 Valediction RoadKings Park, NSW 2148, SydneyTel. +61 2 9831 7788Fax +61 2 9831 5553Great BritainBosch Rexroth LimitedCromwell RoadSt. Neots, HuntingdonCambs. PE19 2ESTel. +44 1480 223 298Fax +44 1480 470 789CanadaBosch Rexroth Canada Corp.3426 Mainway DriveBurlington, Ontario L7M 1A8Tel. +1 905 335-5511Fax +1 905 335-4184USABosch Rexroth Corporation14001 South Lakes DriveCharlotte, NC 28273Tel. +1 800 REXROTH+1 800 739 7684Fax +1 704 583 0523SingaporeBosch Rexroth Pte. Ltd.15D Tuas Road638520 SingaporeTel. +65 6861 8733Fax +65 6861 1825© Bosch Rexroth AG 2006Printed in Germany3 842 537 784 (2006.04)EN • BRL/MKT4