2. trocadero shower enclosure - Kohler - Kohler Co.

2. trocadero shower enclosure - Kohler - Kohler Co.

2. trocadero shower enclosure - Kohler - Kohler Co.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

�<br />

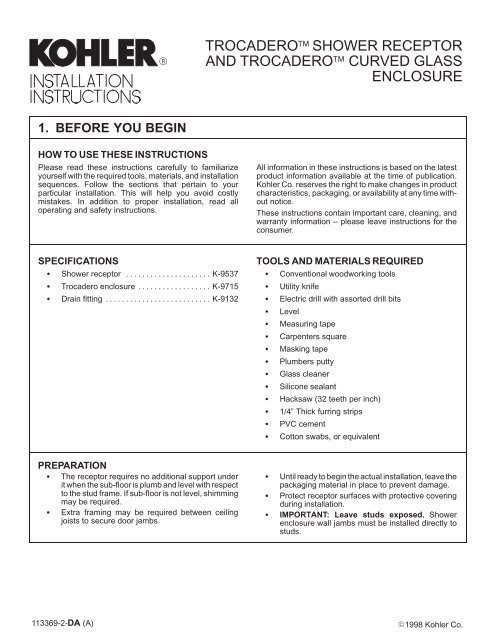

1. BEFORE YOU BEGIN<br />

HOW TO USE THESE INSTRUCTIONS<br />

Please read these instructions carefully to familiarize<br />

yourself with the required tools, materials, and installation<br />

sequences. Follow the sections that pertain to your<br />

particular installation. This will help you avoid costly<br />

mistakes. In addition to proper installation, read all<br />

operating and safety instructions.<br />

SPECIFICATIONS<br />

� Shower receptor . . . . . . . . . . . . . . . . . . . . . K-9537<br />

� Trocadero <strong>enclosure</strong> . . . . . . . . . . . . . . . . . . K-9715<br />

� Drain fitting . . . . . . . . . . . . . . . . . . . . . . . . . . K-9132<br />

PREPARATION<br />

� The receptor requires no additional support under<br />

it when the sub-floor is plumb and level with respect<br />

to the stud frame. If sub-floor is not level, shimming<br />

may be required.<br />

� Extra framing may be required between ceiling<br />

joists to secure door jambs.<br />

TROCADERO SHOWER RECEPTOR<br />

AND TROCADERO CURVED GLASS<br />

ENCLOSURE<br />

All information in these instructions is based on the latest<br />

product information available at the time of publication.<br />

<strong>Kohler</strong> <strong>Co</strong>. reserves the right to make changes in product<br />

characteristics, packaging, or availability at any time without<br />

notice.<br />

These instructions contain important care, cleaning, and<br />

warranty information – please leave instructions for the<br />

consumer.<br />

TOOLS AND MATERIALS REQUIRED<br />

� <strong>Co</strong>nventional woodworking tools<br />

� Utility knife<br />

� Electric drill with assorted drill bits<br />

� Level<br />

� Measuring tape<br />

� Carpenters square<br />

� Masking tape<br />

� Plumbers putty<br />

� Glass cleaner<br />

� Silicone sealant<br />

� Hacksaw (32 teeth per inch)<br />

� 1/4” Thick furring strips<br />

� PVC cement<br />

� <strong>Co</strong>tton swabs, or equivalent<br />

� Until ready to begin the actual installation, leave the<br />

packaging material in place to prevent damage.<br />

� Protect receptor surfaces with protective covering<br />

during installation.<br />

� IMPORTANT: Leave studs exposed. Shower<br />

<strong>enclosure</strong> wall jambs must be installed directly to<br />

studs.<br />

113369-2-DA (A)<br />

��<br />

�1998 <strong>Kohler</strong> <strong>Co</strong>.

<strong>2.</strong> TROCADERO SHOWER ENCLOSURE<br />

The Trocadero Curved Glass Shower Enclosure can be<br />

constructed with either right or left-hand door hinges, see<br />

Fig. #1 .<br />

Striker<br />

Center<br />

Jamb<br />

Showerhead<br />

Wall Jamb<br />

Side Panel<br />

Provide Structural Ceiling Support<br />

Pivot<br />

Center<br />

Jamb<br />

Door Door<br />

Wall Jamb<br />

Side Panel<br />

Receptor<br />

Jamb Bases Jamb Bases<br />

RIGHT-HAND DOOR HINGES LEFT-HAND DOOR HINGES<br />

Fig. #1<br />

Striker<br />

Center<br />

Jamb<br />

Showerhead<br />

Wall<br />

Jamb<br />

Side<br />

Panel<br />

113369-2-DA (A) 2<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

3. PRODUCT DIMENSIONS<br />

The receptor dimensions are illustrated in Fig. #2 .<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

3/8” R.<br />

1-1/2”<br />

ÉÉÉÉÉÉ<br />

ÉÉÉÉÉÉ<br />

ÉÉÉÉÉÉ<br />

ÉÉÉÉÉÉ<br />

FINISHED WALL<br />

44”<br />

6-1/8” 4-5/8”<br />

The <strong>enclosure</strong> dimensions are illustrated in Fig. #3 .<br />

FINISHED WALL<br />

44”<br />

2-1/8”<br />

18-1/4”<br />

44”<br />

22-1/4”<br />

Fig. #2<br />

32”<br />

18-1/4”<br />

22-1/4”<br />

44”<br />

3-3/8” D.<br />

1/8”<br />

TOP VIEW FRONT VIEW<br />

Fig. #3<br />

72”<br />

10’-0” MAX.<br />

6’-6” MIN.<br />

3 113369-2-DA (A)

4. MOUNTING HARDWARE, JAMBS AND SEALS<br />

The hardware provided for receptor and <strong>shower</strong><br />

<strong>enclosure</strong> installation is illustrated in Fig. #4 for<br />

identification purposes.<br />

#8 x 2-1/2”<br />

Truss Head Screw<br />

2 ea. per ceiling<br />

Mounting Base<br />

Drill 1/8” hole<br />

#8 x 3/8”<br />

Soc. Setscrew<br />

2 ea. per<br />

Anti-Rotation Key<br />

3/8” x 8”<br />

Stud, Ceiling Mount<br />

1 ea. per<br />

Center Jamb<br />

Stud Mounting<br />

Jamb<br />

#8 x 1-1/2”<br />

Flat Head Screw<br />

Drill 1/8” hole<br />

#8 x 1/4”<br />

Soc. Setscrew<br />

2 ea. per Ceiling<br />

Sleeve<br />

Fig. #4<br />

#8 x 3/4”<br />

Flat Head Screw<br />

2 ea. per Top End<br />

Cap, Wall Jamb<br />

Base and Towel Bar<br />

#8 x 3/4”<br />

Soc. Setscrew<br />

1 ea. per Top Pivot<br />

Bracket<br />

Wall Jamb Wall Jamb<br />

Base<br />

Seal (Dry Side) Center Jamb Center Jamb<br />

Base<br />

Center Jamb Seal<br />

Shower (Wet)<br />

Side<br />

Pivot Seal Vinyl Filler Strip<br />

1/4” x 5/8”<br />

Flat Head Soc.<br />

Screw<br />

4 reqd.<br />

Door Hinges<br />

#8 x 2”<br />

Flat Head Screw<br />

5 ea. per Wall Jamb<br />

Wall Jamb Seal<br />

Shower (Wet)<br />

Side<br />

Latching Seal<br />

Water Deflector<br />

Assembly<br />

113369-2-DA (A) 4<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

5. PREPARATION AND NEW CONSTRUCTION<br />

The Shower Receptor is packaged in a single carton and<br />

the Curved Glass Profile Enclosure is packaged in two<br />

cartons. The cartons will fit through any standard door. Do<br />

not remove the units from cartons until ready to install<br />

them.<br />

If units must be stored outdoors before installation,<br />

protect them from the elements.<br />

Place a clean protective covering such as a drop cloth in<br />

the <strong>shower</strong> receptor to prevent damage during<br />

installation.<br />

Ensure the installation area is clean and free of all debris.<br />

If remodeling, remove all finished wall material to expose<br />

framing, and remove all floor coverings to expose<br />

subfloor.<br />

<strong>Co</strong>nstruct framing that is square vertically and<br />

horizontally in accordance with dimensions illustrated in<br />

Fig. #5. These dimensions are critical for proper<br />

installation. <strong>Co</strong>nstruct recess and plumbing accurately.<br />

Walls that do not meet these requirements or are not<br />

plumb will prohibit proper installation of the <strong>shower</strong> unit.<br />

NOTE: A variety of installations are possible.<br />

Illustrations depict suggested framing only.<br />

If grab bars are to be installed, provide backing in framing.<br />

If a firewall is required, roughing-in dimensions will have<br />

to increase according to the thickness of the firewall<br />

material.<br />

If installing this unit to a masonry wall, make provisions for<br />

plumbing connections. <strong>Co</strong>nstruct a separate frame wall a<br />

minimum of 6” from masonry wall.<br />

NOTE: Structural ceiling support must be provided for<br />

center jambs. Ceiling mounting plates must be securely<br />

fastened to framing members. Hollow wall anchors will not<br />

provide adequate support for door assembly.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Double Studs<br />

As Shown<br />

44” 44”<br />

Fig. #5<br />

Double<br />

Studs As<br />

Shown<br />

1/4” Thick<br />

Furring Strip<br />

3/4” MIN.<br />

1-1/2” MAX.<br />

FINISHED<br />

WALL<br />

THICKNESS<br />

Structural Support<br />

Required In Ceiling<br />

Above These Center<br />

Jamb Locations<br />

5 113369-2-DA (A)

Install rough plumbing. Locate drain line and hot and cold<br />

supply lines for <strong>shower</strong> and fittings used. Follow the<br />

manufacturer’s installation instructions for proper installation.<br />

If possible, provide an access at the back of the plumbing<br />

wall in the event that servicing the supply and waste piping<br />

is necessary.<br />

Install a 2” drain pipe to extend 3/8” above the sub-floor<br />

or slab. A pocket is required in slab construction to<br />

accommodate the drain fitting.<br />

6. INSTALLATION<br />

INSTALL RECEPTOR<br />

Install drain fitting (K-9132 is recommended) to drain<br />

outlet of receptor in accordance with instructions supplied<br />

with drain fitting.<br />

Place receptor in framing. Ensure receptor is level. If<br />

shimming is required to level, place shims under wood<br />

block feet on underside of receptor. Ensure all wood block<br />

feet are supported when receptor is leveled.<br />

1-1/2” MIN.<br />

WOOD SUB-FLOOR<br />

3/8”<br />

4-5/8” DIA. MIN.<br />

CONCRETE SUB-FLOOR<br />

3/8”<br />

4-5/8” DIA. MIN.<br />

Fig. #6<br />

Fig. #7<br />

113369-2-DA (A) 6<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

After receptor is positioned snugly, install drain per drain<br />

manufacturers installation instructions. Use a non-hardening<br />

mastic sealant to achieve a watertight seal.<br />

Other installation methods are possible. For gasket<br />

connection of this drain to 2” iron or other PVC materials,<br />

consult Fernco Inc., 300 S. Dayton St., Davison, MI 48423<br />

[Phone: 1-800-521-1283] about their PSD 200 <strong>shower</strong><br />

drain connector or other suitable gasket.<br />

CAUTION: Risk of product damage. If<br />

watertight seal of drain is not achieved, receptor<br />

bottom and sub-floor may be damaged.<br />

CAUTION: Risk of product damage. Holes<br />

drilled in following steps must be countersunk to<br />

avoid cracking receptor surface layer when receptor<br />

flange is screwed in place.<br />

Using 1/8” diameter drill bit, drill holes in receptor flange<br />

at each wall stud location. <strong>Co</strong>untersink holes.<br />

Install shims behind receptor flange in areas where flange<br />

is not flush against stud.<br />

Secure receptor flange to studs using screws (not<br />

supplied).<br />

Install 1/4” thick furring strips on all wall studs above<br />

receptor flange. Furring must be full width of double studs<br />

(3-1/2”) at outer ends of receptor.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Rubber<br />

Gasket<br />

Shower<br />

Floor<br />

Fiber Gasket<br />

Nut<br />

Lead To Top Of<br />

Nipple (Tamp<br />

Carefully)<br />

Tamp Oakum<br />

To 5/8” Depth<br />

Seal to Meet<br />

Local <strong>Co</strong>de Shower Drain<br />

Fitting<br />

4-1/2” DIA. MIN. HOLE<br />

IN SUB-FLOOR<br />

Fig. #8<br />

Fig. #9<br />

1/4” Thick<br />

Furring Strip<br />

Double<br />

Wall<br />

Studs<br />

Receptor<br />

Flange<br />

1/8” Drill<br />

Hole<br />

5/8”<br />

2” I.P.S.<br />

Drain Pipe<br />

7 113369-2-DA (A)<br />

Floor

INSTALL SHOWER ENCLOSURE<br />

Install Stud Mounting Jambs: Place center jamb base<br />

on receptor with holes in jamb base aligned with holes in<br />

receptor. Do not mount center jamb base at this time.<br />

Mark location of center hole in center jamb base onto<br />

receptor.<br />

Using carpenters square, mark a line from center jamb<br />

base hole location onto furring strip to locate centerline for<br />

stud mounting jamb.<br />

Using level or plumb line, extend mark up furring strip at<br />

least six feet. Ensure line is plumb, as line is used to align<br />

stud mounting jamb.<br />

Place wall jamb base flat on receptor against nailing<br />

flange and centered with centerline for stud mounting<br />

jamb. The wall jamb base will be used as a height gauge<br />

for installation of the stud mounting jamb.<br />

Center Jamb Base<br />

Mark Hole Location<br />

Center<br />

Jamb<br />

Base Hole<br />

Location<br />

Centerline For Stud<br />

Mounting Jamb<br />

Wall Jamb Base<br />

Fig. #10<br />

Fig. #11<br />

Fig. #12<br />

Receptor Holes<br />

Centerline For<br />

Stud Mounting<br />

Jamb<br />

Carpenters<br />

Square<br />

Nailing<br />

Flange<br />

113369-2-DA (A) 8<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

Place stud mounting jamb on wall jamb base with<br />

chamfered side against furring strip. Plumb stud mounting<br />

jamb using holes and slots in jamb and centerline marked<br />

on furring strip. Check for plumb with level. Attach stud<br />

mounting jamb to studs using four #8 x 1-1/2” flat head<br />

screws.<br />

Remove wall jamb base.<br />

Repeat procedures accompanying Fig. #10 thru Fig. #13<br />

for other stud mounting jamb.<br />

With both stud mounting jambs secured in position, stop<br />

<strong>enclosure</strong> installation until finished wall (wallboard and<br />

tile, etc.) is completed.<br />

Install wallboard horizontally with factory edge (paper<br />

bound) 1/4” maximum above the top of receptor and<br />

extending at least to the next stud beyond unit. Seal<br />

wallboard to nailing flange.<br />

Mud, tape, and finish drywall. Seal area between paper<br />

bound edge of wallboard and unit with a water-resistant<br />

sealer after wall finish has been applied.<br />

For firewall installations, use fire-resistant wallboard<br />

between the framing and 1/2” gypsum wallboard.<br />

Apply a bead of silicone sealant to both sides of stud<br />

mounting jambs at finished wall edge.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Flat Head<br />

Screw<br />

Tile<br />

Galvanized<br />

Nails Or Screws<br />

Edge Down<br />

(Paper Bound)<br />

Fig. #13<br />

Fig. #14<br />

Stud<br />

Mounting<br />

Jamb<br />

Furring<br />

Strip<br />

Wall Studs<br />

Chamfered<br />

Side<br />

Wall Jamb Base<br />

Silicone Sealant<br />

1/4” Furring<br />

Strip<br />

2x4<br />

Framing<br />

1/2” Gypsum<br />

Wallboard<br />

1/4” MAX.<br />

Water-Resistant Sealer<br />

Between Nailing Flange<br />

And Paper Bound Edge<br />

Of Gypsum Board<br />

9 113369-2-DA (A)

Apply silicone sealant to factory-drilled center jamb screw<br />

holes on receptor.<br />

Apply a thin bead of silicone sealant under center jamb<br />

base, and install receptor using factory drilled holes and<br />

two 1-1/2” flat head screws. Apply silicone sealant over<br />

screw heads.<br />

Repeat above step, and install center jamb base at other<br />

receptor center jamb location using factory drilled holes.<br />

Locate appropriate left-hand or right-hand deflector plate<br />

against door side of striker center jamb base. Ensure<br />

deflector angle is toward inside of <strong>shower</strong>.<br />

Mark screw hole location. Remove deflector plate.<br />

CAUTION: Risk of product damage. Hole drilled<br />

in following step must be countersunk to avoid<br />

cracking receptor surface layer when deflector plate<br />

is screwed in place.<br />

CAUTION: Risk of product damage. Ensure<br />

countersink in following step is not deeper than 1/8”<br />

or a breakthrough of receptor surface layer may<br />

occur resulting in a loose fitting deflector plate.<br />

Centerpunch and drill receptor using 1/8” drill bit where<br />

previously marked. <strong>Co</strong>untersink hole using 3/16”<br />

countersink. Do not countersink deeper than 1/8”.<br />

Apply silicone sealant to hole and underside of deflector<br />

plate and install using 1-1/2” flat head screw.<br />

Determine if <strong>shower</strong> door will hinge from left or right hand<br />

side.<br />

NOTE: For purposes of these instructions, <strong>shower</strong> door<br />

is considered hinging from right hand side. See Fig. #1 .<br />

Insert lower hinge pivot pin into lower hinge pivot plate<br />

from below.<br />

1-1/2” Flat Head<br />

Screws<br />

Fig. #15<br />

Center Jamb Base<br />

Receptor<br />

Factory-Drilled Holes<br />

Fig. #16<br />

Fig. #17<br />

1-1/2” Flat<br />

Head Screw<br />

Striker Center<br />

Jamb Base<br />

Deflector Plate<br />

Lower Hinge Pin Plate<br />

Lower Hinge Pivot Pin<br />

113369-2-DA (A) 10<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

<strong>Co</strong>nstruct a cardboard template for use in aligning the<br />

lower hinge pivot plate to the center jamb base using this<br />

template.<br />

Place lower hinge pivot plate in relative mounting location<br />

against pivot center jamb base.<br />

Place template in slots of center jamb base and adjust<br />

lower hinge pin plate until hinge pin is exactly in “V” of<br />

template.<br />

Mark mounting hole locations of lower hinge pin plate onto<br />

receptor.<br />

NOTE: This ensures centerline of door pivot is aligned<br />

with stud mounting jamb. These markings are critical for<br />

proper door function.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

3/8”<br />

5/16”<br />

Hinge Pin<br />

3-1/4”<br />

TEMPLATE<br />

Fig. #18<br />

Lower Hinge<br />

Pin Plate<br />

Fig. #19<br />

Lower Hinge<br />

Pin Plate<br />

Fig. #20<br />

Pivot Center<br />

Jamb Base<br />

Pivot Center<br />

Jamb Base<br />

5/8”<br />

Template<br />

11 113369-2-DA (A)

CAUTION: Risk of product damage. Holes<br />

drilled in following steps must be countersunk to<br />

avoid cracking receptor surface layer when lower<br />

hinge plate is screwed in place.<br />

CAUTION: Risk of product damage. Ensure<br />

countersinking in following step is not deeper than<br />

1/8” or breakthrough of receptor surface layer may<br />

occur resulting a loose fitting lower hinge plate.<br />

Centerpunch and drill receptor using 1/8” drill bit where<br />

previously marked. <strong>Co</strong>untersink holes using 3/16”<br />

countersink. Do not countersink deeper than 1/8”.<br />

Apply a thin coat of silicone sealant to underside of lower<br />

hinge pin plate and screw holes. Install using 1-1/2” flat<br />

head screws.<br />

Install Wall Jambs: Apply a bead of silicone sealant to<br />

mating surface of wall jamb base where shown in<br />

Fig. #2<strong>2.</strong> Ensure sealant does not extend farther than<br />

shown on <strong>shower</strong> (wet) side of wall jamb base.<br />

Install wall jamb base to bottom end of wall jamb using<br />

3/4” flat head screws.<br />

Apply a thin coat of silicone sealant to underside of wall<br />

jamb base.<br />

Apply a bead of silicone sealant in grooves at back side<br />

of wall jamb the entire length of jamb.<br />

1-1/2” Flat<br />

Head Screws<br />

Shower (Wet) Side<br />

Wall Jamb<br />

Wall Jamb Base<br />

3/4” Flat Head Screws<br />

Fig. #21<br />

Pivot Center<br />

Jamb Base<br />

Lower Hinge Pin Plate<br />

Fig. #22<br />

Groove For<br />

Silicone Sealant<br />

Shower (Wet) Side<br />

Silicone Sealant<br />

Mating Surface<br />

113369-2-DA (A) 12<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

Slide wall jamb into stud mounting jamb and secure using<br />

five 2” flat head screws.<br />

Repeat procedures accompanying Fig. #22 and Fig. #23<br />

to install remaining wall jamb.<br />

Install Wall Jamb Seal: Slide wall jamb seal into cavity<br />

in <strong>shower</strong> (wet) side of wall jamb. Ensure seal is fully<br />

seated in wall jamb groove.<br />

Repeat procedure on other wall jamb. Seals are to extend<br />

to the receptor. Trim at top even with wall jamb.<br />

Measure distance from center jamb base on receptor to<br />

ceiling. Cut center jamb 2” shorter than this measurement.<br />

NOTE: Ensure tape measure is plumb while measuring.<br />

NOTE: Using hacksaw, cut center jamb while securely<br />

holding on a flat surface. Use square to draw cut line. Cut<br />

carefully.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Wall Jamb<br />

2” Flat Head<br />

Screws<br />

Jamb<br />

Centerline<br />

Wall Jamb<br />

Seal<br />

Shower (Wet)<br />

Side<br />

Tile<br />

Wall Jamb<br />

Ceiling<br />

Center Jamb Base<br />

Fig. #23<br />

Tile<br />

Fig. #24<br />

Fig. #25<br />

X - 2”<br />

Wallboard<br />

Receptor<br />

Wallboard<br />

13 113369-2-DA (A)

Thread two 3/8”-16 hex nuts and one 3/8” flat washer<br />

approximately 1” onto ceiling mount stud.<br />

Place ceiling mounting base over short end of ceiling<br />

mount stud and insert other end of stud into center top of<br />

center jamb.<br />

Set center jamb into center jamb base and adjust<br />

mounting stud until ceiling mounting base is snug against<br />

ceiling support. Shift location of ceiling mounting base to<br />

accurately plumb center jamb.<br />

CAUTION: Risk of product damage. Ensure<br />

center jamb is accurately plumbed before installing<br />

ceiling mounting base.<br />

CAUTION: Risk of product damage. Ensure<br />

ceiling mounting base is installed into ceiling joist or<br />

other solid support. Toggles or wall anchors cannot<br />

be used.<br />

Accurately mark ceiling mounting base location by circling<br />

mounting base. Mark base mounting holes. Loosen<br />

ceiling stud nut. Remove base and center jamb. Drill holes<br />

using 1/8” drill.<br />

Install ceiling mounting base using two 2-1/2” truss head<br />

screws in each mounting base.<br />

Repeat procedure for remaining ceiling mounting base.<br />

Thread two 3/8” setscrews into anti-rotation key. Install<br />

assembled key into slot at bottom of center jamb used as<br />

door striker (striker center jamb). Allow key to protrude<br />

1/8” from bottom of jamb and tighten setscrews.<br />

Ceiling Mounting Base<br />

Ceiling Mount Stud<br />

Center Jamb<br />

Ceiling<br />

Mounting<br />

Base<br />

Striker Center Jamb<br />

Fig. #26<br />

Mark Outline And Holes<br />

Anti-Rotation Key<br />

Fig. #27<br />

Fig. #28<br />

Hex Nut<br />

Ceiling<br />

Mounting<br />

Base<br />

2-1/2” Truss<br />

Head Screw<br />

Setscrews<br />

1/8” Protrusion<br />

113369-2-DA (A) 14<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

Snap center jamb seal into <strong>shower</strong> side of striker center<br />

jamb.<br />

Install latching seal in opposite side of striker center jamb<br />

with thin angled wiper facing dry side of <strong>shower</strong>. Trim<br />

bottom of latching seal to fit over anti-rotation key at<br />

bottom of jamb.<br />

Install vinyl filler strips in gaps between top of seals and<br />

top of striker center jamb. Trim filler strips flush with top<br />

of jamb.<br />

Thread two #8-32 x 1/4” setscrews partially into ceiling<br />

sleeve. Apply masking tape vertically to striker center<br />

jamb to protect paint finish. Apply tape to 1’ section above<br />

latching seal. Slide sleeve over striker jamb and allow to<br />

rest on latching seal.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Striker Center Jamb<br />

Center<br />

Jamb Seal<br />

CENTER JAMB SEAL<br />

#8-32 x 1/4”<br />

Setscrews<br />

Fig. #29<br />

Vinyl Filler Strips<br />

Fig. #30<br />

Shower (Wet) Side<br />

Latching Seal<br />

LATCHING SEAL<br />

Ceiling Sleeve<br />

Masking<br />

Tape<br />

15 113369-2-DA (A)

Insert glass side panel into striker side wall jamb.<br />

Set striker center jamb onto center jamb base. Carefully<br />

slide striker center jamb onto glass side panel.<br />

Hold in position by adjusting mounting stud until tight in<br />

ceiling mounting base. Ensure jamb is plumb. Lock stud<br />

in place by tightening upper and lower lock nuts together.<br />

Striker Side<br />

Wall Jamb<br />

Glass Side<br />

Panel<br />

Ceiling<br />

Sleeve<br />

Fig. #31<br />

Striker Center<br />

Jamb<br />

Lock Nuts<br />

Striker<br />

Center<br />

Jamb<br />

Center Jamb Base<br />

Fig. #32<br />

Glass Side Panel<br />

Ceiling Mounting<br />

Base<br />

Adjust Stud<br />

113369-2-DA (A) 16<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

Slide ceiling sleeve up to ceiling and secure by tightening<br />

setscrews. Screws should face inside of <strong>shower</strong> unit.<br />

Remove masking tape from striker center jamb.<br />

Thread two 3/8” setscrews into anti-rotation key. Install<br />

assembled key into slot at bottom of pivot center jamb.<br />

Allow key to protrude 1/8” from bottom of pivot center<br />

jamb and tighten setscrews.<br />

Snap center jamb seal into <strong>shower</strong> (wet) side of pivot<br />

center jamb.<br />

Cut vinyl fill strip 72-1/4” long. Insert into pivot jamb, door<br />

side slot. Slide down to cover anti-rotation key, flush with<br />

bottom of pivot jamb.<br />

Thread two #8-32 x 3/8” setscrews into upper hinge pivot<br />

plate. Thread pivot pin into upper hinge pivot plate until it<br />

is flush with top of plate. Lock pivot pin in place with one<br />

#8-32 x 3/4” setscrew.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Pivot Center Jamb<br />

Fig. #33<br />

Anti-Rotation Key<br />

Fig. #34<br />

#8-32 x 3/8”<br />

Setscrews<br />

Top Pivot Pin<br />

#8-32 x 3/4”<br />

Setscrew<br />

Pivot<br />

Center<br />

Jamb<br />

Ceiling Sleeve<br />

Setscrews<br />

Protective<br />

Masking Tape<br />

Setscrews<br />

1/8” Protrusion<br />

Center<br />

Jamb Seal<br />

Shower (Wet) Side<br />

CENTER JAMB SEAL<br />

Fig. #35<br />

Fig. #36<br />

Pivot Plate<br />

17 113369-2-DA (A)

Set locking plate over setscrews installed in upper hinge<br />

pivot plate. Slide assembly into slot in pivot center jamb<br />

above vinyl filler strip.<br />

NOTE: Do not tighten screws at this time.<br />

Install one vinyl filler strip in the gap between the top of the<br />

seal and the top of the pivot center jamb. Install the other<br />

vinyl filler strip in the gap between the top pivot plate and<br />

the top of the pivot center jamb. Trim the filler strips flush<br />

with the top of jamb.<br />

Thread two #8-32 x 1/4” setscrews partially into ceiling<br />

sleeve. Apply masking tape vertically to pivot center jamb<br />

to protect paint finish. Apply tape to one foot section<br />

above seal. Slide sleeve over pivot jamb and allow to rest<br />

on pivot seal.<br />

Insert glass side panel into pivot side wall jamb.<br />

Locking Plate<br />

#8-32 x 1/4”<br />

Setscrews<br />

Glass Side Panel<br />

Locking<br />

Plate<br />

Pivot Plate<br />

Fig. #37<br />

Vinyl Filler Strips<br />

Fig. #38<br />

Fig. #39<br />

Filler Strip<br />

Grooves<br />

Pivot Center<br />

Jamb<br />

Ceiling Sleeve<br />

Masking<br />

Tape<br />

Pivot Side<br />

Wall Jamb<br />

113369-2-DA (A) 18<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

Set pivot center jamb onto center jamb base and carefully<br />

slide pivot jamb onto glass side panel.<br />

Hold in position by adjusting mounting stud until tight in<br />

ceiling mounting base.<br />

Ensure pivot center jamb is plumb. Lock in place by<br />

tightening upper and lower lock nuts together.<br />

Slide ceiling sleeve up to ceiling and secure by tightening<br />

setscrews. Screws should face inside of <strong>shower</strong> unit.<br />

Remove masking tape from pivot center jamb.<br />

Install top end cap onto pivot side and striker side wall<br />

jambs. Use two #8 x 3/4” flat head screws in each top end<br />

cap.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Center Pivot Jamb<br />

Ceiling Sleeve<br />

Glass Side<br />

Panel<br />

Lock Nuts<br />

Pivot<br />

Center<br />

Jamb<br />

Center Jamb Base<br />

Fig. #40<br />

Fig. #41<br />

Ceiling Mounting<br />

Base<br />

Ceiling Sleeve<br />

Setscrews<br />

Mounting<br />

Stud<br />

Adjust Stud<br />

Protective<br />

Masking Tape<br />

#8 x 3/4” Flat Head Screws<br />

Fig. #42<br />

Top End Cap<br />

Wall Jamb<br />

Glass Side Panel<br />

19 113369-2-DA (A)

Position the bottom outside hinge plate on the glass door<br />

to determine the proper installation location of the<br />

deflector assembly.<br />

Apply clear silicone sealant inside the deflector channel,<br />

position the deflector channel against the hinge plate, and<br />

press firmly onto the bottom of the door. Remove any<br />

excess sealant immediately.<br />

DO NOT trim away the extra deflector material from the<br />

hinge pivot side of the door at this time.<br />

At the door opening end of the deflector assembly, trim off<br />

the extra length of deflector strip flush with the end of the<br />

deflector channel.<br />

Assemble the hinge, gaskets, and inside backing plates<br />

to the glass door with four 1/4-20 x 5/8” flat head socket<br />

screws included.<br />

When assembling the bottom inside backing plate, BE<br />

SURE the hinge plate clamps the extra length of the<br />

deflector.<br />

Slide the spacer into the handle hole in the door.<br />

Assemble the door handle to the glass door, installing the<br />

washers between the handles and glass. Lubricate the<br />

washers with glass cleaner to prevent them from<br />

bunching up during the installation of the handles.<br />

Deflector<br />

Backing Plate<br />

1/4-20 x 5/8”<br />

Flat Head<br />

Socket Screws<br />

Door Handle<br />

(Inside)<br />

Washer<br />

Spacer<br />

Washer<br />

Door<br />

Handle<br />

(Outside)<br />

Fig. #43<br />

Fig. #44<br />

113369-2-DA (A) 20<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Door<br />

Wiper<br />

Apply<br />

Sealant<br />

Bottom<br />

Door Seal<br />

Channel<br />

Gasket<br />

Top<br />

Hinge<br />

Plate<br />

Glass Door

NOTE: Due to the weight and shape of the door, two<br />

people are required to perform the door installation<br />

procedures.<br />

Position bearing washer over lower pivot pin.<br />

Lift door into position and insert lower pivot pin into hole<br />

in bottom of lower door hinge.<br />

Slide upper pivot bracket up, position door, and slide<br />

upper pivot bracket down to engage pivot pin with hole in<br />

upper door hinge.<br />

Open the door.<br />

Install the pivot seal in position, as shown. Extend beyond<br />

the bottom edge of the door glass to the top surface of the<br />

bottom hinge plate.<br />

Trim the pivot seal even with the top of the door.<br />

At the door opening end of the deflector assembly, trim the<br />

wiper so it barely touches the deflector plate.<br />

Trim the deflector as needed to clear the vertical latching<br />

seal.<br />

Carefully trim the hinge backing plate end of the deflector<br />

diagonally to match the vertical pivot seal, as shown.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

Upper Pivot Bracket<br />

Bearing Washer<br />

Pivot Seal<br />

Vertical<br />

Pivot Seal<br />

TOP<br />

BOTTOM<br />

Fig. #45<br />

Lower Door<br />

Hinge Plate<br />

Deflector<br />

(Shaded for Clarity)<br />

Fig. #46<br />

Upper Door Hinge<br />

Lower<br />

Door<br />

Hinge<br />

Bearing<br />

Washer<br />

Lower Pivot Pin<br />

Wall Jamb<br />

Shower Door<br />

Upper Door Hinge<br />

VIEWED FROM INSIDE<br />

Wiper<br />

21 113369-2-DA (A)

Slide vinyl filler up to expose setscrews in upper pivot<br />

plate. Tighten setscrews.<br />

Check door latching operation. To adjust, loosen hinge<br />

screws, shift door as required and tighten hinge screws.<br />

<strong>Co</strong>ver screw heads using supplied touch-up paint.<br />

Slide each glass side panel toward center jamb until tight<br />

against jamb.<br />

Spray glass cleaner into space between glass and inside<br />

edge of center jambs and wall jambs the entire length of<br />

each jamb.<br />

Press dry side seals into place in each center jamb first<br />

and then into each wall jamb.<br />

Dry Side<br />

Seal<br />

Glass<br />

Cleaner<br />

Vinyl Filler<br />

Setscrews<br />

VIEWED<br />

FROM<br />

INSIDE<br />

Side Panel<br />

Fig. #47<br />

Fig. #48<br />

Wet Side<br />

Seal<br />

Glass Side Panel<br />

Dry Side Seal<br />

Fig. #49<br />

Upper Pivot Plate<br />

Hinge Screws<br />

Side<br />

Panel<br />

113369-2-DA (A) 22<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI

INSTALL TOWEL BAR (OPTIONAL)<br />

Measure distance (X) between wall jamb(s) and pivot or<br />

striker center jamb 30-1/2” above receptor curb.<br />

Cut each towel bar 5/32” shorter than measured distance.<br />

Use enclosed touch-up paint to cover cut end of towel<br />

bars.<br />

Insert brackets into ends of towel bars.<br />

Hold each towel bar in position 30-1/2” above receptor<br />

curb. Mark locations of screw holes. Remove towel bars.<br />

Centerpunch screw locations and drill using 1/8” drill bit.<br />

CAUTION: Drill only through outershell of jambs.<br />

Do not drill deeper or you may damage glass panel.<br />

Install towel bars using two #8 x 3/4” flat head screws for<br />

each towel bar.<br />

<strong>Co</strong>ver screw heads using supplied touch-up paint.<br />

APPLY SILICONE SEALANT<br />

Door seals are an integral part of this <strong>shower</strong> door.<br />

However, seal with a quality clear silicone sealant or<br />

equivalent is required to ensure a properly functioning,<br />

watertight unit. Seal where the glass side panel meets the<br />

receptor.<br />

The recommended procedure for sealing is as follows:<br />

Mask both edges of joint to be sealed, maintaining a joint<br />

width of 1/8” to 3/16”.<br />

Apply a uniform bead of sealant between hinge bracket<br />

and seal. Smooth bead with finger.<br />

Remove tape from sealed joint immediately after<br />

smoothing bead.<br />

Repeat for all areas to be sealed.<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI<br />

30-1/2”<br />

Masking Tape<br />

1/8”-3/16<br />

Seal Locations<br />

X<br />

Fig. #50<br />

Fig. #51<br />

#8 x 3/4”<br />

Flat Head<br />

Screw<br />

23 113369-2-DA (A)

7. IMPORTANT CONSUMER INFORMATION<br />

CONSUMER RESPONSIBILITIES<br />

Your <strong>Kohler</strong> Trocadero Curved Glass Profile Shower<br />

Enclosure will remain beautiful if you take care of it. It is<br />

recommended that you replace seals, when they show<br />

signs of wear, yellowing, or are not watertight. Refer to the<br />

parts explosion in the SP3B Catalog for <strong>Kohler</strong> Service<br />

Parts.<br />

Water conditions in various parts of the country will<br />

determine any extra cleaning attention you may have to<br />

give your new <strong>shower</strong> <strong>enclosure</strong>. A simple routine of daily<br />

care will keep your <strong>shower</strong> <strong>enclosure</strong> looking like new.<br />

<strong>Kohler</strong> <strong>Co</strong>. does not recommend the use of harsh<br />

abrasive cleansers on any of its products. Harsh<br />

cleansers will damage the metal or glass finish on your<br />

<strong>shower</strong> <strong>enclosure</strong>.<br />

REQUESTING SERVICE<br />

Please take a moment to familiarize yourself with the<br />

<strong>Kohler</strong> Warranty, its benefits, and limitations. <strong>Kohler</strong> <strong>Co</strong>.<br />

and its distributors support you with one of the largest<br />

Service Networks of its type. Here’s what you need to do<br />

if you require service:<br />

FIRST: <strong>Co</strong>ntact the dealer or contractor who sold and<br />

installed the product. They should be able to<br />

solve any problems you may have.<br />

SECOND: If your dealer or contractor cannot solve the<br />

problem, they will contact or supply you with<br />

the name of the local <strong>Kohler</strong> Distributor and<br />

the:<br />

KOHLER TECHNICAL SPECIALIST<br />

THIRD: If you are unable to obtain warranty service<br />

through either your contractor or <strong>Kohler</strong> <strong>Co</strong>.<br />

distributor, please write us directly at <strong>Kohler</strong><br />

<strong>Co</strong>., Attn: Customer Service Department, 444<br />

Highland Drive, <strong>Kohler</strong>, WI 53044 U.S.A.<br />

FOURTH: Include all pertinent information regarding<br />

your claim, including a complete description of<br />

the product, model numbers, colors, finishes,<br />

and the date the product was installed.<br />

Include a description of the problem, and a<br />

photocopy of your invoice for the products<br />

involved. Also give us the name of the<br />

contractor and distributor.<br />

Apply a glass cleaner with a sponge and immediately<br />

rinse off.<br />

Please save these instructions as they contain warranty<br />

and maintenance information.<br />

For replacement parts, please contact the dealer where<br />

you purchased the <strong>shower</strong> <strong>enclosure</strong>.<br />

LIMITED ONE-YEAR WARRANTY<br />

<strong>Kohler</strong> plumbing fixtures and fittings are warranted free of<br />

manufacturing defects.<br />

<strong>Kohler</strong> <strong>Co</strong>. will, at its election repair, replace, or make<br />

appropriate adjustment where <strong>Kohler</strong> <strong>Co</strong>. inspection<br />

discloses any such defects occurring in normal usage<br />

within one year after installation. <strong>Kohler</strong> <strong>Co</strong>. is not<br />

responsible for installation costs.<br />

To obtain warranty service, contact <strong>Kohler</strong> <strong>Co</strong>. either<br />

through your Dealer or Plumbing <strong>Co</strong>ntractor or by writing<br />

<strong>Kohler</strong> <strong>Co</strong>., Attn: Customer Service Department, 444<br />

Highland Drive, <strong>Kohler</strong>, WI 53044 U.S.A., or by calling<br />

1-800-4-KOHLER from within the U.S.A.<br />

Implied warranties, including that of merchantability<br />

and fitness for a particular purpose, are expressly<br />

limited in duration to the duration of this warranty.<br />

To the extent permitted by law, <strong>Kohler</strong> <strong>Co</strong>. disclaims<br />

all implied warranties including merchantability and<br />

fitness for a particular purpose. <strong>Kohler</strong> <strong>Co</strong>. disclaims<br />

any liability for special, incidental, or consequential<br />

damages.<br />

Some states do not allow limitations on how long an<br />

implied warranty lasts or the exclusion or limitation of<br />

incidental or consequential damages, so this limitation<br />

and exclusion may not apply to you. This warranty gives<br />

you specific legal rights. You may also have rights which<br />

vary from state to state.<br />

This is our exclusive written warranty.<br />

KOHLER CO., KOHLER, WISCONSIN 53044<br />

113369-2-DA (A) 24<br />

<strong>Kohler</strong> <strong>Co</strong>., <strong>Kohler</strong>, WI