E_KM_AHEAD-Magazin_2-12.pdf - Netstal

E_KM_AHEAD-Magazin_2-12.pdf - Netstal

E_KM_AHEAD-Magazin_2-12.pdf - Netstal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

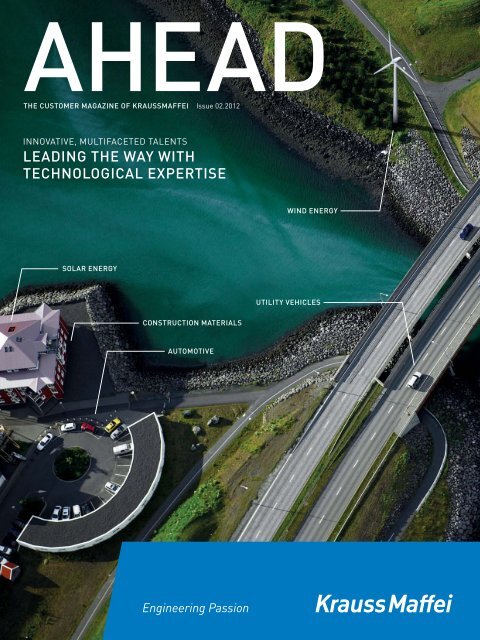

ahead<br />

The CUSTOMeR <strong>Magazin</strong>e Of KRaUSSMaffei Issue 02.2012<br />

InnovatIve, multIfaceted talents<br />

Leading The way wiTh<br />

TeChnOLOgiCaL expeRTiSe<br />

SOLaR eneRgy<br />

COnSTRUCTiOn MaTeRiaLS<br />

aUTOMOTive<br />

wind eneRgy<br />

UTiLiTy vehiCLeS

ediTORiaL COnTenTS<br />

Dear Customers and Readers,<br />

Many athletes have produced inspiring peak performances at the Olympic Games in<br />

London. In addition to being impressed by the athletes “wanting to give their best,”<br />

I was often struck by the reasons they gave for what they were trying to achieve and<br />

what drove them on. Usain Bolt, for example, declared with self-assurance, “I always<br />

wanted to drive myself towards achieving what no one else has ever managed<br />

to do before. I always wanted to be a trendsetter.”<br />

As is often the case, there is a close analogy between sport and the world of<br />

business. What is it that makes a businessman a trendsetter in his sector? He can<br />

do more than the competition. He sets new standards. He is innovative and exudes<br />

enormous passion and conviction for what he does. All of that also applies to<br />

KraussMaffei and, in this edition of <strong>AHEAD</strong>, we will show you how we are setting<br />

new trends in the sector time and time again. And so, we have assembled here for<br />

you many interesting contributions and market and project reports all related to this<br />

topic, which will show you how we are using our first-class machines, technologies,<br />

and solutions to bring your production to the peak of its potential.<br />

For instance, with our new GX range in 2012, we have already set a new international<br />

standard in powerful injection molding machines for numerous sectors. We are<br />

also ahead of the field in solutions for global trends in plastics. For example, when<br />

the main concern is to reduce energy consumption by following the trends in lightweight<br />

construction. In this edition, we show you some of our trendsetting solutions<br />

from MuCell to CoverForm through to high-pressure RTM processes.<br />

We are naturally proud when sector experts recognize our performance, as, for<br />

example, when we received the JEC Europe Innovation Award and the SPE Award<br />

for our brochures on fiber composite solutions this year.<br />

As a sector leader, we want to continue to set trends and are therefore developing<br />

our organization with this in mind. Through a new orientation in injection molding<br />

and reaction process machinery, we are ideally positioned in relation to our customers‘<br />

fields of activity and in future, will be able to react even more constructively<br />

to your individual needs.<br />

And you can rest assured that we protect our innovations against undesirable imitation,<br />

which is of course all to your advantage. We are maintaining our intuitive<br />

sense for forward-looking trends with currently around 1,450 patents and an annual<br />

production of between 30 to 50 inventions. Take advantage of the situation and be<br />

<strong>AHEAD</strong> with us, not just today but also tomorrow and the day after!<br />

I hope you enjoy reading the magazine.<br />

Frank Peters<br />

Executive Vice President Sales<br />

coveR stoRy<br />

4 Leading the way with technological<br />

expertise<br />

7 interview: developing the cutting edge<br />

further<br />

BRand & maRKets<br />

8 wide-ranging expertise in the field of<br />

injection molding<br />

9 first technology-spanning energy<br />

analysis<br />

10 30 years of KraussMaffei automation<br />

12 The new benchmark: The gx Series<br />

14 Major order from Saudi arabia<br />

14 “ Competence Show” in the Land of the<br />

Rising Sun<br />

15 The right man for the job<br />

15 Concentrated expertise for customers<br />

16 positive signals from southern european<br />

markets<br />

PRocesses & PRoducts<br />

20 efficient manufacturing of<br />

fiber composite components<br />

21 gx: great potential in lightweight<br />

construction<br />

21 30 percent lighter airbag housing<br />

PaRtneRs & PRojects<br />

22 Rapid growth in north america<br />

23 “ pURtrain” is on target for the automotive<br />

industry<br />

KRaussmaffeI gRouP<br />

24 group presence without borders<br />

25 Technical treats for the far east<br />

26 energy efficiency: Smart pipes<br />

26 eLiOn 3200: a successful concept<br />

26 plant expansion in Slovakia and China<br />

27 property rights secure<br />

technological advantages<br />

27 imprint

KraussMaffei Contents<br />

4<br />

Technology leadership KraussMaffei is a pioneer in several<br />

fields, which enables it to help its customers be technological<br />

leaders.<br />

16<br />

Southern Europe The classic holiday countries offer more than just sun and sea. They also have some good news,<br />

especially when it comes to the plastics sector. The CX 300-1400 PolySet completes the machinery package offered<br />

by the Greek company Dasyc S.A.<br />

10<br />

30 years of KraussMaffei automation Exciting exhibition<br />

pieces demonstrated what industrial and linear robots can do.<br />

3

4 Cover story<br />

<strong>AHEAD</strong> Issue 02.2012<br />

DEMANDING<br />

In many business areas, such as automotive and commercial vehicle manufacturing,<br />

the component requirements are becoming more demanding.<br />

The typical demands include greater mechanical strength and lower weight.

KraussMaffei Cover story<br />

INNoVaTIVe, MulTIfaCeTed TaleNTS<br />

LEADING THE wAy wITH TEcHNoLoGIcAL ExpErTISE<br />

Technological leaders are characterized by their tendency to not only detect important market trends, but also to<br />

set them in the first place. KraussMaffei is carrying out pioneering work in several fields, which enables it to help its<br />

customers be technological leaders.<br />

TexT: JoaCHIM WebeR, eVa MÜNZeNMaIeR PHoToS: HaRald MeHNeRT<br />

T<br />

he JEC Europe Innovation Award, which KraussMaffei won in<br />

April 2012 (more information on page 23), was symptomatic<br />

of its excellence. On one hand, it proved yet again that innovation<br />

frequently springs from collaboration between different<br />

disciplines. On the another hand, it reaffirms KraussMaffei’s<br />

strategy with regard to innovation and technology, in which lightweight<br />

construction plays an important role as one of the biggest technological<br />

trends.<br />

“Developing innovative and ready-to-use operational process solutions<br />

to replace conventional materials with plastic is one of our core<br />

competencies,” explains Jochen Mitzler, Manager of the Strategic<br />

Product Management Department. “Our clients’ requirements are<br />

increasing across sectors: the plastic parts have to be lighter than<br />

conventional materials yet just as stable. At the same time, several<br />

functions must be integrated, which makes the manufacturing process<br />

more complex, yet the assembly costs must be reduced. In order<br />

to appear high-quality, the visible parts must also be visually attractive<br />

and must have pleasant haptics – and all of this at optimized manufacturing<br />

costs.” KraussMaffei has reinforced its expertise: Munich<br />

is home to the world’s most versatile TechCenter for lightweight components<br />

and fiber composite technology. Customers benefit from<br />

KraussMaffei’s expertise in the fields of injection molding machinery<br />

and reactive materials processing, which produce a wide range of customized<br />

and process-specific solutions.<br />

Supporting customers throughout the entire value-adding chain<br />

According to Thomas Elfroth, Sales and Product Manager Composite/Surfaces:<br />

“When it comes to new processes, our customers demand<br />

a clear reduction in costs along with qualitative improvements<br />

throughout the process.” These requirements can be seen not only<br />

in the automotive sector, but also in the consumer electronics sector,<br />

the household appliances sector, and the packing industry. At the<br />

same time, there is also a standing order to increase the efficiency<br />

of the manufacturing process. Ever-decreasing cycle times, lower<br />

HoLISTIc<br />

KraussMaffei’s new light construction center is<br />

opening up new horizons for processspanning<br />

solutions.<br />

scrap rates, lower energy consumption, and reducing material costs –<br />

all these are additional goals that have to be attained simultaneously.<br />

Since the keyword is “multifunctionality,” an ever-increasing level of<br />

integration between the operations has to be achieved as well.<br />

A facility that KraussMaffei installed for a large European car manufacturer<br />

reveals what lies behind this approach. Two double swivelplate<br />

machines use a fully automated process to produce components<br />

having an outer skin and a sub-structure. Both of them are injectionmolded<br />

separately, joined together accurately by rotating the two<br />

swivel plates, and connected tightly with a third plastic component.<br />

This serves to integrate a large part of the assembly process into the<br />

plastics processing phase.<br />

High and versatile expertise in process engineering across sectors<br />

KraussMaffei’s process engineering is always impressive. The<br />

“FiberForm” process is ideally suited to applications in which<br />

strength is more important than the surface aesthetics, such as the<br />

supporting structures found in vehicles. The so-called organic sheets<br />

or endless fiber fabrics that are found in the thermoplastic matrix are<br />

thermally reformed in the injection mold. They are then over-molded,<br />

back-molded, or over-fed with another thermoplast, such as a glassfiber-reinforced<br />

polyamide. This makes it possible to “integrate”<br />

other functions, such as stiffening ribs or extension elements. With<br />

its high degree of automation and cycle times of less than 60 seconds,<br />

FiberForm is ideally suited to the large-series production of<br />

new, light structural components.<br />

The HP-RTM process, which is another process used for the production<br />

of structural components, is generally used for small and medium-sized<br />

series because its current cycle times range from three<br />

to five minutes, depending on the size of the component. In this process,<br />

a pre-finished reinforcing material, such as carbon fiber tissue,<br />

is soaked into a sealed, evacuated mold that has no air voids with the<br />

help of an epoxy resin, which eventually hardens.<br />

Hp-rTM – HIGH-prESSUrE rESIN TrANSFEr MoLDING<br />

8.<br />

1. 2.<br />

3.<br />

1. Semifinished products from the roll<br />

2. Handling the readymade semifinished<br />

products<br />

3. Transfer to the preform station<br />

4. Preforming<br />

7.<br />

6.<br />

5.<br />

5. Transfer the preform<br />

to HPRTM station<br />

6. Pull vacuum (optional)<br />

7. Resin transfer/hardening<br />

8. Component removal<br />

4.<br />

5

6 Cover story<br />

<strong>AHEAD</strong> Issue 02.2012<br />

cELLForM (MUcELL TM )<br />

Rear RSP<br />

(nonreturn valve)<br />

SCf injector<br />

front RSP<br />

(nonreturn valve)<br />

Complete<br />

SCf dissolution<br />

in the melt<br />

SCf<br />

injection<br />

Plasticizing the<br />

plastic melt<br />

SCf interface kit<br />

SCf metering system<br />

Erich Fries, Manager of the Composites/Surfaces business unit,<br />

thinks the carbon fiber composite parts have a lot of potential. “If, in<br />

the course of future E-mobility, the automotive industry is forced to<br />

make up for heavy batteries in other places, there is hardly an alternative<br />

to structural components based on RTM. In the future, the process<br />

will also be used in large-scale production,” he says. “Our goal<br />

is to enable automation of the entire process, right from unwinding<br />

the carbon fiber to cutting the finished part.” He believes that cost reduction<br />

options are present not just with regard to fiber material, but<br />

also with regard to plastics: “There have already been attempts to<br />

replace the epoxy resin with polyurethane or modified polyamides.”<br />

The process of producing thermoplastic foam structures with the<br />

help of chemical or physical foaming technology is another lightweight<br />

construction method. In the case of CellForm processing or<br />

foaming, the granulated or gaseous blowing agent is fed into the melt<br />

in order to reduce the density of the plastic. Chemical and physical<br />

foaming make it possible to reduce the density and eliminate the<br />

holding pressure of the plastic, which has several advantages: faster<br />

cycles, less material usage, dimensional stability and lower costs.<br />

Improved surfaces through innovative processes The goals of several<br />

surface techniques, which combine various process steps into a<br />

single step, lie between achieving aesthetic value and attaining costeffectiveness.<br />

For example, SkinForm combines injection molding<br />

processes and reaction process machinery: a thermoplastic component<br />

is injected into a mold and it is then flow-coated with polyurethane<br />

during the second cycle. This produces a component that is<br />

characterized by, among other things, leather-like haptics, soft touch,<br />

high scratch-resistance, and polychromatic if required.<br />

The ColorForm process has a similar functionality, in that it makes<br />

it possible to imprint thin layers of lacquer onto various plastics directly<br />

in the mold. In a single step, it creates perfect high-gloss surfaces<br />

in conjunction with the production of the parts, without having<br />

to go through the usual process steps, such as cleansing or prime<br />

coating. The CoverForm process was the result of interdisciplinary<br />

collaboration with the material manufacturing company Evonic.<br />

Here, the PMMA injection-molded parts are given a thin, transparent,<br />

scratch-resistant and chemical-resistant surface using a<br />

multi-component reactive system, which has an acrylate base, both<br />

in a mold and a process.<br />

N2<br />

Premium-quality clean-room standards Various plastic components<br />

are also coming to the fore in medical technology and the pharmaceutical<br />

industry. Irrespective of whether they are used as product<br />

components or as packaging material, hygiene is always the top<br />

priority. Consequently, plastic processing machines that conform to<br />

clean-room technology standards are in great demand. Conformity<br />

with the strict guidelines is guaranteed by various engineering-<br />

related details, such as encapsulated lubrication, using water cooling<br />

instead of air cooling, flat surfaces, anti-static paints, and control<br />

systems that satisfy the strict documentation-related requirements,<br />

including those applicable to the production of pharmaceuticals.<br />

Even in this context, various group sectors work together closely. According<br />

to Mitzler, this is because: “In our case, new products and<br />

processes are increasingly the result of close collaboration with our<br />

clients and the synergy that exists between our areas of expertise,<br />

which are injection molding technology, extrusion technology, and<br />

reaction process machinery. This unique combination really sets us<br />

apart and is what our Technology 3 formula stands for.”<br />

→ rEAD MorE!<br />

We would be happy to send you brochures about the automotive<br />

industry, fiber composite technology, surface technology, RTM<br />

or other innovative technology. For more information, visit:<br />

www.kraussmaffei.com<br />

YOUR CONTACT<br />

The Mx 400024500 uses the process known as structural foam<br />

injection molding. Components are created with a compact outer<br />

skin and foam structure on the inside.<br />

Jochen Mitzler<br />

Manager – Strategic Product Management –<br />

Injection Molding Machinery<br />

KraussMaffei Technologies GmbH<br />

jochen.mitzler@kraussmaffei.com

KraussMaffei Cover story<br />

7<br />

DEvELopING THE cUT-<br />

TING EDGE FUrTHEr<br />

When it comes to reducing the weight and thus<br />

vehicles’ energy consumption (which in future will<br />

include an everincreasing number of electric<br />

cars), lightweight construction solutions and, in<br />

particular, fiberreinforced plastics are of critical<br />

importance. erich fries, Manager of the Composites/Surfaces<br />

(fiber composite and surfaces) business<br />

unit talks about the challenges and potential<br />

opportunities facing composite parts.<br />

THe INTeRVIeW WaS CoNduCTed by MaRKuS beTSCHe.<br />

<strong>AHEAD</strong>: what goals you have set for yourself?<br />

Fries: As always, fiber composite and lightweight components have<br />

a lot of potential. New reports dealing with new fields of application,<br />

technology, or materials are coming in almost every day. our goal is<br />

to expand our cutting edge in this business area further and to adapt<br />

our technology to “carbon,” the fiber of the future. our motto is “one<br />

must pray for miracles, but work hard for changes” (Thomas Aquinas).<br />

we are going to encounter a wide range of new and interesting<br />

technology. we consider this challenge to be an opportunity that we<br />

can overcome as a team.<br />

<strong>AHEAD</strong>: what are the target groups you are looking at?<br />

Fries: our clients from the automotive industry, the utility vehicle<br />

sector, the transport sector (for example rail transport), and the<br />

aircraft construction sector are looking for a competent partner who<br />

can support them across the entire process chain, which ranges from<br />

the very first component idea to series production. In this regards, we<br />

are currently well placed with our products and services, as well as<br />

with our partners Dieffenbacher, Fraunhofer, and Lcc, for example.<br />

our goal is to further strengthen and expand this collaboration. For<br />

us, being a frontrunner also means assuming a leading role vis-à-vis<br />

networks and clusters.<br />

<strong>AHEAD</strong>: when it comes to composites, which materials do you think<br />

will come out on top?<br />

Fries: Even today, when they hear the word “composites,” most<br />

people think of carbon-fiber-reinforced components in an epoxy<br />

resin matrix. For us, the field is a lot wider than that. In the case of<br />

reactive materials, we see polyurethane and casting polyamides as<br />

good alternatives, and when it comes to thermoplastic materials, pA<br />

and polypropylene have already proven themselves. when it comes<br />

to reinforcement, the situation can involve any of the different types<br />

of fibers that are more or less well established, depending on the<br />

client’s requirement. There is not yet a clear trend in this dynamic<br />

developmental environment but at the moment, everything seems<br />

to be pointing toward carbon. However, you cannot ignore the hybrid<br />

formulations either: the vehicles of the future will have a combination<br />

of different materials (carbon/aluminum combinations).<br />

ErIcH FrIES considers the market for composite facilities to be a growing market.<br />

<strong>AHEAD</strong>: Are the processing techniques already well established?<br />

Fries: In the field of composites, there are several old and wellknown<br />

manufacturing processes that have already proven themselves<br />

in production environments and there are several new approaches<br />

as well. The highly complex requirements due to the required unit<br />

numbers, the automated processes, the need to guarantee reasonable<br />

material costs, and the maximum possible reduction in the<br />

component’s weight lead to many variants. Developing this procedure<br />

definitely has not yet reached its conclusion. In case of the Hp-rTM,<br />

two process variants, namely compression rTM and wet molding,<br />

were developed recently and both have their own specific advantages.<br />

For example, in case of wet molding, the carbon fibers (scrap produced<br />

during the preform production) can be recycled as piece goods.<br />

<strong>AHEAD</strong>: what motivates you?<br />

Fries: when customers reward our performance with orders! At the<br />

moment, we are particularly happy about successfully completing<br />

a development project that we carried out in collaboration with a<br />

well-known car manufacturer, who awarded a contract worth several<br />

million euros to us and Dieffenbacher, one of our partners. right from<br />

the beginning, we were closely involved with the component development<br />

process and working out the manufacturing process. And we<br />

are already looking forward to the next step, which involves activating<br />

the complete Hp-rTM line.

8 Brand & markets<br />

<strong>AHEAD</strong> Issue 02.2012<br />

brand & markets<br />

wIDE-rANGING ExpErTISE<br />

IN THE FIELD oF INjEcTIoN MoLDING<br />

„ We want to use our performance capabilities and outstanding<br />

machine technology to generate even more value added for our<br />

customers along their entire valueadding chain. To this end,<br />

we will maintain the separate market presence of the <strong>Netstal</strong><br />

and KraussMaffei brands with a clearly defined product portfolio<br />

and their independently operating sales organizations.“<br />

dr. Hans ulrich Golz, President of the Injection Molding Machinery Segment<br />

our motto is: Together, we are stronger. Since<br />

1 July 2012, the KraussMaffei Group has added a<br />

comprehensive sector: injection molding machinery.<br />

It unites the KraussMaffei and <strong>Netstal</strong> brands.<br />

The company has consciously decided to take<br />

this step, to increasingly align its services to its<br />

customers’ requirements along the valueadding<br />

chain, to utilize the market potentials better, and to<br />

use the innovative strengths of both these brands<br />

more aggressively by joining them together.<br />

The advantage for our customers: both the brands’ strengths are retained<br />

with a clearly defined product portfolio. The most important<br />

objective is “to offer the customer the best solution, irrespective of<br />

the brand and the location.” Dr. Hans Ulrich Golz, President of this<br />

sector, is very happy that he “could virtually fill all management positions<br />

in the Injection Molding Machinery sector with experienced<br />

and highly competent managers from the KraussMaffei Group.”<br />

In addition to his task as the head of the sector, Dr. Golz has also assumed<br />

the task of leading the sales division for the <strong>Netstal</strong> brand.<br />

Mr. Frank Peters is the Executive Vice President Sales. Dr. Karlheinz<br />

Bourdon is responsible for the Technology fields (among<br />

others, Research and Development, Processing, and Automation).<br />

„ by pooling the excellent knowhow of two strong brands, we<br />

can offer our customers the right product of the right brand for<br />

them from our wide and powerful product portfolio, as well as<br />

the corresponding services tailored to their individual needs.<br />

We are also emphasizing our technology leadership on the<br />

market. We are highly motivated and are gaining momentum.“<br />

frank Peters, executive Vice President Sales<br />

Dr. Bernd Thurat heads the Operations Department and Renzo<br />

Davatz heads the Service Department, including the Used Machinery<br />

Business.<br />

The Injection Molding Machinery sector is presenting itself to customers<br />

with a new consolidated distribution channel. The entire<br />

injection molding business will be divided into seven business<br />

units in the future and these will be oriented towards the target<br />

markets:<br />

• Automotive, led by Mr. Bengt Schmidt, under the KraussMaffei<br />

brand<br />

• Technology, led by Mr. Klaus Bange, under KraussMaffei with the<br />

KraussMaffei and <strong>Netstal</strong> brands<br />

• Logistics and Packaging (thick-walled), led by Mr. Bengt Schmidt,<br />

under the KraussMaffei brand<br />

• Packaging (thin-walled), led by Mr. Markus DalPian, under the<br />

<strong>Netstal</strong> brand<br />

• Screw-cap closures (CAP), led by Mr. Markus DalPian, under the<br />

<strong>Netstal</strong> brand<br />

• PET, also led by Mr. Markus DalPian, under <strong>Netstal</strong> with the<br />

KraussMaffei and <strong>Netstal</strong> brands<br />

• “In the Medicine BU, we will continue with the two-brand strategy<br />

under the leadership of Mr. Patrick Blessing,” said Dr. Golz. “This<br />

is because we have two complementary product portfolios and excellent<br />

expertise in the field medical technology at both locations.<br />

Therefore, we believe that we can better tap growth opportunities<br />

in this way.” EM

KraussMaffei Brand & markets<br />

fIRST TeCHNoloGy-SPaNNING eNeRGy aNalySIS<br />

“BLUE powEr” MEETS “THINK BLUE. FAcTory.”<br />

It was a first: Together with Siemens, KraussMaffei carried out an extensive, energyrelated machinesystem analysis for<br />

Volkswagen. The goal was to evaluate the energy consumption associated with the production of instrument panels. The holistic<br />

inspection of the complex process provided the fundamental principles for further optimization of the processes, the drive technology,<br />

and the thermal budget.<br />

The production lines for instrument panels are highly complex structures.<br />

The overall process incorporates several different processing<br />

techniques and automation components. In order to be able to work economically<br />

and in a way that makes efficient use of resources and energy,<br />

the separate process steps must first be aligned with each other in a<br />

manner that cuts across different technologies. Concrete measures can<br />

be derived from the product-specific total energy consumption. Several<br />

analyses of this nature have already been carried for individual injection<br />

molding machines and extrusion lines. But Volkswagen, Siemens, and<br />

KraussMaffei were the first to examine an entire production line.<br />

Challenging roles As part of the “Think Blue. Factory.” program,<br />

Volks wagen has set clear goals for itself in terms of an ecological installation:<br />

based on the annual values for the year 2010, the company<br />

is planning to reduce the environmental pollution caused by all of its<br />

facilities by 25 percent by the year 2018. This applies to the CO 2 emissions,<br />

the amount of waste produced, the energy consumption of each<br />

vehicle, and the amount of water consumed by the factories. These<br />

goals are being met with the help of KraussMaffei’s “BluePower” initiative,<br />

which is aimed at the efficient use of energy and resources.<br />

Every journey begins with the first step Each optimization process begins<br />

with a detailed analysis of the energy consumption of every single<br />

consumer load. The list of the included system components makes<br />

clear just how important the holistic approach is. In the case of the production<br />

line for instrument panels, the list included, along with the injection<br />

molding machine and the facility for the production of the slush<br />

skins, a prewarming station, a round table with 12 mold carriers (each<br />

with a clamping station and an opening), a mixing machine, a metering<br />

machine, three robots, several heating units and heaters, and various<br />

pumps. A total of 25 measuring devices had to be installed on the round<br />

table, after which they had to be connected to a central PC via a WLAN<br />

connection, thus enabling data recording. The measurements were recorded<br />

over more than ten days so that the energy-related interaction<br />

between the system components during downtimes and over the weekend<br />

can be recorded. The power consumption levels of various injection<br />

units were measured and counters were used to measure the consumption<br />

of compressed air and cooling water. The recorded data was<br />

used to determine the specific energy consumption of every component.<br />

Process management determines the potential for savings The biggest<br />

consumer of the round table was the process of tempering the<br />

molds, followed by the vacuum supply, the metering system, and the<br />

exhaust system. The detailed analysis of different system statuses<br />

provided interesting savings potentials. The results can be applied to<br />

other productions as they are, after which they are incorporated into<br />

the development of new generations of machines. For example, an optimized<br />

operation with individual components of the round table that<br />

were designed in accordance with the results opened up savings potential<br />

of up to 10 percent. The system control unit plays a decisive role<br />

in this process: In this case, it is possible to save intelligent processes<br />

that control the operational behavior of the system components, depending<br />

on the process requirements. The individual measures alone<br />

can save up to 30 MWh of electrical energy per annum. MB<br />

TaKING CoMPlex PRoduCTIoN SySTeMS INTo CoNSIdeRaTIoN<br />

kWh/cycle<br />

2.0<br />

1.85<br />

1.8<br />

1.76<br />

1.50<br />

1.6<br />

1.33<br />

1.4<br />

1.2<br />

1.0<br />

0.72<br />

0.8<br />

0.6<br />

0.61<br />

0.52<br />

0.4<br />

0.2<br />

0<br />

0.14 0.12<br />

0.15 0.10<br />

0.19<br />

0.18 0.07<br />

0.33<br />

0.23<br />

0.22<br />

0.13<br />

0.06<br />

<strong>KM</strong>130012000Mx <strong>KM</strong>270024500Mx <strong>KM</strong>320017200Mx<br />

Power consumption [kW]<br />

0.65<br />

kWh/kg<br />

0.60<br />

0.55<br />

0.50<br />

0.45<br />

12:39:02<br />

Poly<br />

Iso<br />

Pump P<br />

12:39:46<br />

12:40:29<br />

Puming<br />

station<br />

12:41:12<br />

Stirring device<br />

Pump<br />

disc filter<br />

Venting<br />

Tempering unit<br />

Poly Heat exchanger<br />

°C<br />

Stirring device<br />

Pump<br />

disc filter<br />

Venting<br />

Iso<br />

12:41:55<br />

Timeline<br />

Tempering unit<br />

Heat exchanger<br />

°C<br />

Compressed air<br />

Compressor<br />

cooler<br />

Hydraulic<br />

power pack<br />

Chiller for<br />

water supply<br />

Pump I Mixing head hydraulic<br />

ExTENSIvE MEASUrEMENTS AND EvALUATIoNS provide a thorough<br />

understanding of the energy consumption that is required by the process<br />

and their correlations.<br />

12:42:38<br />

12:43:22<br />

12:44:05<br />

Specific gas consumption Mean value<br />

12:44:48<br />

12:45:31<br />

0.40<br />

200,000 240,000 280,000 320,000 360,000 400,000<br />

9

10 Brand & markets<br />

<strong>AHEAD</strong> Issue 02.2012<br />

vErSATILE<br />

Several exhibits demonstrated to visitors the<br />

versatility of the KraussMaffei industrial and<br />

linear robots.

KraussMaffei Brand & markets<br />

30-yeaR aNNIVeRSaRy of KRauSS-MaffeI auToMaTIoN aG<br />

ExpErIENcING roBoTS<br />

FIrST-HAND<br />

TexT: eVa MÜNZeNMaIeR PHoToS: STefaN KRuPPa<br />

did you known that robots can tell<br />

different brands of candy bars<br />

apart? No? And that they can put<br />

on a puppet show? Again, no? A<br />

few peculiar exhibits at the event<br />

marking this year’s 30th anniversary of<br />

Krauss-Maffei Automation AG made it clear<br />

that, in the world of robots, there are few<br />

limits. When it comes to plastic processing,<br />

KraussMaffei’s industrial and linear robots<br />

perform the most complex tasks throughout<br />

the production flow. They are always accurate,<br />

quick, and efficient.<br />

The highlights among the exhibits were a<br />

robot equipped with a camera system, which<br />

served guests the candy bars of their choice,<br />

and an industrial robot produced by Kuka,<br />

which used meticulous movements to perform<br />

a puppet show – entertainment of a different<br />

kind. “The more complex the task, the<br />

more it delights our technicians,” explains<br />

General Sales Manager Thomas Marufke<br />

with a smile. “Regardless of the application,<br />

we find a way of setting it up as efficiently as<br />

possible for our clients.”<br />

Efficient production and complex robotics<br />

were just two of the themes that held the<br />

attention of over one thousand visitors, clients,<br />

suppliers, and employees who were<br />

present at the Schwaig facility in July. “Our<br />

company has been ordering machines made<br />

by KraussMaffei, including the associated<br />

automation solutions, for twelve years.<br />

Thanks to KraussMaffei’s consistently positive<br />

and quick implementation, we are looking<br />

forward to a successful collaboration<br />

with them in the future as well,” explains<br />

Erhard Dietsch, who is responsible for automation<br />

technology at Schaeffler Technologies<br />

AG & Co KG. “These anniversary celebrations<br />

gave us the opportunity to once<br />

again get to know several new approaches<br />

and ideas, some of which came from our interactions<br />

with other clients, regarding how<br />

we could use automation to make our production<br />

more efficient.”<br />

“After all the work we have done together<br />

over so many years, it was great to see so<br />

many familiar faces at a celebration of this<br />

nature. All you can do is congratulate them<br />

for throwing such a wonderful birthday<br />

party,” agrees Johann Kerler, Maintenance<br />

Manager at Mouldtec Kunststoff GmbH,<br />

which is located in the city of Kaufbeuren. “I<br />

was particularly impressed by the Augsburg<br />

Puppet Theater exhibition. We have been a<br />

client of KraussMaffei Automation for more<br />

than 20 years. Their innovative and sustainable<br />

solutions never cease to amaze us!<br />

Many of our oldest systems are still running<br />

in a three-shift operation.”<br />

Steady growth with automation solutions<br />

At present, work can be carried out simultaneously<br />

in up to 15 production cells in the<br />

workshops in Schwaig. KraussMaffei develops<br />

between 300 and 350 three-axis linear<br />

robots and about 50 six-axis industrial robots<br />

every year. “And the numbers are going up,”<br />

according to Thomas Marufke. Six months<br />

ago, the production and assembly facilities in<br />

Schwaig were doubled to about 1,700 square<br />

meters. It is now working at full capacity and<br />

nine vacancies have been announced at the<br />

company’s headquarters.<br />

In order to ensure that the company’s growth<br />

continues to be sustainable and successful,<br />

the people in Schwaig are banking on a longterm<br />

relationship with professionals and<br />

trainees from the region. Mechatronics engineers<br />

and managers are trained on a regular<br />

basis. On the open house day, guests were<br />

able find out about the current job openings<br />

and training opportunities. “This is the third<br />

year in a row since 2009 in which we have<br />

outdone ourselves,” reports Marufke. The<br />

export share is already 60 percent and we<br />

thus need to think carefully about further expansions.<br />

“These days, even non- European<br />

clients want us to set up production facilities<br />

in their countries.” Krauss-Maffei<br />

Automation AG, which was founded by Josef<br />

Neureder, has expanded steadily over the<br />

last 30 years. It now has a total workforce of<br />

about 180 employees, ten of whom are apprentices,<br />

at the main plant in Schwaig and<br />

the branches in Munich and Schwerin. Since<br />

2002, the company has been a subsidiary of<br />

the KraussMaffei Group.<br />

According to Thomas Marufke, Sales and<br />

Commercial Manager, the company’s strategy<br />

has been conclusively confirmed by the<br />

fact that it was necessary to constantly increase<br />

the workforce and production area<br />

in the last three decades in order to cope<br />

with the demand for automation solutions<br />

in the industry: “As a mechanical engineering<br />

specialist, we are very successful thanks<br />

to our flexible size and the expertise of our<br />

skilled workers. We supply customers both<br />

with standard products and with customized,<br />

highly complex automation solutions. We will<br />

continue to apply this recipe for success in<br />

future as well and will market our products<br />

even more extensively throughout the world.”<br />

1,000th large robot from Schwerin There was<br />

yet another reason to celebrate, too. Just in<br />

time for the company’s anniversary, the branch<br />

factory in Schwerin delivered its 1,000th robot.<br />

The LRX-S 350 linear robot has a payload<br />

of 35 kg and will be installed in future at a<br />

customer in the USA on a KraussMaffei<br />

CX 350-3000 injection molding machine.<br />

The plant in Schwerin was established in<br />

2000 and started producing robots in 2001.<br />

A total of 22 employees now produce large<br />

linear robot devices in the LRX/LRX-S 250<br />

to 1000 Series with a payload of between<br />

25 and 100 kg, as well as side-entry robots.<br />

Along with standard “pick-and-place” tasks,<br />

these devices can also perform challenging<br />

tasks, such as inserting metal parts like contacts,<br />

rings, sockets, and plugs. However, the<br />

product portfolio also includes complete solutions<br />

for demolding injection molded parts<br />

and for separating, sorting, or packing product<br />

units (for example a cutlery set comprising<br />

a knife, fork, spoon, and serviette).<br />

11

12 Brand & markets<br />

<strong>AHEAD</strong> Issue 02.2012<br />

prEMIUM-cLASS<br />

The Gx Series sets new standards in terms of<br />

performance, usability, and value retention.<br />

WITH a “NeW dIMeNSIoN” oN THe Global MaRKeT<br />

THE NEw BENcHMArK: THE Gx SErIES<br />

TexT: eVa MÜNZeNMaIeR PHoToS: HaRald MeHNeRT<br />

A murmur went through the 400 guests, the drum roll rang out,<br />

the fireworks went off, and the curtain fell, giving the world its first<br />

glimpse of the first next-generation machine: the GX – a new dimension<br />

in injection molding.<br />

But the audience of trade professionals was treated to a lot more than<br />

just that. At the world premiere of the GX Series, which took place<br />

in May, KraussMaffei unveiled and operated a total of six machines<br />

of various sizes, which boasted clamping forces of between 400 and<br />

650 tons and were fully equipped for the production requirements<br />

of a variety of sectors. A light tap on the notebook-sized touchscreen<br />

maneuvered parts of the machinery that weighed several tons – as<br />

easy as operating an iPad.<br />

As if by magic, the bulk of plastic moved through the various production<br />

flow stations until it was finally turned into a bottle cap, a box<br />

for vegetables, or cheese packaging. The “self-test” on the clamping<br />

dummy proved to be especially popular. Everyone was able to personally<br />

experience the clamping unit’s free movement. Premium-quality<br />

technical presentations and a successful celebration with music, and<br />

lots of good food rounded off the launch ceremony. A special success:<br />

KraussMaffei managed to sell all six exhibits, including the laboratory<br />

machine.<br />

“Our clients were particularly interested in the modular automation<br />

cells, which featured linear and industrial robots in many different<br />

configurations,” explains Dr. Karlheinz Bourdon, Vice President<br />

Technology (injection molding machines) at KraussMaffei. “And<br />

I would like to emphasize that the GX is the best machine concept on<br />

the market!”<br />

The GX Series widens the product portfolio in the hydro-mechanical<br />

dual-plate machine sector in the medium clamping force range.<br />

The passionate engineering of the developers is manifested in a firstclass<br />

machine concept featuring intelligent product innovations such<br />

as the GearX locking device and the GuideX guide shoe. The GX Series<br />

sets new standards in terms of performance, usability, and value<br />

retention. The GX machines are impressive during the production of<br />

free-falling packaging parts and premium-quality articles for the<br />

automotive industry or the consumer goods sector.

KraussMaffei<br />

A powerful team: GearX and GuideX The GX Series’ hydro-mechanical<br />

clamping unit raises the bar when it comes to quality and productivity.<br />

The excellent dual-platen technology scores highly with a wide range of<br />

innovations. "In my opinion, the GX machines represent the best overall<br />

concept," underlined Bourdon. "We talk about a new dimension because<br />

our customers can use the machine to get the best results from<br />

their production." With the ingenious GuideX guide shoe, forces are ideally<br />

absorbed and the service life of the molds is increased. As an intelligent<br />

fixed bearing joint with an optimized FEM design, the GuideX is<br />

not just an “eye-catcher” but a genuine highlight, which ensures excellent<br />

platen parallelism due to its stable design and guarantees smooth,<br />

energy-saving movements.<br />

The innovative GearX locking system is reliably activated straightaway<br />

within the shortest possible time and continuously produces quick<br />

machine movements. Arranged in a space-saving way behind the<br />

moving mold-fixing platen, it facilitates simple access and numerous<br />

customer-specific options. With a patented locking system and a<br />

guide shoe, the new generation of machines gives the sector exactly<br />

what it wants: even faster production, lower material consumption,<br />

and better-quality products. Furthermore, the machines really save<br />

when it comes to energy consumption because they can be adapted to<br />

the production capacity utilization.<br />

Powerful injection unit with a tried-and-tested plasticizing system<br />

When it came to the GX Series, the designers stuck to KraussMaffei’s<br />

proven screw system, which guarantees a wide field of application. Our<br />

standard plasticizing unit assures optimal melting quality and high<br />

throughput. “Being an expert in specialty polymers, our company also<br />

offers our clients a plethora of material-specific plasticizing solutions,”<br />

explains Frank Peters, Executive Vice President Sales at KraussMaffei.<br />

The Plasticizing Competence Center provides customers with competent<br />

advice and there are hardly any limits on areas of application.<br />

The new MC6 control system offers a multifaceted degrees of<br />

freedom “With the MC6, we have developed a control system that<br />

satisfies all our clients’ usability-related requirements,” explains<br />

Bourdon. “Thanks to the SplitScreen and the ProcessDesigner functions,<br />

it is clear and unbelievably easy to operate.” In keeping with<br />

our overall energy-efficient design, the MC6 control system has been<br />

equipped with a so-called eco button for the first time. The machine<br />

can thus be optimally configured in terms of energy consumption at<br />

the touch of a button.<br />

The perfect symbiosis of automation and machinery KraussMaffei is<br />

also one step ahead when it comes to fully integrated production systems<br />

comprising both machinery and automation. Machine and handling<br />

form a functional unit in this combination. The MC6 can also be<br />

used in this way. As a common control system, it allows both functional<br />

units – the machine and the automation – to be controlled from<br />

any control panel, which represents added value for clients.<br />

The dialog-based programming wizard in the MC6 control system<br />

even allows beginners to create basic demolding processes in the<br />

shortest possible time. The interactive communication between the<br />

user and the control system makes manual programming superfluous<br />

and eliminates programming errors.<br />

oN THE rIGHT TrAcK<br />

The launch was successful: the product demand and the sales figures endorse<br />

the overall concept of the Gx Series.<br />

“ When it came to the launch of the Gx, our team really did accomplish<br />

a lot. The overall machine concept is marvelous, and<br />

I think the company is going to continue to concentrate passionately<br />

on the task at hand. and the rewards are being reaped:<br />

the worldwide demand for the products and the sales figures<br />

that we have generated so far have exceeded our expectations.<br />

The numerous worldwide product presentations are proceeding<br />

smoothly. We even managed to sell all the machines that<br />

were exhibited at the world premiere in Munich in May.”<br />

frank Peters, executive Vice President Sales<br />

The new international dimension The GX Series is also on the right<br />

track internationally. Several customer events took place after the<br />

world premiere in Munich, including in the United Kingdom and in<br />

Mexico, among others. The GX 550-4300, which can run a 450-gram<br />

packaging application with a cycle time of 9.8 seconds, was presented<br />

in Mexico. Various technical presentations provided information about<br />

the new, innovative technology and mechanisms of the series. Numerous<br />

visitors were clearly impressed.<br />

Read MoRe abouT IT<br />

Our product brochure “Gx Series<br />

Machines” contains further information<br />

about the new dimension<br />

of injection molding. Your sales<br />

partner would be happy to send<br />

you a copy.<br />

The new dimension<br />

of injection molding<br />

Machines in the GX Series<br />

Engineering Passion<br />

Brand & markets 13

14 Brand & markets<br />

<strong>AHEAD</strong> Issue 02.2012<br />

SuCCeSS SToRy<br />

MAjor orDEr FroM<br />

SAUDI ArABIA<br />

SabIC is one of the largest petrochemical companies in<br />

the world. The Saudi arabian company has had a business<br />

relationship with KraussMaffei for several decades. a major<br />

order that was placed in June provided yet more evidence<br />

of the trusting teamwork that has existed between the two<br />

sides for so many years: KraussMaffei and KraussMaffei<br />

berstorff are to set up a fully fledged technological laboratory<br />

at the new SabIC Plastics applications development<br />

Center in Riyadh, the capital of the kingdom of Saudi arabia.<br />

Such packages of orders don’t come along every day: complete extrusion<br />

lines for the PVC pipe, profile, and sheet extrusions as well<br />

as a twin-screw extruder, a few particularly powerful injection<br />

molding machines from the C3 and EX Series – all of this was on the<br />

“wish list” turned in by SABIC Plastics Applications Development<br />

Center. These systems are to be used by the company’s newest development<br />

center to equip the technological laboratory in Riyadh.<br />

The laboratory is eventually supposed to develop and test new materials<br />

and innovative production processes. SABIC currently operates<br />

a total of 17 specialized technological and innovation units of<br />

this nature in Saudi Arabia, the USA, the Netherlands, Spain, Japan,<br />

India, and South Korea. More than 8,000 patents bear witness to the<br />

expertise of SABIC’s researchers and developers.<br />

With more than 40,000 employees in 40 different countries, a turnover<br />

equivalent to more than 50 billion US dollars, and profits equivalent<br />

to 7.9 billion dollars, SABIC is in the top tier of the global petrochemical<br />

sector. Founded through a royal decree in 1976, the<br />

corporation (70 percent owned by the government, with the rest held<br />

by private investors from Saudi Arabia and other Gulf states) has<br />

grown rapidly. SABIC may be among the most successful companies<br />

that were founded in the Middle East in the 1970s with the goal of not<br />

only producing oil, but also processing it in order to create added<br />

value in their countries.<br />

SABIC has been working with KraussMaffei for several decades,<br />

which is an expression of the trust shared by the two companies<br />

– something that always plays an important role in relationships<br />

with Arabian companies. “We will do everything we can to once<br />

again completely and thoroughly justify this trust,” said Dr. Karlheinz<br />

Bourdon, Vice President Technologies, after the contract was<br />

awarded. “This contract, which has been awarded by a company<br />

whose technological requirements are extremely high, attests to our<br />

overarching expertise with respect to our unique technology.” MB<br />

“CoMPeTeNCe SHoW” IN THe laNd of THe RISING SuN<br />

In just six years, KraussMaffei’s Japanese subsidiary,<br />

which was founded in 2006, has become the market<br />

leader in the Japanese market for reaction process machinery.<br />

This is reason enough to celebrate this success<br />

as part of a “competence show,” whose primary theme<br />

is “Composite Materials & Combined Systems.”<br />

This competence show, which included technical lectures delivered<br />

by international experts as well as a trade show, took<br />

place in July in Okazaki, in Japan. More than 40 practical examples<br />

held the undivided attention of the more than 200 visitors.<br />

The displayed components were grouped according to individual<br />

processes in a theme-oriented manner. The visitors were<br />

especially interested in the fiber composite technology featuring<br />

HP-RTM (high-pressure RTM) and the fiber spray process,<br />

as well as the process combinations like SkinForm and<br />

ColorForm.<br />

KraussMaffei’s employees had their hands full answering visitors’<br />

questions, addressing inquiries, and acquiring projects.<br />

The presentations supplied the listeners with the latest information<br />

regarding the latest developments and trends in fiber<br />

composite technology and the production of premium-quality<br />

surfaces. “For us, the event was a complete success, as evidenced<br />

by the visitors’ reactions and the many new projects<br />

that we acquired during the event,” says Noriyuki Kanoh, Representative<br />

Director of the Krauss-Maffei Japan Corporation.<br />

The Japanese workers and their colleagues from Munich then<br />

celebrated the company’s six-year anniversary with a traditional<br />

Japanese dinner and a visit to a hot spring. On the way<br />

there, they stopped at the “<strong>KM</strong>26,” a 120-year-old KraussMaffei<br />

locomotive, which is considered to be a tourist attraction in<br />

Japan. The local press and three television channels were<br />

present when Mr. Nishi, chairman of the regional tourism<br />

office, inquired whether this well-preserved locomotive could<br />

be made operational again, and thus fulfill a childhood fantasy<br />

of many Japanese people. MB

KraussMaffei Brand & markets<br />

ReaCTIoN PRoCeSS MaCHINeRy<br />

THE rIGHT MAN<br />

For THE joB<br />

Composites/Surfaces business unit<br />

Erich Fries<br />

After working with various companies, the environmental<br />

engineer who also has management expertise<br />

joined KraussMaffei in 2003. In August 2012, he was<br />

appointed as the head of the Fiber Composites/Surfaces<br />

business unit. Thomas Aquinas provided him<br />

with the guiding principle for his work: “One must pray for miracles, but<br />

work hard for changes.” He is already looking forward to the challenges<br />

that will arise in the future as a result of new and interesting technology:<br />

“We will overcome them as a team.” He is already focusing on a new<br />

development: using carbon fibers in large series production. Fries enjoys<br />

traveling, playing handball, and is interested in Japanese gardens.<br />

Construction/Insulation business unit<br />

Dr. Michael Loferer<br />

He has been responsible for the Construction/Insulation<br />

business unit since August 2012. He is highly<br />

qualified for this role. After completing a degree<br />

in production engineering at the technical university<br />

in Munich, he worked as the Head of Design and<br />

the Head of Technology at Siempelkamp Handling Systeme GmbH. “In<br />

this era of ever-diminishing resources, the importance of energy-efficient<br />

buildings is ever-increasing”, he believes. “Our aim is to develop<br />

new products and tailor-made solutions for our customers using innovative<br />

ideas combined with tried-and-tested production technology.”<br />

In his spare time, Dr. Loferer likes to spend time in the mountains,<br />

both in the summer and winter.<br />

White Appliances business unit<br />

Gabriele Amodeo<br />

The Italian is not new to the KraussMaffei Group. As<br />

a General Manager, he is responsible for managing<br />

KraussMaffei’s Italian subsidiary. In August 2012, he<br />

took on an additional role as the head of the White<br />

Appliances business unit. His degree in mechanical<br />

engineering and his years of professional experience make him the<br />

ideal candidate for this role. In his free time, he likes to go sailing or<br />

skiing, depending on the time of year. His motto is based on experiences<br />

gained from sport and throughout his career: “A person is<br />

stronger when in a team.”<br />

Molded Flex/Interior Trim business unit<br />

Wolfgang Frehsdorf<br />

Wolfgang Frehsdorf has been responsible for heading<br />

the Reaction Process Machinery Technology and<br />

Production department for KraussMaffei since 1999.<br />

As of 2009, he has been the head of Reaction Process<br />

Machinery Operations. In August 2012, he became the<br />

head of the Molded Flex/Interior Trim business unit. “The new business<br />

units can be quickly adapted to specific customer requirements<br />

and offer a uniform organizational structure across the world. This allows<br />

us to prepare offers and execute orders quickly,” he said, when<br />

speaking about the advantages of the new organization. The skilled<br />

electronic engineer spends his free time on the golf course.<br />

coNcENTrATED<br />

ExpErTISE<br />

For cUSToMErS<br />

Since July, KraussMaffei’s Reaction Process<br />

Machinery sector has had a new customer<br />

orientation. In an interview with aHead,<br />

Nicolas beyl, the head of the sector, explained<br />

the advantages for customers and the opportunities<br />

that will open up for the company.<br />

The fact that both of these points are closely<br />

linked is not a surprise.<br />

THe INTeRVIeW WaS CoNduCTed by IMRe SZeRdaHelyI.<br />

<strong>AHEAD</strong>: Mr. Beyl, what are the special<br />

features of the new customer orientation?<br />

And wherein lie the significant<br />

differences to your sector’s current position<br />

within the KraussMaffei Group?<br />

Beyl: with our product ranges, we are<br />

orienting ourselves to our customers’<br />

fields of work. For the white Appliances,<br />

construction/Insulation, Molded<br />

Flex/Interior Trim, and Fiber composites/Surfaces<br />

product ranges, we have defined business units<br />

that match the customers’ specific requirements. These units<br />

integrate customer-oriented functions, such as Technical Sales<br />

Support, project Engineering, and Application Technology, to<br />

particularly link the Sales and project Engineering departments<br />

more closely. we will continue to integrate extensive<br />

cross-sector functions. These include construction, Development,<br />

Service, and the “supply chain” function, which covers<br />

the Assembly and Logistics coordination.<br />

<strong>AHEAD</strong>: what are the advantages of this orientation for our<br />

customers?<br />

Beyl: The new orientation allows us to better adapt our<br />

wide-ranging and high-performance product spectrum to our<br />

customers’ requirements. we would like to use our wide range<br />

of products and services, as well as our concentrated expertise,<br />

more than ever, to ensure that our customers get individual<br />

support throughout their entire value-adding chain, and we<br />

want to do this in all our markets.<br />

<strong>AHEAD</strong>: you wish to increase your potential for growth in this<br />

manner. what makes you so confident that you will be able do<br />

this?<br />

Beyl: primarily, it is, of course, all down to our dedicated and<br />

efficient employees who have played a part in every one of our<br />

success stories up until now. we have excellent technological<br />

expertise and we are market leaders, or at least one of the<br />

lead ing global companies, for many of our product sectors. we<br />

are also part of a group that gives us innumerable possibilities<br />

to cooperate with one another – be it technically, organizationally,<br />

or simply collectively and personally.<br />

15

16 Brand & markets<br />

<strong>AHEAD</strong> Issue 02.2012<br />

poSITIvE SIGNALS<br />

FroM SoUTHErN<br />

EUropEAN MArKETS<br />

Stories about the worrying situation in southern european countries dominate our<br />

media headlines on a daily basis. but there is another way. despite the difficult economic<br />

situation, there is encouraging news from the real economy, especially from<br />

the plastics industry. Classic holiday countries offer more than just sun, sea, and sand.<br />

The following examples are certainly impressive.<br />

TexT: MaRKuS beTSCHe<br />

SoUTHErN EUropE<br />

Classic holiday countries offer more than<br />

just sun, sea, and sand.

KraussMaffei Brand & markets<br />

ITaly’S PlaSTICS PRoCeSSoRS aT THe PlaST 2012 TRade faIR<br />

THrEE SUccESS STorIES<br />

This year’s Plast 2012 trade fair provided a good opportunity to cast an eye over the Italian<br />

plastic processing industry. We have taken a closer look at three Italian manufacturers of injection<br />

molded parts for the automotive and domestic appliance industries who have benefited<br />

from KraussMaffei’s expertise in energysaving, premiumquality investment casting solutions<br />

and advanced integrated processing technology.<br />

Cromaplast srl has its headquarters in Valdagno<br />

in the province of Vicenza, where it employs<br />

140 staff and in 2011, achieved an estimated<br />

turnover of 16 million euros with the<br />

manufacture of chrome-plated automotive<br />

molded parts. All of the company’s ten injection<br />

molding machines are units with hydraulic<br />

drive provided by KraussMaffei. Their<br />

machinery includes one machine each with<br />

65, 120, 200, and 300 tons of clamping force,<br />

four with 420 tons and two with 650. Most<br />

of the KraussMaffei machines were introduced<br />

as part of a machinery modernization<br />

program in 2010. The last four Italian units<br />

were replaced by the four KraussMaffei<br />

CX machines with 420 tons of clamping force<br />

in 2011.<br />

According to Managing Director Stefano Tecchio,<br />

the grease- and dust-free KraussMaffei<br />

machines are optimally suited to meeting tight<br />

dimension tolerances and achieving the perfect<br />

surface quality that is demanded of automotive<br />

molded parts. The parts are chromeplated<br />

on production lines with a plating<br />

capacity of 1,800 square meters per day.<br />

Plast3 srl in Fiume Veneto in the province<br />

of Pordenone is one of the three injection<br />

molding companies of the Pezzutti Group.<br />

The group employs 150 staff and possesses<br />

140 injection molding machines. In 2011,<br />

their turnover achieved an estimated 42 million<br />

euros. At Plast3, 30 employees work on<br />

23 injection molding machines.<br />

The company operates with four KraussMaffei<br />

machines: one MX 850-12000 and now three<br />

C2 machines with 420 tons of clamping force,<br />

the last of which was not acquired until 2012.<br />

All machines are equipped with robots from<br />

KraussMaffei.<br />

A KraussMaffei C2 420-3500 molds transparent<br />

red and white, rectangular carry<br />

boxes made of recycled PET for the furniture<br />

manufacturer IKEA. To qualify as a supplier<br />

at IKEA, KraussMaffei’s “Blue Power” energy<br />

saving procedures, such as cylinder insulation<br />

and short cycle times, were a decisive<br />

contributory factor, because in this case,<br />

ecological aspects and a low level of CO 2<br />

emission played a special role, reports Managing<br />

Partner Ivano Castelli. Another product,<br />

which is manufactured with a Krauss-<br />

Maffei 420-ton machine, is a one-piece child<br />

seat insert made of PET.<br />

A highly integrated, 60 percent glass-fiberreinforced<br />

polyamide part manufactured<br />

with an 850-ton MX type machine is used<br />

as a component in textile machines. In this<br />

case, it was possible for the temperature of<br />

the compound to be reduced by 40 degrees<br />

through the use of a KraussMaffei HPS highperformance<br />

screw. As a result, Plast3 was<br />

able to dispense with a master batch charged<br />

with micro balls. This was previously necessary<br />

in order to achieve a better flow rate and<br />

the high level of dimensional accuracy required,<br />

as well as an aesthetically pleasing,<br />

uniformly colored surface.<br />

Sole, a manufacturer of automotive molded<br />

parts founded in 1964 with its headquarters<br />

in Oderzo (region of Veneto, province of Treviso)<br />

is part of the Gruppo Prima. The company<br />

has an eventful history. It passed from<br />

Zanussi (1973) to Electrolux and Gränges<br />

with Plastal, and entered insolvency in 2009.<br />

QUALITy GUArANTEE<br />

KraussMaffei Cx 200750 with a linear robot from<br />

KraussMaffei at Cromaplast<br />

In 2010, Plastal was taken over by the Gruppo<br />

Prima and re-assumed its original name,<br />

Sole SpA.<br />

With around 740 employees, Sole achieved<br />

an estimated turnover of 183 million<br />

euros in 2011. The eleven Italian companies<br />

in Italy and the five European non-domestic<br />

factories of Gruppo Prima probably<br />

turned over 343 million euros in 2011.<br />

The large-scale factories in Oderzo and<br />

Suzzara (three injection molding machines<br />

up to 3,000 tons in Suzzara) are<br />

supported by German firms in Ulm (assembly)<br />

and Wörth (four KraussMaffei<br />

machines). In Oderzo, Sole uses 50 injection<br />

molding machines from various leading<br />

17<br />

ContinuEd on pagE 18

18 Brand & markets<br />

aHeaD Issue 02.2012<br />

Continued from page 17<br />

providers, which, apart from the Krauss-<br />

Maffei units, are mainly Italian machines.<br />

Among the KraussMaffei machines, the six<br />

“SpinForm” machines particularly stand out<br />

and these were introduced for the first time<br />

in 2007. Five of them have a clamping force<br />

of 650 tons and one has 180 tons.<br />

A 650-ton machine (CXW 650-2000/1400),<br />

which was installed in February 2011, produces,<br />

among other things, hard-soft dual-<br />

component door sill covers made of ABS<br />

(acrylonitrite butadiene styrene)/TPU for the<br />

BMW 3 Series. Two ABB multi-axis robots<br />

(articulated arm or “industrial” version) are<br />

used for removing parts, attaching fastening<br />

clips, and fitting a metal strip to the door sill<br />

molded part.<br />

50 years of successful collaboration<br />

Coscollola – our longest partnership<br />

As early as September 1962, Coscollola (Barcelona)<br />

became the KraussMaffei agency for<br />

injection molding machinery in Spain, and<br />

from this cooperation, the first injection molding<br />

machine was delivered in January 1963,<br />

which at that time was still of the 150S MONOmat<br />

type (manufacturer: Eckert&Ziegler).<br />

But the first KraussMaffei V110-700 injection<br />

molding machine came to Spain as early<br />

as 1964. In 1966, turnover already exceeded<br />

1 million DM, a respectable result in the<br />

plastics industry, which at that time was still<br />

emerging, not least because, before its accession<br />

to the EU in 1986, Spain levied an import<br />

tax of a full 45 percent on plastics machines.<br />

Today, 22 Coscollola employees attend to<br />

the needs of Spanish customers. In addition<br />

to KraussMaffei injection molding machinery<br />

and KraussMaffei Berstorff extrusion<br />

technology, they offer their customer base a<br />

wide range of peripheral equipment for processing<br />

plastics. The Coscollola team does<br />

not just regard itself as an agency, but rather<br />

as a competent partner for its customers.<br />

“Our focus is on the customer and their needs<br />

and requirements throughout the entire production<br />

period,” explains Ricardo Coscollola,<br />

Managing Director of Coscollola Comercial<br />

SL. “We therefore regard it as extremely important<br />

that we ourselves also possess competence<br />

in engineering, technical support,<br />

When Sole introduced the SpinForm machines,<br />

there was, according to Giuseppe<br />

Maiarelli, Head of Business Development, a<br />

“plan B” under which it was intended to use<br />

them with two separate molding tools as<br />

well. So far, plan B has not been implemented<br />

because Sole uses all SpinForm machines<br />

at full capacity with the usual horizontal rotary<br />

cube tool. The SpinForm technology is<br />

now also used for the manufacture of highgloss<br />

parts with a piano-lacquer-look finish<br />

in black. In this process, the first operation<br />

using transparent PMMA polymer is followed<br />

by a second that uses colored ABS/PC on the<br />

other side of the rotary cube tool. “Selectively<br />

chrome-plated” parts made of two materials,<br />

only one of which can be chrome-plated,<br />

are also created on the SpinForm.<br />

commissioning, and service. That makes us<br />

unique in the Spanish plastics market.”<br />

There is enormous competitive pressure<br />

among Spanish plastics processors, which is<br />

increased all the more due to intense global<br />

competition. And so in the current situation,<br />

many investments are postponed or completely<br />

canceled. But there are also companies<br />

with good basic conditions that operate<br />

successfully with a pronounced orientation towards<br />

exports. Some of them recently placed<br />

financially interesting orders with us, especially<br />

for injection molding machines.<br />

FPK (Bilbao) – IMC injection molding compounder<br />

for automotive structural components<br />

made of long glass-fiber-reinforced<br />

thermoplasts. This rapidly growing company<br />

ordered another MX 2700-24500 IMC injection<br />

molding compounder, including an extensive<br />

KraussMaffei automation solution for a factory<br />

in Brazil.<br />

Johnson Controls Plastics (Alicante) – Injection<br />

molding machines from the CX range<br />

with between 200 and 650 tons of clamping<br />

force produce plastic parts for batteries in the<br />

Spanish factory. With more than 20 further<br />

machines, JCP has far more than doubled its<br />

production capacities in both of the last two<br />

years.<br />

energy saving<br />

A KraussMaffei C2 420-3500 injection molding<br />

machine manufactures PET carry boxes for IKEA<br />

at Plast3.<br />

Herolse (Barcelona) – Flexible multi-color<br />

machines based on the MX range. With the<br />

newly ordered MX-Z 1450-4300/1400, the<br />

toolmaker is investing in a flexible manufacturing<br />

system for multi-color/multi-part components.<br />

A particular highlight of the machine<br />

is the movable injection units, which are able<br />

to serve the various sprue positions in the<br />

molds and as a result, is suitable for all standard<br />

sprue positions. The machine is ideally<br />

suited to carrying out trials of new molds for<br />

well-known OEM customers and also for the<br />

production of small and pre-series batches.<br />

As far as extrusion machines bearing the<br />

KraussMaffei Berstorff name are concerned,<br />

our machines made in Hanover – particularly<br />

compounding extruders – were in high demand<br />

in 2012, too. In spite of a difficult market<br />

situation in the building industry, it was possible<br />

to realize some successful projects in pipe<br />

extrusion.

KraussMaffei Brand & markets<br />

rELIABLE<br />

The Polyload aZ guarantees a constant flow<br />

of material in bMC (bulk molding compound)<br />

processing.<br />

ALL GooD THINGS<br />

coME IN THrEES<br />

Wet polyester processing in Greece<br />

In July this year, a brand new injection<br />

molding machine for wet polyester processing<br />

was delivered to Dasyc S.A. (form<br />

erly known as Technika Plastika S.A.) in<br />

Greece and put into operation. The CX 300-<br />

1400 PolySet completes the machine package<br />

in which Dasyc invested around a million<br />

euros. Two further PolySet machines<br />

for processing BMC (bulk molding compound<br />

= wet polyester) were already delivered<br />

in 2010 and 2011. And so the company<br />

has now installed the first production line<br />

for BMC parts in Greece in its factory in<br />

Thiva.<br />

Dasyc S.A. was established in 1979 and produces<br />

molded parts made of plastic and<br />

BMC as well as composites. The company<br />

provides a comprehensive service including<br />

component design and construction,<br />

component mounting, toolmaking, component<br />

manufacture, and preassembly. Extensive<br />

export experience and many years<br />

of collaboration with well-known, international<br />

industrial customers complete their<br />

areas of expertise. Today, components are<br />

produced and delivered to the automotive,<br />

military, aerospace, electrical/electronics,<br />

and domestic appliance industries.<br />

Extensive experience with duroplastic<br />

materials PolySet injection molding machines<br />

are suitable for the continuously precise<br />

processing of BMC. Based on expertise<br />

in the processing of cross-linked plastics<br />

since 1958, KraussMaffei PolySet machines<br />

stand out due to their highly effective, lowwear<br />

conveyor techniques and screws, as<br />

well as robust mechanics on the closing<br />

side in dual-platen technology.<br />

SPe (SoCIeTy of PlaSTICS<br />

eNGINeeRS) auToMoTIVe aWaRd<br />

Visualizing complex technologies and processes<br />

for customers in a clear and understandable<br />

way always poses a new challenge.<br />

KraussMaffei have been successful<br />

once again in this endeavor with their brochure<br />

on fiber-compound technology. But<br />

that’s not enough. As part of their 11th Automotive<br />

Award, the International Society<br />

of Plastic Engineers (SPE) has awarded 1st<br />

place in the image/product brochure category<br />

to the product brochure “Fiber compound<br />

solutions – for sophisticated lightweight<br />

components.” The jury recognized<br />