CQI-9 Special Process: Heat Treat System Assessment, 2 Edition ...

CQI-9 Special Process: Heat Treat System Assessment, 2 Edition ...

CQI-9 Special Process: Heat Treat System Assessment, 2 Edition ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CLARIFICATION TO "GENERAL NOTES FOR AMS 2750D"<br />

PAGES 16 & 17, <strong>CQI</strong>-09 2 nd <strong>Edition</strong><br />

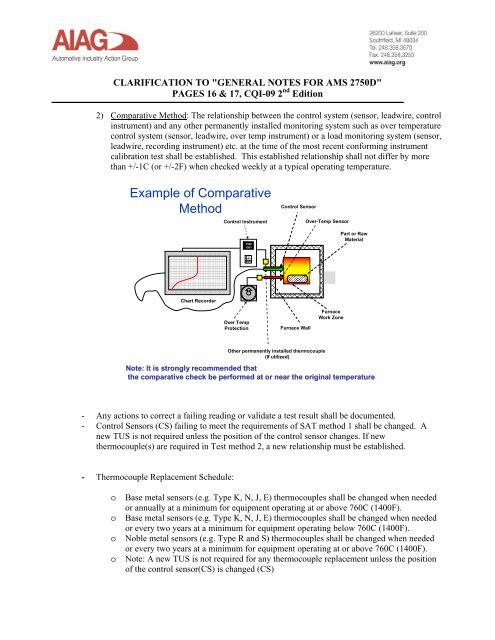

2) Comparative Method: The relationship between the control system (sensor, leadwire, control<br />

instrument) and any other permanently installed monitoring system such as over temperature<br />

control system (sensor, leadwire, over temp instrument) or a load monitoring system (sensor,<br />

leadwire, recording instrument) etc. at the time of the most recent conforming instrument<br />

calibration test shall be established. This established relationship shall not differ by more<br />

than +/-1C (or +/-2F) when checked weekly at a typical operating temperature.<br />

Example of Comparative<br />

Method<br />

Chart Recorder<br />

Control Instrument<br />

1500<br />

1501<br />

Control Sensor<br />

Over Temp<br />

Protection Furnace Wall<br />

Other permanently installed thermocouple<br />

(If utilized)<br />

Over-Temp Sensor<br />

Furnace<br />

Work Zone<br />

Part or Raw<br />

Material<br />

Note: It is strongly recommended that<br />

the comparative check be performed at or near the original temperature<br />

temperature<br />

- Any actions to correct a failing reading or validate a test result shall be documented.<br />

- Control Sensors (CS) failing to meet the requirements of SAT method 1 shall be changed. A<br />

new TUS is not required unless the position of the control sensor changes. If new<br />

thermocouple(s) are required in Test method 2, a new relationship must be established.<br />

- Thermocouple Replacement Schedule:<br />

o Base metal sensors (e.g. Type K, N, J, E) thermocouples shall be changed when needed<br />

or annually at a minimum for equipment operating at or above 760C (1400F).<br />

o Base metal sensors (e.g. Type K, N, J, E) thermocouples shall be changed when needed<br />

or every two years at a minimum for equipment operating below 760C (1400F).<br />

o Noble metal sensors (e.g. Type R and S) thermocouples shall be changed when needed<br />

or every two years at a minimum for equipment operating at or above 760C (1400F).<br />

o Note: A new TUS is not required for any thermocouple replacement unless the position<br />

of the control sensor(CS) is changed (CS)