Rail Freight Task Force - Final Report (7737 kb) - City of Mitcham

Rail Freight Task Force - Final Report (7737 kb) - City of Mitcham

Rail Freight Task Force - Final Report (7737 kb) - City of Mitcham

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

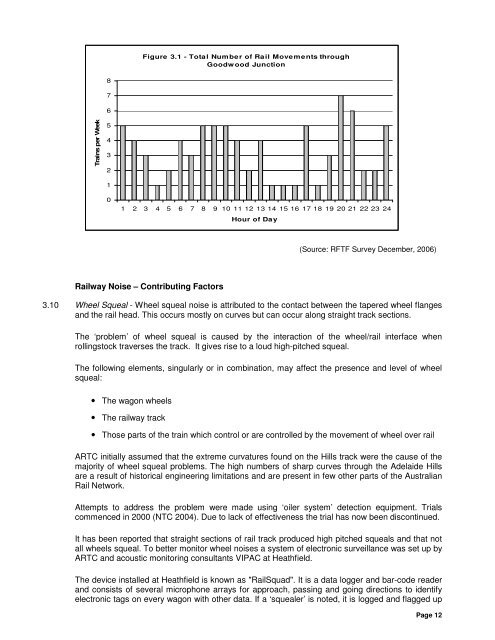

Figure 3.1 - Total Number <strong>of</strong> <strong>Rail</strong> Movements throughGoodwood Junction876Trains per Week5432101 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24Hour <strong>of</strong> Day(Source: RFTF Survey December, 2006)<strong>Rail</strong>way Noise – Contributing Factors3.10 Wheel Squeal - Wheel squeal noise is attributed to the contact between the tapered wheel flangesand the rail head. This occurs mostly on curves but can occur along straight track sections.The ‘problem’ <strong>of</strong> wheel squeal is caused by the interaction <strong>of</strong> the wheel/rail interface whenrollingstock traverses the track. It gives rise to a loud high-pitched squeal.The following elements, singularly or in combination, may affect the presence and level <strong>of</strong> wheelsqueal:• The wagon wheels• The railway track• Those parts <strong>of</strong> the train which control or are controlled by the movement <strong>of</strong> wheel over railARTC initially assumed that the extreme curvatures found on the Hills track were the cause <strong>of</strong> themajority <strong>of</strong> wheel squeal problems. The high numbers <strong>of</strong> sharp curves through the Adelaide Hillsare a result <strong>of</strong> historical engineering limitations and are present in few other parts <strong>of</strong> the Australian<strong>Rail</strong> Network.Attempts to address the problem were made using ‘oiler system’ detection equipment. Trialscommenced in 2000 (NTC 2004). Due to lack <strong>of</strong> effectiveness the trial has now been discontinued.It has been reported that straight sections <strong>of</strong> rail track produced high pitched squeals and that notall wheels squeal. To better monitor wheel noises a system <strong>of</strong> electronic surveillance was set up byARTC and acoustic monitoring consultants VIPAC at Heathfield.The device installed at Heathfield is known as "<strong>Rail</strong>Squad". It is a data logger and bar-code readerand consists <strong>of</strong> several microphone arrays for approach, passing and going directions to identifyelectronic tags on every wagon with other data. If a ‘squealer’ is noted, it is logged and flagged upPage 12