Criticality Assessment- Identification of Critical Quality Attributes ...

Criticality Assessment- Identification of Critical Quality Attributes ...

Criticality Assessment- Identification of Critical Quality Attributes ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

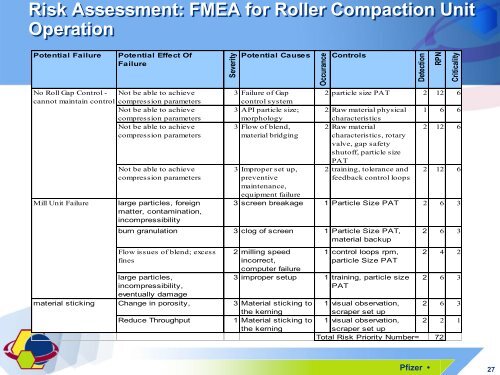

Risk <strong>Assessment</strong>: FMEA for Roller Compaction Unit<br />

Operation<br />

Potential Failure Potential Effect Of<br />

Failure<br />

No Roll Gap Control - Not be able to achieve<br />

cannot maintain control compression parameters<br />

Not be able to achieve<br />

compression parameters<br />

Not be able to achieve<br />

compression parameters<br />

Mill Unit Failure<br />

material sticking<br />

Not be able to achieve<br />

compression parameters<br />

large particles, foreign<br />

matter, contamination,<br />

incompressibility<br />

Severity<br />

Potential Causes<br />

Occurance<br />

Controls<br />

3 Failure <strong>of</strong> Gap<br />

control system<br />

2 particle size PAT 2 12 6<br />

3 API particle size; 2 Raw material physical 1 6 6<br />

morphology<br />

characteristics<br />

3 Flow <strong>of</strong> blend, 2 Raw material<br />

2 12 6<br />

material bridging characteristics, rotary<br />

valve, gap safety<br />

shut<strong>of</strong>f, particle size<br />

PAT<br />

3 Improper set up, 2 training, tolerance and 2 12 6<br />

preventive<br />

maintenance,<br />

equipment failure<br />

feedback control loops<br />

3 screen breakage 1 Particle Size PAT 2 6 3<br />

burn granulation 3 clog <strong>of</strong> screen 1 Particle Size PAT,<br />

material backup<br />

Flow issues <strong>of</strong> blend; excess<br />

fines<br />

large particles,<br />

incompressibility,<br />

eventually damage<br />

equipment<br />

2 milling speed<br />

incorrect,<br />

computer failure<br />

1 control loops rpm,<br />

particle Size PAT<br />

3 improper setup 1 training, particle size<br />

PAT<br />

Detection<br />

RPN<br />

2 6 3<br />

2 4 2<br />

2 6 3<br />

Change in porosity, 3 Material sticking to 1 visual observation, 2 6 3<br />

the kerning<br />

scraper set up<br />

Reduce Throughput 1 Material sticking to 1 visual observation, 2 2 1<br />

the kerning<br />

scraper set up<br />

Total Risk Priority Number= 72<br />

Pfizer • 27<br />

<strong><strong>Critical</strong>ity</strong>