The Whole World Of Contract Packaging â Kallfass - R.V. Evans

The Whole World Of Contract Packaging â Kallfass - R.V. Evans

The Whole World Of Contract Packaging â Kallfass - R.V. Evans

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

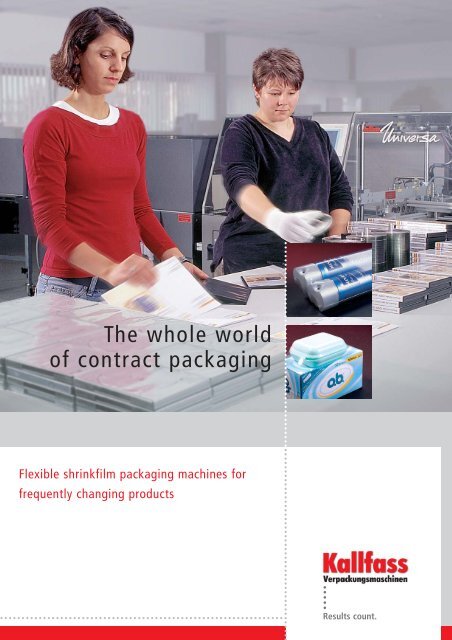

<strong>The</strong> whole worldof contract packagingFlexible shrinkfilm packaging machines forfrequently changing productsResults count.

Perfect answers to your questionsFlexible throughout the dayAt the end of the day for you counts: no break down,no frustrated employees, all orders processed – andabove all: perfectly packed products. Thus you relyon our experience in the field of co-packing andstemming from it our expertise in this field. Withonly a few machines out of the KALLFASS productionrange you can cover the most diverse products andavoid in the future many costly changes in systemsand in providers.<strong>The</strong> performance fitsWe know exactly what you need – and we knowhow to convince you. First of all with an unbeatableprice-performance ratio. Because we relate to youprice advantages coming from our tight procurementmanagement. And once you have decided for aKALLFASS film packaging machine we deliver on timeand take good care of you with fast and reliable aftersales service.

That’s what satisfied customers sayMULTIPACK Advertising andMailing Company KleveTask:confectioning of frequently varying sizesDIN A7 to A3.Solution:. KC 8060 UNIVERSAL. SERVO JET 400 with shrink tunnel<strong>The</strong> maximum performance of the continuousmotion side seal machine SERVO JET 400 allowsfor a notably increased output compared to anintermittent motion side sealer.<strong>The</strong> continuous motion mode of the SERVO JEToffers a maximum smoothness of running for theproducts during the packaging process.Advantage: many multipacks don’t require bundlingprior to film packaging. At the same time: timeadvantage by omission of one work step. With thesame amount of personnel the processing time forany one order will be drastically reduced.Westfalia Life Aid,Ansbach“I do need such a flexible partner”“KALLFASS does support us when through neworders on short term notice the machine requirementsshift. Machines can be modified or the possibility ofbeing bought back exists. Due to the broad KALLFASSrange the highly performing sales force always finds asolution which does carry us further.”Angela Stauffert, assistant production manager,Phone +49 (0)981/9525-246

Efficient packaging ensures your profitabilityTime is money: simple format changeYou want your employees to quickly change overthe film packaging machine without any specialists ?Many KALLFASS machines do offer in addition to theproduct data memory (i.e. UNIVERSA 400) a pathcontrol: when changing the product size or whenchanging the packaging speed one simply entersthe new values or they are being extracted from theproduct data memory and on it goes. <strong>The</strong> path controlis a pioneer achievement of KALLFASS.Operating: safe and easy – even with trainedpersonnelIn particular handicapped workshops and co-packersknow: the safety of the operators and the avoidanceof wrong machine settings help to prevent unproductivedown time. Machines from KALLFASS are equippedwith touch panel and a self explaining operatorguidance. Its use is quickly comprehensible and thelanguage can easily be changed.Less maintenance efforts: that’s how you do itOur trick: to keep wear and tear as lo as possible orto prevent them altogether by intelligent engineering.This increases availability and reduces your costof ownership.Less maintenance cost with KALLFASS:* maintenance free lower seal bar roller* solid state temperature relays* plastic mesh inside the shrink tunnel* exchangeable sealing blade* good all around accessibility

That’s what satisfied customers sayKAY-SER, BielefeldTask:confectioning, packaging and bundling of CD’s,DVD’s and printed matterSolution:. UNIVERSA 400 with shrink tunnel. SUPER WRAP 650 de Luxe in-line. KC 5040 UNIVERSAL“High reliability of the KALLFASS machines, whichare also well designed and built, even with complexand more challenging packaging applications.Flexible and quick reaction time on complex andshort term customer requirements.Opinion:Competent and fair advice by KALLFASS is always inthe interest of the customer. Service and spare partsarrive the next day at 95 %. We only invest in KALL-FASS”Wolfrad Michael, sales managerPhone +49 (0)521/40085-0HANAUERLAND workshops, Kehl-Kork“<strong>The</strong> most important features for us are safeand easy operation”.Film packaging machines by KALLFASS unite ourdemand for safety for our operators with ease ofoperation and short set-up times. <strong>The</strong> automaticfilm packaging line UNIVERSA 400 does haveseveral handicapped work places. We employabout 300 handicapped people in our work shop”Berthold Löffler, production managerPhone +49 (0)7851/84-506

Service: we are here for you<strong>The</strong> ideal service for co-packersYou want to be sure before you buy. <strong>The</strong>refore ourexperts advise you oriented on your needs. What doyou need to pack and do you need a new machineafter all ?Sometimes, an existing KALLFASS machine can beadapted, in many cases our hints provide an easysolution.Our knowledgeable field technicians are therequickly, because our various locations make forshort distances. <strong>The</strong>se experts are at your disposaland inform you also about pre-owned machinesand leasing options.DRUCK+PACK SERVICE, HamburgTask:product sampling for sales enhancement at the POSfor trade marked hygienic and cosmetic goods.Solution:nine KC 5040 Universal combine highest flexibilitywith shorted changeover times, i.e. uncomplicated andfast changes for product sampling. After that, regularproduction resumes without a big time loss.Opinion:“Easy maintenance and accessibility are important tous because we do most of it on our own. <strong>The</strong> KALL-FASS Service Hot Line provides for fast and accuratesupport and remote diagnose.”Heinz Holert, managing directorPhone +49 (0)40/731039-0

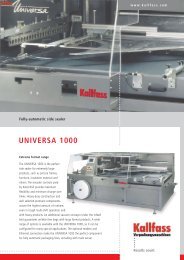

Full programFor co-packers and service providersKALLFASS shrink film packaging machines areequipped exactly with those technologies whichallow you on a daily basis to pack rationally andeasily. This allows you at any time to workefficiently and most economically.If really at some time in the future a new machine isrequired we take back your used machine and furnishyou out of our vast production range with a perfectsolution in every perspective.L-sealersModel range KW, KC, UNIVERSA 5050 .Application area Full-wrap with centre-folded film . manual, semi-automated andfully-automated operationPerformance Up to approx. 20 cycles/min. in case of semi-automatic operation and up toapprox. 40 cycles/min. in case of fully-automatic operation. Standard and combinedL-sealer with shrink tunnel with patented electromechanic sealing frame.Side sealersintermittent motionModel rangeApplication areaPerformanceUNIVERSA 400 / 700 / 1000 . fully automatic, intermittent motionFull-wrap with centre-folded film or flat film via film folding deviceUp to max. 85 cycles/min.For any length of product, for easy size change-over.Continuous side sealing unit, intermittent motion.Also available as forming shoe machine with bottom overlap-seal.Side sealerscontinuous motionModel rangeApplication areaPerformanceUNIVERSA 500 SERVO . fully automatic, continuous motionFull-wrap with centre-folded film or flat film via film folding deviceUp to max. 120 cycles/min.Continuous side sealing unit, travelling cross seal bar.Continuous packaging process without product stop.Also available as forming shoe machine with bottom overlap-seal.Side sealerscontinuous motionModel rangeApplication areaPerformanceSERVO JET 400 / 80 . 400 / 120 . 400 / 170 . fully automatic, continuous motionFull-wrap with centre-folded film or flat film via film folding deviceUp to max. 170 cycles/min.Continuous side sealing unit, travelling cross seal bar.Continuous packaging process without product stop.Also available as forming shoe machine with bottom overlap-seal.SleevewrappersModel rangeApplication areaPerformanceSUPER WRAP 650 / 950 / 1300 / 1600 . fully automatic, intermittent motionBull-eyed transport packaging with two flat films.Exclusive by <strong>Kallfass</strong> - fully enclosed transport packaging withHV shrink tunnel technology.Up to max. 30 cycles/min.Large bundle packaging machines with 1,300 and 1,600 mm seal bar.Energy-saving shrink tunnelsModel range Compact-, universal, large-scale and special shrink tunnels for the most diverse .Application areaPerformanceapplications areas, with HV technology too.Presentation and transport packaging and as drying or heating trackHighly effective heat insulation of tunnel hoods. COMPACT models withpatented ring nozzle heating system for minimised energy consumption.SO models - additional insulation hood for enhanced shrink performanceand minimised energy consumption.

<strong>Kallfass</strong> Verpackungsmaschinen GmbHSiemensstraße 8 . D-72622 Nürtingen-ZizishausenPhone: +49 (0)7022/607-0 . Fax: +49 (0)7022/607-200info@kallfass.com . www.kallfass.comwww.marschner-kuehn.de