Download Catalog - Econoline

Download Catalog - Econoline

Download Catalog - Econoline

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

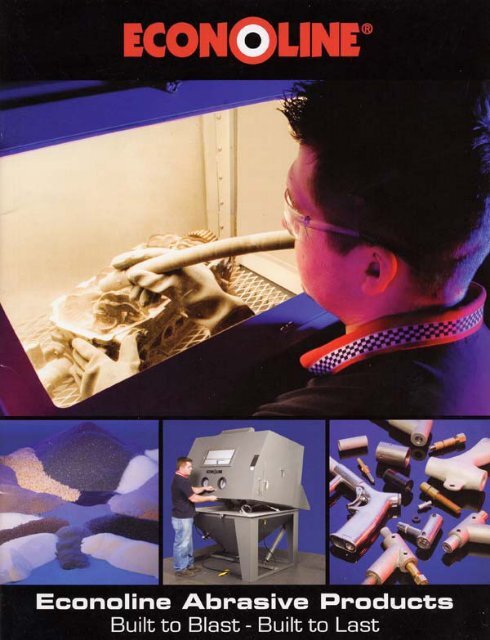

Blast Cabinets–SiphonAbrasive BlastingThe abrasive blasting process itself is simple:It works by rushing compressed air througha specifically designed delivery system thatcombines compressed air with abrasive media.This combination of air and abrasive slams into thetargeted piece, cutting, etching, abrading, cleaning orotherwise changing the appearance or condition ofthat surface.Abrasive blasting is valuable as an efficient, highqualitymethod of surface preparation. No othermethod of metal cleaning allows better control ofthe surface preparation or cleans the surface asthoroughly. By beginning with a screened abrasive,you control and obtain a consistent profile on thetargeted surface. This clean, etched surface aidsin adhesion and allows the coating to lock onto thesurface. This combination of clean and etch greatlyenhances the ability to obtain a superior qualityfinish. Blasting also allows access to irregularlyshaped parts that can’t be reached by traditionalsanding or solvent cleaning methods.Blasting is also used for other purposes beyondsurface preparation, such as removing microscopicmachining burrs from engine parts, etching glass,carving of names and designs in wood and stone orsurface hardening of manufactured parts.2 Blast Cabinets - Siphon60 x 48 CBOverall Dimensions Openings WindowHeight Width Depth Top 48” x 60” Height 12”92” 65” 86” Side 20” x 30” Width 24”Working Approx. Weight Mfg. Number40” 60” 48” 1100 lbs 101701CB-AWith 60” of workingwidth and 48” ofworking depth, the60 x 48 CB is a 25CFM foot-operatedblast cabinet that is aslarge as it is powerful.Comes with a 400CFM dust collector(not shown) andtungsten carbidenozzle and air jet thatprovides you with aspacious solution thatfits in most shop environments. Optional equipmentincludes carbon screen, turntable, 45 CFM gun,tumble basket, 150 or 600 CFM dust collector andreclaim system.60 x 30 FTDouble StationOverall Dimensions Openings WindowHeight Width Depth Top 30” x 60” Height 12”82” 62” 74” Side 24” x 21” Width 24”Working Approx. Weight Mfg. Number40” 60” 30” 570 lbs 102765R-AClam shell and sideaccessfeatures makeloading and unloadingthis roomy machine asnap. Lower hopperdoor allows for simplemedia changes andcloth lined gloves allowsthe operator to workin comfort and safety.Standard fluorescentlighting, 25 CFM footpedal blast gun withtungsten carbide nozzle and air jet, and 150 CFM dustcollector (not shown) provide excellent visibility. Optionalfeatures include airline filter, carbon screen, doublegun system, 45 CFM gun, boron carbide nozzle, tumblebasket, turntable, 400 or 600 CFM dust collector,reclaim system and dust blow off gun.48 x 48 FTOverall Dimensions Openings WindowHeight Width Depth Top 48” x 48” Height 12”94” 52” 90” Side 20” x 30” Width 24”Working Approx. Weight Mfg. Number40” 48” 48” 675 lbs 101699R-AWith a clam shelldesign for ease inloading, this blastcabinet features abackrest welded to theunit for strength andstability. The windowis also easily changed,and a hopper doormakes media changessimple. 25 CFMfoot pedal blast gunand 100 CFM dustcollector (not shown)are standard. Optional features include: dust blow offgun, tumble basket, turntable, 150, 400, or 600 CFMdust collector.48 x 48 CB 48-2 SuperOverall Dimensions Openings WindowHeight Width Depth Top 48” x 48” Height 12”94” 52” 90” Side 20” x 30” Width 24”Working Approx. Weight Mfg. Number40” 48” 48” 750 lbs 101699CB-AThis blasting cabinetopens wide to 48” x48” and provides 40”of operating heightfor your most bulkyprojects. A 25 CFMfoot-operated blastgun, 100 CFM dustcollector (not shown),and tungsten carbidenozzle and air jet arestandard. Optionalfeatures includeairline filter, carbonscreen, rubber cotton-lined gloves, dust blow off gun,45 CFM blast gun, boron carbide nozzle, tumblebasket, turntable, 400 or 600 CFM dust collector andreclaim system.Flip Top andCounterbalance CabinetsCounterbalance(right) cabinets havean enclosed springmechanism, offeringsmooth movementand ease of use whenopening or closing thecabinet lid.Flip Top (left) cabinetsfrom <strong>Econoline</strong>feature springs toassist the operatorin opening the lid ofthe blasting unit.Overall Openings WindowHeight Width Depth Top 48” x 13” Height 12”63” 51” 25” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number22” 48” 23” 370 lbs 101695S-ATwo side doors allowendless placementoptions in this footoperatedblasting unit.Featuring a 100 CFMdust collector, 25CFM foot pedal gun,fluorescent lightingand cloth lined workgloves; the 48-2 Superis a complete blastingsolution with muscle.Options include airlinefilter, carbon screen,rubber cotton lined gloves, dust blow off gun, 12 CFMblast gun, boron carbide nozzle, tumble basket, andturntable.<strong>Econoline</strong> Abrasive Products 3

Blast Cabinets–Siphon48 x 36 RH Vert DR48 x 24 FTOverall Opening WindowHeight Width Depth Side 27” x 34” Height 12”81” 51” 36”Width 24”Working Approx. Weight Mfg. Number40” 48” 36” 1100 lbs 101771S-RVOverall Dimensions Openings WindowHeight Width Depth Top 48” x 24” Height 12”65” 52” 54” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number23” 48” 24” 380 lbs 101697R-AThis versatile blasting cabinet features a large sideopening that allows for options such as the turntable,track and vertical door shown. Standard featuresinclude a 100 CFM dust collector, fluorescent lighting,cloth lined work gloves and a 25 CFM foot-operatedblast gun. Other optional features include an airlinefilter, carbon screen, dust blow off gun, 45 CFM gun,boron carbide nozzle, tumble basket, 400 or 600 CFMdust collector, and a reclaim system. Also availableas Mfg. Number 101771S-RH in a horizontal doorconfiguration. Turntable and track are also optionalin the horizontal door model.With four feet ofworking width, thisclam shell design hasa backrest assemblystandard, as wellas a 100 CFM dustcollector, fluorescentlighting, 25 CFMfoot-operated blastgun, hopper door foreasy media changesand more. Optionalfeatures include airlinefilter, carbon screen,dust blow off gun, boron carbide nozzle, tumble basketand turntable.Clam shell design permitsthe operator to easily loadheavy objects.Clam Shell DesignWindow ReplacementAll of <strong>Econoline</strong>’s cabinets have an easily replaceablewindow. See the feature on page 6 for moreinformation.The 48x36 RH Vert DR shown with optionaltrack.42 x 24 Super FTOverall Dimensions Openings WindowHeight Width Depth Top 42” x 24” Height 12”65” 46” 54” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number23” 42” 24” 360 lbs 101696R-AA clam shell designallows for easy loadingand unloading. Anexcellent choice fora mid-sized flip topmachine. The 42 x24 Super FT blastcabinet also includesa backrest assembly,100 CFM dustcollector, fluorescentlighting, 25 CFM footpedal operated blastgun, and a hopper doorthat makes media changes simple. Optional featuresinclude airline filter, carbon screen, dust blow off gun,12 CFM blast gun, boron carbide nozzle, tumble basketand turntable.<strong>Econoline</strong> offers a variety of methods of access tothe blast chamber area of the cabinet.Larger cabinets are constructed with both a sidedoor and split-top access, also known as a clamshell. We use the term clam shell to describe theopenings of these cabinets in that the entire uppersection of the cabinet opens. It is hinged alongthe back and the top section pivots up and backallowing full access to the interior.This large access area allows a user to load heavyitems with a fork truck or crane and affords theuser more blasting area because they are notlimited in size by what they can get through aside door. This feature combined with our heavyduty materials make <strong>Econoline</strong> units popular withcustomers who have large, heavy items to blast.All split-top cabinets have a spring assistmechanism and can easily be opened by asingle operator.4 Blast Cabinets - Siphon<strong>Econoline</strong> Abrasive Products 5

Blast Cabinets–Siphon40 x 40 FTBB 36-0 Budget36-1 SuperWindow and Light ReplacementThe window in the cabinet is a clear Plexiglas. <strong>Econoline</strong>chooses to use Plexiglas as over time, the window willbecome etched by the abrasive blast process and thePlexiglas is less expensive to replace.Overall Dimensions Openings WindowHeight Width Depth Top 40” x 40” Height 12”82” 44” 74” Side 20” x 30” Width 24”Working Approx. Weight Mfg. Number32” 40” 40” 560 lbs 101698R-AThis blasting cabinetoffers a flip top, clamshell design with a full40” of work area at aheight of 30”. Featuresa steel screen worksurface, 25 CFMfoot pedal blast gunand 100 CFM dustcollector. The operatorcan access projectsusing large side door ifdesired.40 x 40 CBOverall Openings WindowHeight Width Depth Top 36” x 13” Height 12”63” 39” 25”Width 24”Working Approx. Weight Mfg. Number23” 36” 24” 260 lbs 101717R-AThe BB 36-O Budgetblasting cabinetfeatures a triggeroperated 12 CFMblast gun and ceramicnozzle. Includes a 100CFM dust collector,steel air jet, top flipperaccess door, andlower hopper door forquick media changes.Other optionalfeatures include anairline filter, carbonscreen, tumble basket, turntable, blow off gun, footpedal, 25 CFM blast gun upgrade, and regulator andgauge.30-0 SuperOverall Openings WindowHeight WIdth Depth Top 36” x 13” Height 12”63” 39” 25” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number23” 36” 24” 280 lbs 101694S-AThe 36-1 Superfeatures a standard25 CFM blast gunwith tungsten carbidenozzle and air jet, 100CFM dust collector andfluorescent lighting.This is <strong>Econoline</strong>’smost popular modeland includes side dooraccess as well as easyto use flipper dooron the front. Manyoptional features addversatility to this mid-sized cabinet, but a popular choiceis a media reclaim system.24-0 SuperWe also provide a thin film we call windowunderlaymentthat protects thewindow from blastdamage. This film isinexpensive and easyto replace. The usersimply removes thewing nuts that securethe window frame tothe cabinet, and thenremoves the frameand the window. Theused underlayment is discarded and replaced with anew piece. The user then replaces the window andframe. The entire process takes approximately twominutes.For more information about <strong>Econoline</strong> replacementwindows and lamp shields, please see page 29.Overall Openings WindowHeight Width Depth Top 40” x 40” Height 12”82” 43” 72” Side 20” x 30” Width 24”Working Approx. Weight Mfg. Number30” 40” 40” 580 lbs 101698CB-AThis blastingcabinet offers acounterbalanced clamshell cabinet stylesimilar to the 40 x 40FT, with a full 40” ofwork area at a heightof 30”. This unit comescomplete with a 100CFM dust collector,fluorescent lighting,steel screen worksurface and cloth linedwork gloves.A hopper door allows for easy media changes and a footoperatedblast gun allows an operator optimal controlof the 25 CFM blast gun. Options include upgrades toa 400 or 600 CFM dust collector, or the addition of atumble basket or turntable.Overall Opening WindowHeight Width Depth Top 30” x 13” Height 11 1 / 2 ”63” 32” 25”Width 12”Working Approx. Weight Mfg. Number22” 30” 23” 250 lbs 101693S-AWith a tungstencarbide nozzle and airjet standard, the 30-0Super is a powerfulmidsize model blastcabinet with a footoperated12 CFMblast gun and 100CFM dust collector.Fluorescent lightingimproves visibilitythrough the easyto-changewindow.Optional featuresinclude an airline filter, carbon screen, dust blow offgun, boron carbide nozzle, tumble basket, 150 CFMdust collector and turntable.Overall Opening WindowHeight Width Depth Top 24” x 13” Height 11 1 / 2 ”63” 26” 25”Width 12”Working Approx. Weight Mfg. Number23” 24” 24” 230 lbs 101692S-AWith welded andcross-braced legsand a 100 CFM dustcollector included,the 24-0 Super isa complete blastcabinet solution. Otherstandard featuresinclude a 12 CFMfoot-operated blastgun, tungsten carbidenozzle and air jet,and hopper door foreasy media changes.For more versatility, add a tumble basket, turntable orupgrade to a 25 CFM blast gun.6 Blast Cabinets - Siphon<strong>Econoline</strong> Abrasive Products 7

Blast Cabinets – Siphon24-0 Budget BenchOverall Opening WindowHeight Width Depth Top 24” x 13” Height 11 1/2”47” 25” 21”Width 12”Working Approx. Weight Mfg. Number20” 23” 19” 150 lbs 101692B-AThe 24-0 Budget Bench from<strong>Econoline</strong> has a trigger operated12 CFM blast gun, fluorescentlighting and an expanded metalwork surface. Adjustable legsare standard. A ceramic nozzleis also standard. A largerversion of the Mini Bench, theBudget offers an optional freestanding, adjustable leg kit.Other optional features includea media tray kit,12 or 25 CFMfoot pedal gun kit, and shopvacuum.8 Blast Cabinets - SiphonStandard adjustable legson the Budget Bench.Mini BenchOverall Opening WindowHeight Width Depth Top 18” x 12” Height 6”33” 19” 17”Width 12”Working Approx. Weight Mfg. Number16” 18” 16” 95 lbs 101691R-AThe <strong>Econoline</strong> Mini Bench is a compact blast cabinet withall the bells and whistles of a big unit on a smaller scale.This bench model comes with a standard shop vacuumdust collector, work gloves, easy to change window, doorsafety switch, foot-operated blast gun with 12 CFM anda tungsten carbide nozzle and air jet. Optional featuresinclude an airline filter, carbon screen, dust blow off gun,6 CFM blast gun, boron carbide nozzleand tumble basket.Mini Bench foot pedal.ESB 007 Spot BlastHeight Width Depth Approx. Weight Mfg. Number44” 20” 18” 80 lbs 101765S-AThe <strong>Econoline</strong> ESB007 Spot Blastunit is a portable,dust free solutionto your blastingneeds. Low abrasiveconsumptionrecycles abrasivemedia separate fromdust and debris.Includes a standard12 CFM trigger gun,regulator and gauge,water filter, recyclingSpot Blast with lid open.head and a .5 microncartridge filter. This unit weighs just 55 lbs when empty,and with a 1” blast pattern, it’s perfect for small jobs andtouch ups.Other Portable Units are available on page 13, andReplacement Filter information is available on page 28Air IntakeHopperBlast GunSiphon TubeMixing ChamberMedia HoseAbrasive MediaSiphon Tube Cross-SectionCompressedAir InInside a Siphon System<strong>Econoline</strong> siphon cabinets are economically priced,have a minimum number of moving parts and requireless maintenance than a direct pressure system.Siphon cabinets, also known as suction cabinets, permitcontinuous blasting without pausing to refill abrasivemedia. Production rates are not as high as with a directpressure system, but resulting finishes are comparablein quality. <strong>Econoline</strong> siphon cabinets meet the challengewhere initial costs and maintenance are concerns.A siphon system works as follows: Abrasive is held in thestorage hopper of the blast machine and delivered to thesuction gun through a media hose. Compressed air isbrought into the suction gun from the regulator throughan air hose. As dry and regulated compressed air flowsthrough the air jet, it passes through a mixing chamberbefore it enters the blast nozzle. Negative pressure, orsuction, is created in the mixing chamber of the gun bodyand media is drawn into the blast nozzle, much as wateris sucked through a straw. Incoming compressed airaccelerates the media to a velocity of approximately 60to 100 CFM, depending upon the air pressure selected.The CFM of compressed air required to operate asuction gun is determined by the orifice in the air jet,combined with the orifice in the blast nozzle.Our siphon machines are available in a variety of sizesand styles with factory options available that contributeto greater productivity and ease of operation. <strong>Econoline</strong>advises the use of a reclaim system when recoverablemedia is used. This option will typically pay for itselfquickly in terms of media saved. Please see page 14for more information about <strong>Econoline</strong> reclaim models.<strong>Econoline</strong> Abrasive Products 9

Blast Cabinets–Direct PressureWD 48 x 24 FTWD 40 x 38NozzleMedia HoseOverall Openings WindowHeight Width Depth Top 48” x 24” Height 12”71” 51” 54” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number23” 48” 24” 600 lbs 101697WD-AOverall Opening WindowHeight Width Depth Side 33” x 26” Height 24”96” 42” 39”Width 24”Working Approx. Weight Mfg. Number35” 40” 38” 795 lbs 102760R-APressureVesselCompressedAir InAbrasive MediaMediaControlValveThe WD 48 x 24FT offers 6” moreworking width thanthe 42 x 24 model.Regulator and gauge,fluorescent lighting,steel screen worksurface, 400 CFMdust collector, 1/8”I.D. tungsten carbidenozzle, carbon screenand cloth-lined workgloves are standard.Optional featuresinclude an airline filter, dust blow off gun, tumble basketand turntable.<strong>Econoline</strong>’s WD 40 x 38 blast cabinet features a raisedsteel work platform for the operator and a large windowfor easy project viewing. Oval armports hold standardrubber cotton-lined work gloves. Other standard featuresinclude regulator and gauge, fluorescent lighting, a 14and 11 gauge welded steel cabinet, tungsten carbidenozzle, moisture filter, media regulator, 1/2” internaldiameter abrasive hose, foot pedaloperation, 400 CFM dust collectorand 10-120 PSI ASME code pressurepot with a media capacityof 1 cubic foot.How Direct Pressure WorksPressure Systems utilize a pressure pot that whenpressurized with media in the pot, accelerates the mediafrom the pot through the blast hose to the nozzle.A direct pressure unit has the same amount ofpressure in the pressure pot vessel and passing throughthe air line that connects to the outlet of the abrasivemetering valve.Sometimes direct pressure systems are referred to asgravity fed or equal pressure units. While the abrasive‘free flows’ into the air stream, the operator can bettercontrol, or direct, the blasting process at both low andhigh end pressures.In most applications, work can be done four times fasterthan with a siphon cabinet as the abrasive is deliveredat a much higher velocity. Media Control valve shown infull open position in the illustration above. Under normaloperating conditions, the valve handle would be in the7 o’clock position.10 Blast Cabinets - Direct PressureWD 42 x 24 FTOverall Openings WindowHeight Width Depth Top 42” x 24” Height 12”71” 45” 54” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number36” 24” 23” 580 lbs 101696WD-AThe WD 42 x 24FT direct pressureblast cabinet deliversabrasive at highervelocity than doesa siphon systemto maximize yourproduction rates.Clam shell openingallows easy access toprojects and includesa standard 400 CFMdust collector. The footpedal operated 1/8”I.D. tungsten carbide nozzle permits easy operation andcontrol. Other optional equipment includes a dust blowoff gun, tumble basket, turntable and more.DP 36-1 WD 36 x 30Overall Openings WindowHeight Width Depth Top 36” x 13” Height 12”65” 60” 25” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number23” 36” 24” 350 lbs 101694D-AA state-of-the-artpressure pot dry blastsystem designed forthe high volume shopseeking excellentcontrol for blastingapplications. Featuringa side mountedpressure pot for easyoperation, holds upto 110 pounds ofblasting media for long,uninterrupted blasting.Wide front and sidedoors allow for quick and easy placement and removalof objects. A convenient pressure control gauge andfoot-operated 25 CFM tungsten carbide blast nozzlereduce fatigue for the operator ready to get the jobdone. Unit includes a 100 CFM dust collector.Overall Openings WindowHeight Width Depth Top 36” x 13” Height 12”70” 38” 31” Side 17” x 11” Width 24”Working Approx. Weight Mfg. Number35” 36” 30” 480 lbs 103098R-4The WD 36 x 30 blastcabinet from <strong>Econoline</strong>has a standard 400CFM dust collector andASME code pressurevessel. Other standardfeatures includeoval armports, footpedal operation anda tungsten carbidenozzle.26” side opening allowsfor easy project loading.<strong>Econoline</strong> Abrasive Products 11

Blast Cabinets–Direct PressureMP 36 Slot BlasterEC-90 DMOverall Openings WindowHeight Width Depth Top 34” x 18” Height 14”76” 84” 32” Side 35” x 3” Width 26”Working Approx. Weight Mfg. Number36” 36” 30” 480 lbs 101760D-AThe <strong>Econoline</strong> MP 36 Slot Blaster features vertical andhorizontal slots and load bearing arms on both sides foreasy loading of tall and wide projects ready to be blasted.Adjustable rollers aid blasting and dual floodlight lightingprovides excellent visibility. With foot pedal operation andcloth-lined work gloves, this machine is built for comfortand safety. A regulator and gauge, steel screen worksurface and 1/8” I.D. tungsten carbide nozzle are alsostandard. The 100 CFM dust collector is standard, but150, 400 and 600CFM dust collectorsare available asoptions.Inside the MP 36Slot Blaster100 CFM Dust CollectorDust collector andreplacement bag<strong>Econoline</strong>’s 100 CFM DustCollector is standard onmost blast cabinet models.It was created especially forthe removal of dust and dirtparticles created while blastingwithin a cabinet. While theblast cabinet is in operation,the collector draws dust anddirty air from the cabinet intothe canister where the heavierparticles are deposited into thebottom of the barrel housing.The air is then drawn throughthe filter which removes thefiner dust particles. This bagstyle dust collector requiresonly minor maintenance.For more information on <strong>Econoline</strong>’s full range of dustcollectors and replacement bags, please see catalog pages15 and 28.Height Diameter Approx. Weight Mfg. Number60” 10” 75 lbs 102461D-AThe portability and 90lb abrasive capacity ofthe EC-90 DM from<strong>Econoline</strong> makesthis model ideal forquick touchups. Deadman handle designmeans the blastshuts off when thehandle is released. Apull up closure plugadds to this model’sconvenience and itslow-cost operation. Fiveceramic nozzles, 10 ft. of heavy duty 1/2” I.D. abrasiveresistant hose are standard. The pressure relief valvemeets OSHA requirements and the tall vertical tankdesign makes this modular unit a handy addition to yourfacility. Also comes with a light duty protective hood andbump cap.EC-90 RHeight Diameter Approx. Weight Mfg. Number60” 10” 80 lbs 102461R-AAll the portability andconvenience of the EC-90 DM, with remoteblast control, waterfilter and gauge, for theultimate in operatorsafety. Remote blastcontrol offers fullcontrol at nozzlehandle. System shutsoff at the tank.90 lb abrasive capacityallows for 30 to 50minutes of blast time,and the pressure relief valve and pressure relieving ballvalve both meet OSHA requirements. Comes standardwith a light duty protective hood and bump cap.Abrasive Blast EngravingAbrasive blast engraving is a process where ahard object such as glass, ceramic, or marbleis engraved by abrasive media. This process isalso commonly referred to as etching.The actual etching process is controlled byattaching an abrasive blast resistant mask onthe item to be blasted. The detail of this maskcreates the highly detailed etched areas in theobject. The durability of the mask allows theuser to etch very deep in the piece, which alsoincreases its value.Abrasive blasting is a unique process thatallows both small and large businessesto create beautiful work completely withintheir own facility, without the need to sendartwork out to a supplier. We believe productimprovements, and more variety of etchedproducts have increased the awareness andappreciation of this attractive, artistic lookto consumers.12 Blast Cabinets - Direct Pressure<strong>Econoline</strong> Abrasive Products 13

Dust Collectors400-PT Reclaim D/CHeight Width Depth Approx. Weight Mfg. Number72” 50” 24” 345 lbs 101767PT-4Vac. Hose Diameter Vac. Hose Length CFM HP4” 6’ and 10’ 400 1/2400 D/CHeight Width Depth Approx. Weight Mfg. Number72” 26” 20” 180 lbs 101716GY-4CVac. Hose Diameter Vac. Hose Length CFM HP4” 10’ 400 1/2150 CFM D/CWhisper VacHeight Width Depth Approx. Weight Mfg. Number65” 15” Diameter 65 lbs 202672-AVac. Hose Diameter Vac. Hose Length CFM HP2 1/2” 5’ 150 1/2Choosing the RightDust Collector<strong>Econoline</strong>’s dust collector system is designed for theremoval of dust and dirt particles created while blastingwithin a cabinet. In operation, the collector draws dustand dirty air from the cabinet into the canister, wherethe heavier particles are deposited into the bottom ofthe housing. The air is drawn through the filter, whichremoves the finer dust particles. Filtered air is returned tothe room. The dust collector you choose should match thework that you’re doing at your facility.Keep in mind that blast cleaning is by its very naturea dusty process, and the primary function of thedust collector is to maintain visibility while blasting byexchanging the air in the cabinet. To maintain this level ofvisibility, a dust collector should provide 6 to 8 air changesper minute. <strong>Econoline</strong>’s bag style dust collector filters at50 microns, and cartridge style dust collector filters are99.98% efficient, filtering .5-micron particles.Primary considerations in choosing the right dustcollector include noise, usage – at a time and over time,cost, maintenance, filtration, and operating area (howlarge, how clean, how humid and what sort of ventilationis available).For high volume production work, we recommend theuse of a reclaim system. The <strong>Econoline</strong> abrasive reclaimsystem provides the removal of dust and dirt like a dustcollector while also centrifugally separating broken downblast media, dust and foreign material from usable blastmedia, utilizing a direct drive pressure blower. This allowsfor less media waste and for prolonged media life. Reclaimsystems require the addition of a pickup tube to thecabinet hopper.The 400-PT ReclaimDust Collector provides400 CFM and is bothan abrasive reclaimerand dust collector,separating usablemedia from dust andother foreign materials.The front access dooris 12” wide by 21 3/4”tall, and the hopper trapdoor allows for easydust removal. An easilyreplaced cartridgefilter comes with model shown as well as an air actuatedvibrator for filter cleaning and a 9” direct drive pressureblower. A 600 CFM model is also available.400 EB Reclaim D/CHeight Width Depth Approx. Weight Mfg. Number66” 40” 24” 175 lbs 101768EB-4Vac. Hose Diameter Vac. Hose Length CFM HP4” 10’ 400 1/2The 400 EB ReclaimDust Collector is a400 CFM externalbag media reclaimerwith a large externaldust bag and 1/2 hpmotor standard. Theremovable filteringsystem is easy tochange and makesmaintenance of thismodel easy. The 600CFM model (Mfg.Number 101768EB-6)has standard 1 hp motor for even more power in yourworkshop. Please see the <strong>Econoline</strong> Master ProductChart on the inside cover.<strong>Econoline</strong>’s 400 CFMDust Collector featuresan easy to replacecartridge style filter.This design permitsmaximum air flow whilereducing the likelihoodof filter clogging. Italso has a 12” x 213/4” access door andhopper trap door foreasy dust removal. A600 CFM model is alsoavailable, and both the400 and 600 CFM models are available in a bag styledust collector with manual shaker. See the <strong>Econoline</strong>Master Product Chart on the inside cover for moredetails.100 CFM D/C Bag StyleHeight Width Depth Approx. Weight Mfg. Number59” 15” Diameter 40 lbs 201768G-B5Vac. Hose Diameter Vac. Hose Length CFM2 1/2” 5’ 100The 100 CFM BagStyle dust collector isan efficient and safesolution to your dustcollection needs. Itreturns filtered air tothe room, and featuresa self-cleaning featurein the bag. The 50micron polyfelt bagfilter can be laundered.Fabricated of 24 gaugesteel, this unit requireslimited maintenance.The 201768G-B10 model (not shown) comes with 10’vacuum hose standard.The 150 CFM D/CWhisper Vac earnsits name! At less than85db at 12 inches, thismodel is the choicefor the shop wherenoise reduction is animportant feature.The Whisper Vac alsooffers higher efficiencythan 100 CFM modelsand is a smart upgradefor businesses lookingfor a longer term dustcollector investment. The 50 micron polyfelt bag filter iseasily laundered and replaced.100 CFM D/C CartridgeHeight Width Depth Approx. Weight Mfg. Number28” 18” Diameter 35 lbs 201768GY-C5Vac. Hose Diameter Vac. Hose Length CFM2 1/2” 5’ 100The 100 CFMCartridge DustCollector is theworkhorse of the family.This lower profile, lowmaintenance, highefficiency machinehas a .5 microncartridge filter and is99.9% efficient. Model201768GY-C10 (notshown) comes with astandard 10” hose.Information on replacement filters is available onpage 28.14 Dust Collectors<strong>Econoline</strong> Abrasive Products 15

Blast Gun Assemblies45 CFM Pistol Grip25 CFM GunPistol Grip TriggerMfg. Number DescriptionA 201542 45 CFM Pistol Grip CompleteB 410209 45 CFM Carbide Nozzle 7/16” I.D.C 201775 25/45 CFM Gun Body OnlyD 201541 45 CFM Air Jet AssemblyAMfg. Number DescriptionA 201381 25 CFM Gun Assembly CompleteB 201382 25 CFM Carbide Nozzle 5/16” I.D.C 201757 25 CFM Gun Body OnlyD 201383 25 CFM Air Jet Assembly 5/32” I.D.ADescriptionA Full Assembly 12 CFM Tungsten Carbide Nozzle12 CFM Ceramic Nozzle25 CFM Ceramic NozzleB Nozzle 12 CFM Ceramic25 CFM Ceramic12 CFM Steel25 CFM Steel12 CFM Tungsten Carbide25 CFM Tungsten CarbideMfg. Number201647201788201789201790201791497055497061497010497060C Nozzle Holder 12 & 25 CFM Trigger Gun 410535AD Air Jet 12 CFM 1/8 I.D.25 CFM 5/32 I.D.E Washer -Air Jet Seal41053741053812 & 25 CFM Trigger Gun 410536BDBDACCBlast Gun Assembly Construction &Replacement PartsAll <strong>Econoline</strong> 12 and 25 CFM Blast GunAssemblies are cast of aluminum. This lighter,less fatiguing gun also features a cast-in ribbedpick-up tube. You will find the machining onour gun bodies superior to that of many ofour competitors, thus not only extending thelife of the gun body, but also enhancing theperformance of the assembly itself.We carry a full line of replacement parts makingit easy for you to keep your Blast Guns in perfectworking order.25 CFM Pistol GripMfg. Number DescriptionA 201540 25 CFM Pistol Grip CompleteB 201382 25 CFM Carbide Nozzle 5/16” I.D.C 201775 25/45 CFM Gun Body OnlyD 201851 25 CFM Air Jet AssemblyAA Boron Carbide nozzle Mfg Number 410207 isalso available (not shown) .12 CFM GunMfg. NumberDescriptionA 201379 12 CFM Gun Assembly CompleteB 410201 12 CFM Carbide Nozzle 1/4” I.D.C 201756 12 CFM Gun Body OnlyD 201394 12 CFM Air Jet Assembly 1/8” I.D.ABCThe Pistol Grip Triggeris the standard gun forBudget Blast Modelsand the ESB 007Portable unitDEDBDBCDAir jet detailCA Boron Carbide nozzle Mfg Number410208 is also available (not shown).18 Blast Gun Assemblies<strong>Econoline</strong> Abrasive Products 19

Blast Gun Assemblies6 CFM Gun Pencil GunMfg. Number DescriptionA 201538 6 CFM Gun Assembly CompleteB 410200 6 CFM Carbide Nozzle 1/8” I.D.C 410101 6 CFM Gun Body with hose barbD 201539 6 CFM Air Jet 1/16” I.D.BCATungsten Carbide Nozzles, Holder and HoseDMfg. Number DescriptionNot Shown 410250 Gun Assembly 1/16” TipShown 410253 Gun Assembly 1/8” TipThe <strong>Econoline</strong> PencilGun allows users tofinish smaller parts.The pencil gun has a5 foot flexible hose foreasy maneuverability.Abrasive flow iscontrolled by a thumbscrew on the flowcontrol assembly.Offered in 1/16”and 1/8” Tip GunAssembly options. Also available with the followingnozzle options: 1/16” carbide (Mfg. Number 410251),1/16” flat tip (Mfg. Number 410252) and 1/8” carbide(Mfg. Number 410263).Dust Blow Off GunMfg. NumberApprox. Weight201749 2 lbsThe Dust Blow Off Gunfrom <strong>Econoline</strong> cleansprojects of dust anddebris, right insideyour blast cabinet.The gun mounts onthe side of the blastcabinet and connectsdirectly to the airsupply. The Dust BlowOff Gun is excellentfor detail work andfinishing. Individual replacement components are alsoavailable.Ceramic NozzlesChoosing the Right NozzleNozzle Selection for Direct Pressure unitsCompressors can be overtaxed by using a nozzle that is toolarge. A large nozzle consumes a greater amount of mediawithin a given period. The nozzle I.D. (inner diameter) dictatesthe required size of the compressor. Refer to the selectionchart to determine which nozzle size is appropriate to do thejob with your compressor.ABCMfg. Number DescriptionA 416529 1/8” I.D. Carbide Nozzle416530 3/16” I.D. Carbide Nozzle416531 1/4” I.D. Carbide Nozzle416532 5/16” I.D. Carbide Nozzle416533 1/16” I.D. Carbide Nozzle416534 3/32” I.D. Carbide NozzleB 410461 Nozzle HolderC 413411 1 1/8” O.D. Media HoseAll <strong>Econoline</strong> direct pressure cabinets includethe 1/8” I.D. nozzle, holder and media hose.Mfg. Number I.D.448847 1/4”448848 3/16”448849 3/32”448850 5/16”448851 5/32”448852 3/8”448857 1/8”I.D. CFM PSIBlast AreaSq. Ft/MinuteAbrasiveUnit/Hr3/32” 7 80 ½ 100 lbs1/8” 15 80 1 to 1 ½ 150 lbs5/32” 25 80 1 to 2 ½ 200 lbs3/16” 40 80 3 to 3 ½ 300 lbs1/4” 80 80 4 to 4 ½ 500 lbsAs the nozzles wear out the I.D. increases, requiring agreater volume of air. Due to this change, you may want tostart with a smaller size nozzle.Nozzle Selection for Siphon Method unitsThe orifice in the air jet, combined with the orifice in theblast nozzle determines the CFM (cubic feet per minute) ofcompressed air required to operate a suction gun. The blastnozzle orifice size should be at least twice the size of theorifice in the air jet. The chart below shows the CFM requiredat various pressures to properly support various air jet/nozzle combinations.Air Requirements CFM) 40 PSI 60 PSI 80 PSI 100 PSI1/4” nozzle, 3/32” air jet 7 CFM 10 CFM 12 CFM 15 CFM1/4” nozzle, 1/8” air jet 12 CFM 17 CFM 21 CFM 26 CFM3/16” nozzle, 1/8” air jet 12 CFM 17 CFM 21 CFM 26 CFM5/16” nozzle, 5/32” air jet 19 CFM 27 CFM 34 CFM 42 CFM7/16” nozzle, 7/32” air jet 38 CFM 52 CFM 66 CFM 80 CFM20 Blast Gun Assemblies<strong>Econoline</strong> Abrasive Products 21

Media DeliveryAir Line FilterMedia Delivery SystemRegulatorand Gauge AssemblyAll of our standard blast cabinets include regulatorand gauge assemblies, allowing the user to controlthe velocity of the blast stream. With this feature, auser can control both the speed at which the work iscompleted and flexibility in achieving the desired finish.Mfg.NumberPortSizeBowl Options411119 3/4” PolycarbonateMetal Bowl guard/twist drain411136 3/8” PolycarbonateAuto Drain411151 1/2” PolycarbonateMetal Bowl guard/twist drainElements40 micron40 micron40 micron<strong>Econoline</strong> stronglysuggests that theoperator have a water/air separator installed infront of the regulator toassure that no moistureenters the system. Thisensures a clean, dryflow of air to your blastcabinet and promotesa consistent and evenflow from your nozzle.Moisture may lead toclogging of the abrasivemedia. A unique deflectorplate and shroud createsa swirling of the airstream and ensures maximum separation of dirt andwater. The Air Line Filter is especially recommended forhumid climates.Deluxe Plus(pictured)*DeluxeBasicPlusBasicComponents Included: 101804-A 101803-A 101802-A 101801-A12 CFM TungstenX X X XCarbide Gun AssemblyUniversal Siphon Tube X X X XHoses and connectors X X X XRegulatorX X Xand Gauge KitFoot pedal X XDoor Safety SwitchXApprox. Weight 12 lbs 12 lbs 10 lbs 6 lbsUpgrade your blast cabinet with a smooth flowing <strong>Econoline</strong>Media Delivery System. The Basic Delivery System kit includesa 12 CFM Tungsten Carbide Assembly, a Universal SiphonTube, and all hoses and connectors. The Deluxe Delivery SystemKit includes all the items in the Basic Media Delivery Kit plus aRegulator and Gauge Kit. Foot pedal and Door Safety Switchoptions are also available for added functionality and safety.Users savetime becausethey don’t needto change thepressure at theirair compressor,which they may beusing for a varietyof air driven toolsin their shop. Theycan simply adjustthe air pressureat the cabinet.The <strong>Econoline</strong>Regulator and Emergency shut-off switchGauge Assemblyincludes a connection to the emergency shut-offswitch for additional safety and security.Piggy Back Filter/RegulatorMfg. NumberSpecs411133 3/8” for ESB-007411145 1/2” for EC-90 RUniversal Siphon TubeMfg. NumberApprox. Weight201785 2 lbsThe Universal SiphonTube is positioned inthe bottom of a cabinethopper and pullsmedia into the MediaHose, and thus intothe nozzle. In siphonsystems, this is howthe media moves fromthe hopper to the hose.For more information,please refer to thediagram on page 9.Clear Abrasive HoseMfg. NumberApprox. Weight413403 1/4 lbsThe Clear AbrasiveHose connects theUniversal Siphon Tubeand the nozzle. Thishose has 5/8” I.D.and is sold by the foot.For more information,please refer to thediagram on page 9.22 Media Delivery<strong>Econoline</strong> Abrasive Products 23

Media DeliveryMedia ValveHD Media ValveGun Mounting BracketMfg. NumberApprox. Weight411128 2 lbsMfg. NumberApprox. Weight411160 1 lbMfg. NumberApprox. Weight101841-A 2 lbsUsed on the EC-90 R, constructed of steel.Retrofit KitMfg. NumberApprox. Weight201962 81 lbsThe <strong>Econoline</strong> Retrofit Kit converts the 36-1 from a siphonsystem to a direct pressure system. The kit mounts to theoutside of the cabinet and assembly is required.Used on the 36-1 DP, constructed of aluminum.The Gun MountingBracket providesthat ‘extra hand’users need tohold projects,leaving bothhands of theoperator freeto maneuverthe work. GunMountingBrackets canbe mountedon the wall orceiling inside Bracket with gun in placeany <strong>Econoline</strong>blast cabinet. Blast Gun can be easily put in or removedfrom the bracket. Telescopic functionality is designedto provide easy length adjustment, from 7 3/4” to 123/4”, with rotation of 360 degrees.Steve Johnson, President, Monarch Powder CoatingMuskegon, MICustomer Profile:Monarch Powder Coating“We’ve had our <strong>Econoline</strong> 48-2 Blast Cabinet anda portable blast unit since purchasing MonarchPowder Coating 4 years ago. We use them forpreparing parts for coating, cleaning rust or oils,and other surface needs. As a job shop with a batchtype operation, everything we coat must be manuallyprepared, hand spray coated, and then oven cured.Our niche is lower volume parts and/or specialtyitems that will not fit on a conventional powder coatconveyor line.With these units, we can quickly blast smaller parts,touch up where needed, change media quickly, anduse glass bead abrasive without having to start-upour large blast room system.We have enjoyed a good working relationship with<strong>Econoline</strong> and it’s employees.Everyone knows that time is money. These units aredesigned so that replacement and wear parts can bechanged quickly and easily – which means less downtime!”24 Media Delivery<strong>Econoline</strong> Abrasive Products 25

Replacement PartsCartridge FiltersDust Collector BagReplacement GasketsMfg. NumberApprox. WeightA 495114 9 lbsB 495171 4 lbsThe <strong>Econoline</strong>Cartridge Filter hasbeen tested to be99.9% efficient,Afiltering .5 microns.The Cartridge Filteris manufactured fromcellulosic filter mediawith corrugationdesigned for dustBcollection applicationsrequiring highcollection efficiencyand minimum airrestriction. The cartridge style air filter is also easyto replace. Small filter fits 100 CFM Cartridge D/Cand ESB 007. Large filter fits 400 and 600 CFMCartridge D/C.Mfg. NumberApprox. Weight414436 2 lbsThe Dust CollectorBag from <strong>Econoline</strong> ismade of dense polyfelt,which is ratedat 10 microns (95%efficient). It’s standardequipment on the100 CFM Bag DustCollector, as seen onpage 12 and the 150CFM D/C WhisperVac . When the unit ispowered off, the sewninweight at the bottom of the bag drops, shaking up thebuilt up dust from the bag each time the collector motoris shut off.Mfg. Number Description (Note: Gaskets are sold by the foot)A 411401 Flipper door gasket 5/16” x 1/2”B 411403 Window/Door Gasket 1/2” x 1”C 411402 Arm port gasket 1/4” x 2”D 411419 Dust Collector door gasket 1/4” x 1”ABCD100 CFM D/C Motor1/2 & 1 HP MotorsReplacement Windows and Lamp ShieldsLight Box AssemblyMfg. NumberApprox. Weight414414 5 lbsHP Mfg. Number Approx. Weight1/2 414500 19 lbs1 414501 36 lbsMfg. Number DescriptionA 311535 Window Underlayment Roll – 24” x 120”B 313286 Window Underlayment 10 pack – 12” x 24”C 411423 Lamp shield - 7” x 12”D 411422 Lamp shield - 12” x 25”E 411410 Window - 6” x 12”F 411405 Window - 12” x 24”NotShown411429 Window - 24” x 24”<strong>Econoline</strong> light box assembly features are the resultof listening to our customers to provide safer andmore efficient lighting in our blast cabinets.Our lights are located outside the work area andprotected by a lamp shield. The placement of thelight assembly eliminates the chance of accidentaldamage to both the bulbs and the light fixture andalso reduces the chance of injury to the user ordamage to the product. Spot lights located inside acabinet can be easily broken when shifting productinside the cabinet.Works with the 100 CFM Dust Collector, as seen onpage 15.1/2 HP fits 400 and 150 CFM Dust Collectors; 1 HPfits 600 CFM dust collectorsEAFCDBDual fluorescent bulbs featured in <strong>Econoline</strong> lightbox assemblies provide omni-directional lighting.Unlike the spot light bulb lighting systems usedby many other manufacturers, fluorescent lightsreduce shadows. Spot lights provide poor lighting bycasting shadows, making it difficult to see what youare doing. Our dual fluorescent bulbs are positionedacross the width of the cabinet and illuminate thecabinet more evenly and efficiently.See page 6 for Window and Light Replacementinformation.28 Replacement Parts<strong>Econoline</strong> Abrasive Products 29

Replacement Gloves1Glove ClampsMfg. NumberArmport DiameterReplacement GlovesMfg. NumberDescriptionA2414510-2 6”414511-2 7”414512-2 8”414513-2 9”A 412402 Gloves 24” x 6” Seamless Rubber Pairfor DP unitsB 412007 Gloves 33” x 7” Pair for 40 x 40 and upC 412001 Gloves 18” x 5” Pair for Mini Bench onlyD 412002 Gloves 24” x 6” Pair for 24-0 through 48-2BD34<strong>Econoline</strong>’s gloves are designed to withstand the harshenvironment within a blast cabinet. Gauntlet-style glovesare manufactured of reinforced neoprene and vinyl,with a cotton lining. <strong>Econoline</strong> also offers natural rubbergloves, which are comfortable and aid in eliminatingstatic shock as well as providing superior flexibility andfeel. Gloves are available in seamless and/or cotton linedmodels where indicated. All <strong>Econoline</strong> gloves provideexcellent durability and functionality.C5Glove Replacement and MeasurementGlove clamps sold in pairs.Replacement Gloves67Replacement of gloves in <strong>Econoline</strong> blast cabinetsis a very easy process that can be completed witha screwdriver or air tool in less than 10 minutes.When you take the measurement of the armports, be sure to take the vertical diameter ofthe opening. This is particularly important forcabinets with oval-shaped holes, such as the WD40 x 38 or the WD 36 x 30.<strong>Econoline</strong> replacement gloves also fit mostcompetitors’ cabinets.Work SurfaceCarbon ScreenMfg. #ApproximateDimensionsExpanded MetalMfg. #311137 16” x 16” 201346311134 24” x 24” 201342311131 30” x 24” 201344311135 36” x 24” 201345311140 40” x 40” 201337311136 42” x 24” 201338311141 48” x 24” 201347311138 40” x 38” 202692311139 48” x 48” 201340Mfg. Number Size (Length/Armport) Description412001 18” X 5” Pair; Seamless Rubber412402 24” X 6” Pair; Seamless Rubber - Cotton Lined412402-L 24” X 6” Left; Seamless Rubber - Cotton Lined412402R 24” X 6” Right; Seamless Rubber - Cotton Lined412002 24” X 6” Pair; Neoprene/Vinyl - Lined412003L 24” X 6” Left; Neoprene/Vinyl - Lined412003R 24” X 6” Right; Neoprene/Vinyl - Lined412004 24” X 7” Pair; Neoprene/Vinyl - Lined412019L 24” X 7” Left; Neoprene/Vinyl - Lined412019R 24” X 7” Right; Neoprene/Vinyl - Lined412007 33” X 7” Pair; Neoprene/Vinyl - Lined412008L 33” X 7” Left; Neoprene/Vinyl - Lined412008R 33” X 7” Right; Neoprene/Vinyl - Lined203475-A 60” x 48” 201358412005 24” X 8” Pair; Neoprene/Vinyl - Lined8412020R 24” X 8” Right; Neoprene/Vinyl - Lined412020L 24” X 8” Left; Neoprene/Vinyl - Lined412009 33” X 8” Pair; Neoprene/Vinyl - Lined412010R 33” X 8” Right; Neoprene/Vinyl - Lined412010L 33” X 8” Left; Neoprene/Vinyl - Lined412403 32” X 9” Pair; Seamless Rubber - Cotton Lined9412403R 32” X 9” Right; Seamless Rubber - Cotton Lined412403L 32” X 9” Left; Seamless Rubber - Cotton Lined412011 33” X 9” Pair; Neoprene/Vinyl - Lined412012R 33” X 9” Right; Neoprene/Vinyl - Lined412012L 33” X 9” Left; Neoprene/Vinyl - Lined30 Replacement Gloves<strong>Econoline</strong> Abrasive Products 31

Abrasive MediaAbrasives Overview<strong>Econoline</strong> Abrasive Products strives to maintain a varied inventory of blasting abrasives. Utilizing a worldwide base of reputablesuppliers, <strong>Econoline</strong> is able to provide consistent delivery of quality abrasive products. We look forward to servicing yourabrasive needs.Cleaning, Finishingand PeeningCleaning: Abrasive blasting removes corrosion oxides, fluxslag, heat treat scale, surface discoloration and paint.Finishing: Blasting can impart a shiny-bright, matte oretched surface to your project and will blend defects andmarks.Peening: Peening can increase the fatigue life of your workpiece by hammering to leave the surface under residualcompressive stress.Choosing the RightMedia TypeThe type of abrasive determines cost and effectivenessof the blast-cleaning process. The variables are quality offinish desired and the time required to obtain that finish.Start with a lasting, durable abrasive using the smallestsize that will do the job, then work up to the largest sizethat does an acceptable job in the shortest time.Grading Abrasive MediaAbrasive media is graded based on mesh size. Meshsize refers to the number of holes in a 1” square screen.As mesh size gets larger, the number of holes per inchincreases, the size of each individual hole decreases, andthe media becomes finer. Size comparisons shown inchart at right.Factors ThatDetermine EfficiencyShape: Particles can either be smooth or sharp. Smooth,round particles hammer the base material to impart apeened finish and to dislodge brittle scale better thansharp particles do. Sharp edged particles remove materialfrom your project quickly, leaving an etched or matte finish.Size: The size of the particles determines the finishedroughness of your work. Large particles bring more kineticenergy to the work surface, but excessively large particlesremove more material than small ones. As the abrasiveworks, particles break into smaller and smaller sizes.Hardness: The harder the abrasive, the deeper itpenetrates and the faster it works. Soft abrasives deformand waste kinetic energy. Brittle abrasive wastes energy byfracturing during the blasting process.Mass: For equal size, denser particles have more kineticenergy and work faster than particles that are less dense.Break Down Rate: This is the rate of fracture of theabrasive media during blasting. The more resistant toimpact fracture, the more consistent the blasting action.Mesh Screen Size Comparison16-40 Ground coffee30-50 Fine ground pepper30-80 Table salt50-80 Granulated sugarGeneral Application Guide for Abrasive Media*1 = best2 = effective3 = acceptableApplicationETCH PEEN DEBURR REMOVE PAINT CLEANSTEEL123Silicon CarbideAluminum OxideBlack Beauty SlagCast S.S. ShotSteel ShotGlass BeadSteel GritSilicon CarbideAluminum OxideSilicon CarbideAluminum OxideBlack Beauty SlagSilicon CarbideAluminum OxideGlass BeadALUMINUM123Ground GlassGlass/Aluminum OxideAluminum OxideGlass BeadAgricultural ShellsPlastic GritAgricultural ShellsPlastic GritGlass/Aluminum OxideGlass BeadSoda BlastAgricultural ShellsGlass BeadSoda BlastPlastic GritPLASTIC123Ground GlassGlass/Aluminum OxidePlastic GritGlass BeadPlastic GritAgricultural ShellsPlastic GritAgricultural ShellsGlass/Aluminum OxidePlastic GritSoda BlastAgricultural ShellsSoda BlastPlastic GritAgricultural ShellsWOOD123Plastic GritAgricultural ShellsSoda BlastN/AN/AN/AN/AN/AN/ASoda BlastPlastic GritGlass BeadSoda BlastPlastic GritGlass Bead*This chart is for comparitive purposes only.32 Abrasive Media