You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Dear customer, dear business partner,<br />

Due to the financial and economic crises, 2009 was a difficult year. With the slogan “Mutually, we show<br />

strength in the crisis” we fortunately managed to withstand the national and international crisis. We have<br />

believed in our success and lived our visions. Hence, commonly we have mastered the last year in spite of<br />

the worldwide difficulties.<br />

The attached <strong>BIBKO</strong>® Paper News gives an overview about our successful activities this year. It shows<br />

projects we have commissioned and gives information about international shows we have attended.<br />

Without a doubt the “Bauma” show in Munich will be one of the highlights in 2010. This is the largest<br />

construction show worldwide and we will again display our product line. We are looking forward to see you<br />

at our booth 906A/1 at the open-air exhibition ground F9.<br />

We would like to thank you for your trust in 2009 and wish you all the best and a successful year 2010.<br />

Markus Kloiber<br />

Sales Manager<br />

<strong>NEWS</strong> <strong>PAPER</strong> V O L U M E 2 0 0 9<br />

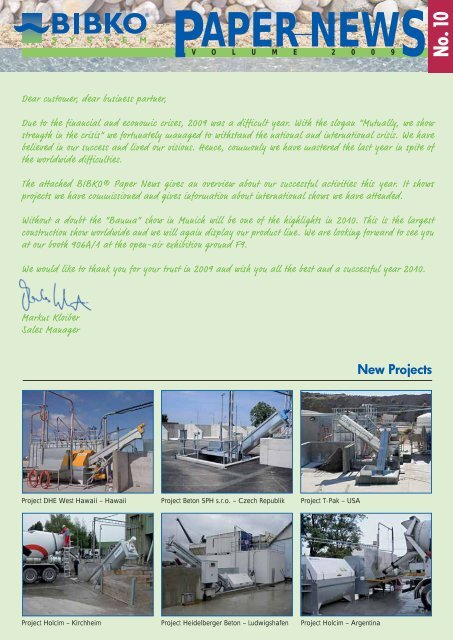

Project DHE West Hawaii – Hawaii Project Beton SPH s.r.o. – Czech Republik Project T-Pak – USA<br />

Project Holcim – Kirchheim Project Heidelberger Beton – Ludwigshafen Project Holcim – Argentina<br />

New Projects<br />

No. 10

Shows Shows 2010<br />

SibStroyExpo 2009 – Novosibirsk (Russia)<br />

SibStroyExpo – the largest exhibition in Siberia<br />

Beginning on the 29th of September construction<br />

equipment and extraordinary technology from international<br />

manufacturers was displayed until the 2nd of<br />

October in Novosibirsk (Russia).<br />

Goal of the show was to exchange information among<br />

experts and to intensify contacts to our customers and<br />

business partners.<br />

As the attendance<br />

of the show was<br />

very good a lot of<br />

potential customers<br />

have been informed<br />

about the subject<br />

“Recycling of<br />

leftover readymix<br />

and washwater with<br />

the <strong>BIBKO</strong> ® equipment”. With its expertise and competence<br />

the <strong>BIBKO</strong> ® staff has given valuable information.<br />

The result of the show indicates that <strong>BIBKO</strong> ® is one of the<br />

most successful manufacturers of recycling systems in<br />

this business area.<br />

<strong>BIBKO</strong> ® GmbH develops recyclingand<br />

handling concept for precast plant<br />

VALCKE PREFAB BETON in Vlamertinge, Belgium<br />

invests in new recycling- and handling system for<br />

leftover concrete.<br />

Since 1960 VALCKE manufactures different precast<br />

elements. Besides pre-stressed beams, wall elements<br />

of various shapes, colours and designs are part of the<br />

product line.<br />

The entire production facility of the company is<br />

spread out on an area of 25 ha. As a result washwater<br />

as well as leftover concrete is generated at different<br />

locations throughout the plant. Currently both<br />

washwater and leftover concrete is led and collected<br />

locally in settling pits. An in-house excavator empties<br />

these settling pits on a regular basis and loads the<br />

material on a truck. At a designated area the material<br />

is discharged. Due to the cementitious fines the material<br />

is hardening.<br />

Concrete Show 2009 (Brazil)<br />

„Concrete Show 2009“ in Brazil took place from 26th<br />

of August until 28th of August 2009 in Sao Paulo. This<br />

show is considered the most important show of the concrete<br />

and construction industry in South America. Machinery<br />

as well as tools, plant and technical equipment<br />

was displayed there.<br />

In 2009 the “Concrete show” had 17.145 attendees.<br />

Compared to 2008 this is a plus of 23,5%. Hence, the<br />

show was a great success<br />

for <strong>BIBKO</strong> ® .<br />

In conjunction with our<br />

Brazilian representatives,<br />

<strong>BIBKO</strong> ® displayed<br />

the proven <strong>BIBKO</strong> ® systems<br />

to recycle leftover readymix and washwater in the<br />

readymix and precast industry.<br />

World of Concrete (Las Vegas)<br />

2010-02-02 – 2010-02-05<br />

Bauma 2010 (Munich)<br />

2010-04-19 – 2010-04-25<br />

Concreto Latinoamérica (Mexico)<br />

2010-08-18 – 2010-08-20<br />

Engineering Projects<br />

After a certain time a crusher is needed to break the<br />

material and transport it off side. Washwater is<br />

collected in a settling pond. As the fines settle to<br />

the groud the volume of the pond decreases continuously.<br />

Since this solution involves extensive costs to hold<br />

and maintain the storage area transport the crushed<br />

material as well as the operational costs of the crusher<br />

<strong>BIBKO</strong> ® has been contacted to work out a new<br />

recycling concept for the plant.<br />

Recycling concept<br />

Due to the large distances between the different locations<br />

where washwater and leftover concrete is generated,<br />

in conjunction with the customer it was agreed<br />

to keep the internal transport system as it is. However,<br />

goal of the <strong>BIBKO</strong> ® -recycling concept was that the<br />

large storage area as well as the function of the settling<br />

pond is no longer needed. Another goal of the<br />

concept was to simplify the handling of the residual<br />

material.

Recycling solution<br />

Especially to address the request for easier handling<br />

of the residual material, it was agreed to install the<br />

<strong>BIBKO</strong> ® -recycling system in the ground. This allows<br />

the truck to easy access the discharge point of the<br />

material. By lifting its loading platform the material<br />

slides straight into the recycling system.<br />

The recycling process takes place in 4<br />

stages<br />

Stage 1 – Material charge<br />

The material charge takes place from top through a driveover<br />

grid. The material is collected in a 10 m long<br />

buffer with a buffer volume of 10 m³. The length of 10 m<br />

has been chosen, to give sufficient buffer volume.<br />

Within the dosing buffer the material is moved to the side<br />

where the recycling system type ComTec is located.<br />

A bucket row takes the material and dicharges it onto a<br />

screw conveyor. This conveyor moves the material continuously<br />

into the recycling system.<br />

Stage 2 – Recycling system type ComTec<br />

Within the recycling system the fines < 0,2 mm<br />

(cement, fine sand) are washed out. Together with the<br />

residual water they are collected in the pump sump<br />

attached to the recycling system. From there the water-fine-mixture<br />

is pumped to an agitator tank.<br />

Material with a size > 0,2 mm is taken by a bucket<br />

row and discharged onto a screw conveyor. The conveyor<br />

moves the material into a material box.<br />

Stage 3 – Agitatior tank<br />

In the above ground agitator tank made of steel the<br />

water-fine-mixture of the recycling system is buffered.<br />

An agitator prevents the fines from settling to the<br />

ground.<br />

Layout<br />

Engineering Projects<br />

Stage 4 – Water treatment<br />

Goal of the process is to get cleared water. Hence,<br />

the water buffered in the agitator tank is fed into a<br />

chamber filter press. The removed fines are compacted<br />

to a filter cake and disposed. The cleared water<br />

is collected in the former settling pond. Unlike before<br />

the pond only holds the water but is no longer used<br />

as a settling pond.<br />

Conclusion<br />

With the decision to go for a <strong>BIBKO</strong> ® -recycling concept<br />

VALCKE PREFAB has made a trend-setting decision.<br />

In the future residual material will be recycled<br />

and could be reused in the batch process. Costs to<br />

crush hardened material as well as the costs to transport<br />

the material off site do no longer occur. In addition<br />

there is the possibility to reuse the cleared water<br />

which is buffered in the pond in the batch process,<br />

too.<br />

Therefore, the reuse of the reclaimed material saves<br />

money and makes the purchase of a <strong>BIBKO</strong> ® recyc -<br />

ling system a profitable investment.<br />

Ecological benefit<br />

Besides the economical savings there are other<br />

aspects involved in the concept of reusing the reclaimed<br />

material.<br />

■ Due to the material loop when using a <strong>BIBKO</strong> ® -<br />

recycling system natural ressources are preserved<br />

■ CO2-Emissions from mining minerals do not occur<br />

at all.<br />

Besides the economic benefit the use of a <strong>BIBKO</strong> ® -<br />

recycling system is an active contribution to protect<br />

the environment and to preserve natural ressouces.

<strong>BIBKO</strong> 11/2009<br />

Press News<br />

82<br />

Bibko Umwelttechnik & Beratung GmbH, 71717 Beilstein, Germany<br />

Residual concrete recycling system<br />

for Warbud Beton Sp. z o.o.<br />

CONCRETE TECHNOLOGY<br />

The fourth ComTec residual concrete recycling system has been installed together with a dosing buffer at the Polish company Warbud Beton<br />

Sp. z o.o., a long-standing and satisfied customer of the German company Bibko Umwelttechnik & Beratung GmbH from Beilstein.<br />

A powerful dosing buffer has been placed<br />

upstream of the ComTec 30 wash-out<br />

machine. This has the advantage that the<br />

vehicles can empty the residual concrete<br />

intermittently. The dosing buffer consists of<br />

a 5 m long trough that can accept approx.<br />

6 m3 of residual concrete in a short space<br />

of time. As a result, there are no waiting<br />

times like those that occur in systems without<br />

a dosing buffer. The 6 m wide charging<br />

hopper of the dosing buffer offers enough<br />

space to be able to wash out 3 vehicles at<br />

the same time and to discharge the residual<br />

concrete.<br />

The residual concrete and the washing<br />

water are initially all buffered intermediately<br />

in the dosing buffer. The residual con -<br />

crete is transported in the direction of the<br />

built-in bucket conveyor via a cylindrical<br />

screw conveyor in a semi-circular trough.<br />

Bibko recycling plant with dosing buffer during the washing process<br />

CPI – Concrete Plant International – 4 | 2009 www.cpi-worldwide.com<br />

At home:<br />

Closed buckets lift the material up and de -<br />

posit it in the washout machine.<br />

Water and residual concrete are discharged<br />

into the washout machine in a defined<br />

manner via the bucket conveyor. The wash -<br />

ing quality, the separation cut and, hence,<br />

the density in the residual water tank are<br />

thus independent of the emptying speed of<br />

the plant user.<br />

An above-ground steel tank equipped with<br />

three agitators was selected for the accumulating<br />

residual water. The residual water<br />

from the Bibko recycling machine is transported<br />

to the residual water tank via a<br />

pump sump. The built-in agitators keep the<br />

fines < 0.2 mm in the residual water in suspension.<br />

Settling of the fines is thus pre -<br />

vented. The residual water is used in the<br />

mixing process and for washing out the<br />

vehicles.<br />

FURTHER INFORMATION<br />

Bibko Umwelttechnik & Beratung GmbH<br />

Steinbeisstraße 1-2<br />

71717 Beilstein, Germany<br />

T +49 7062 92640<br />

F +49 7062 926440<br />

info@bibko.com<br />

www.bibko.com<br />

Warbud SA<br />

Al. Jerozolimskie 162A<br />

02-342 Warschau,Poland<br />

T +48 22 5676000, F +48 22 5676001<br />

warbud@warbud.pl<br />

www.warbud.pl<br />

� Transportbeton Dachser GmbH & Co. KG –<br />

Türkheim<br />

� TBG Lieferbeton Karlsruhe GmbH & Co. KG<br />

� Siegl GmbH – Wörth a. d. Isar<br />

� TBG Reichenbach GmbH & Co. KG<br />

� TSN-Beton Wolfenbüttel Betriebs-GmbH –<br />

Schöppenstedt and Seesen<br />

� Klösters – Beton GmbH & Co. KG – Kempen<br />

� Kraichgau Beton GmbH & Co. KG – Bretten<br />

IMPRESSUM<br />

Publishing Company: <strong>BIBKO</strong> ® Umwelttechnik & Beratung GmbH<br />

Steinbeisstr. 1+2 · 71717 Beilstein · Germany<br />

Tel.: +49(0)70 62 / 92 64-0 · Fax: +49(0)70 62 / 92 64-40<br />

E-Mail: info@bibko.com · Internet: www.bibko.com<br />

Editor:<br />

Esther Elek, Frank Häussermann, Markus Kloiber<br />

Logos and pictures: <strong>BIBKO</strong> ® GmbH<br />

Frequency of publication: annually · Circulation: 2.500<br />

Grafic Design: Typographie-Studio Kircher, Beilstein<br />

Print: Lithographix, Ulm<br />

74<br />

Bibko Umwelttechnik & Beratung GmbH, 71717 Beilstein, Germany<br />

Bibko is one of the leading suppliers in this<br />

field with more than 1,250 recycling<br />

systems in use worldwide. The Bibko system<br />

offers a recycling capacity of 20 m3 /h and<br />

is fully equipped with a corresponding recycling<br />

water treatment facility. As in the case<br />

of stationary plants, solids of > 0.2 mm are<br />

washed out accordingly. The water containing<br />

fine particles < 0.2 mm is fed to a parallel<br />

recycling water reservoir. The fine particles<br />

are kept in suspension here by means<br />

of cyclic stirring. The fine particles and the<br />

residual water are fed back to the mixing<br />

process.<br />

The main feature of the mobile version is<br />

that the entire plant with the corresponding<br />

steel bath is installed on a frame construc -<br />

tion. Elaborate on-site building measures for<br />

reservoirs and installations provided by the<br />

factory are hence dispensed with. The plant<br />

was manufactured ready for connection in<br />

the Bibko factory and all parts of the plant<br />

were hot-dip galvanised. Only the electrical<br />

and water connections needed to be made<br />

on site.<br />

The plant was delivered with an appro -<br />

priate winter package in order to cope with<br />

the enormous temperature fluctuations in<br />

Russia. The plant’s features include the following<br />

technical details (fig. 1):<br />

1 Lateral cladding of the bath with<br />

sandwich panels<br />

2 Heating unit on the screw conveyor<br />

plus additional insulation and heating<br />

3 Two lateral heating units<br />

4 Cover for the hopper aperture (in the<br />

machine)<br />

5 Cladding and insulation of the pump<br />

sump<br />

6 Lateral cladding of the trough made of<br />

galvanised steel panels, insulated with<br />

sandwich panels<br />

CONCRETE TECHNOLOGY<br />

Mobile residual concrete recycling plant with winter<br />

equipment for Russian concrete factory<br />

Cooperation between the Heidelberg Cement Group and Bibko Umwelttechnik & Beratung GmbH has led to a successful result. Among<br />

others, a mobile recycling plant with a winter package has recently been delivered to a concrete factory in North-West Russia. The<br />

company group Industry PetroBeton (Heidelberg Cement Group) in St. Petersburg, Russia, uses a recycling plant made by Bibko from<br />

Beilstein in Germany for residual quantities of concrete and the water that remains after washing out the ready-mix concrete trucks.<br />

FURTHER INFORMATION<br />

INDUSTRY<br />

PETROBETON<br />

HEIDELBERGCEMENTGroup<br />

OOO Industry Petrobeton<br />

St. Krupskoj 40<br />

192148 St. Petersburg, Russia<br />

T +7 812 3465807<br />

F +7 812 3465809<br />

office@petrobeton.ru<br />

www.petrobeton.ru<br />

Bibko Umwelttechnik & Beratung GmbH<br />

Heidelberg Cement Group<br />

Steinbeisstraße 1-2<br />

71717 Beilstein, Germany<br />

T +49 7062 92640<br />

Fig. 1: The residual concrete recycling plant with winter equipment Fig. 2: Thanks to its mobility, the plant can be installed at a different<br />

site at any time.<br />

CPI – Concrete Plant International – 1 | 2009 www.cpi-worldwide.com<br />

Abroad:<br />

New Customers<br />

� Beton Frais – France<br />

� Beton SPH s.r.o. – Czech Republik<br />

� Hormigones del Odon – Spain<br />

� Holcim – Venezuela<br />

� Ibera, SA – Portugal<br />

� Kamenolon Gorjak d.o.o. – Kroatia<br />

� Carpat Beton – Romania<br />

� Lujabetoni Oy – Finland<br />

� Severnay Kompania OOO CK – Russia<br />

� Transco-Kelowna – USA