William Hickey - Metal Center News

William Hickey - Metal Center News

William Hickey - Metal Center News

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

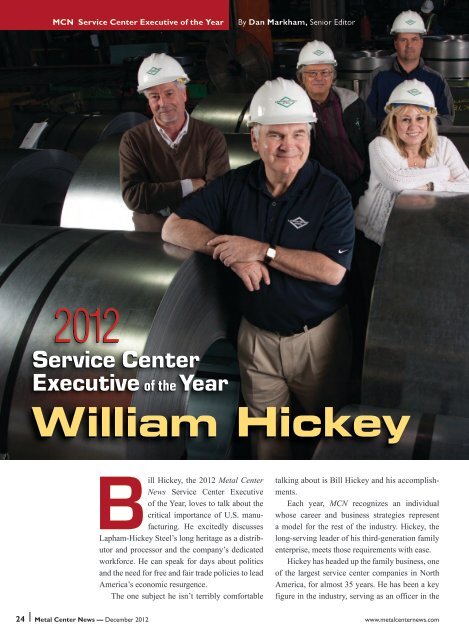

MCN Service <strong>Center</strong> Executive of the YearBig Success, Small EgoBill <strong>Hickey</strong>,president ofLapham-<strong>Hickey</strong>Steel in Chicago,personifies leadership,both of histhird-generationfamily business andthe service centerindustry at large.Exec of the Year Bill <strong>Hickey</strong> gives much credit forhis company’s success to key managers, including (flanking<strong>Hickey</strong> from front to back) Jeff Hobson, vice president ofoperations and systems, Michele Summey, purchasing manager,Bob Piland, chief financial officer, and Dave Conrad,sales manager. (Photo by Marc Berlow)products for Edgar T. Ward’s service center company. Eachwas looking for something more. They found it through theFitzsimmons Bar Co., which was looking to sell its colddrawnbar depot in Chicago. The partners intended to openthe new service center business on Jan. 1, 1926, but foundthemselves short of funds. With the help of another minoritypartner, George Clifford, they opened Lapham-<strong>Hickey</strong> Steela month later.The company grew slowly through the early years. Bythe end of the Korean War, the Lapham Brothers had reachedretirement age and wanted out of the business. They soldtheir shares to the <strong>Hickey</strong> family, where son <strong>William</strong> hadjoined his father. The Clifford family maintained a sharethrough the 1970s, then sold its portion of the business. Buteven when the company fell under the sole ownership ofAt-a-GlanceLapham-<strong>Hickey</strong> Steel Corp.5500 W. 73rd St.Chicago, IL 60638Phone: 708-496-6111Fax: 708-496-8504Web site: www.lapham-hickey.comMMFounded: 1926MMLocations: Six in Chicago and Madison, Ill.,Oshkosh, Wis., Little Canada, Minn., Columbus, Ohio,Pawcatuck, Conn., and Fairfield, Ala.MMEmployees: 500+<strong>Metal</strong>s Service <strong>Center</strong> Institute and other trade groups. Andhe has become an increasingly important voice in the policyarena, leading the industry’s appeal for a comprehensivedomestic manufacturing agenda and stronger enforcementof trade laws (see sidebar). But <strong>Hickey</strong>, in keeping with hismodest tradition, sees his role as more of a cog in the machinethan a driving force.Lapham-<strong>Hickey</strong> Steel was founded 86 years ago by hisgrandfather, Frank <strong>Hickey</strong>, and the Lapham brothers, Edwardand Burnham. His grandfather had been an executivewith Wisconsin Steel, while the Laphams were selling barMMProducts: Cold-Finish Bar, Hot-Roll Bars,Hot-Roll Structurals, Hot-Roll Plate/Sheet, G&P/ TG&P,Alloys, Coil/Sheet, Spring Steel, Mechanical Tubing, Aluminum/StainlessSteel, Steel Reference DataMMServices: Sawing, Stretch Leveling, Coil Processing,Slitting, Shearing, Edge Conditioning, Cut-to-Length, Oscillating, Laser Cutting, Plasma/Punch Plasma,Oxy Burning, Forming, Shot Blasting, Stress Relieving,Blanchard Grinding, Heat Treating, Weldingwww.metalcenternews.com <strong>Metal</strong> <strong>Center</strong> <strong>News</strong> — December 2012 ❘ 25

MCN Service <strong>Center</strong> Executive of the Yearthe <strong>Hickey</strong> family, the operation never stopped giving theLaphams top billing on the marquee.“It was my father’s idea because that was the brandname. That’s what we’d worked so long for, and that’s whatwe were recognizable for,” Bill <strong>Hickey</strong> says. “All of us, asindividuals, are replaceable.”That ego-free approach remains a guiding principle for<strong>Hickey</strong>, who says his company’s success is the byproductof all its family members, not just the ones who share hislast name. “This award is a reflection of the great group ofpeople we have,” he says of becoming the 16th recipient ofMCN’s Executive of the Year honor. “The people here makethis place work. It certainly isn’t me.”His colleagues would vigorously dispute that assertion.“I can’t say enough about him; otherwise I wouldn’t havebeen here for 40 years,” says Jeff Hobson, the company’svice president of operations and systems. “He sets a directionthat we try to follow, but he’s always open to suggestions,ideas and thoughts. He allows us to do what wehave to do.”Bob Piland, the chief financial officer, has been withLapham-<strong>Hickey</strong> for 18 years, which makes him a “shorttimer”in an operation where the long-standing employeeis the norm. The 69-year-old steel industry veteran says heshould have retired several years ago, “but I just enjoy workingwith Bill. He’s very focused and very dedicated.”Though <strong>Hickey</strong> himself recently reached age 60, he remainsas committed to the job as ever, establishing a workethic that permeates throughout the organization. His sonBrian, one of three children who have joined the familybusiness, jokes that his father’s favorite hobby is Lapham-<strong>Hickey</strong> Steel. “I kid about it, but on weekends he will comeTireless ChampionBill <strong>Hickey</strong> discusses politics in his Chicago office, withLapham-<strong>Hickey</strong>’s original handwritten ledger from the1920s in the foreground. <strong>Hickey</strong> is a vocal advocate forgovernment policies that better support U.S. manufacturers.“There are only three ways of creating wealth—youmine, you manufacture or you grow,” <strong>Hickey</strong> says. “How weas a society don’t understand that manufacturing is a wayof creating wealth is beyond my comprehension.”For many Americans, the first Tuesday inNovember represented the welcome end to thepolitical campaigning that dominated much of thecalendar year. But for Bill <strong>Hickey</strong>, the cause doesn’t endwith the vote.For more than a decade, <strong>Hickey</strong> has been one of themetals distribution industry’s most prominent and effectivevoices, championing the need for free and fair trade,less cumbersome government regulation and a comprehensiveU.S. manufacturing policy. When he wasn’tdirecting his own business, <strong>Hickey</strong> spent much of his freetime this year speaking out on manufacturing’s behalf,primarily through the <strong>Metal</strong>s Service <strong>Center</strong> Institute,Rolling Meadows, Ill. He was a regular speaker duringmany of MSCI’s Manufacturing Summits leading up to the2012 election.The topic of manufacturing is an issue that interestshim like few others. One of his primary activities awayfrom the office is reading about the domestic and globaleconomy. “There are only three ways of creating wealth– you mine, you manufacture or you grow,” <strong>Hickey</strong> says.“How we as a society don’t understand that manufacturingis a way of creating wealth is beyond my comprehension.”He has made it his mission to rectify that misunderstanding.But just as he does in business, he goes about thatduty thoughtfully, intelligently and respectfully.“He is the voice of reason, conviction and order,” says28 ❘ <strong>Metal</strong> <strong>Center</strong> <strong>News</strong> — December 2012 www.metalcenternews.com

MCN Service <strong>Center</strong> Executive of the YearWith its sophisticated slittingequipment, includingthis line at its Chicagoheadquarters, Lapham- facility in St. Louis and a third<strong>Hickey</strong> can offer one ofin Neenah, Wis. Since then,the widest gauge rangesLapham-<strong>Hickey</strong> has grown toin the industry, from0.001 to 0.312 inch, with seven locations with over 500superior edge registry and employees and more than $300tight slit width tolerances. million in annual revenue.(Photo courtesy Lapham- While substantial, the growth<strong>Hickey</strong> Steel)was not done simply to get larger.Each new facility, none ofwhich is identical in products and services, was the result ofa careful examination of each market and what it offered tothe company and its customers.A prime example is the Wisconsin operation, which hadrelocated from its original facility in Neenah to nearby Oshkosh.The Oshkosh facility is a dramatically different operationthan Chicago’s, which specializes in a number of differentcoil processing functions. The Wisconsin branch focuseson long products and its more recently opened fabricationoperation. The fab shop was launched when one of the facility’slarger customers informed Lapham-<strong>Hickey</strong> that it was nolonger going to buy steel, but fabricated parts. So, Lapham-<strong>Hickey</strong> did what was necessary to keep the valued customer.“We see more and more customers who want to buycomponents that are part of an assembly. They don’t wantto invest money in capital equipment they’re going to runmaybe one shift a day,” he says. “So we put in a laser, we putin a press brake.”The transformation from traditional service center to firststepmanufacturer wasn’t embraced by all, as some customerswere concerned their supplier was now competing withthem. “I just said I was following my customer,” he explains.That customer-driven mindset and adaptability havebeen hallmarks of Lapham-<strong>Hickey</strong> Steel and key contributorsto the company’s success. They are evident in examplesboth large and small.At the Chicago facility, the company specializes in slitting,with a broad range of widths. That includes small slitterscapable of shaving strips into pieces no wider than afingernail. This type of processing is not in high demand,nor high supply, resulting in highly specialized orders fromall over the country. But such capabilities also create theirown issues.Standard packaging options aren’t appropriate for someof these products, many of which are shipped through UPS.Lapham-<strong>Hickey</strong>’s solution: devote a small section of the facilityto an internal lumber yard, manned by a carpenter whospends each day making customized skids and boxes for theuncommon orders, while the company purchases the standardsizes elsewhere.Likewise, Lapham-<strong>Hickey</strong> uses a mix of companyownedvehicles and common carriers to handle the largerorders. The fleet includes several closed vans for customers32 ❘ <strong>Metal</strong> <strong>Center</strong> <strong>News</strong> — December 2012 www.metalcenternews.com

MCN Service <strong>Center</strong> Executive of the Yearyears to ensure that multiple lines aren’t down atthe same time.Such a slow process is OK with <strong>Hickey</strong>, for anumber of reasons. For starters, as a family-ownedbusiness, the company feels less pressure for immediatereturns on any investment. “I think it’s acompetitive advantage. There’s not some farawayoffice making the decisions. I want to make surethat 10 years from now we have the right set ofpeople, the right set of facilities, the right set ofassets and the right set of capabilities in place forour markets,” he says.MCN photo by Tim TriplettLapham-<strong>Hickey</strong> Steel was one of the first to invest in a stretch leveling linemade by Leveltek International, Benwood, W.Va., and Butech Bliss, Salem,Ohio, putting the company in good position to capitalize on the surgingdemand for memory-free, stay-flat steel. Above right, a technician checks astretched sheet for flatness. (Photo courtesy Lapham-<strong>Hickey</strong> Steel)who want their orders protected from the elements. Companytrucks also make daily runs to the branches in Minnesotaand Wisconsin, allowing all of them to share and effectivelyexpand their inventories. “It’s a game of chess,” <strong>Hickey</strong> saysof the mixing and matching of the different capabilities andproducts at each of the company’s operations. “But you’rerunning a portfolio of assets.”The company is constantly in search of ways to improvethe performance and reduce the costs associated with thoseassets. The 225,000-square-foot Chicago facility, the oldestin the system, is in the early stages of a major overhaul,where cranes will be replaced, the layout changed andbays renovated. The process will take place over severalFurthermore, it suits one of his chief managerialqualities: patience. In a business environmentwhere every decision needs to be made 15 minutesago, or so it seems, <strong>Hickey</strong> has no problempulling back on the reins and saying, “Wait.”“The cycle of business decisions has beencompressed substantially in the last 10 to 15 years,which I think is a detriment. A lot of decisions areforced, because there’s a perception you have toreply now. I think some great decisions are made because youthink about them for a day,” he says.“He’s always been deliberate in his decisions. Our philosophyhas always been that just because somebody else isdoing something doesn’t mean we have to jump on the bandwagon.We methodically look at the pros and cons,” saysHobson, who along with Piland and Executive Vice PresidentSteve Ford, serves with <strong>Hickey</strong> on Lapham-<strong>Hickey</strong>’sexecutive committee.The bigger the decision, the more voices <strong>Hickey</strong> will seekout. The company’s growth initiatives— whether opening anew location or adding a major piece of equipment such asthe one-of-a-kind combination Butech Bliss/Leveltek stretch36 ❘ <strong>Metal</strong> <strong>Center</strong> <strong>News</strong> — December 2012 www.metalcenternews.com

MCN Service <strong>Center</strong> Executive of the Yearleveler the company installed in Chicago—tend to be collaborativedecisions. “It’s a conversation between our managementgroup, the salespeople, the operations people, thepurchasing people,” <strong>Hickey</strong> says. “When you do a majorchange, you have to have more people giving you input.”While larger service center organizations have madeinquiries about buying the company, Lapham-<strong>Hickey</strong> hasopted to remain independent and family run. As an acquireritself, <strong>Hickey</strong> concedes there aren’t a lot of service centersthat are appropriate acquisition targets. Fortunately, buyingmarket share is not a necessity.“We’re growing our business. We’ll continueto grow in 2013 with existing capacityand existing facilities. There’s nobody puttinga gun to our heads saying we have to be twiceas big. We’re big enough now to participatein the marketplace, to get competitive pricingfrom producer industries. All we need to be is big enough fora competitive price,” he says.Perhaps the biggest challenge to any acquisition is findinga target, not with the right products or markets, but withthe right people. “The biggest problem in any industry ishaving good people to run your business,” <strong>Hickey</strong> says. “Ilook at some of the largest service center chains and wonderhow they found 50 good managers. This is a very difficultbusiness to manage properly because we’ve had so muchtransition in the last 10-12 years.”Yet Lapham-<strong>Hickey</strong> has been able to manage throughthe chaos. It’s done so by blending the traditional values establishedupon the company’s founding with an embrace ofnewer ideas and managerial techniques.<strong>Hickey</strong> recognizes the value in managing inventorylevels, but not at the expense of having material to sell. Heunderstands that the ups and downs of pricing are a fundamentalreality of the service center business, but doesn’t ruleout using some of the latest hedging mechanisms with customerswho are determined to get a more concrete price fora longer period.Perhaps nothing better exemplifiesthe Lapham-<strong>Hickey</strong>approach to the business thanthe company’s inventory managementsystem. The legacysystem has been continuallyupdated over the years. Whileshort on appearance—itsgreen screen format reveals itsage—it is long on functionality,with mountains of usefuldata at each user’s fingertips.Employing bar codes, the systemtracks each piece of metalevery step of the way from orderentry to loading the truck.The company has consideredupgrading to newer technology,but has yet to find softwarethat offers much better functionalitythan its homegrown system.One area of leadership that <strong>Hickey</strong>emphasizes is his relationships withothers, both inside the building and out.It starts with treating people with respect.“That’s the duty and responsibilityof a manager, to make sure everyoneunderstands how their individual participation contributes ahuge part to the success of the organization,” he says.The company’s extended family includes the relativesand friends of current employees who make personal recommendations,which <strong>Hickey</strong> considers a source of pride.“It might make things more difficult when there’s a problem,but by and large these people are committed. It’s tellingwhen an employee says he’d like to have his family memberwork here. It says they believe this is a fine organization, anorganization with a future.”Bill <strong>Hickey</strong> demonstrateshis company’s homegrowncomputer system, which hesays provides managementand sales with up-to-theminuteinformation comparableto the latest off-theshelfsoftware products.(Photo by Marc Berlow)40 ❘ <strong>Metal</strong> <strong>Center</strong> <strong>News</strong> — December 2012 www.metalcenternews.com

MCN Service <strong>Center</strong> Executive of the Year<strong>Hickey</strong> is equally committed tobuilding trusting, reciprocal relationshipswith folks up and down the supplychain. He is invested in the success ofhis mill suppliers and his endusercustomers, and actsaccordingly. “Everyproduct that comesout of here has myname on it. My customersare going toget a quality productto make sure they keepcompetitive in their businesses.”His suppliers and customers havenothing but praise for the way Lapham-<strong>Hickey</strong> operates. “His organizationconducts its business with the utmostprofessionalism, which is a reflection ofBill,” says Jim Sarwark, executive vicepresident with Nelsen Steel & Wire,Franklin Park, Ill. “They’re people you want to do businesswith because they have integrity.”“He’s a fair, balanced, honest businessman,” says TimAs the 16th recipient of MCN’s Service <strong>Center</strong> Executive of theYear Award, Bill <strong>Hickey</strong> joins an illustrious group of past honorees:NNMichael Siegal,Olympic Steel, BedfordHeights, OhioNNDavid Hannah,Reliance Steel & Aluminum Co.,Los AngelesNNNorm Gottschalk Jr.,Marmon/Keystone Corp., Butler, Pa.NNAl Glick, Alro Steel Corp.,Jackson, Mich.NNSandy Nelson, Earle M.Jorgensen Co., Lynwood, Calif.Elite CompanyNNArnold Tenenbaum,Chatham Steel Corp., Savannah, Ga.NNBud Siegel, Russel <strong>Metal</strong>s Inc.,Mississauga, Ont.Lapham-<strong>Hickey</strong> Steel is not only a major general line distributor of steel products, itis also a major steel processor and fabricator, with seven locations in the eastern halfof the U.S. Its value-added processing services range from leveling and slitting to lasercutting and welding. (Photo courtesy Lapham-<strong>Hickey</strong> Steel)NNDave Lerman, Steel WarehouseCo., South Bend, Ind.NNBill Jones, O’Neal Steel,Birmingham, Ala.NNDon McNeeley, Chicago Tube& Iron Company, Romeoville, Ill.NNWayne Bassett, Samuel,Son & Co. Ltd., Mississauga, Ont.Hill, sales and marketing manager for Nucor Crawfordsville.The same sentiment is shared by his customers. “Anybodycan sell on price. He delivers on quality,” says RebBanas, president of Chicago’sNNGary Stein, Triple S Steel, HoustonNNMike Petersen, PetersenAluminum Co., Elk Grove Village, Ill.NNRichard Robinson, NorfolkIron & <strong>Metal</strong>, Norfolk, Neb.N N Michael Hoffman,Macsteel Service <strong>Center</strong>s USA,Newport Beach, Calif.Stanley Spring Stamping. “He’s agreat guy with a great family anda great company.”Eventually, the time will cometo turn that great company overto the next leader. <strong>Hickey</strong> hasno formal succession plan at themoment, though he knows fromhistory that sometimes these decisionsare out of one’s control.“We have people in seniorleadership who are in their mid tolate ’50s. If something happenedto me tomorrow, I’m sure one ofthem would step up and take onmore responsibilities. If I retire8-10 years from now, it may besomeone who’s now in their 30s.I think we have enough qualitypeople we’ll continue the organizationalexcellence we’ve hadfor a long time.”n42 ❘ <strong>Metal</strong> <strong>Center</strong> <strong>News</strong> — December 2012 www.metalcenternews.com