THE LOUISIANA CIVIL ENGINEER - lasce

THE LOUISIANA CIVIL ENGINEER - lasce

THE LOUISIANA CIVIL ENGINEER - lasce

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>THE</strong> <strong>LOUISIANA</strong><strong>CIVIL</strong> <strong>ENGINEER</strong>ACADIANA BRANCH • BATON ROUGE BRANCHNEW ORLEANS BRANCH • SHREVEPORT BRANCHJournal of The Louisiana SectionOn line at http://www.<strong>lasce</strong>.orgVolume 16 • Number 4 August 2008FEATURE:Implementation of LRFD driven pile designNEWS:Context sensitive outreachCareer BenchmarksANNOUNCEMENTS:Louisiana Civil Engineering ConferenceSeptember 24-25, 2008Section Annual Meeting in ShreveportSeptember 19, 2008

SERVICES AND SUPPLIERS2 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008

<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong>CONTENTSPresident’s Message. ................................. 4Implementation of LRFD driven pile design .............. 5Branch News and Leadership Forum .................... 8New Orleans SEI Chapter report. ...................... 10Student Chapter News ............................... 11Section News and Information ........................ 13Conference and meeting in Section. .................... 14Context sensitive outreach. ........................... 15Editor’s Journal .................................... 16Professional Listings ....................... 21-23 (25-27)Services and Suppliers. ........................ 2, 24 (28)PUBLICATIONS COMMITTEE:Ali M. Mustapha, PE, Chair (318) 673-6035Branch Presidents, MembersJames C. Porter, PE, Editor (225) 242-4556PUBLISHER:Baton Rouge Printing, Inc., Port Allen, LAThe Louisiana Civil Engineer quarterly journal is an official publication ofthe Louisiana Section of the American Society of Civil Engineers with anaverage circulation of approximately 1800. The Section neither guaranteesthe accuracy of the information provided nor necessarily concurs with opinionsexpressed. It does not claim the copyrights for the contents in thispublication. Please submit letters and articles for consideration to be publishedby email to jimporter@dotd.la.gov, facsimile to (225) 379-1797 ormail to the Publications Committee c/o James C. Porter, PE • 2608 TerraceAvenue • Baton Rouge, LA 70806-6868.<strong>LOUISIANA</strong> SECTION • AMERICAN SOCIETY OF <strong>CIVIL</strong> <strong>ENGINEER</strong>SLouisiana Engineering Center • 9643 Brookline Avenue • Baton Rouge, Louisiana 70809 • (225) 923-1662SECTION BOARD OF DIRECTORSPresidentE.R. DesOrmeaux, PEE.R. DesOrmeaux, Inc.President-ElectAli M. Mustapha, PECity of ShreveportVice PresidentChristopher P. Knotts, PELouisiana DNRSecretary-TreasurerPatrick J. Landry, PELouisiana DNRPast PresidentTimothy M. Rupperrt, PEU.S. Army Corps of EngineersDirectors-at-LargeChristopher G. Humphreys, PEProfessional Services Industries, Inc.Dax A. Douet, PEC.H. Fenstermaker & Associates, Inc.C. Eric Hudson, PEAlliance, IncorporatedJeffrey L. Duplantis, PECH2M HILLBranch DirectorsJoseph P. Kolwe, Jr., PECivil and Structural Engineers, Inc.Robert W. Jacobsen, PETaylor Engineering, Inc.Ronald L. Schumann, Jr., PEDMJM HARRIS|COMRusty L. Cooper, PEAlliance, Inc.Assigned Branch DirectorsLuke E. Lebas, PELouisiana DNRChristopher L. Sanchez, PEStuart Consulting GroupBRANCH OFFICERSAcadiana BranchPresidentJoseph P. Kolwe, Jr., PECivil and Structural Engineers, Inc.President-ElectClint S. McDowell, PESITE Engineering, Inc.Vice PresidentJoushua P. Stutes, PELouisiana DOTDTreasurerShaun R. Simon, PEEustis Engineering Services, LLCSecretaryLuke Hebert, EIC.H. Fenstermaker & Associates, Inc.Past PresidentM. Jamal Khattak, PEUniversity of Louisiana at LafayetteBaton Rouge BranchPresidentRobert W. Jacobsen, PETaylor Engineering, Inc.President-ElectWilliam H. Wall, PENTB Associates, Inc.Vice PresidentJeffrey L. Duplantis, PECH2M HILLSecretary-TreasurerAdam M. Smith, EIOwen and White, Inc.Past PresidentBrant B. Richard, PEStanley Consultants, Inc.Director - EducationClinton S. Willson, PELouisiana State UniversityDirector - ProgramsRudolph A. Simoneaux, III, EILouisiana DNRDirector - MembershipR.J. (Joey) Coco, PEEngensus, LLCNew Orleans BranchPresidentRonald L. Schumann, Jr., PEDMJM HARRIS|COMPresident-ElectNathan J. Junius, PELinfield, Hunter and Junius, Inc.Vice PresidentBenjamin M. (Ben) Cody, PEEustis Engineering Company, Inc.TreasurerJohann L. Palacios, PEZehner and AssociatesSecretaryMargaret S. (Meg) Adams, PEMSA Technical ServicesDirectorMalay Ghose Hajra, PEProfessional Services Industries, Inc.DirectorReid L. Dennis, PESewerage and Water Board of New OrleansPast PresidentChristopher L. Sanchez, PEStuart Consulting GroupShreveport BranchPresidentRusty L. Cooper, PEAlliance, Inc.President-ElectTodd E. Henry, PEAlliance, Inc.SecretaryEric T. McClannahan, EITetra TechTreasurerJ. Daniel Thompson, EIAillet, Fenner, Jolly and McClellandPast PresidentElba U. Hamilton, EIAillet, Fenner, Jolly and McClellandBRANCH TECHNICAL COMMITTEE CHAIRSBaton RougeStructuresDanny J. Deville, PEMcKee & Deville Consulting Engineers, Inc.GeotechnicalGavin P. Gautreau, PELouisiana Transportation Research CenterEnvironmentalStephen D. Fields, PEWater ResourcesMorris Sade, PEMiraj EnvirotekManagementMichael N. Dooley, PESigma Consulting Group, Inc.PipelineRoy A. Wagenspack, PEOwen and White, Inc.TransportationP. Brian Wolshon, PELSU Baton RougeNew OrleansSEI ChapterM.A. (Mike) Choudhry, PEURS CorporationGeotechnicalWilliam W. Gwyn, PEEustis Engineering Company, Inc.Environmental and Water ResourcesDennis ReedNew Orleans Sewerage and Water BoardSTUDENT CHAPTERSPresidents/Faculty AdvisorsLSUAmanda HamlinClifford J. MugnierLa.Tech James S. EllingburgLuke S. Lee, PEMcNeese Renus KelfkensJanardanan (Jay) O.Uppot, PESouthern Brandon DeJeanYvette P. Weatherton, PEULLDebra HunterEmad H. HabibUNORebecca SchererGianna M. Cothern, PERepresentative to Region 5 Board of GovernorsGovernor, Louisiana SectionNorma Jean Mattei, PEUniversity of New OrleansThe Louisiana Section is located in ASCE Region 5that consists of the Louisiana, Mississippi, Alabama,Georgia and Florida Sections.<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008 3

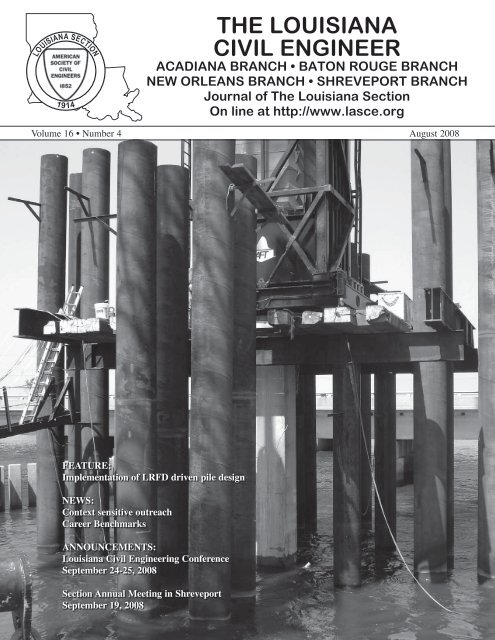

President’s MessageBy E. R. (Ray) DesOrmeaux, PENational electionASCE has made it exceptionally easy formembers to vote in its national election. Amember may elect to vote either by paper, mailinballot, or through the internet with an e-signature.If you are not aware of your personale-signature, you may access the ASCE web sitefor information on how to obtain it. In pastnational elections, there has been a low percentageof members voting. Let’s attempt to changethat in this election by casting our individualvote and encouraging fellow members to do thesame.The Louisiana Section is part of Region 5.This year the Region has two candidates forRegion Director of which one is Norma JeanMattei, PE, the current Region 5 Governor fromthe Louisiana Section, and the other is Jorge A.Jaramillo, PE, the current Region 5 Governorfrom the Florida Section. The LouisianaSection sent a nomination letter on behalf ofNorma Jean on February 23, 2008. Voting endsAugust 13, 2008.PE exam reviewThe ASCE live PE exam review course onthe web is designed to aid civil engineeringinterns in preparing to successfully pass PEexam. Taught by a team of experienced PEexam review instructors, the course will be presentedin a series of 12 two-hour modules heldover a 6-week period. The popular ASCE liveweb seminar format will be used. TheLouisiana Section, with the Acadiana, BatonRouge, and New Orleans Branches is coordinatingplans in each area for presenting this examreview course at a very reasonable cost to participants.All civil engineering interns in theSection who are preparing to sit for the PEexam in the near future are hereby encouragedto contact the sponsoring ASCE Branch in theirrespective area to register.Section members Matthew J.Granberry, PE, Nathan Earl Jordan, PE,Brett A. Misenheimer, PE, Byron D. Racca,PE, John C. Savoie, PE, and Kelly C. Tucker,PE recently earned their professional engineeringlicense in Louisiana. If you are in contactwith any of them, please offer your congratulationson thier accomplishment.Louisiana residents Daniel E. Beyke, PE,Akhilendra S. Chauhan, PE, Lori AnnEngland, PE, John A. Gates, PE, Bruce J.Hix, PE, Robie J. Lasseigne, PE, Charles W.Munce, PE, Jennifer R. Nicaud, PE, BrianD. Nunes, PE, Marcus N. Redford, PE, NinaJ. Reins, PE, Patrick J. Shepherd, PE,– Career Benchmarks –Section Operating GuideWith the assistance of long-time memberand Section journal editor, Jim Porter, theSection’s Operating Guide has been reviewingand revised after a several years of being a staticdocument. The Section’s committee chairsand the Branch Presidents are also reviewingvarious sections of the document, and revisingits contents to reflect current operating practiceswhere appropriate. The revised document willbe distributed to the Section Board of Directorsfor review and comment during its next meetingscheduled in August.Body of knowledgeDuring the Louisiana Civil EngineeringConference and Show sponsored by the NewOrleans Branch and the Louisiana Chapter ofthe American Concrete Institute scheduled tobe in Kenner September 24-25, 2008, there willbe a 2-part session on the body of knowledge(BOK) related to ASCE Policy Statement 465 -Academic Prerequisites for Licensure andProfessional Practice. It will be presented byASCE members Jeffrey S. Russell, PE,Kenneth J. Fridley, PE, and Kenneth L.McManis, PE, that have been substantiallyinvolved with its development and are quiteknowledgeable of the subject. It is importantfor all ASCE members to become familiar withthe initiatives and goals of the BOK. This isthe second opportunity for Section members toattend a session addressing the BOK in thisyear, and all members are encouraged to attendand become familiar with the issues. Russell,who made the previous presentation during the2008 Annual Spring Meeting and Conferencein Lafayette, has been a key leader in thedevelopment of the BOK and ASCE PolicyStatement 465.For many years, ASCE has studied theissues concerning future educational require-Steven R. Skeele, PE, and Dishili S. Young,PE recently earned their professional engineeringlicense in Louisiana. They are civil engineersor in a related discipline and they are notmembers of the ASCE. A copy of this issue ofthe journal is sent to them as an informal introductionto the Section. If any of them wish tojoin and/or find out more about the ASCE,they are hereby invited to visit the ASCEnational website, http://www.asce.org. If youare in contact with any of these engineers,please consider formally introducing them tothe Section by inviting them to attend a branchmembership meeting as your guest.__________________________________________________________________________________Editor’s note: The environmental, structural and architectural engineering disciplines licensed bythe Louisiana Professional Engineering and Land Surveying Board may be considered closelyrelated to civil engineering. As of June 2008, the active engineering licenses conferred by the Boardwere approximately 4871 in civil, 706 in environmental, 105 in structural and 17 in architectural.ments of for civil engineers, including the typesof education and experience required to obtainprofessional licensure and recognition. YourSection President authored an article publishedin the November 1995 issue of this journal thataddresses the issues that future civil engineeringgraduates may face.Leadership ConferenceEach of the ASCE student chapters inLouisiana will be awarded a $700 grant fromthe Section to offset the expenses to send delegatesto the workshop for student chapter leadersand the ASCE Eastern Regional YoungerMember Council meeting to be held in conjunctionwith the Multi-Regional LeadershipConference for Regions 1, 2, 4 and 5 scheduledfor February 6-7, 2009 in Cherry Hill, NewJersey. The Conference that also features aworkshop for section and branch leaders is animportant element for the development of thecurrent and future leaders in the ASCE. It providesopportunities for section, branch, and studentchapter members in the 4 regions to networkand attend outstanding presentations onproven leadership techniques and activities.The Section traditionally sends thePresident Elect to this conference. Each Branchis also encouraged to send delegates. TheASCE notes that the branches that have traditionallysent representatives to these annual conferenceshave experienced excellent results andrenewed member participation in subsequentyears.About the cover: The need for a larger databasefrom a more extensive load testing programfor precast prestressed concrete test pilesis discussed in the feature article. A test pileinstallation and test over the waters of LakePonchartrain are depicted. This load test is fora 36 inch square precast prestressed concretepile. The load test is a Statnamic load test thatis part of the pile load test program for the I-10Twin Span bridge that is being replaced followingthe extensive damage to the existing bridgeduring the coastal surge caused by HurricaneKatrina.4 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008

Implementation of LRFD driven pile designBy Ching-Nien Tsai, PEAbstractThe American Association of StateHighway and Transportation Officials(AASHTO) and the Federal HighwayAdministration (FHWA) have spearheaded achange in the design philosophy from allowablestress design (ASD) to load and resistance factordesign (LRFD) for highway bridge structuresand foundations. The implementation ofthis change greatly impacts the practice of geotechnicalengineering. The AASHTO LRFDBridge Design Specifications referred to hereinas the bridge specifications provides someguidelines to the LRFD method, but offers verylittle direction in procedures to assist in LRFDimplementation. The resistance factors in thebridge specifications for its geotechnical applicationsare very conservative in comparison tothe current ASD practice.Presented herein is the background for —and the effort of — the Louisiana Departmentof Transportation and Development (DOTD) inthe calibration of the resistance factors for itsdriven pile design. In comparison to theAASHTO resistance factors, it will be shownthat the DOTD calibration results in resistancefactors that are much closer to the traditionalASD practice. Also presented are the LRFDcurrent implementation efforts by DOTD alongwith the implications of this implementation.IntroductionCurrent geotechnical practice uses the ASDmethod with its safety factors to account for theuncertainties. Prior service experience is thebasis for safety factor selection without considerationof the inherent variability in the siteconditions, test procedures, and design methods.There are several deficiencies associated withthe ASD method. The primary deficiency isthat it does not uniformly define the reliabilityor risk level of the failure of the foundation system.Because of this, it is possible and it can bedemonstrated that there is a variable risk levelat which a design will fail to perform usingASD and its customarily safety factors.The ASD gives a false impression of thesafety of a design because of the stochastic(random) nature of both the load and the resistance.The randomness may be caused byuncertainty in the measurements, inherent materialdifference, or the assumptions made in adesign method. This uncertainty is especiallysignificant for soils since Mother Nature doesnot necessarily produce a homogeneous soilnaturally. To overcome the deficiency of theconventional safety factors in ASD accountingfor uncertainty, the LRFD method accounts foran acceptable risk level using reliability analysis.The LRFD method does not end with thedesign. Its reliability analysis extends to theconstruction process and life cycle cost analysis.The current AASHTO LRFD incorporates constructionverification testing but it does notinclude life cycle cost analysis.Reliability analysisThe reliability concept for structural designis not new. The concept originated in Russia inthe late 1920s (NCHRP 2004) when it was presentedusing a probability of failure as the criterionfor structural design. This reliability-baseddesign concept was introduced to the UnitedStates in the late 1940’s. The AmericanPetroleum Institute first included LRFD in apractice oriented document (API RP2A-LRFD)in 1989. Five years later, the American Instituteof Steel Construction published its first reliability-baseddesign code in 1994 followed by theAmerican Concrete Institute in 1995. TheAASHTO published its first LRFD bridge specificationsin 1994 with its most recent versionpublished in 2007.Reliability analysis in geotechnical application(Duncan 2000, Harr 1984, Tsai 2000) hasbeen used to compensate for uncertainty — theproblem associated with using the safety factorsin the ASD method. However, implementingthe reliability analysis of the LRFD method intothe routine geotechnical design practice hasencountered serious road blocks. The perceptionof practicing geotechnical engineers thatthere is extra work and data required to estimatethe stochastic properties of the soils is the primaryimpediment to implementation. Otherimpediments contributing to this reluctance toimplement the LRFD method are• a lack of understanding of statistics andprobability• foundations of existing facilities appearto be safe and• inertia or resistance to change.In a discussion about the LRFD between awell known consulting engineer and the author,the viability of the LRFD was questionedbecause it was anticipated that there will beinsignificant savings and possibly higher costsassociated with it. What he fails to understandis that the goal of implementing the LRFDmethod is to provide a technological platform tomanage the risk level for failure in constructedfacilities.Conventional methodsFrequently, practicing design professionalsselect conservative soil parameters for a designin addition to the use of the safety factors toimprove the safety in the design. This gives afalse sense of confidence in the safety of thedesign because of the perception that safety isincreased by applying a higher safety factor. Inaddition, the results may be unnecessary conservatism.Using a reliability-based design, onedesigns for a controlled risk level. This risklevel may be adjusted based on the importanceof the structure or the likely impact on propertyand human life its failure may have. The contri-Figure 1. Probability density function for load.Figure 2. Probability density function for resistance.Ching-Nien Tsai, PE, is currently employed by the Louisiana Department of Transportation and Development in its Pavement and GeotechnicalSection. His duties in addition to regular design projects, include the development of the Geotechnical Design Manual, internal technical training,and special projects. Tsai earned his BS in civil engineering in 1978 from National Chung-Hsing University and his PhD in civil engineering in 1999from LSU. He has 22 years experience in geotechnical engineering practice of which 20 years were in private practice and 2 years employed by theLouisiana DOTD. Tsai is a member of the ASCE and he is a licensed engineer in Louisiana, Texas and Mississippi.<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008 5

Figure 3. Probability of failure.bution to the risk level associated with additionalor arbitrary increases applied to soil parameterscan be estimated and appreciated relative to theneed.ImplementationThe effort of AASHTO in facilitating theimplementation of its LRFD method for bridgeshas forced the geotechnical engineering communityto accept the reliability-based design. Tosimplify the LRFD reliability analysis and makeit more user friendly, the method greatlyimproves the usability of the reliability-baseddesign. The only knowledge of statistics andprobability needed to use the AASHTO LRFDformulation is the ability to estimate two elementarystatistical properties — the mean andthe standard deviation.The AASHTO LRFD method requires thegeotechnical engineer to estimate the uncertaintiesassociated with the individual load componentsand resistance parameters and assign factorsto account for their individual uncertainties.Individual load factors are applied to each loadcomponent applied to the foundation to accountfor its variability while individual resistance factorsare applied to each resistance parameterused in the foundation design method to accountfor its variability in estimating the resistance ofthe foundation. The goal is to optimize thedesign between the superstructure and substructureand thereby achieve a predetermined andconsistent risk level for both.AASHTO specifies the design risk level forfailure to be 1/1000 or, in other words, the probabilityof failure is 0.1 percent for the designload conditions applied to the structure andfoundation and resistance of the same to failure.Note that failure does not necessary imply thecollapse of a structure or foundation system. Itsimply implies a failure of the structure or foundationsystem to perform according to the individualparameters evaluated in the design.a resistance, R — a factored resistance parameter— the load factors (γ i ) and the resistancefactor (ϕ) can be calculated so that the designmeets a specified probability of failure.The probability of failure is selected by acode development professional through extensiveresearch into the experience with constructedfacilities and the current design practice. Theprobability of failure is chosen by the AASHTOis one not to exceed 1/1000 for non-redundantpile foundations. The target failure probabilityfor redundant piles — those in a pile group is 1percent or 1/100. This leads to the estimation ofrational design factors consistent with the probabilityof failure. Alternatively, this process cantarget a quantity called the reliability index relatedto the probability of failure. An LRFD designcode requires the development of the load factorsand resistance factors such that the overlappingarea between the load and resistance probabilitydensity functions is no greater than 1/1,000— the code accepted probability of failure. Theprobability density functions for all load componentsand resistance parameters are demonstratedconceptually in Figures 1 and 2 for load andTable 1. Load distribution properties used forresistance calibration.resistance respectively and they define the variabilityof load and resistance.The probability of failure as shown inFigure 3 is defined as the probability that thedesign load, Q m given thatQ m ≥ Σ η i γ i Q i (1)whereη i = load modifier for ductility, redundancyand importanceγ i = load factorsQ i = load componentexceeds a selected value of material resistance,R m given thatR m = ϕ R n (2)whereϕ = resistance factorR n = nominal strengthor where R – Q is a negative and it representedby the shaded area shown in Figure 3. One candesign for a pre-determined risk level once thevariability of the load components and resistanceparameters are determined. The statistical analysisprocedure to evaluate the reliability level isquite tedious for routine use. The AASHTOLRFD method simplifies this procedure by representingthe statistical properties of the loadcomponents and resistance parameters by usingtwo parameters — load and resistance factors.These pre-calibrated factors can be found in theAASHTO LRFD Bridge Design Specifications(2007). The designer, without needing theknowledge of statistics, can properly perform arisk analysis by simply using the pre-calibratedload and resistance factors.Field testing during constructionThe goal of traditional field quality controland quality assurance in the ASD method is toprovide field verification tests such as the pileload tests to verify that a minimum value isachieved that includes a pre-determined safetyfactor based on the ASD procedures. Therefore,the amount of field verification testing does notLRFD conceptA good discussion of the reliability conceptwas presented by Chang (2006). In summary,the reliability-based design takes into accountthe statistical variability and the probability densityfunctions of all the load components appliedand the resistance parameters. Given a load, Q— the sum of factored load components — andTable 2. AASHTO resistance factors for driven piles.6 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008

Table 3a. (above) AASHTO resistance factors for projects with static load tests.Table 3b. (right) AASHTO resistance factors for projects with dynamicload tests and signal matching analysis.impact the ASD method nor do the results aslong as the outcome meets the minimum criteria.Under the ASD method, the results of the testingmay impact the type or size foundation to meetthe safety factor requirement.LRFD is a design philosophy not a designmethod. The resulting design process is simplythe transformation reflecting the philosophicalchange. As such, the design process is only onepart of the solution. To reasonably ensure thatthe reliability of a structure is as designed, thereliability concept has to extend to field testingin the construction phase. However, variabilityin construction is an integral part of designmethod in the LRFD concept. The field testingprogram has to be designed to reasonably assurethat the variability achieved in the constructionprocess does not exceed the variability assumedfor it in the design method. To accomplish this,the number of verification tests and the interpretationof the results are important to achieve therequired reliability level. The ultimate goal forconstruction testing is to provide feedback to beincorporated into future design process revisionswhere the results of the construction testing mayimpact the selection of the resistance factor usedin the design formulation.AASHTO LRFD calibrationRecognizing that other factors also contributeto the reliability level selection, AASHTOLRFD procedures incorporate a factor η toaccount for importance, ductility, and redundancy.The AASHTO LRFD formulation is as follows:R = ϕ R n ≥Σ η i γ i Q i = Q (3)published resistance factors for these materialsare generally accepted by most state transportationagencies. However, the practice of geotechnicalengineering in state transportation agenciesvaries as do the soils in their regions. Therefore,AASHTO encourages local calibration for theresistance factors for the geotechnical applications.To calibrate the resistance factor,AASHTO used the load distribution propertiesthat are tabulated in Table 1 where the Bias isthe spectrum bias and the ratio of the measuredvalue and the predicted value in the probabilitydensity function and the COV is the coefficientof variation, and the ratio of the standard deviationand the mean of the loads in the probabilitydensity function.Another required parameter for calibrationis the dead load to live load ratio. The greaterthis ratio is, the smaller the resistance factorbecomes. However, once this ratio exceeds 3,the change in the resistance factor is insignificant.This ratio depends on the type of bridgestructure and the span length. Longer bridgespans produce greater dead load to live loadsratios. The published AASHTO resistance factorsare based on the dead load to live load ratioof 3. The AASHTO resistance factors for staticpile calculations are provided in Table 2. Thesefactors are rounded down to the nearest 0.05increment and they are based on some assumedredundancy built into the foundation resulting ina probability of failure used in the calibrationapproximated to be 1 percent. To achieve the.01 percent probability of failure, AASHTOresistance factors require a 20 percent reductionfor non-redundant foundations.Soil properties depend significantly onmany local conditions such as geology, stresshistory, inclusions and secondary structures andcan be highly variable across different geologi-whereR = factored resistanceR n = nominal strength (e.g. ultimate bearingcapacity)Σ Q i = nominal load effectϕ = statistically-based resistance factorη i = load modifier for ductility, redundancyand importanceγ i = statistically-based load factor andQ i = load component andQ = factored load.AASHTO has published the load factors andmodifiers. Since structural materials are typicallymanufactured by nationally recognized standardspecifications in statistically controlled processes,they are more likely to behave with predictablevariability and less likely to vary fromregion to region. Because of this, the AASHTOTable 4. Equivalent safety factor based on AASHTO resistance factors.Table 5. Summary of the pile load test database used for resistance factor calibration.(Continued on Page 19)<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008 7

BATON ROUGEBy Robert W. Jacobsen, PE, PresidentTeaming together with the LouisianaDepartment of Natural Resource and the LSUDepartment of Civil and EnvironmentalEngineering, the Branch, sponsored the firstLouisiana Coastal Engineering Conference. Itwas held May 29-30 in the Hilton CapitolConference Center. Some of the key presentationsincluded:• Coastal processes by David R. Basco, OldDominion University• Fundamentals of wave theory and tides byJim Chen, LSU• Dredging equipment and costs by BobRandall, Texas A&M• Developments of the Louisiana CoastalProtection and Restoration Authority andrelated programs by Garret Graves,Director of the Governor’s Office ofCoastal Affairs• Future of coastal engineering in Louisianaby Chris Knotts, Louisiana DNR CoastalEngineering DivisionThose in attendance were treated to a series ofmany excellent technical presentations describingrestoration projects. The Conference hasreceived rave reviews and the Branch and theBranch News and Leadership Forumnewly reorganized Coastal Protection andRestoration Implementation Team hope to organizemore conferences in the future!The June membership meeting was theBranch’s annual Past Presidents luncheon. Wewere pleased and honored to have 19 of ourBranch Past Presidents in attendance, includingLouis J. Capozolli, PE, the first president of theBranch in 1962. We were all saddened to learnof the recent death of Leo “Bill” Gagnon, PE,who was president of the Branch in 1984-85.Paul B. Fossier, PE, who is also a past presidentof the Branch (1988-89) made the technical presentationand may have set a new precedent forpresentations by past presidents.The 2008 Branch awards recipients foroutstanding civil engineers were announcedduring the June Branch membership meeting.They will also serve as the nominees from theBranch for the corresponding Louisiana Sectionoutstanding civil engineer awards. The officialpresentations of the commemorative plaques forthe Branch awards will be made during themembership meeting scheduled for August 28.The recipients are:C. Carter Brown, PE, Wall of FameGordon P. Boutwell, PE, LifetimeAchievementBilly R. Prochaska, PE, Outstanding CivilEngineerKim M. Garlington, PE, OutstandingGovernment Civil EngineerGeorge Voyiadjis, PE, Educator of the YearJeffrey L. Duplantis, PE, OurtreachAdam M. Smith, PE, Young Civil EngineerRudolph A. Simoneaux, EI, YoungGovernment Civil EngineerTwo Branch membership meetings andluncheons were held May 15th and June 19th.The May meeting was a joint meeting with theBaton Rouge Chapter of the LouisianaEngineering Society. Hats off to their board fororganizing a fantastic joint meeting. It featuredthe technical presentation, “EstablishingAccurate Survey Control Points InexpensivelyUsing the Recently Expanded CORS Network”presented by Roy Dokka, Director of the Centerfor Geoinformatics at LSU. The second meetingfeatured a presentation of the “Status ofLouisiana DOTD Bridge Projects” by Paul B.Fossier, PE, an Assistant State Bridge DesignEngineer, Louisiana DOTD.SHREVEPORTRusty L. Cooper, PE, President — No EntryACADIANABy Joseph P. Kolwe, Jr., PE, PresidentThe start of a new administrative year forBranch is near. The election of the new officersfor the Branch Board of Directors willtake place in August/September and nomineesare actively being sought for the office ofSecretary. Please begin to consider your fellowmembers and yourself as potential nomineeswho may be prepared to meet the challengeand service to be an elected leader in ourprofession.We will soon be sending out informationabout the Branch membership meeting to bescheduled in August. This will be the meetingwhere nominations for the Branch offices willbe opened and accepted from the floor followedby the election of the officers to serveon the Branch Board of Directors for the 2008-2009 administrative year. The current Board isin the process of planning a tentative membershipmeeting schedule for the 2008-2009administrative year. The schedule is beingplanned with the intent to facilitate the attendanceof more Branch members by betterenabling them to attend. To this end, anymember of the Board is open to consideringand relaying your suggestions.On a local level, the Branch will be continuingits student out-reach program with thelocal high schools. To sustain this program,we will be seeking Branch members to volunteertheir services.The Branch Board would like to congratulatethe several nominees from the Branch forthe various Section Membership Awards. TheSection Membership Awards ceremonies willbe held during the Section Annual Meetingscheduled to be in Shreveport September 19,2008. These exceptional Branch membershave truly demonstrated outstanding leadershipand involvement in the ASCE as their fellowmembers in the Branch have taken notice innominating them. The 2008 Acadiana Branchnominees are:• Shirley A. Stutes, PE, LifetimeAchievement• Allison J. “Sonny” Launey, PE,Outreach• Raymond J. Reaux, PE, OutstandingCivil Engineer• Luke Hebert, EI, Outstanding Young CivilEngineer, and• Joshua P. Stutes, PE, Outstanding YoungGovernment Civil Engineer.Congratulations to all of these nominees andgood luck in Shreveport.Did you know......that a report from the Urban Institute (http://www.urban.org) “Into the Eye of the Storm:Assessing the Evidence on Science andEngineering Education, Quality, and WorkforceDemand” 10/29/07 finds that American studentsare as good and often score better than studentsfrom many leading countries? Authors HaroldSalzman and Lindsey Lowell claim that in theUnited States• Students well-prepared to compete in hightechfields are plentiful.• Students do well and are gaining groundcompared to math and science students abroad.• Colleges graduate far more scientists andengineers than are hired each year — triplethe growth rate of the labor market.• The science and engineering labor marketis strong.• Colleges and universities grant an annualaverage of 435,000 bachelor’s, master’s,and doctoral degrees to domestic studentsstudying science and engineering.• The students who make up a large segmentof the population needed to fill the millionsof jobs that keep the economy productiveand efficient are among the poorest performers— a serious weakness in education....that there are about 2.1 million engineers inthe United States and about 400,000 to 450,000of them (20 percent) hold the 750,000 engineeringlicenses issued in the United States. Anengineer does not have to be licensed to be amember of the ASCE.8 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008

NEW ORLEANSBy Ronald L. Schumann, Jr., PE, PresidentThis is the year that the Branch essentiallyreturns to its normal operations; 3 years afterour lives in the New Orleans region were sodramatically affected by Hurricane Katrina. Asit is now well known, the Branch operationswere brought to a complete halt in the aftermathof the storm during the late months of 2005.Operations remained disrupted well into theearly months of 2006. The results of the timeand energy invested during this period by thoseoften serving shorthanded in the Branch leadershipthat includes the Board and the variousappointed committees was clearly evident in themany events, seminars, meetings and otheractivities that emerged during these tryingmonths. The time and energy that was investedis even more impressive when it is appreciatedthat it was often divided between the businessof the Branch and getting personal lives back ontrack in the aftermath of the storm.These unusual efforts dedicated to our professionare the reason for the return of theBranch leadership back to normal operationsthis year. It has been extremely gratifying towitness and to be a part of the progress theBranch has made since late 2005 to return tonormal operations. On behalf of the Branch’smembership, I wish to express their gratitude towhich I humbly add my own for the efforts ofour Branch leadership and all of the Branchmembers who served in the aftermath of thestorm including this year’s leadership and theexcellent programs it is providing to make thisyear such a success. Without their initiative,service and support that have come to beexpected but surely not taken for granted, theprogress reported here would not be possible.BillboardThe Branch billboard committee is activelydeveloping plans for a billboard to promote theASCE and the civil engineering profession.The billboard will be funded by the nationalASCE State Public Affairs Grant (SPAG) programthrough — and supplemented by — theSection. It is based on a Branch proposal thatwas approved as part of the SPAG program.The financial support provided by the SPAGprogram was established by the ASCE toencourage public relations and outreach activitiesat the Section and Branch level. Theseactivities are to enhance the image of civil engineersas leaders and experts on America’s vitalinfrastructure systems and encourage advocacyon issues important to civil engineers.Current plans include both a digital billboardthat delivers a number of rotating messagesand a standard billboard. The companywe are working with has offered to throw in thestandard billboard at no additional cost. NathanJunius who chairs the committee has requestedideas from the Branch membership for messagesthat could be displayed on the billboard topromote the civil engineering profession. It hasbeen decided to make his request into a contest.Those members who submit the messages thatare chosen to be displayed will receive a freelunch at a branch meeting during the upcomingyear. Please send suggestions to Nathan at njunius@lhjunius.com.Board of DirectorsThe Branch Board of Directors for the2008-2009 administrative year was elected duringthe May Branch membership meeting and itwill be installed at an installation banquet tentativelyscheduled for Thursday, September 25,2008. The new Board members are• Nathan J. Junius, PE, President• Benjamin M. (Ben) Cody, PE, President-Elect• Margaret S. Adams, PE, Vice President• Malay Ghose Hajra, PE, Treasurer• James R. Martin, Jr., PE, Secretary• Donald E. Barbe, PE, Director• Reid L. Dennis, PE, Director, and• Ronald L. Schumann, Jr., PE, PastPresident.AwardsThe Board approved the recipients of theBranch outstanding member awards recognizingthe exceptional achievements of these civilengineers in the Branch community. They are• Robert A. Turner, Jr., PE, OutstandingGovernment Civil Engineer• Daniel L. Bolinger, PE, Outstanding CivilEngineer• Anthony J. Lamanna, PE, OutstandingYoung Civil Engineer• Subhash V. Kulkarni, PE, Outreach• William W. Gwyn, PE, LifetimeAchievement• Thomas L. Jackson, PE, Wall of Fameand• Reid L. Dennis, PE, President’s Award.These Branch awards were presented and therecipients honored during the July Branch membershipmeeting and luncheon that was held atCommander’s Palace.Life MembersAlso during the July Branch membershipmeeting, the following Branch members havingrecently achieved ASCE Life Member statuswere recognized and they were presented withtheir Life Member certificates to commemoratethe event:• Ataur R. Bhatti, PE• Thomas W. Wells, PE and• Laurence L. Lambert, PE.Other Branch members that also achieved LifeMember status include:• Fernando Estevez, PE, and• Robert B. Anderson, PE.Daniel Bolinger (right) the Branch OutstandingCivil Engineer of the Year receives his awardfrom President Schumann.Robert Turner (right) the Branch OutstandingGovernment Civil Engineer of the Year receiveshis award from President Ronald Schumann.Tony Lamanna (right) Branch OutstandingYoung Civil Engineer of the Year receives hisaward from President Schumann.Tom Jackson (right) the Branch Wall of Famerecipient receives his award from PresidentSchumann.<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008 9

SEI New Orleans Chapter ReportBy Om P. Dixit, PE, Newsletter EditorIn May University of New Orleans StudentChapter solicited financial aid from the Chapter,and from the Section and the Branch. It wasimmediately needed to partially defray the travelexpenses for its steel bridge team to make thetrip to the national steel bridge competitionhosted by the University of Florida inGainesville, Florida. In response to the request,the Chapter donated $1000.Chapter members provided engineeringoriented entertainment for the children in theKID’S TENT during the New Orleans Jazz andHeritage Festival held in April. Norma JeanMattei coordinated the services of the volunteers,who donated their time in support of thisgood cause and public outreach effort for theprofession.A Chapter hosted seminar titled WhatEngineers Should Know About Contracting waspresented June 19, 2008. This seminar featuredguest speakers Robert S. Boh, CEO, BOHBrothers and Larry Gibbs, CEO, GibbsConstruction, and moderators William H.Sewell, Jr., PE, and Thomas M. Smith. Themoderators asked pre-prepared questions posedby the members and the speakers responded tothem. The major topics addressed concerned• design-build projects• performance based specifications• quality control by contractors• value engineering• partnering workshops• contractor preferences in engineering plansand• suggestions for engineers to make plansclearer.All of the over 100 members in attendanceappreciated the valuable advice and insight providedby both speakers who are principals ofmajor construction firms from New Orleansarea.There are two future seminars beingplanned by the Chapter. The dates scheduledand topics announced for these future seminarsbeing planned are tentative at this time and asmore details are known and the plans are firmedup and finalized the information will be postedon the New Orleans Branch website.The seminar titled Local Building DesignCodes and IBC 2008 Code is scheduled forAugust 12, 2008. Several building officialsfrom the parishes of Orleans, Jefferson, St.Tammany, and St. Bernard will be invited toshare their knowledge and experience and discussthe latest building codes includingInternational Building Code 2008. The presentationwill be followed by a question andanswer session. This discussion is expected tohelp the engineering community to better understandand interpret IBC 2008 and appreciate itsimpact on structural design.The Annual Marine Structure Seminar isscheduled for October 16, 2008. The guestspeaker planned at this time is Paul Verowsky.He will discuss the API RP2A Offshore DesignCode changes and its effect on the design ofoffshore structures.The Chapter is looking for interesting topicsand speakers for future presentations.Members with expertise in above areas are welcometo join the Chapter’s ExecutiveCommittee. To make any suggestion or expressan interest in joining the Executive Committeeplease contact the Executive CommitteeChairman Mike Choudhry at Mike_Choudhry@URSCorp.com.All seminars sponsored by the Chapter areheld at the University of New Orleans. Seminardates, and registration and other pertinent informationcan be found on the New OrleansBranch website at www.asceneworleans.org. Toadd your name to the Chapter’s mailing list,email Om P. Dixit at om@fenstermaker.com.From the left are Tom Smith and Bill Sewell who served as the panelists for the seminar, “Whatengineers should know about contracting”; Mike Choudhry, Chairman of the SEI Chapter; andguest speakers Larry Gibbs and Robert Boh.Relationships:When people say you’re not part of theteam, it means they want you to be part of the fanclub. Susan Leal was fired as general managerof the San Francisco Public Utilities Commission.She claims that she was forced out by MayorGavin Newsom because she was too independent.She got along well with members of theBoard of Supervisors when he could not. - SanFrancisco Chronicle — Relationships 101: Akey to a subordinate’s success includes respondingwell and consistently to the expectations andneeds of the supervisor. Supervisors generallyappreciate independence and aggressiveness intheir subordinates because their success reflectswell on them. There can be a number of motivesfor a negative reaction by a supervisor towardthe aggressive and independent behavior of asubordinate. It can be founded on everythingfrom inappropriate jealousy to distrust. Both- Observation -subordinate behavior traits are good but theyhave to be framed in a healthy team relationshipto be effective. Most supervisors need to be inthe loop to some degree in subordinate transactions.It is a principal responsibility of a subordinateto discover and satisfy the supervisor’sneeds. An effective subordinate will develop aconservative relationship with the supervisor bykeeping in close communication as the clarityand trust needed in their relationship evolves andreveals itself. It appears that Susan Leal wasperceptive enough to appreciate the value of herassets but not her responsibilities in her relationshipwith Mayor Newsom. Her consequencesexplain clearly why it is the primary responsibilityof the subordinate to cultivate an effectiverelationship with the supervisor founded on trustand clarity. - Editor❖ Quote ❖Global Warming: I still have a hard time envisioninghow we will know when the apocalypse(due to global warming) arrives. Nobody willring a bell to announce that a climate-changeevent has begun, and it is easy to ignore thesignals that the climate is changing. After all,we’ve always had extreme weather, and it’s possiblethat what signifies the point of no returnwill not be in the realm of weather anyway butrather a derivative effect such as a financialcrisis or crop failure... At some point it willdawn on us that the weather is making us poorerand sicker... We know what we know, and westill do nothing. That’s going to have futurehistorians scratching their heads.- Eugene Linden, authorSunday Advocate 8/6/0610 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008

STUDENT CHAPTER NEWSCanoe and bridge teams compete nationallyUNOBy Christopher RauThe 2007-08 academic year was a majorturning point for the Chapter. After a number ofyears of poor performance in the regional competitions,and thus a long absence from competingat the national level, and in the midst ofcontinuing to deal with the aftermath ofHurricane Katrina, our members this past yeardecided to make a serious change. We wantedto destroy the notion that the Chapter was nolonger capable of succeeding in the regionalcompetitions. Under the leadership of AliTareh, captain of the Chapter’s steel bridgeteam qualified for an appearance at the NationalStudent Steel Bridge Competition for the firsttime in 8 years. Joining him in the effort wereteammates Daniel Bobeck, Joe Guillory, ChrisRau, Carlos Zarraga and Daniel Flores, and facultyadvisor, Michael D. Folse, PE. The teamcombined for a 600-hour effort on the projectspending the majority of several weekends duringthe spring semester working from the earlymorning until late night hours.The 2008 National Student Steel BridgeCompetition was held May 23-24 inThe steel bridge competition teams fromthe University of New Orleans and theLouisiana State University Student Chapterswere the top two finishers in the steel bridgecompetition held during the 2008 Deep SouthConference hosted by the LSU ASCE StudentChapter in Baton Rouge April 3-5, 2008. Thisqualified both of them to compete in the 2008ASCE/AISC National Student Steel BridgeCompetition that was hosted by the Universityof Florida in Gainesville, Florida May 23-24,2008. In the field of 42 competitors that qualifiedfrom their respective regional competitionsthe LSU and UNO teams placed as follows:Team LSU UNOCategory:Overall 17 23Economy 18 28Display 37 14Construction Speed 12 32Stiffness 19 12Lightness 20 5Efficiency 19 8Gainesville, Florida hosted by the University ofFlorida ASCE Student Chapter. A total of 42schools from across the United States competed.They came from as far away as Alaska andHawaii to participate in this event.Though the precise rules have changedover the years, the steel bridge competitionfocuses on fabricating and constructing a20-foot long steel bridge in a timed competitionover a hypothetical river as quickly as possiblein a timed competition. The teams begin studyingand discussing the rules and thinking of differentdesigns at the beginning of the schoolyear. After extensive review and analysis ofdifferent concepts, they finalize the design andbegin the fabrication, generally at the start ofthe spring semester. Following the fabrication,they assemble the bridge and perform load testsso that they are confident that their bridge willpass the load test during the competition.Teams hold numerous practice sessions to selectthe best builders for the team, and to discoverThe concrete canoe competition team fromthe Louisiana Tech University Student Chapterfinished first place in the concrete canoe competitionduring the 2008 Deep SouthConference. This qualified the team to competein the 2008 National Concrete CanoeCompetition hosted by the École deTechnologie supérieure in Montreal, CanadaJune 19-21, 2008. In a field of 22 competitorsthey finished 21st. There are no details abouttheir placement in the various competition categoriesat this time.the fastest sequence of construction.The top two teams from each regionalcompetition are invited to compete at thenational event. This year, our team capturedfirst place in the Deep South RegionalChampionship competition in Baton Rougesecuring an invitation to participate in thenational competition.On the afternoon of May 23, all competingteams gathered in the University of Florida basketballarena to assemble their bridges for theaesthetics portion of the competition. While thejudges studied the bridges and accompanyingposters, team members, faculty advisors, andspectators were allowed to examine the competitionbridges from each school. After this, allthe teams disassembled their bridges and teamcaptains attended a meeting nearby. Someteams including our’s squeezed in a few moretimed construction practices in a parking lot thatthe University reserved off campus.(Continued on Page 12)UNO Student Chapter steel bridge team and their supporters attend theawards banquet during the national competition. From the left are DanielBobeck, team captain, Ali Tareh, Chris Rau, Daniel Flores, MichaelFolse, Faculty Advisor, Carlos Zarraga, Donald Barbe, Chair of UNOCivil and Environmental Engineering Department and Kayode Adewumi.The steel bridge team is loading the competition bridge with lengths ofsteel angle to total static test load of 2500 pounds after which the netdeflection under the load is measured as a parameter for the stiffnesscomponent of the judging.<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008 11

(Continued from Page 11)The morning of May 24, the team awokewell before sunrise to perform a few final practices.Five construction lanes and 5 load stationswere set up in the basketball arena toexpedite the competition and allow all 42 teamsto finish in time for the awards banquet plannedfor that evening. Our team was the19th to competein the timed construction portion. Bobeckand Rau, who served as outside builders, ranquickly between staging yard and the river withcomponents of the bridge and helped Tareh andGuillory, who served as barges, assemble thebridge in approximately 13½ minutes. Theteam carried its assembled bridge to the nextload station that opened and performed the horizontaland vertical load tests. The bridge passedboth with the horizontal load test deflectionbeing less than ¼ inch and it supported the 2500pound static load.That evening all the teams gathered at theUniversity Center for the Awards Banquet.Fromy Rosenberg representing the AmericanInstitute of Steel Construction presented trophiesto the teams who finished in the top 3 ineach competition category and overall. TheUniversity of California-Berkeley captured thenational championship. We finished 23rd overall.Though we did not walk away with any trophies,we did walk away with some veryrespectable rankings in 2 categories — 5th inlightness and 8th in structural efficiency. Mostimportantly, we returned home with a strongsense of accomplishment and optimism aboutnext year. While in Gainesville, we discoveredthat some schools did not even know that ourchapter was still in operation.We now hope to be a serious contender inthe steel bridge construction event in the comingyears. The news of this year’s experienceshould encourage more civil engineering students— especially freshmen and sophomores— to join the effort and participate actively nextyear. Their continuing participation should helpbetter establish the Chapter as a serious contenderin the steel bridge competition for yearsto come. After working with a substantiallylimited budget, our team hopes that this year’ssuccess will garner more support from the civilengineering community in the area. All of thispast year’s team members have at least one yearbefore graduation and will be eligible to participatenext year. They have decided they will dowhatever it takes to give our team a greatchance of winning the national crown next yearin Las Vegas.The team is sincerely grateful to the 2 facultymembers who were very supportive withthis year’s effort — Advisor Michael Folse andDonald E. Barbé, PE, chair of the civil andenvironmental engineering department, whohelped with the costs of the trip to Gainesvilleand traveled with us. We thank the familymembers and friends who also traveled to supportus during this event. We would also like tothank the University of Florida ASCE StudentChapter for its outstanding job of hosting thecompetition.The competition bridge is shown assembled and prepared for the display component of the judging.September 19, 2008September 11-12, 2008September 18-19, 2008September 24-25, 2008September 25-26, 2008September 25-26, 2008September 25-26, 2008September 26, 2008October 2-3, 2008October 9-10, 2008October 16-17, 2008November 6-7, 2008November 6-7, 2008November 6-7, 2008November 13-14, 2008November 13-14, 2008November 13-14, 2008November 20-21, 2008November 20-21, 2008November 20-21, 2008November 20-21, 2008November 20-21, 2008November 20-21, 2008December 4-5, 2008December 4-5, 2008December 11-12, 2008December 11-12, 2008December 18-19, 2008— Calendar of Events —ASCE Louisiana Section Annual Meeting, Shreveport. For more information visit http://www.<strong>lasce</strong>.org.ASCE Seminar * Pipe and Pipeline Renewal, San Antonio, Texas.ASCE Seminar * Engineering Design and Performance of Bioreactor Landfills, Nashville, Tennessee.ASCE New Orleans Branch Louisiana Civil Engineering Conference and Show, Kenner. For more informationvisit http://www.<strong>lasce</strong>.org.ASCE Seminar * Construction Cost Estimating for Civil Engineers, San Antonio, Texas.ASCE Seminar * Design of Buildings in Coastal Regions, Pensacola, Florida.ASCE Seminar * Residential Land Development Strategies, New Orleans.Louisiana Engineering Society Life Safety Code Seminar. For more information email les@les-state.ogr, Many,LouisianaZweigwhite Structural Engineer’s Building Conference and Exposition. For more informationvisit http://events.Zweigwhite.com/building/. Atlanta, Georgia.ASCE Seminar * Environmental Bootcamp for Engineers, San Antonio, Texas.ASCE Seminar * Strategic Planning, Valuation & Ownership Transitions for Engineering Firms, Nashville,Tennessee.ASCE Seminar * Advanced Detention Routing: Improving the Operation & Effectiveness of Detention Facilities,Austin, Texas.ASCE Seminar * Perfect Your Negotiating Skills: Increase Your Profitability, San Antinio, Texas.ASCE Seminar * Wind and Seismic Retrofit of Buildings, Memphis, Tennessee.ASCE Seminar * Design and Evaluation of Highway Bridge Superstructure Using LRFD , Houston, Texas.ASCE Seminar * Leadership Development for the Engineer , Dallas, Texas.ASCE Seminar * Liability of Engineers: How to Stay out of Trouble , Atlanta, Georgia.ASCE Seminar * Wind Loads for Buildings & Other Structures, Dallas, Texas.ASCE Seminar * Slope Stability Probabilistic Analysis and Instrumentation, Atlanta, Georgia.ASCE Seminar * Project Management, San Antonio, Texas.ASCE Seminar * Treatment Plant Hydraulics for Civil Engineers, Nashville, Tennessee.ASCE Seminar * HEC‐HMS Computer Workshop, Nashville, Tennessee.ASCE Seminar * Instrumentation and Monitoring Bootcamp: Planning, Execution and Measurement Uncertaintyfor Structural and Geotechnical Construction Projects, Atlanta, Georgia.ASCE Seminar * Design and Strengthening of Shallow Foundations for Conventional and Pre‐EngineeredBuildings, Atlanta, Georgia.ASCE Seminar * Leadership Development for the Engineer, Atlanta, Georgia.ASCE Seminar * Introduction to Detention Pond Design for Parking Lots and Urban Drainage, Dallas, Texas.ASCE Seminar * Structural Design of Industrial Facilities, New Orleans.ASCE Seminar * Design and Renovation of Wood Structures, New Orleans.*For more information, call ASCE toll free at (800)548‐2723 or visit the ASCE website: www.asce.org.For the schedule and registration for the ASCE web seminar continuing education regularly offered: Visit the ASCE website / continuingeducation / distance learning / live interactive web seminars.12 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008

Section News and InformationHighlights of the May Board of Directors meetingThere was significant concern expressedby the Section leadership concerning the recentlow attendance experienced during the awardsbanquet held in conjunction with the Section’sAnnual Spring Meeting and Conference hostedby the Acadiana Branch in Lafayette. It wasnoted that there were two important nationalASCE leaders and a Louisiana statewide officialwho were featured speakers during theplenary sessions scheduled during theConference. They discussed the general themeof higher education and the important transitionsthat are being planned and anticipated inthe civil engineering curriculum and possiblythe entire engineering curriculum. It is notuncommon — though unfortunate — that theSection conferences hosted by the Branches donot attract much of a statewide audience butmostly one exclusive to local branch membersas was the case in Lafayette.The plenary sessions that were notembedded in the technical session programsuch as the concluding Thursday eveningawards banquet were very poorly attended relativeto the total attendance during theConference and the expectations of theSection’s leadership. This was attributedsomewhat to the changing character of theaudiences that now attend Section conferences.They are mostly those who are principallyseeking professional development hours to sustaintheir engineering licenses and they arethose who more typically appear to have littleor no interest in the ASCE or the importantprofessional engineering issues of our times.One “incentive” for this lack of participationmay have been the billing structure for theConference. The fee for the awards banquetwas separate form the general conference fee.It was suggested that in the future this fee forthe awards banquet be included in the generalconference registration fee and also offered toindividuals who are not attending theConference but wish to attend the event.Since the election of the 2008-2009Section Board of Directors during the SectionAnnual Spring Meeting and Conference, thetwo Director-at-Large positions for which therewere no official nominees provided and forwhich there were no nominees offered fromthe floor of the meeting and for which no onewas elected have since been appointed by theBoard of Directors. They are Dax A. Douet,PE, from the Acadiana Branch and ChristopherG. Humphreys, PE, from the New OrleansBranch. They will be installed in their respectiveoffices with the remainder of the electedBoard of Directors during the Section AnnualMeeting to be hosted by the Shreveport Branchduring a noon meeting September 19, 2008.A Baton Rouge Branch representativeacknowledged that there was some outstandingbusiness concerning a State Public AffairsGrant (SPAG) that had been granted to theBranch through the Section during the 2005-2006 administrative year. The events followingHurricane Katrina led to a failure by theBaton Rouge Branch to file the required reportof the completion of its planned public affairsactivities that were funded through the SPAG.There was no reaction by the ASCE nationalorganization to this oversight and failure toreport the completed SPAG work. The Branchwas advised by the Section to complete andfile the report necessary to meet this obligation.The Section’s allotment to each studentchapter in response to receiving the chapter’sannual report was made to each student chapterthat provided its annual report to theSection’s Secretary-Treasurer by the deadlinethat is now passed. There were two delinquentannual reports from the Southern Universityand the McNeese State University ASCEStudent Chapters. A better effort to make reasonablysure that chapter advisory personnelare aware of the allotment and the requirementto obtain it so they can counsel the chapterleaders to appropriately respond.Attendance to headquarters orientationworkshop for Section and Branch leaders wastouted by the ASCE headquarters staff. Itsgoal is to introduce Section and Branch leadersto the assets and opportunities available tothem through the ASCE headquarters staff andits resources. It was conjectured that thisnationally unfunded activity in Washington,DC, seemed somewhat redundant in content tothe annual bi-regional conferences for branch,section and student chapter leaders. Thoughthe Section has not participated in these pastworkshops, it was decided to make it a policyto send the Section’s Secretary-Treasurer to theworkshop beginning in October 2008. Anamount of $800 was budgeted to cover the aexpenses of atteding.Ryan C. Koenig one of the organizingcommittee members for the Louisiana CivilEngineering Conference and Show is makingthe arrangements for a panel discussion duringa luncheon plenary session and a separate technicalsession during the Conference dedicatedto discussing the latest developments concerningthe Body of Knowledge associated withASCE Policy 465 - Academic Prerequisites forLicensure and Professional Practice.Tentatively, Kenneth J. Fridley, DepartmentHead and Professor of Civil Engineering at theUniversity of Alabama, Jeffrey Russell, Chairand Professor of the Department of Civil andEnvironmental Engineering at the Universityof Wisconsin-Madison, and Kenneth L.McManis, Department Head and Professor ofCivil Engineering at the University ofLouisiana at Lafayette who are active in thisprocess will be invited to make these interactivepresentations.It is also planned that this same group willbe scheduled to attend a series of meetingswith key engineering faculty members at the 6universities in Louisiana with civil engineeringcurricula. The Section anticipates that it willcover approximately $1200 their undefrayedexpenses.The future plans for continuing the publicationof the Section journal are still somewhattentative. The ad hoc committee tasked tostudy the options for a future direction for theSection journal recommended that• steps be taken to reasonably ensure thecontinued publication and quality of thejournal• the Publication Committee will consist of4 members including the President-Electand 3 unspecified directors who wouldserve as the chair and members respectively• the part time services of a professionalwriter be retained to serve as a text andcontent editor.President DesOrmeaux informally obtainedsome data from the Texas Section concerningits costs to have its journal professionally produced.He roughly estimates that it will costthe Section $30,000 a year. Considering currentcosts and revenues, this does not appear tobe a viable option.In other matters• It was announced that the ShreveportBranch will host the Section AnnualMeeting September 19, 2008 at theUniversity Club in Shreveport around12:00 noon. It will be a 2-hour eventincluding installation of Section officersand the presentation of awards to outstandingSection members.• It was noted that in the Highlights of theFebruary Board meeting that appeared inthe May 2008 issue of the journal, it wasincorrectly observed that the SectionPresident-Elect would have first refusal toattend the legislative Fly-In. It is theSection Vice President that has first refusal.• Region 5 is sponsoring a grant fundedworkshops in each section of the Region toattempt to revive new grassroots membershipparticipation in ASCE activities. Thismay be in conjunction with the LouisianaCivil Engineering Conference and Show.• President DesOrmeaux will update andrevise the Section Operating Guide.• The next Section Board meeting will bedevoted exclusively to developing a clearand positive direction for the future of theSection’s journal and a review of theSection’s revised/proposed OperatingGuide.• The Section Special Activities and AwardsCommittee Chair advised that the deadlinedates for the Section awards program havebeen revised to better administer theSection awards.<strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008 13

Conference and meeting in SectionDetailed information and access to registrationfor the conferences and meetingsscheduled and discussed here are provided onthe home page of the Section website underSection-wide conference opportunities.Section Annual MeetingDate: September 19, 2008Time: 11:30 amPlace: University Club in the American Towerin downtown ShreveportReservations: rcooper@alliance-ae.comEnding a long tradition, the 2008 SectionAnnual Meeting will not be hosted in NewOrleans by the New Orleans Branch followingthe Louisiana Civil Engineering Conferenceand Show. Instead the Annual Meeting will beDeathsLeo William Gagnon, Jr., PEhosted by the Shreveport Branch inShreveport. This Section general membershipmeeting will be a noon luncheon where theceremonies will be held to present awards toseveral outstanding Section members beingrecognized for their career accomplishments,and their service to their communities and profession.It will also feature the installation ofthe Boards of Directors for the Section andShreveport Branch that will serve during the2008-2009 administrative year.The new members of the Section Board ofDirectors were elected in April during the2008 Annual Spring Meeting in Lafayette.Their installation will mark the beginning ofthe 2008-2009 administrative year for theSection.Henry Karl Schott, PELouisiana Civil EngineeringConference and ShowRegistration is now open for the 2008Annual Louisiana Civil EngineeringConference and Show in Kenner that is scheduledfor September 24-25, 2008. Registrationand information is available on a newConference website and it may be accessedthrough the announcement on the Section website.Sponsored by the New Orleans Branchand the Louisiana Chapter of the AmericanConcrete Institute, the Conference may be thebest opportunity in the Section for civil engineersto attend a local conference offering twofull days of three concurrent, high quality technical/professionalsessions and the opportunityto acquire up to 11 professional developmentunits over the two-day period. As the speakercommitments for the technical sessions of theConference are being filled out, the planningstatus and the access to opportunities to participateas a vendor, sponsor or speaker are alsoavailable on the New Orleans Branch website.Bill Gagnon who will be remembered as afriend and colleague to so many in the BatonRouge and New Orleans Branches died June15, 2008. He was 66 years old. A long timeresident of Baton Rouge and an associate withthe engineering firm Professional EngineeringConsultants Corporation located in BatonRouge Bill was an active member of the BatonRouge Branch serving in its volunteer andelected leadership rising to its presidency duringthe 1984-1985 administrative year. Anative of New Orleans Bill was a resident ofMetairie at the time of his death. He is survivedby his wife of 41 years Nancy and theirtwo children Darren and Mary. Bill earned hisBS degree in civil engineering from LouisianaTech University and he held licenses in civiland environmental engineering in Louisiana.Bill served his country in the U.S. Air Force inThailand during the Vietnam War and he wasactive in his community. He is a past memberof Bacchus and the Krew de Mystique and apast master of St. James Masonic Lodge 47 inBaton Rouge. Bill was a member of theMasonic Louisiana Lodge 102 in River Ridgeand belonged to the York Scottish Rite and theNational Scottish Rite.Henry Schott a member of the ASCE since 1943and a long-time resident and member of theBaton Rouge Branch died October 5, 2007. Hewas also a member of the Louisiana EngineeringSociety. Born Heinrich Karl Schott October 19,1919 in Harleshausen (now Kassel), Germanyhe immigrated with his parents to the UnitedStates in 1927. Henry and his family settled inElizabeth, New Jersey and he earned his civilengineering degree from the Newark College ofEngineering (now the New Jersey Institute ofTechnology) in near-by Newark. In 1943, Henryand his wife Elsie Fraatz Schott were marriedand he was employed by the engineering firmParsons, Brinkerhoff, Quade and Douglas inNew York City. In 1959 his firm transferred himto it offices in Baton Rouge where Henry splithis employment tenure between the private sectorand the Baton Rouge City-Parish Departmentof Public Works. Once Henry rejoined theDepartment as its subdivision engineer, heremained until his retirement in 1984 as its chiefengineer. Henry is survived by his wife, Elsie,their 3 children, 5 grandchildren and 7 greatgrandchildren. He was a member of St. PaulLutheran Church in Baton Rouge for 48 yearswhere he served in several leadership roles.Your invitation:PE/CE exam reviewThe Section and its branches are cooperatingto make the very popular ASCE live PEExam Review Course that is offered on theweb available at a site in each of the branchareas and open to all of the Engineer Internsin Louisiana who are preparing to take thecivil engineering discipline component in thenear future. This course is intended to helpthe Engineering Intern prepare to pass the PEExam. It is taught by a team of experiencedPE Exam Review instructors who will presentit in a series of 12 2-hour modules over a6-week period.The participating organization pays a singlesite registration fee of approximately$2000 and an unlimited number of people inthe organization can be admitted to attend thecourse at the site. By this means, the coursecan be offered at a very reasonable cost toeach participant. Potential participants areinvited to register for the course by contactinga member of the branch leadership in theirrespective branch area. Currently, it is anticipatedthat the once-a-week sessions areexpected to begin in September and be offeredon Thursdays at 3:00 pm.To facilitate attendance, the Section leadershiprequested the Louisiana ProfessionalEngineering and Land Surveying Board staffto provide it with the list of Engineer Internsscheduled to take the civil engineering disciplinecomponent of the next PE Exam scheduledfor October 24, 2008. The list of candidatesapproved to take the civil engineeringcomponent was provided by LAPELS BoardExecutive Director, Donna D. Sentell. Theindividual branch leadership will be responsibleto see that these individuals in theirbranch be contacted and advised of thisopportunity.14 <strong>THE</strong> <strong>LOUISIANA</strong> <strong>CIVIL</strong> <strong>ENGINEER</strong> / FEBRUARY 2008