Design and Construction of A Solar Dryer for Mango ... - Tropentag

Design and Construction of A Solar Dryer for Mango ... - Tropentag

Design and Construction of A Solar Dryer for Mango ... - Tropentag

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

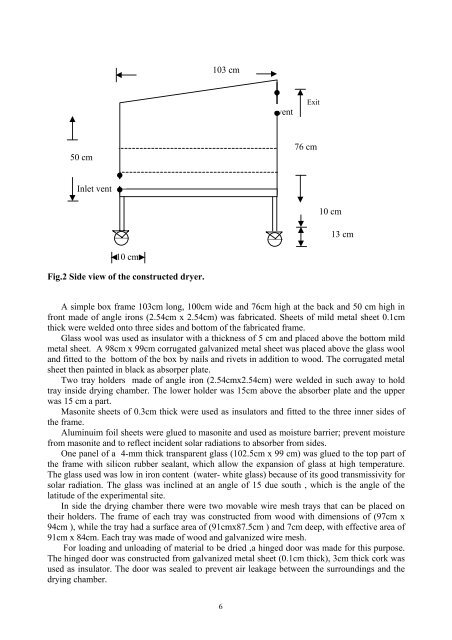

50 cm<br />

Inlet vent<br />

10 cm<br />

Fig.2 Side view <strong>of</strong> the constructed dryer.<br />

103 cm<br />

6<br />

vent<br />

Exit<br />

76 cm<br />

10 cm<br />

13 cm<br />

A simple box frame 103cm long, 100cm wide <strong>and</strong> 76cm high at the back <strong>and</strong> 50 cm high in<br />

front made <strong>of</strong> angle irons (2.54cm x 2.54cm) was fabricated. Sheets <strong>of</strong> mild metal sheet 0.1cm<br />

thick were welded onto three sides <strong>and</strong> bottom <strong>of</strong> the fabricated frame.<br />

Glass wool was used as insulator with a thickness <strong>of</strong> 5 cm <strong>and</strong> placed above the bottom mild<br />

metal sheet. A 98cm x 99cm corrugated galvanized metal sheet was placed above the glass wool<br />

<strong>and</strong> fitted to the bottom <strong>of</strong> the box by nails <strong>and</strong> rivets in addition to wood. The corrugated metal<br />

sheet then painted in black as absorper plate.<br />

Two tray holders made <strong>of</strong> angle iron (2.54cmx2.54cm) were welded in such away to hold<br />

tray inside drying chamber. The lower holder was 15cm above the absorber plate <strong>and</strong> the upper<br />

was 15 cm a part.<br />

Masonite sheets <strong>of</strong> 0.3cm thick were used as insulators <strong>and</strong> fitted to the three inner sides <strong>of</strong><br />

the frame.<br />

Aluminuim foil sheets were glued to masonite <strong>and</strong> used as moisture barrier; prevent moisture<br />

from masonite <strong>and</strong> to reflect incident solar radiations to absorber from sides.<br />

One panel <strong>of</strong> a 4-mm thick transparent glass (102.5cm x 99 cm) was glued to the top part <strong>of</strong><br />

the frame with silicon rubber sealant, which allow the expansion <strong>of</strong> glass at high temperature.<br />

The glass used was low in iron content (water- white glass) because <strong>of</strong> its good transmissivity <strong>for</strong><br />

solar radiation. The glass was inclined at an angle <strong>of</strong> 15 due south , which is the angle <strong>of</strong> the<br />

latitude <strong>of</strong> the experimental site.<br />

In side the drying chamber there were two movable wire mesh trays that can be placed on<br />

their holders. The frame <strong>of</strong> each tray was constructed from wood with dimensions <strong>of</strong> (97cm x<br />

94cm ), while the tray had a surface area <strong>of</strong> (91cmx87.5cm ) <strong>and</strong> 7cm deep, with effective area <strong>of</strong><br />

91cm x 84cm. Each tray was made <strong>of</strong> wood <strong>and</strong> galvanized wire mesh.<br />

For loading <strong>and</strong> unloading <strong>of</strong> material to be dried ,a hinged door was made <strong>for</strong> this purpose.<br />

The hinged door was constructed from galvanized metal sheet (0.1cm thick), 3cm thick cork was<br />

used as insulator. The door was sealed to prevent air leakage between the surroundings <strong>and</strong> the<br />

drying chamber.