02.Separate ways. - Contec

02.Separate ways. - Contec

02.Separate ways. - Contec

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

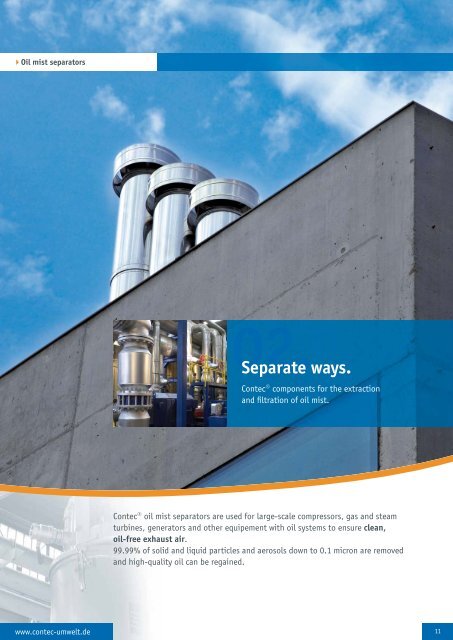

Oil mist separators02. Separate <strong>ways</strong>.<strong>Contec</strong>® components for the extractionand filtration of oil mist.<strong>Contec</strong>® oil mist separators are used for large-scale compressors, gas and steamturbines, generators and other equipement with oil systems to ensure clean,oil-free exhaust air.99.99% of solid and liquid particles and aerosols down to 0.1 micron are removedand high-quality oil can be regained.www.contec-umwelt.de11

<strong>Contec</strong>® GmbH. Clean solutions on demand.You can take a deep breath.With <strong>Contec</strong>®oil mist separators.MAN turbo gas turbines,Package THM 1304with a <strong>Contec</strong>® oil mist filterof the series 2200/630.Since 1974, <strong>Contec</strong>® GmbH has been workingon filtration technology for industrial applications.Already in 1987 a filter system forthe extraction and filtration of oil mist wasdeveloped in close cooperation with one ofour customers: this was the starting point ofthe <strong>Contec</strong>® oil mist separators (awarded theEnvironmental Technology Prize for 1990).These special high-performance filters areusually installed on the lubrication oil tanksof turbines, compressors and turbo-engines.They replace simple filters or separators, sothat no oil mist can be released into theatmosphere.<strong>Contec</strong>® oil mist separators are equippedwith a side channel blower that generatesadjustable negative pressure in the oilsystem. This prevents the leakage of oilmist from the bearings, shaft guide andcrankshaft ventilation systems. As thefilter elements have a long service lifeand an automatic oil recycling system,they require little maintenance.The core of the <strong>Contec</strong>® oil mist separatorare the glass fiber filter elements developedespecially for these applications.The two-layer design with integratedreinforcement fibers optimizes the coalescenceeffect and ensures a constantlyhigh level of oil separation. The degree ofefficiency is 99,99% at a droplet size of0.1 micron, which means that the exhaustair is far cleaner than that required byGerman TA regulations for clean air.Due to their very compact design,<strong>Contec</strong>® oil mist separators are alsoeasy to use under all difficult or restrictedspatial conditions. Versatile options and amodular design make it possible to adaptour filtration systems individually toalmost all requirements.InstallationCompact series with optionalcomplete bypass and externalair bypass.SG series with side mountedmotor/blower unitand optional bypass.1. Housing2. Blower3. O-Ring Seal4. Filter Base5. Fastening Screw6. Seal7. Hand valve8. Tie Rod9. Filter Element10. Retaining Cap11. Air suction filter12. Catch13. O-Ring Seal14. Housing Cover15. Inlet T-Piece16. Exhaust17. Pillar Tube with Flange18. Negative Pressure Gauge19. Filter Element Base20. Oil Drain Connection21. Hold22. Bracket23. Frame24 Compensator25. Complete filtersystem bypass26. Non return valve27. Bypass foradmixing air12

Basic configurations/compact series• All compact series with housingmade of mild steel, completelygalvanized and painted on the outside• Internal parts and filter coversmade of aluminum• Filter elements made of glass fiberfleece with an inorganic binder• Electric motor, 230/400V, 50 Hz,IP 55 protection• Motor/blower integrated unitmounted on top of the coverCompact seriesType 180/435 to 2200/630• 20 Nm 3 /h to 270 Nm 3 /h at 50 Hz• ATEX version for applicationsup to Zone 2 (3/3G)• Space-saving construction by mountingthe motor/blower unit entirely on thecoverConfiguration variants/Special versionsSide channel blower with engines in• ATEX version• EX protective version• EX pressure-resistant• Special voltagesOther versions, e.g.• without side channel blowers• with other connections• made of stainless steel• with special paint coatings,e.g. for off-shore applications• for higher flow ratesSG seriesType 180/435-SG to 2200/630-SG• 20 Nm 3 /h to 270 Nm 3 /h at 50 Hz• ATEX version for applicationsup to Zone 1 inside and outside (2/2G)• Compact construction for large and heavyZone 1 side channel blowers and motor/blower unitsOUR PRODUCTS PROMISE:HIGH EFFICIENCY,COMPACT CONSTRUCTION,MINIMAL MAINTENANCE ANDCLEAN AIR AS A RESULT.RG seriesType 4000/630 to 9200/762• 450 Nm 3 /h to 1200 Nm 3 /h at 50 Hz• ATEX version for applicationsup to Zone 1 inside and outside (2/2G)• Compact frame constructionDL seriesCompressed air powered filter type 13/138• Flow rate 8 Nm 3 /h• Powered by compressed air,resulting in problem-free utilizationin EX areas Zone 1 and 2• Connection female pipe thread 1“• Outlet 22 mm connection pipewith silencer13

<strong>Contec</strong>® GmbH. Clean solutions on demand.Optional accessories:External air bypass• Hand valve for admixingsystem-internal, purifiedexhaust air to control thenegative pressure• Specially suitable for applicationsin Zone 1 environmentsor with very dirtyor polluted environmentalairOptional accessories:Complete filter systembypass• Complete bypass withintegrated check valve.• The integrated bypasson the oil mist separatormeans that an additionalbypass of the completefilter system is not required• „Emergency“ bypass toavoid high pressure in thelubrication oil system inthe event of system failureOptional accessories:Double blower• Redundant motor/blowerunit on a special frameconstruction• The motor/blower unitscan be controlledindependentlyfrom each other,using hand valves andcheck valvesOptional accessories:Additional micro filterhead Piece• Additional downstreamair filter cell H11 foraerosol-free exhaust• Reduction of oil aerosolsin the exhaust air to lessthan 0.2 mg/m 3Optional accessories:Hinged cover• Only for compact series,especially forType 1500/980and Type 2200/630• Specially developedmechanical eccentriclifter• Slight lifting of the filtercover and easy replacementof filter elements,especially when no indoorcrane is availableOptionally accessories:OG version• Filter system without anmotor/blower unit• Filtration and separationof oil mist for lubricationsystems with sufficienthigh pressureTechnical data for<strong>Contec</strong>® oil mist separatorsAt present, nine standard types with flow volumes from 8 Nm 3 /h to 1200 Nm 3 /h at 50Hz operationand 60 mbar differential pressure are available.Type 13/138 180/435 300/935 550/980 1500/980 2200/630 4000/630 7500/762 9200/762Flow rate 8 Nm 3 /h 20 Nm 3 /h 50 Nm 3 /h 110 Nm 3 /h 190 Nm 3 /h 260 Nm 3 /h 470 Nm 3 /h 710 Nm 3 /h 1200 Nm 3 /hMotor powered by 0,25 kW 0,37 kW 0,75 kW 1,10 kW 2,20 kW 3,00 kW 5,50 kW 9,20 kWpower compressed air<strong>Contec</strong>® oil mist separators comply with all of the legal requirements.The air quality is by far better than that required by the German TA regulations for clean air.14

Our direct dials:Sales management/International salesT. +49.(0)2224.9893-15Technical management/Air and gas filtersT. +49.(0)2224.9893-13Oil mist separatorsT. +49.(0)2224.9893-12Liquid filtersT. +49.(0)2224.9893-16Liquid level measurement technologyT. +49.(0)2224.9893-17Administration/AccountingT. +49.(0)2224.9893-11<strong>Contec</strong>® GmbH IndustrieausrüstungenP.O. Box 614853594 Bad HonnefAegidienberger Straße 6953604 Bad HonnefGermanyT. +49.(0)2224.9893-0F. +49.(0)2224.9893-20www.contec-umwelt.deinfo@contec-umwelt.deAir and gas filtersOil mist separatorsLiquid filtersLiquid level measurement technology