Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

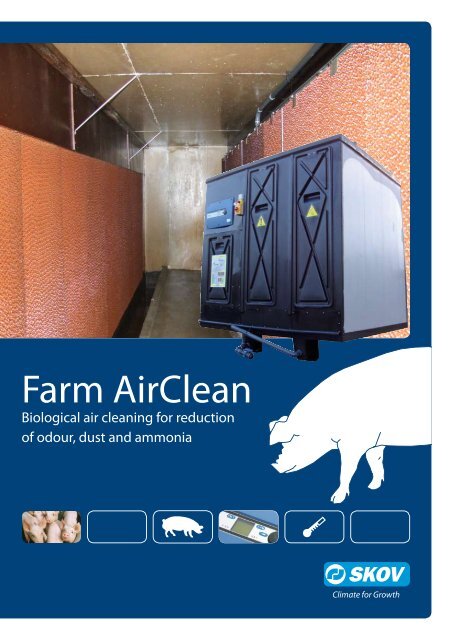

<strong>Farm</strong> <strong>AirClean</strong><br />

Biological air cleaning for reduction<br />

of odour, dust and ammonia<br />

Climate for Growth

Efficient biological Cleaning of the outgoing Air...<br />

Ammonia, Odour and Dust<br />

The incentive to develop systems for<br />

cleaning housing air derives from the agricultural<br />

sector being under great national<br />

and international pressure to reduce its<br />

environmental load. For animal production,<br />

this involves requirements for a reduction<br />

of ammonia emissions, other nitrogen<br />

compounds, etc.<br />

This also applies to odorants from livestock<br />

houses. Producers are facing an increasing<br />

number of limitations when they wish to<br />

establish new house systems or extend<br />

them. These limitations often occur in the<br />

form of protests against the odour load.<br />

On several markets, the authorities have<br />

increased their focus on reducing the dust<br />

quantity discharged from the livestock<br />

houses to the surrounding environment.<br />

Recent research results have shown that<br />

dust from livestock houses can be disease<br />

carriers.<br />

<strong>Farm</strong> <strong>AirClean</strong><br />

<strong>Farm</strong> <strong>AirClean</strong> is a biological air cleaning<br />

system. The system is based on biological<br />

air-cleaning principles. These principles are<br />

effective in reducing odour, ammonia and<br />

dust.<br />

BIO Module or BIO Flex<br />

The <strong>Farm</strong> <strong>AirClean</strong> systems can be divided<br />

into two groups - BIO Module and BIO Flex.<br />

The air volume to be cleaned is crucial for<br />

the choice of system. The positioning of<br />

the air cleaner and the duct layout from<br />

the livestock house to the air cleaner can<br />

be factors as well.<br />

The BIO Module is used when the required<br />

air cleaning level is low and if the<br />

air cleaner is to be placed in the attic of<br />

the livestock house. BIO Flex is used when<br />

the required air cleaning level is high and<br />

if the air cleaner is installed inside or in an<br />

extension to the livestock house.<br />

In full-scale test, <strong>Farm</strong> <strong>AirClean</strong> has<br />

proven that<br />

•<br />

•<br />

•<br />

The ammonia content of the outgoing air is reduced<br />

down to 1 ppm<br />

The pig smell is eliminated from the outgoing air<br />

The dust content in the outgoing air is reduced by 90%<br />

A World of<br />

Customised<br />

Solutions

Only Water and indigenous<br />

Microorganisms...<br />

Patented Filter Construction<br />

The housing air is led through two filters<br />

sprinkled with water. Ammonia and<br />

odorants are removed in both filters while<br />

most of the dust is removed in the first<br />

filter.<br />

The air cleaning process is a biological<br />

process. Biofilms of bacteria and other<br />

microorganisms are formed on the filters.<br />

Ammonia, odorants and dust are removed<br />

when the housing air gets into contact with<br />

the water and the biofilm on the filters.<br />

Natural Cleaning by Microorganisms<br />

The effective bacteria and other microorganisms<br />

are indigenous in the livestock<br />

house environment. Some of the bacteria<br />

are specialists in converting ammonia.<br />

Microorganisms feed on the characteristic<br />

odorants from pig houses and dust. (e.g.<br />

root material and the pigs’ hide)<br />

The water re-circulates through the filters.<br />

When the water in the filters loses its<br />

capacity to convert more ammonia, it is<br />

Ammonia<br />

Odour of Pig<br />

Dust<br />

drained to the slurry tank and fresh water<br />

is supplied to the installation.<br />

The drained water, which is entirely biological,<br />

can be handled together with the<br />

slurry or spread directly on the fields as a<br />

fertiliser supplement.<br />

Only Principle that cleans the Air<br />

of both Odour and Ammonia<br />

The biological principle is the only air<br />

cleaning principle known to remove both<br />

odorants and ammonia from the outgoing air.<br />

A system based on chemicals can reduce<br />

the ammonia emission but has no effect<br />

on the odour emission.<br />

Approved System<br />

A worldwide patent for the <strong>Farm</strong> <strong>AirClean</strong><br />

principles has been applied for and the<br />

system is in operation in a number of<br />

countries around the world.<br />

On some markets, air cleaning is subject to<br />

approval by the authorities. <strong>Farm</strong> <strong>AirClean</strong><br />

is approved by the authorities in Denmark,<br />

Germany, the Netherlands, Belgium and<br />

Japan.<br />

Water<br />

Air Air<br />

Biofilm<br />

Ammonium<br />

Nitrit / nitrat<br />

Organc material<br />

Residual products can<br />

be spread<br />

together with slurry<br />

Kilde: Aron Saunders, Århus Universitet<br />

Ventilation and Air Cleaning<br />

from one Supplier<br />

Based on the system idea, <strong>Farm</strong> <strong>AirClean</strong> is<br />

a natural part of a SKOV ventilation system<br />

and thus optimised in every way.<br />

Furthermore, the customer only has to<br />

approach one supplier when the system<br />

is in operation. We know the correlation<br />

between ventilation and air cleaning and<br />

get the most out of the systems.<br />

CO 2<br />

Odour of wet<br />

forest floor

BIO Flex<br />

BIO Flex is designed to provide ’air<br />

cleaning by the metre’. The system is very<br />

flexible. Producers can optimise the<br />

investment and the operating costs in<br />

relation to the current regulatory requirements.<br />

Furthermore, the requirement for<br />

manual cleaning and maintenance has<br />

been minimised.<br />

BIO Flex is well suited for large air cleaning<br />

systems in connection with central channel<br />

and wall exhaustion.<br />

Flexibility at all Times<br />

BIO Flex is a biological air cleaning system<br />

- a two or three-step biological air cleaner<br />

- designed to provide ’air cleaning by the<br />

metre’. BIO Flex is characterised by:<br />

• Capacity ranging from 10 000 to 360 000<br />

m3 /hour with the same controller<br />

• Length of the system ranging from 2<br />

to 50 metres<br />

• Biological air cleaning<br />

• Optimum investment in relation to<br />

the regulatory requirements<br />

• Different levels of odour reduction<br />

(two or three filters)<br />

• Robust and reliable construction<br />

requiring only little maintenance<br />

In areas where regulatory requirements<br />

are in place (Germany), it is possible to implement<br />

a pH stabilization of the cleaning<br />

process.<br />

Minimum Maintenance<br />

It has been emphasised that the pig<br />

producer should spend as little time as<br />

possible on cleaning and maintaining<br />

the system. BIO Flex is equipped with a<br />

newly developed, patent pending robot<br />

washer (PA2010 00201). The design of the<br />

robot washer is sturdy and reliable and the<br />

robot washer automatically and effectively<br />

cleans the filters.<br />

1 2<br />

Stop

In addition, the utilization of the entire<br />

filter area in the air cleaner has been<br />

optimised and the quantity of dust in<br />

the filters has been reduced by placing a<br />

patent pending air distribution plate in<br />

front of the first filter (PA 2009 01023). The<br />

mechanical principle for sprinkling the<br />

filters under all operating conditions has<br />

been optimised so that the entire filter<br />

area retains the required humidification<br />

level.<br />

These additions improve the “working environment”<br />

for the bacteria in the system.<br />

This makes it easier for the bacteria to<br />

convert the odorants and the ammonia<br />

content in the housing air - and thus obtain<br />

the maximum cleaning effect.<br />

BIO Flex installation in Denmark<br />

Air distribution plate in front of the first filter<br />

Air outlet from the section to the air cleaner<br />

Automatic robot washer on the first filter<br />

Low Power Consumption<br />

BIO Flex is characterised by air cleaning on<br />

large filter areas which results in a minor<br />

pressure loss. The automatic robot washer<br />

and the dust reducing function of the<br />

air distribution plate are in combination<br />

to ensure that the filters are always in<br />

optimum condition and the pressure loss<br />

through the filters is low. The operating<br />

costs for ventilation have been minimised<br />

compared to other filter-based air cleaning<br />

systems.<br />

Control and Monitoring<br />

Optimum air cleaning with minimum resource<br />

consumption is handled by a DOL<br />

356 air cleaning computer. Operating data<br />

is collected and displayed by the <strong>Farm</strong>-<br />

Online® management system. Data documentation<br />

through <strong>Farm</strong>Online® meets<br />

the requirements<br />

of the<br />

international<br />

VERA Protocol.

BIO Modul<br />

The BIO Module is a module-based concept<br />

where the quantity of air cleaning<br />

units ordered is based on the number of<br />

m 3 of housing air to be cleaned.<br />

The idea behind the module-based filter<br />

unit was to standardise the air cleaning<br />

unit into prefabricated concept units.<br />

They are of a very high quality and thus<br />

ensuring the usual advantages: reliability<br />

and reduction of product manufacturing<br />

and mounting costs.<br />

The cleaning units are available in capacities<br />

ranging from 10 000 to 40 000 cubic<br />

metres per hour. For instance, the BIO 3U<br />

can clean 30 000 m 3 of air per hour, which<br />

is equivalent to approx. 300 finisher pen<br />

places according to Danish standards -<br />

calculation is based on approx. 100 m 3 air/<br />

hour/pig.<br />

Housing air<br />

Recirculated water<br />

Filter 1<br />

Biofilm<br />

Recirculated water<br />

By basing the system on modules, SKOV<br />

has made it easy for the pig producer to<br />

implement the system in the construction<br />

process. The cleaning modules can be<br />

placed in the attic, next to the house or in<br />

a cleaning room inside the house.<br />

Contrary to other module systems available<br />

on the market, this solution can be<br />

delivered either fully assembled or to be<br />

assembled on site. If the cleaning modules<br />

are to be installed in an attic, assembly on<br />

site can save the producer the removal of<br />

most of the roofing sheets in connection<br />

with the installation.<br />

Fan<br />

Filter 2<br />

Biofilm<br />

Floor<br />

Experience has showed that it is important<br />

to keep the filters clean. SKOV designed<br />

an automatic filter washer for the cleaning<br />

units. The washer starts at regular intervals<br />

and cleans the filter so it does not clog.<br />

DOL 256 Computer<br />

Each air cleaning module is equipped with<br />

a DOL 256 <strong>AirClean</strong> computer regulating<br />

the air cleaning process in this particular<br />

module. The decentralized control system<br />

ensures optimum cleaning of the individual<br />

section based on the actual requirement.<br />

The computer is very simple and the<br />

information level is confined to the data<br />

that the producer considers to be most<br />

important. On the computer display, the<br />

producer can see whether the controller<br />

is operative and the filter washer is active.<br />

The controller will show an overview of<br />

vital data such as water consumption,<br />

alarms and operation time. This data can<br />

also be shown in a 24-hour report or a<br />

year-to-date report.

Six BIO 2U modules installed next to a livestock house in Japan<br />

Module is lifted into position by a crane Module positioned in the attic<br />

Roofing completed and ventilation connected

kun er behov for en luftrenser med<br />

en kapacitet på ca. 10% af ventilationskapaciteten<br />

for at opnå en reduktion<br />

i ammoniakemissionen på 40%.<br />

Det svarer til det største reduktionskrav<br />

Partial gældende Cleaning for slagtesvinestalde<br />

med If the drænet pig producer gulv ved is required ansøgning to reduce om<br />

miljøgodkendelse the emission of ammonia, i 2009. partial Se tabel cleaning 2.<br />

Renseeffektiviteten could be an option. har dog en betydelig<br />

indflydelse, idet en luftvasker,<br />

der The kun largest kan reduction fjerne 50% of ammonia af ammoemisniakken,sion is achieved nødvendiggør in connection at ca. with 30% the<br />

af first ventilationskapaciteten 20% (0-20%) of the amount kan of ledes air<br />

gennem going through luftrenseren the air cleaner for at whereas opnå en<br />

tilsvarende the last 20% reduktion (80-100%) af do ammoniake-<br />

not add up to a<br />

missionen. huge environmental profit.<br />

henholdsvis høj og lav renseeffektivitet.<br />

Protect the Environment and save Money!<br />

Den SKOV største bases the renseeffekt air cleaning opnås on the step- ved<br />

rensning less outlet, af which op til is ca. running 20% in af a ventila- MultiStep<br />

tionskapaciteten, system. Then additional idet rensning outlets are af conen<br />

større nected andel to the kun air cleaner resulterer until i the en ammomarginalnia reduction reduktion required af ammoniakemissio-<br />

by the authorities<br />

nen. has been achieved.<br />

If partial cleaning is applied, the system is<br />

not dimensioned to clean all the outgoing<br />

air; but perhaps 30-40 percent of the<br />

maximum amount of air. The filters do not<br />

have to be so big and a smaller quantity of<br />

air has to be moved. This reduces the price<br />

of both the investment and the operation<br />

costs. Most of the ammonia will be removed<br />

in winter and only on very few days<br />

during the summer not all the outgoing<br />

air will be cleaned.<br />

Concentrate the Efforts<br />

SKOV plans the location of the air cleaning<br />

units by the livestock houses with the<br />

greatest ammonia and odour emission.<br />

This way the customer is protecting the<br />

environment as well as saving money. This<br />

would typically be finisher or farrowing<br />

sections with drained floors. The customer<br />

can get the best air cleaning effect per<br />

cubic metre of air.<br />

Figur 2. Reduktion af ammoniakemissionen som funktion af kapacitet for en luftrenser med<br />

Figur_3_og_4.xls / Alle_95_50%_20C 03-07-2007<br />

Reduction Reduktion of af NH NH3 NH emission, %<br />

3 % %<br />

3<br />

SKOV supply climate and production management systems for animal<br />

production the world over. Our solutions are technologically advanced,<br />

user friendly and individually adapted to meet the needs of our customers.<br />

SKOV A/S • Hedelund 4 • DK-7870 Roslev<br />

Tel. +45 72 17 55 55 • info@skov.com • www.skov.com<br />

620061-20080627 . Print: SKOV A/S<br />

100<br />

80<br />

60<br />

40<br />

20<br />

act innovate cooperate<br />

0<br />

Luftandel gennem renser, %<br />

Final concentration 1 ppm<br />

Slutkoncentration1ppm<br />

Slutkoncentration 2 ppm<br />

Final concentration 2 ppm<br />

0 20 40 60 80 100<br />

Proportion Luftandel of air gennem through renser, cleaner, % %<br />

1/3 drained_1ppm<br />

drænet_1ppm<br />

25-49%fast_1ppm<br />

25-49% solid_1ppm<br />

1/3 drained_2 drænet_2ppm ppm<br />

25-49%fast_2ppm<br />

25-49% solid_2 ppm<br />

Effect of a reduction of the ammonia emission of a proportion of air through an air<br />

Figur 3. Effekt på reduktion af ammoniakemission af luftandel gennem en luftrenser med<br />

slutkoncentration cleaner with a final på henholdsvis concentration 1 og of 2 1 ppm. and 2 ppm respectively. Source: Grøn Viden (Green<br />

Knowledge) no. 47: Partial cleaning of ammonia in livestock house air. Faculty of Agricultural<br />

Science.<br />

Figur_3_og_4.xls / Alle_1_2ppm 03-07-2007<br />

Climate for Growth