You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BIO Modul<br />

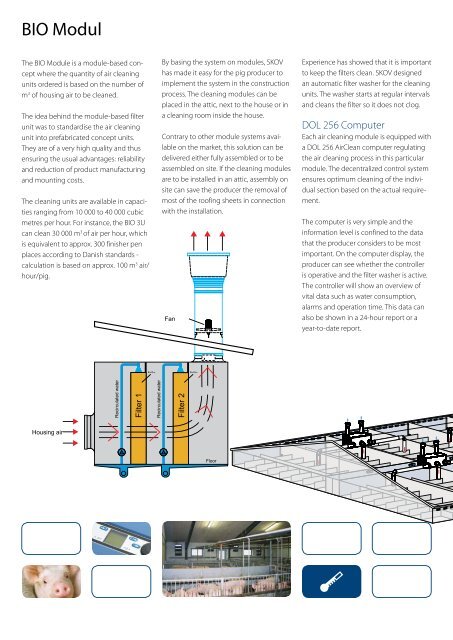

The BIO Module is a module-based concept<br />

where the quantity of air cleaning<br />

units ordered is based on the number of<br />

m 3 of housing air to be cleaned.<br />

The idea behind the module-based filter<br />

unit was to standardise the air cleaning<br />

unit into prefabricated concept units.<br />

They are of a very high quality and thus<br />

ensuring the usual advantages: reliability<br />

and reduction of product manufacturing<br />

and mounting costs.<br />

The cleaning units are available in capacities<br />

ranging from 10 000 to 40 000 cubic<br />

metres per hour. For instance, the BIO 3U<br />

can clean 30 000 m 3 of air per hour, which<br />

is equivalent to approx. 300 finisher pen<br />

places according to Danish standards -<br />

calculation is based on approx. 100 m 3 air/<br />

hour/pig.<br />

Housing air<br />

Recirculated water<br />

Filter 1<br />

Biofilm<br />

Recirculated water<br />

By basing the system on modules, SKOV<br />

has made it easy for the pig producer to<br />

implement the system in the construction<br />

process. The cleaning modules can be<br />

placed in the attic, next to the house or in<br />

a cleaning room inside the house.<br />

Contrary to other module systems available<br />

on the market, this solution can be<br />

delivered either fully assembled or to be<br />

assembled on site. If the cleaning modules<br />

are to be installed in an attic, assembly on<br />

site can save the producer the removal of<br />

most of the roofing sheets in connection<br />

with the installation.<br />

Fan<br />

Filter 2<br />

Biofilm<br />

Floor<br />

Experience has showed that it is important<br />

to keep the filters clean. SKOV designed<br />

an automatic filter washer for the cleaning<br />

units. The washer starts at regular intervals<br />

and cleans the filter so it does not clog.<br />

DOL 256 Computer<br />

Each air cleaning module is equipped with<br />

a DOL 256 <strong>AirClean</strong> computer regulating<br />

the air cleaning process in this particular<br />

module. The decentralized control system<br />

ensures optimum cleaning of the individual<br />

section based on the actual requirement.<br />

The computer is very simple and the<br />

information level is confined to the data<br />

that the producer considers to be most<br />

important. On the computer display, the<br />

producer can see whether the controller<br />

is operative and the filter washer is active.<br />

The controller will show an overview of<br />

vital data such as water consumption,<br />

alarms and operation time. This data can<br />

also be shown in a 24-hour report or a<br />

year-to-date report.