PET Recycling to Bottle - IDB Group Business Forum

PET Recycling to Bottle - IDB Group Business Forum

PET Recycling to Bottle - IDB Group Business Forum

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

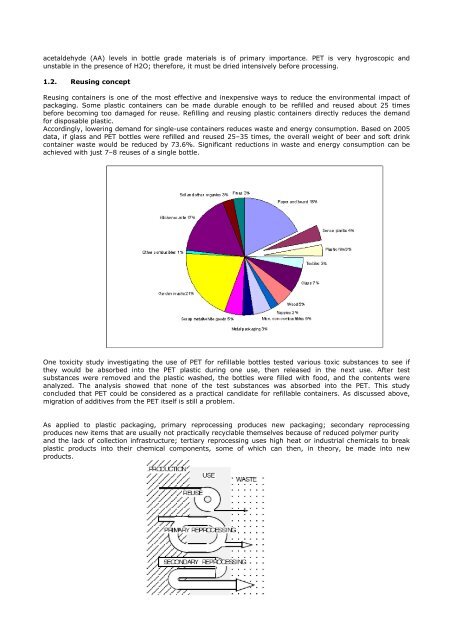

acetaldehyde (AA) levels in bottle grade materials is of primary importance. <strong>PET</strong> is very hygroscopic andunstable in the presence of H2O; therefore, it must be dried intensively before processing.1.2. Reusing conceptReusing containers is one of the most effective and inexpensive ways <strong>to</strong> reduce the environmental impact ofpackaging. Some plastic containers can be made durable enough <strong>to</strong> be refilled and reused about 25 timesbefore becoming <strong>to</strong>o damaged for reuse. Refilling and reusing plastic containers directly reduces the demandfor disposable plastic.Accordingly, lowering demand for single-use containers reduces waste and energy consumption. Based on 2005data, if glass and <strong>PET</strong> bottles were refilled and reused 25–35 times, the overall weight of beer and soft drinkcontainer waste would be reduced by 73.6%. Significant reductions in waste and energy consumption can beachieved with just 7–8 reuses of a single bottle.One <strong>to</strong>xicity study investigating the use of <strong>PET</strong> for refillable bottles tested various <strong>to</strong>xic substances <strong>to</strong> see ifthey would be absorbed in<strong>to</strong> the <strong>PET</strong> plastic during one use, then released in the next use. After testsubstances were removed and the plastic washed, the bottles were filled with food, and the contents wereanalyzed. The analysis showed that none of the test substances was absorbed in<strong>to</strong> the <strong>PET</strong>. This studyconcluded that <strong>PET</strong> could be considered as a practical candidate for refillable containers. As discussed above,migration of additives from the <strong>PET</strong> itself is still a problem.As applied <strong>to</strong> plastic packaging, primary reprocessing produces new packaging; secondary reprocessingproduces new items that are usually not practically recyclable themselves because of reduced polymer purityand the lack of collection infrastructure; tertiary reprocessing uses high heat or industrial chemicals <strong>to</strong> breakplastic products in<strong>to</strong> their chemical components, some of which can then, in theory, be made in<strong>to</strong> newproducts.