New Rulon Catalog

New Rulon Catalog

New Rulon Catalog

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

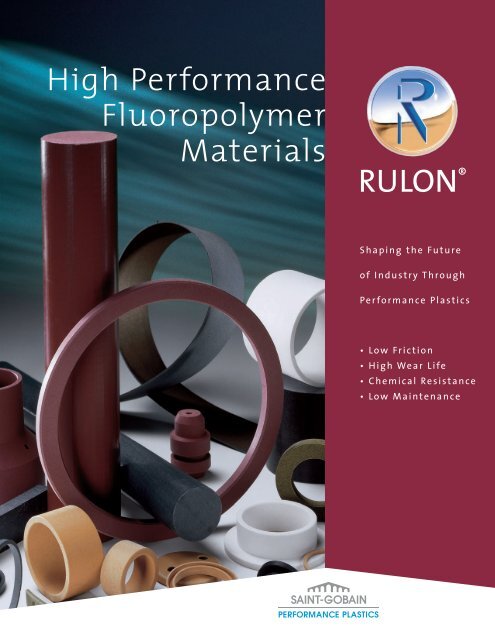

High PerformanceFluoropolymerMaterialsRULON ®Shaping the Futureof Industry ThroughPerformance Plastics• Low Friction• High Wear Life• Chemical Resistance• Low Maintenance

Saint-GobainGlossary of Materials/Saint-Gobain is a worldwide groupwhose history spans more than threecenturies.Created in 1665 in France, Saint-Gobain launched its first industrialDepartment with the production ofmirrors, which adorn the famous Hall ofMirrors at Versailles.Expansion beyond French bordersbegan in the middle of the 19thcentury. An international pioneer,Saint-Gobain established a glassfactory in Germany in 1857, another inItaly in 1889 and one in Belgium in1904. The group moved toward the<strong>New</strong> World in 1937 with the opening ofa plant in Brazil.Early DiversificationStrongly established in flat glassproduction, Saint-Gobain began lookingtoward other activities at thebeginning of the 20th century. Thecompany entered the papermakingbusiness in 1925, and the insulationbusiness in 1936.The 1970 addition of the companyPont-á-Mousson, the world leader incast iron pipes, reinforced Saint-Gobain’s position in the constructionmarket.Throughout the 1970’s and 80’s theSaint-Gobain Group continued topursue both internal and externalgrowth, which culminated with the1990 acquisition of Norton Company,one of the world’s leading abrasivesand ceramics manufacturers.Norton Performance Plastics in turnacquired Furon Company and createdthe new Saint-Gobain PerformancePlastics, combining decades ofexperience and leadership in metalbackedand polymer bearings andcomponents.The <strong>Rulon</strong>® trademark had beenacquired by Furon in the purchase ofDixon Industries Corporation, foundedin 1876 by Ezra Dixon, specializing inself-lubricating bearings for the thenemerging textile industry in thenortheastern United States.1• <strong>Rulon</strong> LR• <strong>Rulon</strong> J• <strong>Rulon</strong> 641• <strong>Rulon</strong> W2• <strong>Rulon</strong> 123• <strong>Rulon</strong> 488• <strong>Rulon</strong> 957• <strong>Rulon</strong> XL• <strong>Rulon</strong> F• <strong>Rulon</strong> 142• <strong>Rulon</strong> 945• <strong>Rulon</strong> 1045• <strong>Rulon</strong> 1337• <strong>Rulon</strong> 1410ProcessesMaroon material with low deformation characteristicsDull gold polymer-filled material for lower abrasion andsofter mating surfacesWhite FDA compliant material for most matingsurfacesExcellent for fresh water applicationsFDA compliant, low and consistent friction material formost mating surfacesInorganic filled material ideal for dry applications,compatible with most surfacesGreen speckled material, excellent bearing grade withnoise dampening capabilityTan, low friction material, suitable for aluminumsurfaces, with excellent outgassing capability foruse in vacuumGreen polymer-filled material with excellent antiabrasioncharacteristicsAqua colored low deformation material suitable forlinear bearings and slidesBlack very low deformation material suitable for highheat / impact applicationsDull gold colored high elongation and moderatedeformation material suitable for bearings,rings and sealsTan FDA compliant material with low frictionalcharacteristics and excellent chemical resistance formost mating surfacesGold colored material for use in high elongationapplications requiring good elongation• <strong>Rulon</strong> 1439 White FDA compliant material most suitable forsubmerged applications with low wearAutomatic MoldingExtrusionHand MoldingMachiningSkivingStamping / Forming• Custom bearings• Components, near-net• Rods & Tubes• Specialty Profiles• Rod, Sheet, and Tube• Custom Machined Parts• Tapes and Thin Sheet• Seals• Washers• Bearings & Glides

ProductsBearings:Sleeve, flanged, and thrust bearings are available in the standardmaterials, <strong>Rulon</strong> LR, J, and 641, through our distribution channels. Pleasecontact Saint-Gobain Performance Plastics customer service for thepreferred distributor in your area, or for other material options.Rings:Solid and split piston rings, featuring a full complement of jointconfigurations, can be manufactured to your custom specifications, orour applications engineers can work with you to design the optimalring for your needs. Please contact the main number and you will beconnected with the district sales manager for your area.Tapes:Most materials can be skived (shaved) into sheets using state of the artequipment. These can be etched for bonding to other materials, or usedas is in a wide assortment of applications where friction reduction isdesired. FDA - compliant materials can be used as non-stick coatingsurfaces for food preparation.Formed Parts:A wide assortment of cup seals is available, either hot-formed to hold aspecific shape, or cold-formed to retain the natural memory of thematerials. These produce a consistent hysteresis in dust sealingapplications, as well as precision electronic applications. Please contactthe main number and you will be connected with the district salesmanager for your area.Basic Shapes:Molded and extruded rods and tubes and molded sheets are available inmost of the materials. Please contact Saint-Gobain Performance Plasticscustomer service for the preferred distributor in your area.Wear Components:Wear components can take a variety of shapes and sizes, other thanthose described above. These can encompass things such as wear bands,pump bodies, and pistons for chemically and thermally demandingenvironments. These are usually manufactured to your specifications orSGPPL can assist you in the design. Please contact the main number andyou will be connected with the district sales manager for your area.Molded Up to 24 x 24"x3" thickTable ofContentsGlossary of Materials . . . . . . .1Products . . . . . . . . . . . . . . . . . .2Materials Selection Guide . . .3RULON LR . . . . . . . . . . . . . . . . . . . .4RULON J . . . . . . . . . . . . . . . . . . . . . .5RULON 641 . . . . . . . . . . . . . . . . . .6RULON W2 . . . . . . . . . . . . . . . . . . .7RULON 123 . . . . . . . . . . . . . . . . . . .8RULON 488 . . . . . . . . . . . . . . . . . .9RULON 957 . . . . . . . . . . . . . . . . . .10RULON XL . . . . . . . . . . . . . . . . . . .11RULON F . . . . . . . . . . . . . . . . . . . . .12RULON 142 . . . . . . . . . . . . . . . . . .13RULON 945 . . . . . . . . . . . . . . . . .14RULON 1045 . . . . . . . . . . . . . . . . .15RULON 1337 . . . . . . . . . . . . . . . . .16RULON 1410 . . . . . . . . . . . . . . . . .17RULON 1439 . . . . . . . . . . . . . . . .18<strong>Rulon</strong> Products . . . . . . . . . . . .19Application Inquiry Form . . .20Other SGPPL Products . . . . . .22Available ShapesExtruded - Up to 10 ft. longMolded - Up to 12 in. longExtruded - 3 in. Max. O. D.Molded - 47" Max.O.D.Precision grinding or machiningavailable for some sizesRod & TubeSheet & TapeTape - 38" width maximumSkived Up to 1/4" thickMolded Up to 24"x3" thickMax thickness 3”Precision grinding or machiningavailable on thicknessCustomContact district sales managerFull machining capabilities available2

Materials Selection Guide<strong>Rulon</strong> GradesPerformance*GradeColorMax Load"P" (psi)MPaMax Speed"V" (fpm)m/sMax "PV"(psi-fpm)(Mpa • m/s)Rb 25 & higherLR J 641 W2 123 488 957 XL F 142 945 1045 1337 1410 1439Maroon Gold White Black Black Turq. Green Tan Green Turq. Black Gold Tan Gold White1,000 750 1,000 1,000 1,000 1,000 1,000 1,200 1,000 1,000 1,000 1,000 1,000 750 1,0006.9 5.2 6.9 6.9 6.9 6.9 6.9 8.3 6.9 6.9 6.9 6.9 6.9 5.2 6.9400 400 400 400 400 400 400 400 400 400 400 400 400 400 4002.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.010,000 7,500 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 7,500 10,0000.35 0.26 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.26 0.35X X X X X X X X X X X XMating SurfaceSteel & Stainless SteelRc 35 & higherRc 50 & higherPainted metaland porcelainAluminumX X XX XXXFDA compliantX X X XSteamX X X X X X X X X X X XEnvironmentWetDryX X X X X X X X X X X X X XX X X X X X X X X X X X X X XVacuumX X X X X X X X X X X XRelative Rating1=Low, 5=HighComments3Coefficient offrictionCreepresistanceInsulative prop.Our Standard <strong>Rulon</strong> bearing grade.High Creep and Abrasion resistance4 1 1 2 2 3 2 1 2 2 4 1 1 1 34 3 4 4 4 4 4 4 4 5 5 2 2 2 4Yes Yes Yes No No Yes Yes Yes Yes No No Yes Yes Yes YesVery good operation in wetenvironments.Good thermal and electrostaticdissipation.Temperature (dry) oven bearings.Lowest Coefficient of Friction of<strong>Rulon</strong> series. Excellent insulator.Widely used in the food processindustry.Excellent abrasion resistance.Low friction/wear against coatedmetal or porcelain surfaces.The best <strong>Rulon</strong> against aluminumsurfaces.Standard tape liner material for<strong>Rulon</strong> composite bearings.Extensively used in machine toolguide ways.Extremely low deformation underload,and high impact resistance.The list above is only a partial list of available formulations of <strong>Rulon</strong>.P,V data may be exceeded based on specific application requirements. Ask to speak to a Saint-Gobain Application Engineer.RATINGS above are relative within <strong>Rulon</strong> family ONLY.For <strong>Rulon</strong> materials, coefficient of friction decreases with increasing load, and wear decreases with increasing surface hardness.For PTFE based materials, wear in steam and wet environments is higher than in dry environments.Saint-Gobain offers enhanced <strong>Rulon</strong> grades which minimize this effect.Most <strong>Rulon</strong> products have excellent chemical compatability. Data available upon request.FDA compliant;Excellent chemicalresistance.A standard material for compressorpiston flip seals.A standard material for compressorpiston flip seals.Ideal for submerged applications.

RULON ® LR ® LR<strong>Rulon</strong>® LR is a maroon colored bearingmaterial best known for its versatile designproperties./It is compatible with most hardened steelsubstrates. Mild steel is acceptable; harderrunning surfaces are better.<strong>Rulon</strong>® has a practically universal chemicalinertness. Of the chemicals encountered incommercial practice, only molten sodiumand fluorine, at elevated temperatures andpressures, show any signs of attack.For continuous non-lubricated service,RULON® LR sleeve bearings are capable ofoperating up to 10,000 PV. Higher values arepossible for intermittent service.Design Criteria<strong>Rulon</strong> LRTemperature - Typical Range ˚F (˚C )Maximum PV (continuous)(MPa+m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (min/um)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)*10,000 (0.35)*1,000 (6.9)*400 (2)*Rc358 - 24 (0.2-0.6)*Steel.15 - .250%Non-FlammableInert2.3Diameter 3.5x10 -5 (6.3)*Length 6.2x10 -5 (11.2)*Diameter 3.5x10 -5 (6.3)*Length 6.2x10 -5 (11.2)*135%2000 psi (13.8)*3%2.25Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Automotive• Insulators• Linear slides• Pipe supports• Wear bandsA more complete data sheet is available upon request.*Metric measurements in parentheses4

RULON ® JRULON ®J/<strong>Rulon</strong>® J is an all-polymeric reinforced, dullgold colored PTFE compound that operatesexceptionally well against soft matingsurfaces such as 316 stainless steel, aluminum,mild steel, brass and other plastics. The unique"shaft friendly" material is also low in frictionand wear and self-lubricating.<strong>Rulon</strong>® J has one of the lowest coefficients offriction of most reinforced PTFE materials. Thismakes it ideally suited for start/stopapplications where stick-slip must beeliminated. The tribological properties of thismaterial also make it suitable for both bearingand wear component applications.Design Criteria<strong>Rulon</strong> JTypical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Printers• Copiers• Air Compressors• Appliances• Automotive• Insulators• Linear slides• Anemometers• Wear bandsTemperature - Typical Range ˚F (˚C )Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)*7,500 (0.26)*750 (5.2)*400 (2)*Rb258 - 16 (0.2-0.4)*316 Stainless Steel andNon-Ferrous.12 - .200%Non-FlammableChart Available2.0Diameter 4.9x10 -5 (8.8)*Length 6.5x10 -5 (11.7)*Diameter 5.2x10 -5 (9.4)*Length 6.8x10 -5 (12.2)*180%2000 psi (13.8)*3%1.95A more complete data sheet is available upon request.*Metric measurements in parentheses5

RULON ® 641 ® 641<strong>Rulon</strong>® 641 is manufactured from FDAcompliant materials which possess excellentload and wear characteristics./It offers excellent, continuous non-lubricatedservice up to 10,000 PV - higher forintermittent service. While the load capacityof <strong>Rulon</strong> 641 is generally limited to 1,000 psiat room temperature, deformation is afunction of wall thickness, temperature andload.Its compatibility with a wide array of matingsurfaces, including mild steel, 303 and 316stainless steels, as well as harder materials,make it a good choice for most food andpharmaceutical bearing applications.Design Criteria<strong>Rulon</strong> 641Temperature - Typical Range ˚F (˚C )Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)*10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Mild, 303 & 316Stainless Steel.10 - .300%Non-FlammableInert2.6Diameter 3.9x10 -5 (7.0)*Length 4.9x10 -5 (8.8)*Diameter 4.2x10 -5 (7.6)*Length 5.7x10 -5 (10.3)*175%2000 psi (19.8)*4%2.25Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Chute Liners• Insulators• Linear slides• Shaft bearings• Wear bands• SealsA more complete data sheet is available upon request.*Metric measurements in parentheses6

RULON ® W2RULON ® W2/<strong>Rulon</strong>® W2 is a black PTFE-based materialdeveloped for use in fresh-water applications.It exhibits low friction and excellent wearcharacteristics (one of the lowest wear rates infresh water) as well as good thermaldissipation, preventing shaft distress. Itsproperties are enhanced when wet.<strong>Rulon</strong>® W2 is DWGV (European) certified forapplications in contact with drinking water.It is compatible with most metal substratesand soft mating surfaces. <strong>Rulon</strong> W2 is a goodalternative to <strong>Rulon</strong> J when superior chemicalresistance is needed. However, it should notbe used on very soft mating surfaces or whereelectrical insulation is desired.Design Criteria<strong>Rulon</strong> W2Typical Product andApplication DescriptionProducts• Automatically moldedbearings &components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Automotive• Fresh water submerged• Thrust bearings• Plating tanks• Wear bands• OvensTemperature - Typical Range ˚FMaximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+55010,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Hard, mild andstainless steels.15 - .300%Non-FlammableInert4.5Diameter 4.7x10 -5 (8.5)*Length 6.0x10 -5 (10.8)*Diameter 4.9x10 -5 (8.8)*Length 6.3x10 -5 (11.3)*70%1800 psi (12.4)*3%2.10A more complete data sheet is available upon request.*Metric measurements in parentheses7

RULON ® 123 ® 123<strong>Rulon</strong>® 123 is a glossy black non-abrasivecompound for softer mating surfaces, suchas stainless steel. This material has excellentchemical resistance and is FDA, USDA, andNSF compliant. It is less expensive than<strong>Rulon</strong> J, but is slightly less flexible and higherin wear./It has a high resistance to deformation, lowcoefficient of friction and good thermal andelectrostatic dissipation. This material has amaximum operating temperature of 550˚F(300˚C).<strong>Rulon</strong> 123 releases black wear debris overtime and should not be used in ultra-dry,vacuum applications, or where electricalinsulation is desired.Design Criteria<strong>Rulon</strong> 123Temperature - Typical Range ˚F (˚C )Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)*10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)Steel.10 - .300%Non-FlammableInert4.6Diameter 4.4x10 -5 (7.9)*Length 7.0x10 -5 (12.6)*150%2500 psi (17.2)*2.5%2.12A more complete data sheet is available upon request.*Metric measurements in parenthesesTypical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Automotive lip seals• Liners• Linear slides• Pipe supports• Wear bands• Dust seals8

RULONRULON ® ® 488/<strong>Rulon</strong>® 488 is a dull turquoise materialoriginally developed for use with paintedsurfaces. It has been used in veneer dryerbearings in the plywood industry.Its excellent wear resistance, especially inextremely dry environments, make it amaterial of choice in hydrogen and natural gascompressors. Its almost universal chemicalresistance enables it to withstand corrosivesand acids sometimes present in trace amountsin these environments.It has a higher load capacity than <strong>Rulon</strong>® J andbetter abrasion resistance than both <strong>Rulon</strong>® Jand <strong>Rulon</strong>® 123.Design Criteria<strong>Rulon</strong> 488Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Automotive• Insulators• Linear slides• Pipe support• Wear bandsTemperature - Typical Range ˚F (˚C )Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Hard, mild andstainless steels.10 - .300%Non-FlammableInert2.6Diameter 5.5x10 -5 (9.9)*Length 7.0x10 -5 (12.6)*Diameter 5.2x10 -5 (9.4)*Length 7.0x10 -5 (12.6)*175%2000 psi (13.8)*4%2.25A more complete data sheet is available upon request.*Metric measurements in parentheses9

RULON ® 957 ® 957<strong>Rulon</strong>® 957 is a speckled green material thatwas developed specifically for noisedampening and abrasion resistance, such asin commercial or residential clothes dryers./It provides low friction operation on softermating surfaces at higher loads than <strong>Rulon</strong>® J.This material also offers excellentperformance on coated metals, particularlyporcelain. Among its many benefits are anoverall reduction of the weight of the finishedproduct, vibration absorption, and costreduction due to rapid manufacturingmethods.Design Criteria<strong>Rulon</strong> 957Temperature - Typical Range ˚F (˚C )Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft/Mating MaterialEngineering InformationFriction - static & dynamic(Dynamic, 20 psi, 360 sfm)Water Absorption ASTM D570Flammability ASTM D635Chemical ResistanceLinear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)*10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)Hard, Mild and StainlessSteel and porcelain coated.15 - .250%Non-FlammableGoodDiameter 3.5x10 -5 (6.3)*Length 6.2x10 -5 (11.2)*200%2200 psi (15.2)*4%2.25Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped glides• Extruded shapes• Machined parts• Molded shapesApplications• Clothes Dryers• Mixers• Compressors• Ovens and Dryers• Automotive• Insulators• Linear slides• Sanders• Wear bandsA more complete data sheet is available upon request.*Metric measurements in parentheses10

RULON ®XLRULON ®XL/<strong>Rulon</strong>® XL is a tan colored material that is bestfor use against aluminum (including anodized)substrates. <strong>Rulon</strong>® XL exhibits very low wearas compared with other <strong>Rulon</strong>® grades.Other advantages offered by this uniquematerial are that it combines low deformationunder load with exceptionally good chemicalresistance.It is compatible with a wide range of matingsurfaces, but is not recommended for use withalkalis. Its non-abrasive character enhancesthe frictional performance to prevent gallingof softer mating surfaces.It is the best material for vacuum service.Design Criteria<strong>Rulon</strong> XLTypical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Vacuum Pumps• Mixers• Compressors• Appliances• Automotive• Insulators• Linear slides• Shaft support• Wear bandsTemperature - Typical Range ˚FMaximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicWater Absorption ASTM D570Flammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,200 (8.3)*400 (2)*Rb258 - 16 (0.2-0.4)*All Steels andaluminum.10 - .250%Non-FlammableInert1.7Diameter 6.4x10 -5 (11.5)*160%1700 psi (11.7)*1.4%1.97A more complete data sheet is available upon request.*Metric measurements in parentheses11

RULON ®/ RULON ® FF<strong>Rulon</strong>® F is a green material with excellentinsulating properties and superior abrasionresistance.It is used in a wide variety of wearcomponent and bearing applications, and iscurrently used as the liner in one of ourcomposite journal bearings (<strong>Rulon</strong>® FCJ).<strong>Rulon</strong>® F exhibits excellent wear resistance,especially in dry conditions. This materialsuitably slides against a wide range ofmating surfaces but is not recommended forcontact with strong bases or steam.Design Criteria<strong>Rulon</strong> FTemperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Stainless andHardened Steel.12 - .20Non-FlammableData AvailableA more complete data sheet is available upon request.*Metric measurements in parentheses2.6Diameter 3.5x10 -5 (6.3)*Length 6.2x10 -5 (11.2)*Diameter 3.6x10 -5 (6.4)*Length 7.0x10 -5 (12.6)*160%1200 psi (8.3)*3%1.89Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Clothes Dryers• Chute Liners• Compressors• Appliances• Automotive• Insulators• Linear slides• Pipe supports• Wear bands12

RULON ® 142RULON ® 142/<strong>Rulon</strong>® 142 is a specially formulated dull bluegreenlinear bearing material that exhibitslow wear, high thermal dissipation, and gooddimensional stability characteristics.Among its many benefits are the virtualelimination of stick-slip, vibrationdampening, self-lubrication, uniform friction,long life, ease of application and designdiversity.<strong>Rulon</strong>® 142 has excellent mechanicalproperties and is the ideal material formachine tool applications. Its lowdeformation characteristics limit the amountof misalignment that can occur with otherbearing materials.Strong acids and bases should be avoided, asthey may attack the fillers.Design Criteria<strong>Rulon</strong> 142Typical Product andApplication Description• PackingsProducts• Sleeve, flanged andthrust bearings• Piston Rings• Stamped parts• Extruded parts• Machined parts• Molded shapes• Wear Bands• Seal rings• LathesApplications• Gibs, guideways• Compressors• Appliances• Rotary tables• Motor mounts• Linear slides• Pipe supports• Hydraulic pressesTemperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum (continuous bonded)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*25,000 (0.88)*1000 (6.9)*400 (2)Rc358 - 16 (0.2-0.4)*Mild/HardenedSteel.0.25 with oilNon-FlammableNo acids or basesA more complete data sheet is available upon request.*Metric measurements in parentheses4.8Diameter 4.9x10 -5 (8.8)*Length 4.9x10 -5 (8.8)*200% mold direction3100 psi (21.4)*3%3.1613

RULON ® 945 ® 945<strong>Rulon</strong>® 945 is a black PTFE-based materialthat has very low wear and deformationunder load, making it ideally suited fordemanding thermal applications. In fact, itsdeformation is the lowest of all <strong>Rulon</strong>®grades. It also possesses excellentchemical resistance and good dimensionalstability./<strong>Rulon</strong>® 945 is best suited for use againsthard mating surfaces, like hardened steelsubstrates since it does have moderateabrasive qualities. It is not suitable inapplications where electrically insulatingproperties are required.Design Criteria<strong>Rulon</strong> 945Temperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Deformation (1500 psi - 24 hr. RT)(1500 psi - 24 hr.RT)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,000 (6.9)*400 (2)*Rc358 - 24 (0.2-0.6)*Steel.20-.35Non-FlammableExcellent4.8Diameter 7.1x10 -5 (12.8)*Length 2.8x10 -5 (5.0)*20%2000 psi (13.8)*0.7%1.4%1.90A more complete data sheet is available upon request.*Metric measurements in parenthesesTypical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Automotive• Insulators• Linear slides• Pipe supports• Wear bands14

RULONRULON ® ® 1045/<strong>Rulon</strong>® 1045 is a dull gold material that hasan excellent ability to elongate in a flip sealapplication. Coupled with excellent frictionalcharacteristics, it offers the added benefit ofenergy savings, as well as increased sealingefficiency.This material is also resistant to many harshchemicals found in the applicationenvironments where it is typically used. It isalso compatible with most commerciallyavailable lubricants for additional reductionin friction.Its low deformation properties allow it to beeffective as a bearing or sliding surface.Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston rings & flip seals• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• AC Compressors• Transmissions• Air Compressors• Appliances• Automotive• Linear slides• Fluid transfer systems• Vacuum Pumps• ValvesDesign Criteria<strong>Rulon</strong> 1045Temperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistanceLinear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Stainless toHardened SteelA more complete data sheet is available upon request.*Metric measurements in parentheses.10-.20Non-FlammableData availableDiameter 6.5x10 -5 (11.7)*Length 6.5x10 -5 (11.7)*450%3900 psi (26.9)*2.1115

RULO1337RULON ® <strong>Rulon</strong>® 1337 is a tan material made entirelyfrom FDA compliant components. It hasexcellent physical properties and ischemically compatible with most chemicals,except concentrated sulfuric acid. This offersmuch flexibility in wash-down environmentsof food and pharmaceutical processingenvironments./It has a slightly lower coefficient of frictionthan <strong>Rulon</strong> J, offering extended life and lessabrasion with softer mating surfaces.It is compatible with most commerciallyavailable natural lubricants for additionalreduction in friction.Design Criteria<strong>Rulon</strong> 1337Temperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient of (78˚-200˚F)Thermal Expansion (26˚ -93˚C)Physical DataElongation ASTM D638Tensile Strength ASTM D638 (MPa)Deformation (1500 psi - 24 hr. RT)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Stainless toHardened Steel.10-.20Non-FlammableVery GoodA more complete data sheet is available upon request.*Metric measurements in parentheses.2.3Diameter 6.1x10 -5 (11.0)*Length 7.4x10 -5 (13.3)*175%2500 psi (17.2)*3.38%2.11Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Pumps• Mixers• Compressors• Appliances• Chute liners• Insulators• Linear slides• Shaft bearings• Wear bands• Seals16

RULONRULON ® ® 1410/<strong>Rulon</strong>® 1410 is a gold material with excellentelongation and tensile strength suitable forflip seal and other flexible sealing applications.Coupled with low frictional characteristics, itoffers the added benefit of energy savingsand/or increased sealing efficiency.This material is also resistant to most harshchemicals. It is also compatible with manycommercially available lubricants foradditional reduction in torque.It can also be used as a liner material forsubstrates requiring any of the abovecharacteristics.Design Criteria<strong>Rulon</strong> 1410Typical Product andApplication DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston rings & flip seals• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• AC Compressors• Transmissions• Air Compressors• Appliances• Automotive• Linear slides• Fluid transfer systems• Vacuum pumps• ValvesTemperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistanceThermal ConductivityBTU/hr/sq. ft./˚F/in.Linear Coefficient ofThermal ExpansionPhysical Data(78˚-200˚F)(26˚ -93˚C)(78˚-300˚F)(26˚-149˚C)(78˚-500˚F)(26˚-260˚C)Elongation ASTM D638Tensile Strength ASTM D638(MPa)Specific Gravity-400/+550 (-240/288)7.500 (0.26)*750 (5.2)*400 (2)*Rb258 - 16 (0.2-0.4)*Stainless to HardenedSteel & cast iron.10 - .20Non-FlammableData AvailableA more complete data sheet is available upon request.*Metric measurements in parentheses1.8Diameter 7.1x10 -5 (12.8)*Length 7.1x10 -5 (12.8)*Diameter 7.5x10 -5 (13.5)*Length 7.5x10 -5 (13.5)*Diameter 8.6x10 -5 (15.5)*Length 8.6x10 -5 (15.5)*210%2150 psi (14.8)*2.2017

RULON ® 1439 ® 1439<strong>Rulon</strong>® 1439 is a white FDA compliantmaterial that is suitable for immersedservice with better wear characteristics thanmost other PTFE compounds. Its color makesit aesthetically pleasing for food andpharmaceutical applications./This material is also resistant to many harshchemicals found in the applicationenvironments where it is typically used. It iscompatible with most commerciallyavailable lubricants for additional reductionin friction.Its properties allow it to be effectivelyutilized as a bearing or sliding surface.Design Criteria<strong>Rulon</strong> 1439Temperature - Typical Range ˚F (˚C)Maximum PV (continuous)(MPa•m/s)Maximum P - psi (static)(MPa)Maximum V -SFM (no load)(m/s)Shaft Hardness - MinimumShaft finish recommended Ra (µ”/µm)Shaft MaterialEngineering InformationFriction - static & dynamicFlammability ASTM D635Chemical ResistancePhysical DataElongation ASTM D638Tensile Strength ASTM D638(MPa)Specific Gravity-400/+550 (-240/288)10,000 (0.35)*1,000 (6.9)*400 (2)*Rb258 - 16 (0.2-0.4)*Stainless toHardened Steel.15 - .25Non-FlammableGood190%1875 psi (12.9)*2.60A more complete data sheet is available upon request.*Metric measurements in parenthesesTypical Productand Application DescriptionProducts• Automatically moldedbearings & components• Sleeve, flanged andthrust bearings• Piston Rings• Stamped and formedseals• Extruded shapes• Machined parts• Molded shapesApplications• Transmissions• Air Compressors• Appliances• Pillow Blocks• Linear slides• Fluid transfer systems• Vacuum Pumps• Valves• Food ProcessingEquipment18

<strong>Rulon</strong> ®Products/Bearings• Wide range of Materials• Various mating surfaces• Food and pharmaceutical• Chemical resistance• Standard sizes availableApplications• Mixers• Pumps• Compressors• Ovens, ToastersPiston Cups & Flip Seals• Wide range of Materials• Various mating surfaces• Long life materials• Chemical resistance• Economical alternativeApplications• Fuel Metering Pumps• AC Compressors• Oxygen Compressors• Automotive Transmissions• Pneumatic ToolsFormed Seals• Low friction• Various surfacecompatability• Long life materials• Chemical resistance• Consistent hysteresisApplications• TPS shaft seals• Emmissions Controls• Dust Seals• Automotive• Medical PumpsPiston/Seal Rings• Molded or machined• Solid or custom joints• Long life materials• Chemical resistance• Low frictionApplications• Pumps• Transmissions• Face seals• Automotive• Medical PumpsWear Components• Low friction• Painted and plastic surfaces• Long life materials• Chemical resistance• High volume manufacturingApplications• Mixers• Pumps• Compressors• Ovens, Toasters19