Kick-off ceremony for Dillinger Hütte! - Siempelkamp

Kick-off ceremony for Dillinger Hütte! - Siempelkamp

Kick-off ceremony for Dillinger Hütte! - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

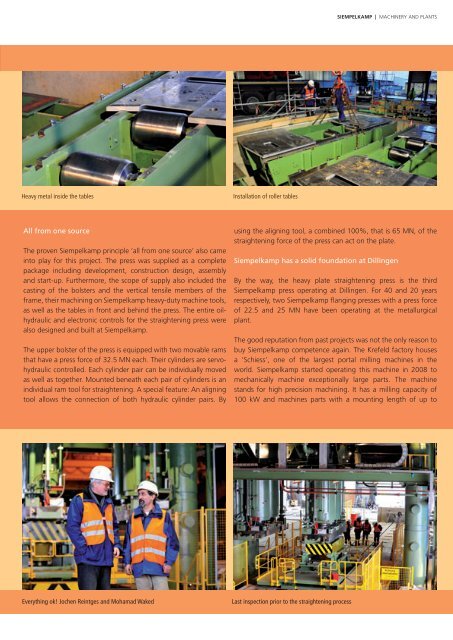

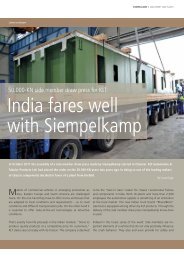

Heavy metal inside the tables Installation of roller tables<br />

All from one source<br />

The proven <strong>Siempelkamp</strong> principle ‘all from one source’ also came<br />

into play <strong>for</strong> this project. The press was supplied as a complete<br />

package including development, construction design, assembly<br />

and start-up. Furthermore, the scope of supply also included the<br />

casting of the bolsters and the vertical tensile members of the<br />

frame, their machining on <strong>Siempelkamp</strong> heavy-duty machine tools,<br />

as well as the tables in front and behind the press. The entire oilhydraulic<br />

and electronic controls <strong>for</strong> the straightening press were<br />

also designed and built at <strong>Siempelkamp</strong>.<br />

The upper bolster of the press is equipped with two movable rams<br />

that have a press <strong>for</strong>ce of 32.5 MN each. Their cylinders are servohydraulic<br />

controlled. Each cylinder pair can be individually moved<br />

as well as together. Mounted beneath each pair of cylinders is an<br />

individual ram tool <strong>for</strong> straightening. A special feature: An aligning<br />

tool allows the connection of both hydraulic cylinder pairs. By<br />

SIEMPELKAMP | MACHINERY AND PLANTS<br />

using the aligning tool, a combined 100%, that is 65 MN, of the<br />

straightening <strong>for</strong>ce of the press can act on the plate.<br />

<strong>Siempelkamp</strong> has a solid foundation at Dillingen<br />

By the way, the heavy plate straightening press is the third<br />

<strong>Siempelkamp</strong> press operating at Dillingen. For 40 and 20 years<br />

respectively, two <strong>Siempelkamp</strong> fl anging presses with a press <strong>for</strong>ce<br />

of 22.5 and 25 MN have been operating at the metallurgical<br />

plant.<br />

The good reputation from past projects was not the only reason to<br />

buy <strong>Siempelkamp</strong> competence again. The Krefeld factory houses<br />

a ‘Schiess’, one of the largest portal milling machines in the<br />

world. <strong>Siempelkamp</strong> started operating this machine in 2008 to<br />

mechanically machine exceptionally large parts. The machine<br />

stands <strong>for</strong> high precision machining. It has a milling capacity of<br />

100 kW and machines parts with a mounting length of up to<br />

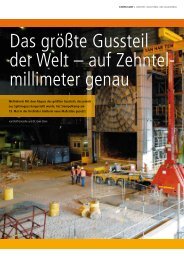

Everything ok! Jochen Reintges and Mohamad Waked Last inspection prior to the straightening process