Kick-off ceremony for Dillinger Hütte! - Siempelkamp

Kick-off ceremony for Dillinger Hütte! - Siempelkamp

Kick-off ceremony for Dillinger Hütte! - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

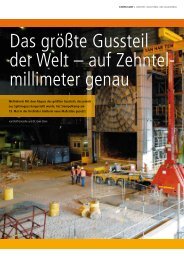

SIEMPELKAMP | MACHINERY AND PLANTS<br />

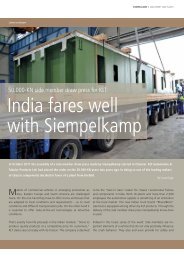

22,500 mm (74 ft), a width of up to 7,000 mm (23 ft), and a<br />

height of up to 6,000 mm (20 ft). This large-sized machine made<br />

the upper bolster <strong>for</strong> the press with a fi nal length of 9,783 mm<br />

(32 ft), a height of 3,300 mm (10.8 ft) and a weight of 250 t<br />

(275 US tons) almost look small.<br />

“Very satisfi ed!”<br />

With that much fi tting accuracy from the beginning on, it was no<br />

surprise that the assembly and start-up took place to the fullest<br />

satisfaction of the customer. “Very satisfi ed!” commented Werner<br />

Finkler from <strong>Dillinger</strong> <strong>Hütte</strong> on the new straightening press. His<br />

colleagues from the Krefeld team concluded: “The cooperation<br />

with our colleagues from the Saarland was outstanding. For all<br />

details and challenges that this order included, one thing proved to<br />

be true: Man is the best computer!”<br />

The hydraulic damping of the roller tables<br />

Werner Finkler and Jochen Reintges Straightening of the sheet plate<br />

48<br />

49<br />

Record project – record key data<br />

With the fi rst straightened plate on March 10, 2010,<br />

<strong>Dillinger</strong> <strong>Hütte</strong> AG celebrated an important milestone<br />

with the new straightening press. During production<br />

of the press in Krefeld, two important key dates were<br />

marked red in the calendar!<br />

May 19, 2009: For the upper bolster of the straightening press<br />

with a raw casting weight of 252 t (278 US tons), <strong>Siempelkamp</strong><br />

poured 270 t (297.6 US tons) of molten iron with a temperature<br />

of 1,350 °C (2,462 °F). This event outper<strong>for</strong>med the<br />

existing world record from 1998. Within two minutes the molten<br />

iron was poured from fi ve pouring ladles simultaneously into a<br />

mold. There, the iron solidifi ed and cooled. This procedure was<br />

not only record-breaking but it was also spectacular to watch.<br />

October 5, 2009: The fi nished upper bolster left <strong>for</strong> Saarland,<br />

Germany. On a heavy-duty vehicle it was transported to the<br />

Krefeld port. From there it went via a ship on the rivers Rhine,<br />

Mosel, and Saar directly to the factory port of <strong>Dillinger</strong> <strong>Hütte</strong>nwerke.