Spark Plugs

Spark Plugs

Spark Plugs

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

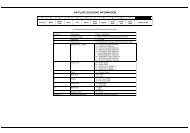

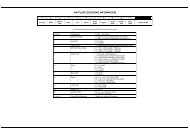

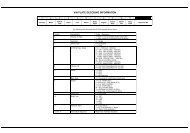

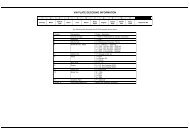

CONSTRUCTION FEATURES AND TERMINOLOGYCONSTRUCTION FEATURES AND TERMINOLOGY1 RIBSInsulator ribs provide added protection against spark or secondary voltage“flashover” and improve grip of rubber spark plug boot.2 INSULATORAluminum oxide ceramic with excellent dielectric strength, high mechanicalstrength, high thermal conductivity and excellent resistance to heat shock.Insulator is molded dry under extreme pressure, then kiln-fired to vitrification at atemperature exceeding the melting point of steel. The final insulator is dense,uniform and held to exacting tolerances.3 DECORATIONIdentifies brand name and spark plug type.4 HEXAGONUsually termed “hex.” Provides a contact for the socket wrench for removal andinstallation. Hex size is industry standard and is generally related to thread size.5 SHELLSteel shell is fabricated to exact tolerances by a cold-extrusion process. Sometypes use process bar stock.6 PLATED SHELL FINISHProvides added protection against rusting and corrosion. Improves appearance.7 ATTACHED GASKETFolded steel design simplifies installation and removal of plugs and maybe reused. The gasket seat provides a smooth surface against which thegasket seals.8 TAPER SEAT SHELLProvides close tolerance installation in cylinder heads that are designed for thisstyle of spark plug.9 PRECISION ROLLED THREADSConform to the specifications established by the SAE and the InternationalStandards Organization.10 REACHThe length of the shell thread area, which engages the engine cylinder headthreads. There are various “reaches” adopted as industry standards.11 THREAD DIAMETERMost common threads are metric. There are various sizes established asindustry standards. They are tailored to fit all domestic and overseas engines.A THREADED POSTWith removable terminal that has same configuration as solid terminal.Threaded post required for special spark plug cable connectors.B SOLID TERMINALFormed by a cold extrusion manufacturing process.C CEMENTApplied with automatic injection equipment. Solid terminal or threaded post istightened to specified torque. Cement is cured, providing a permanentgas-tight assembly.D RESISTOR SUPPRESSORCapsule element reduces electromagnetic Interference (EMI) inrecommended installations.E SPRINGUsed with resistor or suppressor to assure firm contact with terminalor center electrode.F INDUCTIVE SUPPRESSORHigh inductive reactance reduces EMI. Designed for use with certain fast riseCDI systems where resistance must be low.G SILLMENT SEALSCompacted powder seals formed under high pressure. Provide permanentassembly and eliminate troublesome leakage under all operating conditionsthroughout service life of the plug. Impervious to heat, oxidation or corrosion.H INSIDE GASKETProvides a “cushion seal” and good thermal contact between the insulator andshell. Some spark plug types have specially designed shells eliminating theinside gasket.I WIDE BASE INSULATORMore ceramic material provides a wider, easier path for heat dissipation. Allowsa longer insulator nose, which tolerates more residual deposits before fouling.J FINE WIRE ELECTRODESpecial alloys provide design features for easier starts and reduced fouling.K COPPER-CORED CENTER ELECTRODEPure copper encapsulated in nickel alloy transfers combustion heat rapidlyaway between firings. Results in spark plug designs with longer insulatornoses to combat fouling.8 7 616 1514 13EXTERNAL FEATURES512 11 10 94 312 EXTENDED GAPPositions the electrode gap for improved combustion in those engines thatrequire this spark plug type.13 PROJECTED INSULATOR NOSEPermits hotter operation at low speeds to resist fouling. Charge cooled at highspeeds to reduce temperature and electrode erosion.14 GROUND ELECTRODEFabricated from nickel alloys. The materials are developed to resist bothsparking erosion and chemical corrosion under normal and extreme operatingtemperature conditions. Rectangular cross section is utilized to provideincreased gap life.15 CENTER ELECTRODEFabricated from alloys. Designed to resist both sparking erosion and chemicalcorrosion under normal and extreme operation temperature conditions.16 ELECTRODE GAPAlso called “spark gap.” Precision set at the factory to meet the requirements formost engines.AGJCILINTERNAL FEATURESDKL FIRING END CEMENTCompound between the center electrode and the insulator nose may berequired for some spark plug designs. This special compound facilitates quicktransfer of heat through and away from the plug-firing end.M CLOSE CLEARANCE CENTER ELECTRODEThe use of tight tolerances for the electrode and insulator bore diameters canresult in close clearances between the insulator and electrode. These designsare used to facilitate quick transfer of heat away from the spark plug firing end.N SURFACE GAPArc occurs between center electrode and shell, across insulator surface.Used only with special CDI systems.O TUNGSTEN ALLOY ELECTRODEUsed for some surface gap type spark plugs.AEHM2BEN1CFO4