Spiralmate Sheet - Allstate Insulation

Spiralmate Sheet - Allstate Insulation

Spiralmate Sheet - Allstate Insulation

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

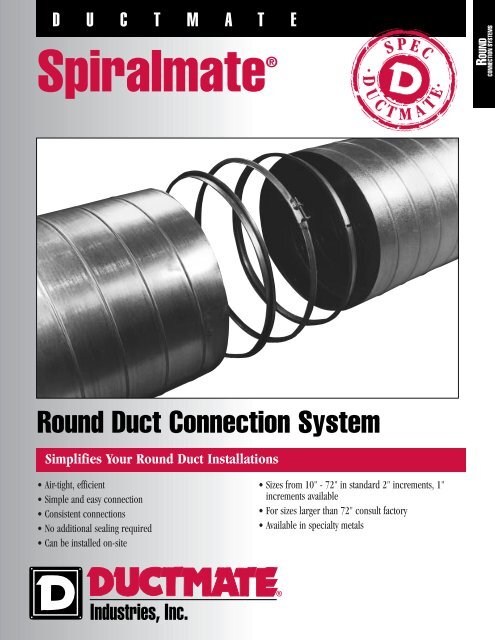

D U C T M A T EROUNDCONNECTION SYSTEMS<strong>Spiralmate</strong>®Round Duct Connection SystemSimplifies Your Round Duct Installations• Air-tight, efficient• Simple and easy connection• Consistent connections• No additional sealing required• Can be installed on-site• Sizes from 10" - 72" in standard 2" increments, 1"increments available• For sizes larger than 72" consult factory• Available in specialty metalsIndustries, Inc.®

<strong>Spiralmate</strong> ®DESCRIPTIONRound duct connection systemBASIC USEThe <strong>Spiralmate</strong> ® Round Duct Connector was developed toprovide a simple method of connecting sections of spiral roundduct work at a lower overall cost.SPECIAL CHARACTERISTICSThe <strong>Spiralmate</strong> ® Duct Connector System has been tested byProfessional Service Industries, Inc., a division of PittsburghTesting Laboratories, with test results as noted. No externalsealant was employed and the certified test results reveal virtuallyno leakage at up to 18" WG positive pressure or down to 10" WGnegative pressure.Complete test data is available on request.The <strong>Spiralmate</strong> ® Round Duct Connector is not recommended forapplications with duct gauges heavier than 16 GA. or lighter than28 GA.Width of pocket is sufficient to accommodate spiral lock.Flange Steel: hot dipped galvanized steelClosure Ring Steel: hot dipped galvanized steelMastic:DM5511MGasket:Ductmate 440 and Ductmate NeoprenePRODUCT GUARANTEERound DuctConnection SystemAll component parts of the <strong>Spiralmate</strong> ® System are guaranteedagainst defective material.PACKAGING INFORMATIONThe <strong>Spiralmate</strong> ® Round Duct Connector system consists of thefollowing components:a. Two mating Round Duct Connector Flanges with anintegral mastic in the duct receiving pocket.b. A Closure Ring roll-formed from hot dipped galvanizedsteel.STEEL Cold-formed, hot-dippedgalvanized.INNER RING FLANGESOne ring is attached to the end ofeach duct section to be mated.CLOSURE RING TighteningClosure Ring applies pressure tothe Inner Ring Flanges to lockthe duct joint into an airtight,permanent connection.DUCTWALLSEALANT A permanentnon-hardening mastic(DM5511M) is injectedinto the pocketduring manufacturing.GASKET DuctmateNeoprene Gasket isapplied to Flange facebefore joining ductsections.FASTENER Forms apermanent attachmentbetween duct and leg of<strong>Spiralmate</strong> Flange.

INSTALLATION INSTRUCTIONS1. Start inner ring(flange) by insertingduct end into flangepocket at the breakin the ring.5. The break in theflange will allow aportion of the leadingedge of the duct to bevisible.* Apply a shortpiece of Ductmate440 gasket to theflange face over thisvisible leading edgeon both matingflanges.2. Seat flangepermanently bypressing it so theleading edge of theduct is seated in thepocket of the flangeand penetrates thesealant.Hold flange inposition with visegripa few inchesfrom the break.6. Complete the gasketapplication byinstalling DuctmateNeoprene gasket onthe face of the flangearound the entirecircumference of oneof the mating flanges.3. Begin securing theleg of the flange tothe duct section byplacing a pop rivet,screw, or spot weldwithin 1/2" of the endof the flange break.The fastener shouldbe placed no closerthan 3/4" or furtherthan 1" from the faceof the flange.7. The end of the gasketshould butt up to thebeginning.4. Continue in the samedirection around theduct at evenly spacedintervals, as notedbelow left. Place thelast fastener within1/2" of the end of theflange ring.8. Slip outer closurering over end of duct.Align flanges using<strong>Spiralmate</strong> alignmentgrips.12" - 18" duct — 8" on center20" - 28" duct — 12" on center30" and larger duct — 18" on centerUsing the Ductmater orRepeater is optional butcan save time andincrease productconsistency.* Because most spiral duct is not true to size it may be necessary to cut alarger gap in the flange at the break. There must be a gap at the break.

9. Slide closure ringover mating flangesand insert bolt.11. A completed, airtight,roundtransverse ductjoint. Fast, neat andclean.10. Tighten the bolt onthe closure ringuntil it makes evencontact around thecircumference ofthe duct sections.Tap around jointwith hammer ifnecessary to seatflange whiletightening.IMPORTANT: On duct sizes 72" and larger consultfactory for additional assembly andinstallation information.Frequently a contractor installing a high velocity duct system will employ a duct joint withwhich either he or his work force have no experience. In such a case, it is stronglyrecommended that the contractor promptly test the initial 100 to 300 feet of duct beforeinstalling any more duct. This test will quickly reveal whether or not the workmen can makethis joint air-tight in an economical manner.Reprinted from SMACNA High Pressure Manual.Distributed By:Industries, Inc.E. MONONGAHELA, PAR.D. #3, Box 113 (Route 136)E. Monongahela, PA 15063-9709800-245-3188412-258-0500FAX: 412-258-5494LODI, CA810 S. Cluff AvenueLodi, CA 95240-3141800-344-3270209-333-4680FAX: 209-333-4678®69/11-96