KOMET KUB K2⢠Replaceable head drill for tiny ... - Power-Tools

KOMET KUB K2⢠Replaceable head drill for tiny ... - Power-Tools

KOMET KUB K2⢠Replaceable head drill for tiny ... - Power-Tools

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

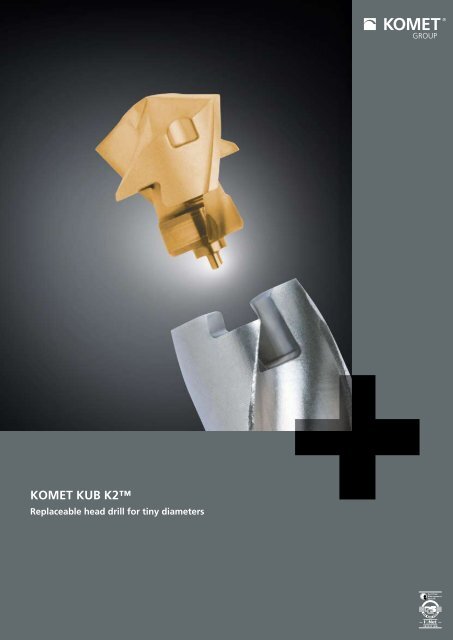

<strong>KOMET</strong> <strong>KUB</strong> K2<strong>Replaceable</strong> <strong>head</strong> <strong>drill</strong> <strong>for</strong> <strong>tiny</strong> diameters

<strong>KOMET</strong> <strong>KUB</strong> K2<strong>Replaceable</strong> <strong>head</strong> <strong>drill</strong> <strong>for</strong> <strong>tiny</strong> diametersApplications:- For diameter range 8 to 18.9 mm- Suitable <strong>for</strong> use with steel, cast metal, aluminiumand stainless materials- <strong>Replaceable</strong> <strong>head</strong> system enables use with a widevariety of sections and coatings.Benefits <strong>for</strong> you:Easy replacement of the carbide <strong>drill</strong> <strong>head</strong>seven in the machine, with secure, user-friendly quick-change connectorMaximum per<strong>for</strong>mance and best possible feedwith the latest coatings and high-end polished sectionsOutstanding tension release propertieswith all materials, due to optimum surface quality of the cutting channelsMaximum per<strong>for</strong>mance and life of the main <strong>drill</strong> bodydue to a special surface treatment<strong>KOMET</strong> <strong>KUB</strong> K2 replaceable <strong>head</strong> <strong>drill</strong>With this new replaceable <strong>head</strong> system <strong>for</strong> thedouble-cutting <strong>KUB</strong> K2 TM , <strong>KOMET</strong> has introduced aningenious system of replaceable <strong>drill</strong> <strong>head</strong>s.The double-cutting carbide <strong>drill</strong> <strong>head</strong>s have a patentedself-fixing and self-centring attachment point makingthem very easy to change.These now also make the most of the economic andflexibility advantages of replaceable cutting <strong>head</strong>swith small <strong>drill</strong>ing diameters up to 8 mm.

<strong>KOMET</strong> <strong>KUB</strong> K2Ø 12,0 – 15,8 mm<strong>Replaceable</strong> <strong>head</strong> <strong>drill</strong> (replaceable <strong>head</strong>/basic body) with cylindrical shank ISO 9677, R.H. cuttinglLNxdxD140°<strong>Replaceable</strong> <strong>head</strong> Basic body Accessories<strong>for</strong>Multi-keyCoatingworkpiece material3×D 5×D 7×DxD Order No. P M K N S H Order No. d×l L NOrder No.Article8,0 .Expanded versionExpandedExpanded.versionversion12,0 H70 12000.01.... 0,006BK842512,3 H70 12300.01.... 0,006BK272512,4 H70 12400.01.... 0,00612,5 H70 12500.01.... 0,007 BK842512,8 H70 12800.01.... 0,007 BK272513,0 H70 13000.01.... 0,008BK842513,5 H70 13500.01.... 0,008BK272513,8 H70 13800.01 .... 0,00814,0 H70 14000.01 .... 0,01014,3 H70 14300.01 .... 0,01014,4 H70 14400.01 .... 0,01014,5 H70 14500.01 .... 0,01014,8 H70 14800.01 .... 0,01015,0 H70 15000.01.... 0,012BK842515,5 H70 15500.01 .... 0,012BK272515,8 H70 15800.01 .... 0,012§ § U55 31200§§ 0,10§ § U55 31250§§ 0,10§ § U55 31300§§ 0,11BK8425 § § U55 31400BK2725 §§ 0,12§ § U55 31500§§ 0,1316×48 93 6516×48 93 6516×48 99 7016×48 106 7516×48 111 80L05 10020size 2.18,9Expanded versionSupply includes: Please order replaceable <strong>head</strong>, basic body and multi-key separatelyOrder No.ShankDrilling depthDrilling rangePatented design (<strong>KUB</strong> K2 TM )

<strong>KOMET</strong> <strong>KUB</strong> K2Fitting the replaceable <strong>head</strong>11 Insert and remove the replaceable <strong>head</strong> atthe attachment point.2 Turn the replaceable <strong>head</strong> manually until itslots into the attachment point.3 Fit the multi-key over theassembly notch. Turn thereplaceable <strong>head</strong>. In thisposition, the requiredtorque is increased, asthe replaceable <strong>head</strong> isscrewed in position.344 Turn the replaceable<strong>head</strong> until it stops.55 Fully fitted replaceable <strong>head</strong>.The multi-key is also used to remove the replaceable <strong>head</strong>. In order to ensure a secure fit, the main body shouldbe fixed in place when screwing the <strong>head</strong> in or out.

<strong>KOMET</strong> <strong>KUB</strong> K2Guideline values <strong>for</strong> solid <strong>drill</strong>ing<strong>KUB</strong> K2 TM 5×DCutting speedvc (m/min)Feedf (mm/U)Material groupStrengthRm (N/mm2)Hardness HBMaterialExample material code/DINminBK8425opt.maxminBK2725opt.maxx8–11,9 x12–14,9 x16–18,9minopt.maxminopt.maxminopt.max1.0 # 500non-alloy steelsSt37-2/1.00379SMn28/1.0715St44-2/1.0044901101300,150,200,252.0500-900non-alloy /low alloy steelsSt52-2 / 1.0050C55 / 1.052516MnCr5 / 1.7131801001200,150,200,25P2.1 < 500 lead alloys9SMnPb28 / 1.0718801001200,200,250,303.0 > 900non alloy / low alloy steels:heat resostant structural, heattreated, nitride and tools steels42CrMo4 / 1.7225CK60 / 1.122170901100,200,250,304.0 > 900high alloy steelsX6CrMo4 / 1.2341X165CrMoV12/1.26015070900,150,200,25M6.0 # 6006.1 < 9007.0 > 9008.0 180stainless steelsstainless steelsstainless / fireproof steelsgray cast ironX2CrNi189 / 1.4306X5CrNiMo1810/1.4401X8CrNb17/1.4511X10CrNiMoTi1810/1.4571X10CrAl7 / 1.4713X8CrS-38-18/1.4862GG-25/0.6025GG-35/0.60357090110504030706050908070Expanded version0,20 0,16 0,18 0,150,30 0,18 0,20 0,200,40 0,20 0,22 0,25Expanded version8.1 250 alloy gray cast ironGG-NiCr202 / 0.666060801000,200,300,40spheroidal graphite cast iron,9.0 # 600 130 ferriticGGG-40 / 0.704060801000,250,350,45K9.1 230spheroidal graphite cast iron,ferritic/perliticGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.80555070900,250,350,4510.0 > 600 250spheroidal graphite cast iron,perliticmalleable ironGGG-60 / 0.7060GTS-65 / 0.81655070900,250,350,45alloyed spheroidal graphite10.1 200 cast ironGGG-NiCr20-2 /0.76613050700,200,250,3510.2 300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,24060800,250,350,45Note: The application details shown depend on the environmental and application conditions (e.g. machine, ambient temperature,use of lubricant/coolant and the machining result required). These are subject to correct operating conditions, correctapplication and compliance with the spindle speed limits given <strong>for</strong> the tools.

<strong>KOMET</strong> <strong>KUB</strong> K2Application examplesStationary applicationin a cyclically-controlled latheRotating applicationin a machining centreMaterial: 42CrMo4vc = 90 m/minf = 0,22 mm/revMaterial: 1.4571, V4Avc = 70 m/minf = 0,2 mm/revRecommendations1.Coolant- internal coolant supply min. 5 bar2.Rotating application- max. concentricity in rotating application 0,05 mm3.Stationary application- max. offset in stationary application 0,025 mm4.For through holes, blind holes and stack plate <strong>drill</strong>ing

Germany<strong>KOMET</strong> GROUP GmbHZeppelinstraße 374354 BesigheimTel. +49(0)7143.373-0Fax +49(0)7143.373-233info@kometgroup.comGermany<strong>KOMET</strong> Precision <strong>Tools</strong> GmbH & Co. KGZeppelinstraße 374354 BesigheimTel. +49(0)7143.373-0Fax +49(0)7143.373-233info@kometgroup.comGermany<strong>KOMET</strong> JEL Precision <strong>Tools</strong> GmbH & Co. KGRuppmannstraße 3270565 Stuttgart / VaihingenTel. +49(0)711.78891-0Fax +49(0)711.78891-11info@kometgroup.comBrazilKomet do Brasil Ltda.Rua Brasileira, 43907043-010 Guarulhos - São PauloTel. +55(0)11.6423-5502Fax +55(0)11.6422-0069info.br@kometgroup.comChina<strong>KOMET</strong> GROUPPrecision <strong>Tools</strong> (Taicang) Co., Ltd.(Headquarter Asia Pacific)No. 5 Schaeffler RoadTaicang, Jiangsu Province, 215400Tel. +86(0)512.535757-58Fax +86(0)512.535757-59info.cn@kometgroup.comFrance<strong>KOMET</strong> S.à.r.l.46-48 Chemin de la BruyèreB.P. 4769572 Dardilly CEDEXTel. +33(0) 4 37 46 09 00Fax +33(0) 4 78 35 36 57info.fr@kometgroup.comGreat Britain India Italy<strong>KOMET</strong> (UK) Ltd.Unit 4 Triton ParkBrownsover RoadSwift ValleyRugby, CV21 1SGTel. +44(0)1788.5797-89Fax +44(0)1788.5797-90info.uk@kometgroup.com<strong>KOMET</strong> Precision <strong>Tools</strong> India Pvt. Ltd.121/B, Bommasandra Industrial AreaBANGALORE - 560 099Tel. +91-80-27834821Fax +91-80-27834495info.in@kometgroup.com<strong>KOMET</strong> Utensili S.R.L.Via Menotti Serrati 7420098 S. Giuliano Mil.Tel. +39-02-98 40 28 1Fax +39-02-98 44 96 2info.it@kometgroup.comJapan Mexico Austria<strong>KOMET</strong> GROUP KK2202-1 Ooyama Komaki city485-0026 AichiTel. +81(0)568-74-7331Fax +81(0)568-74-7332info.jp@kometgroup.com<strong>KOMET</strong> de MexicoS. de R. L. de C.VAcceso „A“, No. 110Parque Industrial Jurica,76120,Queretaro,Qro.MexicoTel. +52-442 2-18-25-44Fax +52-442 2-18-20-77info.mx@kometgroup.com<strong>KOMET</strong> GROUP GmbHWagramer Straße 1731220 WienTel. +43-1-2 59 22-04+43-1-2 59 22-12Fax +43-1-2 59 22 12-76info.at@kometgroup.comPoland<strong>KOMET</strong>-URPOL Sp.z.o.o.ul. Stoczniowców 247-200 Kdzierzyn-KoleTel. +48-77-482 90 60Fax +48-77-406 10 70info.pl@kometgroup.comRussia<strong>KOMET</strong> GROUP GmbHul. Spartakovskaya, 2V420107, KazanTel. +7 843 5704345Fax +7 843 2917543info.ru@kometgroup.comSwedenSquare <strong>Tools</strong> ABBox 917720039 MalmöTel. +46-40-49 28 40Fax +46-40-49 19 95info.se@kometgroup.comSwitzerland<strong>KOMET</strong> Dihart AG Precision <strong>Tools</strong>Industriestrasse 24657 DullikenTel. +41(0)62.2854-200Fax +41(0)62.2854-202info.ch@kometgroup.comCzech Republic<strong>KOMET</strong> GROUP CZ s.r.o.Na Hůrce 1041/2,160 00 Praha 6Tel. +42(0)2 35 01 00 10Fax +42(0)2 35 31 18 90info.cz@kometgroup.comUSA<strong>KOMET</strong> of America, Inc.2050 Mitchell Blvd.SchaumburgIL 60193-4544Tel. +1-8 47-9 23 / 84 00+1-8 47-9 23 / 84 80Fax +1-8 00-8 65 / 66 38customerservice@komet.compresented by:www.kometgroup.com399 01 991 30-2T-09/08 Printed in Germany · © 2008 <strong>KOMET</strong> Precision <strong>Tools</strong> GmbH & Co. KG · We reserve the right to make modifications.