Design innovations of the Cochlear™ Baha® BP100 Sound Processor

Design innovations of the Cochlear™ Baha® BP100 Sound Processor

Design innovations of the Cochlear™ Baha® BP100 Sound Processor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Design</strong> <strong>innovations</strong> <strong>of</strong> <strong>the</strong><br />

Cochlear <br />

Baha ® <strong>BP100</strong> <strong>Sound</strong> <strong>Processor</strong><br />

Mats Dotevall, Director <strong>of</strong> <strong>Design</strong> & Development at Cochlear Bone Anchored Solutions, Go<strong>the</strong>nburg, Sweden<br />

ABSTRACT<br />

The Cochlear Baha ® <strong>BP100</strong> <strong>Sound</strong> <strong>Processor</strong> is a result <strong>of</strong> new thinking within <strong>the</strong> bone<br />

conduction hearing industry. The design is based on <strong>the</strong> results <strong>of</strong> a comprehensive international<br />

study <strong>of</strong> Baha user and Baha pr<strong>of</strong>essional needs. The <strong>BP100</strong> introduces a range<br />

<strong>of</strong> unique design <strong>innovations</strong> and utilises new technology never before available in bone<br />

conduction hearing implants. This paper presents Cochlear’s objectives when designing <strong>the</strong><br />

<strong>BP100</strong> and how <strong>the</strong>se design choices meet <strong>the</strong> needs <strong>of</strong> Baha users.<br />

INTRODUCTION<br />

Before setting out to create <strong>the</strong> Baha <strong>BP100</strong>, Cochlear identified <strong>the</strong><br />

needs <strong>of</strong> Baha users and pr<strong>of</strong>essionals. Hearing performance was<br />

indicated as <strong>the</strong> number one requirement and with 25% improved<br />

speech understanding in noise1-6 <strong>the</strong> <strong>BP100</strong> is <strong>the</strong> benchmark for<br />

hearing performance in bone conduction. But our comprehensive study<br />

highlighted o<strong>the</strong>r requirements that are vitally important to Baha<br />

users and Baha pr<strong>of</strong>essionals. The design objectives were clear: provide<br />

industry leading usability and functionality with design features that<br />

deliver real benefits to our customer and produce a reliable product<br />

that performs in demanding wea<strong>the</strong>r conditions and challenging<br />

environments. These key objectives were <strong>the</strong>n broken down into<br />

micro-goals, which when combined, formed <strong>the</strong> basis for a robust and<br />

innovative new design that meets <strong>the</strong> stringent criteria. This paper<br />

describes <strong>the</strong> challenges we faced, and <strong>the</strong> design solutions that we<br />

presented in <strong>the</strong> Cochlear Baha <strong>BP100</strong>.<br />

DURABILITY & PERFORMANCE<br />

Baha users and pr<strong>of</strong>essionals clearly stated that <strong>the</strong> reliability <strong>of</strong><br />

<strong>the</strong> processor was important to <strong>the</strong>m. One <strong>of</strong> <strong>the</strong> main causes <strong>of</strong><br />

malfunction in conventional bone conduction sound processors<br />

is exposure to moisture and dust that causes breakdown <strong>of</strong> <strong>the</strong><br />

transducer, microphones or electrical components. A device should<br />

withstand exposure to high humidity, dirt, brief exposure to rain<br />

or water spill. Despite such exposure <strong>the</strong> device must function<br />

consistently.<br />

The challenge <strong>of</strong> creating system reliability is that a sound<br />

processor must allow air flow to reach <strong>the</strong> batteries and sound waves<br />

to reach <strong>the</strong> microphones. This open system needs to be maintained<br />

as well as reconsidered and redesigned to deliver a tight seal without<br />

compromise to <strong>the</strong> performance goals.<br />

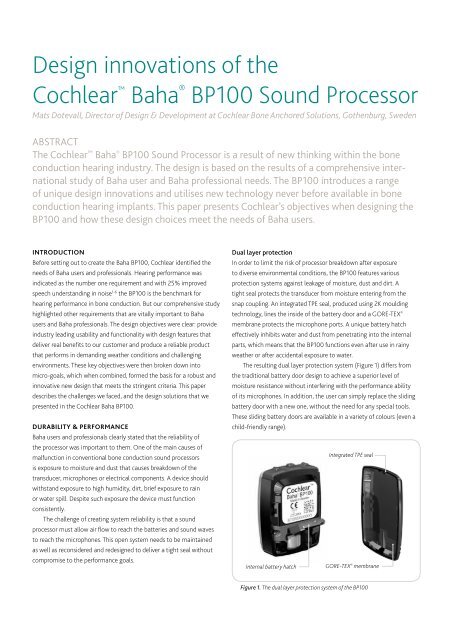

Dual layer protection<br />

In order to limit <strong>the</strong> risk <strong>of</strong> processor breakdown after exposure<br />

to diverse environmental conditions, <strong>the</strong> <strong>BP100</strong> features various<br />

protection systems against leakage <strong>of</strong> moisture, dust and dirt. A<br />

tight seal protects <strong>the</strong> transducer from moisture entering from <strong>the</strong><br />

snap coupling. An integrated TPE seal, produced using 2K moulding<br />

technology, lines <strong>the</strong> inside <strong>of</strong> <strong>the</strong> battery door and a GORE-TEX ®<br />

membrane protects <strong>the</strong> microphone ports. A unique battery hatch<br />

effectively inhibits water and dust from penetrating into <strong>the</strong> internal<br />

parts, which means that <strong>the</strong> <strong>BP100</strong> functions even after use in rainy<br />

wea<strong>the</strong>r or after accidental exposure to water.<br />

The resulting dual layer protection system (Figure 1) differs from<br />

<strong>the</strong> traditional battery door design to achieve a superior level <strong>of</strong><br />

moisture resistance without interfering with <strong>the</strong> performance ability<br />

<strong>of</strong> its microphones. In addition, <strong>the</strong> user can simply replace <strong>the</strong> sliding<br />

battery door with a new one, without <strong>the</strong> need for any special tools.<br />

These sliding battery doors are available in a variety <strong>of</strong> colours (even a<br />

child-friendly range).<br />

Internal battery hatch<br />

Integrated TPE seal<br />

GORE-TEX ® membrane<br />

Figure 1. The dual layer protection system <strong>of</strong> <strong>the</strong> <strong>BP100</strong>

Moisture resistant<br />

To evaluate moisture resistance, we subjected <strong>the</strong> <strong>BP100</strong> to rigorous<br />

testing (Figure 2). A splash test was conducted by exposing sound<br />

processors to water sprayed from different directions at a rate <strong>of</strong> three<br />

litres per minute. The results were conclusive. None <strong>of</strong> <strong>the</strong> tested sound<br />

processors showed any signs <strong>of</strong> leakage <strong>of</strong> water into <strong>the</strong> battery cavity,<br />

nor was any water found inside <strong>the</strong> shell. All processors functioned<br />

correctly and showed no degradation <strong>of</strong> performance. In practice, this<br />

means that <strong>the</strong> <strong>BP100</strong> could be worn if a child was to inadvertently<br />

run through a sprinkler or spend a short period <strong>of</strong> time in <strong>the</strong> rain. The<br />

overall design <strong>innovations</strong> preventing water from entering <strong>the</strong> sound<br />

processor makes <strong>the</strong> <strong>BP100</strong> moisture resistant.<br />

Figure 2. Splash testing <strong>of</strong> <strong>the</strong> <strong>BP100</strong><br />

Wind noise protection<br />

The <strong>BP100</strong> is acoustically transparent and allows sound waves to pass<br />

through to <strong>the</strong> microphones without distortion. The wind-resistant<br />

quality <strong>of</strong> <strong>the</strong> GORE-TEX ® membrane has significantly improved<br />

performance in wind noise compared to <strong>the</strong> Baha Divino ® . To measure<br />

<strong>the</strong> processor’s performance in wind, we took it to <strong>the</strong> wind testing<br />

facility at Chalmers University <strong>of</strong> Technology in Go<strong>the</strong>nburg, Sweden<br />

(Figure 3). The geometry <strong>of</strong> <strong>the</strong> battery door and <strong>the</strong> GORE-TEX ®<br />

membrane was found to have a very positive effect on reducing wind<br />

noise, providing a reduction <strong>of</strong> approximately 5dB compared with <strong>the</strong><br />

Baha Divino.<br />

Figure 3. Wind tunnel at Chalmers University <strong>of</strong> Technology<br />

Transducer stability<br />

We identified transducer failure as one <strong>of</strong> <strong>the</strong> most important factors<br />

impacting processor reliability. At <strong>the</strong> core <strong>of</strong> <strong>the</strong> Baha sound processor,<br />

<strong>the</strong> transducer creates <strong>the</strong> vibrations that transfer sound through <strong>the</strong><br />

skull bone to <strong>the</strong> inner ear. It is a very precise component with <strong>the</strong> air<br />

gap inside <strong>the</strong> vibrator measuring roughly <strong>the</strong> width <strong>of</strong> a hair (50-70<br />

micrometres). The allowed tolerance <strong>of</strong> <strong>the</strong> mechanical components<br />

are smaller still, at only a few micrometres <strong>the</strong>y are less than 1/10 <strong>the</strong><br />

width <strong>of</strong> a hair. As such, <strong>the</strong> transducer is sensitive to excessive force<br />

that could result in its collapse.<br />

To ensure a functioning sound processor <strong>the</strong> <strong>BP100</strong> transducer<br />

was redesigned to improve stability. We reengineered <strong>the</strong> transducer<br />

suspension and integrated new mechanical stops in <strong>the</strong> snap coupling.<br />

The changes prevent excessive movement in ei<strong>the</strong>r direction thus<br />

protecting <strong>the</strong> transducer and reducing <strong>the</strong> risk for collapse (Figure 4).<br />

The <strong>BP100</strong> also utilises <strong>the</strong> latest surface technology, with a diamond<br />

embedded alloy washer used in <strong>the</strong> vibrator that increases friction and<br />

stability.<br />

Figure 4. The transducer suspension and mechanical stops<br />

Titanium foundation<br />

The <strong>BP100</strong> is built on a strong titanium foundation that protects<br />

it against damage. Not only is titanium a light weight, strong and<br />

stable material perfect for platform manufacturing, it has <strong>the</strong> unique<br />

properties <strong>of</strong> being human-friendly and sympa<strong>the</strong>tic to <strong>the</strong> skin,<br />

making it a standard material for medical implants. We use <strong>the</strong> latest<br />

Metal Injection Molding (MIM) technology that allows us to create <strong>the</strong><br />

unique shape and tolerances required in <strong>the</strong> <strong>BP100</strong> design.<br />

We put <strong>the</strong> <strong>BP100</strong> through a series <strong>of</strong> tests to prove that <strong>the</strong> new processor<br />

would provide reliable hearing performance despite repeated exposure to rough<br />

treatment. In total we used 18 different reliability tests: temperature cycling,<br />

damp heat, low temperature, high temperature, temperature shock, atmospheric<br />

pressure, drop (Figure 5), vibration, ingress <strong>of</strong> water, sweat and humidity, EMC<br />

compatibility, ESD immunity, volume control function, switch on/<strong>of</strong>f function,<br />

program change function, snap function, battery change cycles and connector<br />

system. The results showed that <strong>the</strong> <strong>BP100</strong> stands up well to use, even in challenging<br />

environments.<br />

Figure 5. Drop rig top and drop rig bottom.<br />

USABILITY & FUNCTIONALITY<br />

Tactile buttons<br />

To get <strong>the</strong> best performance out <strong>of</strong> an advanced sound processor like<br />

<strong>the</strong> <strong>BP100</strong>, <strong>the</strong> user must be able to make controlled adjustments to<br />

its settings. We designed our tactile buttons to allow precise changes<br />

in volume and program settings. The auditory and visual indicators<br />

confirm changes in program settings so that <strong>the</strong> user and pr<strong>of</strong>essional<br />

are always fully aware <strong>of</strong> <strong>the</strong> processor settings. While fine tuning <strong>of</strong><br />

<strong>the</strong> device can be performed using <strong>the</strong> Cochlear Baha Fitting S<strong>of</strong>tware,<br />

<strong>the</strong> creation <strong>of</strong> <strong>the</strong> tactile button interface allows pr<strong>of</strong>essionals to make<br />

adjustments to <strong>the</strong> device without using a computer.<br />

In addition, <strong>the</strong> tactile buttons are integrated into <strong>the</strong> moisture<br />

resistant design. To keep water and dust out <strong>of</strong> <strong>the</strong> processor <strong>the</strong>y are<br />

constructed from a composite material that is fully integrated with <strong>the</strong><br />

housing. Traditional devices use a rotary volume control wheel, where<br />

experience has shown that <strong>the</strong>se wheels catch dirt and debris and may<br />

be a contributing factor in processor breakdown.<br />

One device for use on both sides<br />

In undertaking our comprehensive study we not only considered <strong>the</strong><br />

needs <strong>of</strong> our users but we also engaged with hearing care pr<strong>of</strong>essionals.<br />

The design goals <strong>of</strong> <strong>the</strong> <strong>BP100</strong> were to maximise <strong>the</strong> usability from<br />

<strong>the</strong> pr<strong>of</strong>essional’s perspective. Conventional bone conduction sound<br />

processors are asymmetrical devices. With <strong>the</strong> introduction <strong>of</strong> a<br />

symmetrical <strong>BP100</strong> (can be used on both <strong>the</strong> left and right side <strong>of</strong> <strong>the</strong><br />

head) we aimed to streamline logistics to bring down real costs for<br />

clinics by reducing stock requirements and by increasing <strong>the</strong> flexibility<br />

for hearing care pr<strong>of</strong>essionals when treating patients.<br />

Universal accessories<br />

The design <strong>of</strong> <strong>the</strong> <strong>BP100</strong> includes a Europlug in order to be compatible<br />

with all accessories and mainstream solutions. By combining <strong>the</strong><br />

Europlug with <strong>the</strong> plug for <strong>the</strong> Cochlear Baha Fitting S<strong>of</strong>tware, we<br />

were able to provide multiple functions in <strong>the</strong> same space. The<br />

Europlug is compatible with industry leading FM systems for classroom<br />

applications and Direct Audio Input (DAI) for phones, MP3 players and<br />

o<strong>the</strong>r audio sources.<br />

Secure snap coupling<br />

The Baha snap coupling connects to <strong>the</strong> inside <strong>of</strong> <strong>the</strong> abutment. This<br />

unique design provides a secure connection with <strong>the</strong> abutment and<br />

ensures optimal transfer <strong>of</strong> vibrations from <strong>the</strong> processor to <strong>the</strong> implant<br />

(Figure 6). Importantly, by connecting to <strong>the</strong> inside <strong>of</strong> <strong>the</strong> abutment, it<br />

reduces <strong>the</strong> risk <strong>of</strong> disturbance to <strong>the</strong> s<strong>of</strong>t tissue. The contact between<br />

sound processor and <strong>the</strong> skin may be an issue that results in revision<br />

surgery. The design <strong>of</strong> <strong>the</strong> <strong>BP100</strong> eliminates <strong>the</strong> risk <strong>of</strong> abutment to skin<br />

contact in normal use.<br />

Figure 6. The snap coupling and abutment<br />

Parental confidence<br />

Children are an important group <strong>of</strong> users for <strong>the</strong> <strong>BP100</strong> whose needs<br />

(along with <strong>the</strong> needs <strong>of</strong> parents and caregivers) dictate specific<br />

design requirements. Parents, teachers and caregivers want a simple<br />

way to monitor <strong>the</strong> status and settings <strong>of</strong> <strong>the</strong> processor. As a safety<br />

requirement, tamper-pro<strong>of</strong> functions are a must. To facilitate<br />

monitoring <strong>the</strong> functionality <strong>of</strong> <strong>the</strong> device, we engineered LEDs that<br />

clearly show if <strong>the</strong> device is on or <strong>of</strong>f, for which side (left or right) <strong>the</strong><br />

device is programmed, <strong>the</strong> status <strong>of</strong> <strong>the</strong> battery, <strong>the</strong> listening settings<br />

and more. We use advanced automated laser engraving technology to<br />

allow <strong>the</strong> LEDs to be visible through <strong>the</strong> protective colour lacquering<br />

<strong>of</strong> <strong>the</strong> front lid (Figure 7). In addition, <strong>the</strong>re are audible indicators<br />

built into <strong>the</strong> device to let parents know that <strong>the</strong> sound processor is<br />

functioning correctly and <strong>the</strong> child is hearing with <strong>the</strong> device.<br />

Figure 7. Light Emitting Diods (LED) on <strong>the</strong> <strong>BP100</strong>

Additional safety measures<br />

Additional safety features reinforce <strong>the</strong> paediatric focus <strong>of</strong> <strong>the</strong> design.<br />

A keylock function is enabled by pressing a combination <strong>of</strong> <strong>the</strong> tactile<br />

buttons, which means that a child cannot inadvertently change <strong>the</strong><br />

settings <strong>of</strong> <strong>the</strong> device. Using an optional tamper-pro<strong>of</strong> battery door,<br />

which contains a small lock that requires a tool to open, prevents a<br />

child from accidentally opening <strong>the</strong> sound processor or exposing <strong>the</strong><br />

battery. An additional secure line can be attached to <strong>the</strong> bottom <strong>of</strong> <strong>the</strong><br />

<strong>BP100</strong> to prevent <strong>the</strong> device from being damaged or lost should it fall<br />

from a child’s Baha S<strong>of</strong>tband or be knocked <strong>of</strong>f <strong>the</strong> implant.<br />

SUMMARY<br />

Based on test results, and already with more than 5,000 users<br />

worldwide, <strong>the</strong> <strong>BP100</strong> meets <strong>the</strong> design objectives <strong>of</strong> <strong>the</strong> third<br />

generation <strong>of</strong> Baha sound processors. By undertaking a comprehensive<br />

international study we have identified <strong>the</strong> needs <strong>of</strong> Baha users and<br />

Baha pr<strong>of</strong>essionals. They want performance, and we created a sound<br />

processor that truly sets a new benchmark in hearing performance.<br />

They want industry leading usability and functionality in a reliable<br />

shell. We revised every component <strong>of</strong> <strong>the</strong> Baha sound processor to<br />

introduce a design that was innovative, with countless new features and<br />

improvements as described in this paper. The <strong>BP100</strong> is both a userfriendly<br />

and flexible solution and leads <strong>the</strong> way in <strong>the</strong> bone conduction<br />

hearing industry.<br />

Manufacturer:<br />

Cochlear Bone Anchored Solutions AB Konstruktionsvägen 14, SE-435 33 Mölnlycke, Sweden Tel: +46 31 792 44 00 Fax: +46 31 792 46 95<br />

Regional <strong>of</strong>fices:<br />

Cochlear Americas 13059 E. Peakview Avenue, Centennial, CO 80111, USA Tel: +1 303 790 9010 Fax: +1 303 792 9025<br />

Cochlear AG European Headquarters, Peter Merian-Weg 4, CH-4052 Basel, Switzerland Tel: +41 61 205 0404 Fax: +41 61 205 0405<br />

Cochlear Ltd (ABN 96 002 618 073) 14 Mars Road, Lane Cove NSW 2066, Australia Tel: +61 2 9428 6555 Fax: +61 2 9428 6352<br />

www.cochlear.com<br />

GORE-TEX is a registered trademark <strong>of</strong> W.L. Gore & Associates.<br />

Baha and Baha Divino are registered trademarks, and Baha Intenso is a trademark <strong>of</strong> Cochlear Bone Anchored Solutions AB.<br />

Cochlear and <strong>the</strong> elliptical logo are trademarks <strong>of</strong> Cochlear Limited.<br />

© 2010 Cochlear Bone Anchored Solutions.JUL10. Printed in Sweden. E81839A<br />

References<br />

1. Davison T, Leese D, Marley S, Johnson IJ (2009). Clinical impressions <strong>of</strong> a new Bone<br />

Anchored Hearing Aid processor. Presented at 2nd International symposium on bone<br />

conduction hearing - crani<strong>of</strong>acial osseointegration; 11-13 June; Go<strong>the</strong>nburg, Sweden.<br />

2. Wong T, Yu J, Soo G, Van Hasselt A. (2009). Comparison <strong>of</strong> hearing performance<br />

between <strong>the</strong> Cochlear Baha <strong>BP100</strong> and Baha Compact in subjects with mixed hearing<br />

loss; Presented at 7th Asia Pacific Symposium on Cochlear Implants and Related<br />

Sciences; 1-4 December, Singapore.<br />

3. Wong T, Yu J, Soo G, Van Hasselt A. (2009). Will <strong>the</strong> new fully programmable sound<br />

processor Cochlear Baha <strong>BP100</strong> provide additional benefits to subjects with conductive<br />

hearing loss and single-sided sensorineural deafness?; Paper presented at 7th Asia<br />

Pacific Symposium on Cochlear Implants and Related Sciences; 1-4 December,<br />

Singapore.<br />

4. Kompis, M. & Pfiffner, F. (2010). A prospective comparative study <strong>of</strong> Baha <strong>BP100</strong> and<br />

Baha Divino. Paper presented at CI 2010; 30 June-3 July, Stockholm, Sweden.<br />

5. Flynn, M., Sadeghi, A. & Halvarsson, G. (2009). Results <strong>of</strong> <strong>the</strong> first clinical evaluation <strong>of</strong><br />

Cochlear Baha <strong>BP100</strong>, white paper; Cochlear Bone Anchored Solutions, Go<strong>the</strong>nburg,<br />

Sweden, E81511.<br />

6. Hällgren M., Larsby B. & Arlinger S. (2006). A Swedish version <strong>of</strong> <strong>the</strong> Hearing In Noise<br />

Test (HINT) for measurement <strong>of</strong> speech recognition. International Journal <strong>of</strong><br />

Audiology;45:227-37.