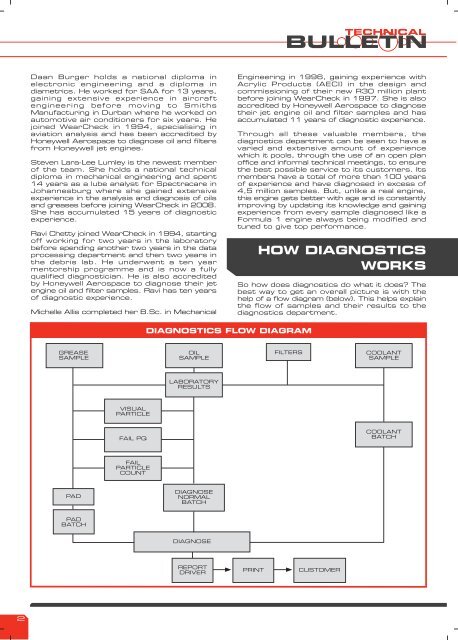

Daan Burger holds a national diploma inelectronic engineering and a diploma indiametrics. He worked for SAA for 13 years,gaining extensive experience in aircraftengineering before moving to SmithsManufacturing in Durban where he worked onautomotive air conditioners for six years. Hejoined <strong>WearCheck</strong> in 1994, specialising inaviation analysis and has been accredited byHoneywell Aerospace to diagnose oil and filtersfrom Honeywell jet engines.Steven Lara-Lee Lumley is the newest memberof the team. She holds a national technicaldiploma in mechanical engineering and spent14 years as a lube analyst for Spectracare inJohannesburg where she gained extensiveexperience in the analysis and diagnosis of oilsand greases before joining <strong>WearCheck</strong> in 2008.She has accumulated 15 years of diagnosticexperience.Ravi Chetty joined <strong>WearCheck</strong> in 1994, startingoff working for two years in the laboratorybefore spending another two years in the dataprocessing department and then two years inthe debris lab. He underwent a ten yearmentorship programme and is now a fullyqualified diagnostician. He is also accreditedby Honeywell Aerospace to diagnose their jetengine oil and filter samples. Ravi has ten yearsof diagnostic experience.Michelle Allis completed her B.Sc. in MechanicalEngineering in 1996, gaining experience withAcrylic Products (AECI) in the design andcommissioning of their new R30 million plantbefore joining <strong>WearCheck</strong> in 1997. She is alsoaccredited by Honeywell Aerospace to diagnosetheir jet engine oil and filter samples and hasaccumulated 11 years of diagnostic experience.Through all these valuable members, thediagnostics department can be seen to have avaried and extensive amount of experiencewhich it pools, through the use of an open planoffice and informal technical meetings, to ensurethe best possible service to its customers. Itsmembers have a total of more than 100 yearsof experience and have diagnosed in excess of4,5 million samples. But, unlike a real engine,this engine gets better with age and is constantlyimproving by updating its knowledge and gainingexperience from every sample diagnosed like aFormula 1 engine always being modified andtuned to give top performance.HOW DIAGNOSTICSWORKSSo how does diagnostics do what it does? Thebest way to get an overall picture is with thehelp of a flow diagram (below). This helps explainthe flow of samples and their results to thediagnostics department.DIAGNOSTICS FLOW DIAGRAMGREASESAMPLEOILSAMPLEFILTERSCOOLANTSAMPLELABORATORYRESULTSVISUALPARTICLEFAIL PQCOOLANTBATCHFAILPARTICLECOUNTPADDIAGNOSENORMALBATCHPADBATCHDIAGNOSEREPORTDRIVERPRINTCUSTOMER2

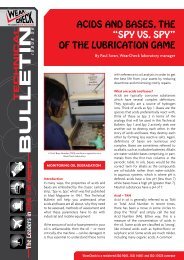

WEARCHECK SAMPLE TURNAROUND TIME:AUGUST 2008 – JULY 200924 HOURS48 HOURS102% SAMPLES DIAGNOSED WITHIN 24/48 HOURS OF THE SAMPLE ARRIVING AT THE LABORATORY10098% SAMPLES9694929088AUG 08 SEP 08 OCT 08 NOV 08 DEC 08 JAN 09 FEB 09 MAR 09 APR 09 MAY 09 JUN 09 JUL 09MONTH<strong>WearCheck</strong> analyses coolant, oil, grease andfilter samples. Many different types of filtersamples are analysed namely aircraft,automotive, industrial and marine filters. Allexcept aircraft samples are analysed anddiagnosed by any of the diagnosticians in thedepartment for wear debris and contaminationlevels. Aircraft filters are analysed and diagnosedby the three diagnosticians who have beentrained and accredited to do this, i.e. RaviChetty, Michelle Allis and Daan Burger. Theaircraft section is run as a separate, specialisedsection of diagnostics with Daan Burger in thepilot seat.Oil, coolant and grease samples all go into thelaboratory and receive various laboratory resultsdepending on the component the sample isfrom. Each sample is given a test class, e.g.coolant, grease or oil. The oil test class canbe broadly broken down into engines, clean oilsystems (such as hydraulics) or drivetrains(such as gearboxes). This test class determineswhat tests are carried out on the sample.These sample results are then married to theinformation provided by the customer and withany prior history held on the database. Thenthey go through to the diagnostics departmentfor their expert opinion and to be given adiagnosis, which is inserted into the finalcustomer report.The diagnostics department divides the samplesinto what it calls “batches” for easy to handlechunks of work. There are three types ofbatches: normal batches, pad batches andcoolant batches. Each diagnostician can thendiagnose a smaller batch. The samples arearranged in these smaller batches in alphabeticalorder using first the customer name, then thevehicle name, keeping customer and vehiclesamples together for diagnosis consistency.Samples that have been in the laboratory thelongest are diagnosed first as quick turnaroundtime is crucial. Over 90% of all samples arediagnosed within four hours of the results beingmade available to the department.Normal batches are samples that have gonethrough the laboratory with no flagged “out oflimit” or “abnormal” results that require themto have a debris pad done on them. They arediagnosed by any of the diagnosticians as andwhen they are ready and the results appear onthe computer system. As they do not havedebris pads done on them, they are normallythe quickest and easiest samples to diagnosewith the most normal results.Pad batches (samples with debris or filtergramanalysis) consist of all samples that have haddebris filter pads performed on them. Eachtest class has a cut-off limit for PQ (ParticleQuantifier Index) and particle count. Once thetest result exceeds this limit the sample is sentfor a filter debris pad to be carried out on itso that the diagnostician can look at the debrispad and ascertain the cause of the higher thannormal PQ or particle count. All grease sampleshave two debris pads, one for magnetic weardebris and one for non-magnetic contaminants.Every debris pad done in the laboratory has anumber of images taken of it: one of the entirepad, and a whole range of magnified images at20 times magnification, of which thediagnostician can choose up to three to sendto the customer.All samples with debris pads carried out onthem will accumulate in a large batch in thecomputer system until the diagnosticsdepartment splits them into smaller batchesaccording to the number of diagnosticiansavailable to diagnose them. It is important tonote that diagnosticians do not spend all day,every day, diagnosing samples; there are manyother tasks that the department carries out.Once this is done the pad batches are assembledand the laboratory staff bring the debris padsthrough to the diagnostics department, witheach diagnostician receiving one pad batch ofanywhere from 5 to 50 samples depending onthe amount of pad samples requiring diagnosisat the time.3