Download PDF - WearCheck

Download PDF - WearCheck

Download PDF - WearCheck

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

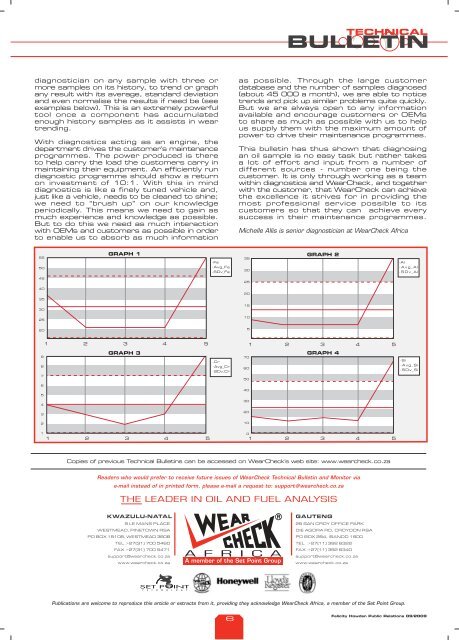

diagnostician on any sample with three ormore samples on its history, to trend or graphany result with its average, standard deviationand even normalise the results if need be (seeexamples below). This is an extremely powerfultool once a component has accumulatedenough history samples as it assists in weartrending.With diagnostics acting as an engine, thedepartment drives the customer’s maintenanceprogrammes. The power produced is thereto help carry the load the customers carry inmaintaining their equipment. An efficiently rundiagnostic programme should show a returnon investment of 10:1. With this in minddiagnostics is like a finely tuned vehicle and,just like a vehicle, needs to be cleaned to shine;we need to “brush up” on our knowledgeperiodically. This means we need to gain asmuch experience and knowledge as possible.But to do this we need as much interactionwith OEMs and customers as possible in orderto enable us to absorb as much informationas possible. Through the large customerdatabase and the number of samples diagnosed(about 45 000 a month), we are able to noticetrends and pick up similar problems quite quickly.But we are always open to any informationavailable and encourage customers or OEMsto share as much as possible with us to helpus supply them with the maximum amount ofpower to drive their maintenance programmes.This bulletin has thus shown that diagnosingan oil sample is no easy task but rather takesa lot of effort and input from a number ofdifferent sources - number one being thecustomer. It is only through working as a teamwithin diagnostics and <strong>WearCheck</strong>, and togetherwith the customer, that <strong>WearCheck</strong> can achievethe excellence it strives for in providing themost professional service possible to itscustomers so that they can achieve everysuccess in their maintenance programmes.Michelle Allis is senior diagnostician at <strong>WearCheck</strong> Africa5550GRAPH 1-Fe-Avg_Fe-SDv_Fe3530GRAPH 2-Al- Avg_Al- SDv_Al4525402035153025102059871 2 3 4 51 2 3 4 5GRAPH 3 GRAPH 4-Cr-Avg_Cr-SDv_Cr706050-Si- Avg_Si-SDv_Si654340302021011 2 3 4 501 2 3 4 5Copies of previous Technical Bulletins can be accessed on <strong>WearCheck</strong>’s web site: www.wearcheck.co.zaReaders who would prefer to receive future issues of <strong>WearCheck</strong> Technical Bulletin and Monitor viae-mail instead of in printed form, please e-mail a request to: support@wearcheck.co.zaTHE LEADER IN OIL AND FUEL ANALYSISA member of the Set Point GroupPublications are welcome to reproduce this article or extracts from it, providing they acknowledge <strong>WearCheck</strong> Africa, a member of the Set Point Group.6Felicity Howden Public Relations 09/2009