Process Safety - Parengg.com

Process Safety - Parengg.com

Process Safety - Parengg.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

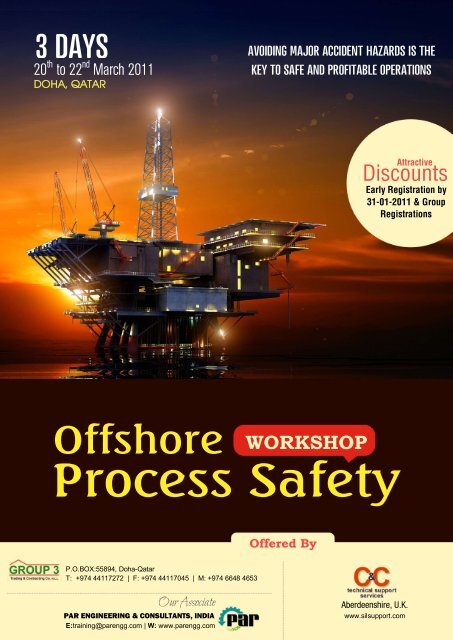

3 DAYS20 th to 22 nd March 2011DOHA, QATARAVOIDING MAJOR ACCIDENT HAZARDS IS THEKEY TO SAFE AND PROFITABLE OPERATIONSAttractiveDiscountsEarly Registration by31-01-2011 & GroupRegistrationsOffshore WORKSHOP<strong>Process</strong> <strong>Safety</strong>Offered ByP.O.BOX:55894, Doha-QatarT: +974 44117272 | F: +974 44117045 | M: +974 6648 4653Our AssociatePAR ENGINEERING & CONSULTANTS, INDIAE:training@parengg.<strong>com</strong> | W: www.parengg.<strong>com</strong>Aberdeenshire, U.K.www.silsupport.<strong>com</strong>

3 days workshop with many practicalmethods, case studies and examples basedon UK Offshore Regulations and experience inWest Africa, Australia and Middle East.CAPITALISE ON THE EXPERT KNOWLEDGE ANDEXPERIENCE TO AVOID MAJOR ACCIDENT HAZARDSAND MAINTAIN SAFE AND PROFITABLE OPERATIONSBY UNDERSTANDING:· Design criteria for subsea and surface shutdown levels· Structuring the requirements for subsea flow line protection· Production well shutdown and protection systems· Structuring hierarchical shutdown levels: Total Platform Shutdown (TPS)Emergency Shutdown levels (ESD)· Structuring the requirements for topsides Surface <strong>Process</strong> Shutdown (SPS)· Assurance of appropriate TPS, ESD and SPS designs· What constitutes a HIPS or HIPPS· The typical generics arrangements for subsea HIPPS· Primary and secondary protective functions· Preventative and mitigating protective systems· Fire and gas systems and their contribution to risk reduction in the offshoreenvironment· How to identify process and operational hazards and the principles ofhazard and operability (HAZOP) studies· What represents risk and how to assess safety, asset and environmental risks· The requirements of <strong>Safety</strong> Management Systems and avoiding improvementnotices and enforced shutdown by the Regulator· The concepts and differences between qualitative and quantitative riskassessment (QRA) methods and when and how to apply them· The concept of reducing risks to as low as reasonably possible (ALARP)· Setting tolerable risk targets for safety, your asset and the environment andmethods to achieve these targets· How to set up, use and apply the most popular risk assessment methodssuch as risk graphs, risk matrices and layers of protection analysis (LOPA)· The principles of fault tree analysis (FTA) and how to model protectivesystems using this technique· The principles and concepts of the internationally agreed standards IEC61508 and IEC 61511 for safety instrumented systems· Learning how to design safety instrumented systems for protecting againstprocess related hazards· Performing basic design calculations such as probability of failure on demand(PFD), safe failure fractions and hardware fault tolerance· How to identify and calculate the impact of <strong>com</strong>mon cause failures (Betafactor) on the reliability of protective systems· The importance of testing and maintaining protective systems and how tocalculate the most optimal test and maintenance strategies· The benefits of partial closure testing of valves.Who Should AttendOffshore Operations Engineers,Maintenance Engineers,Instrument Engineers, <strong>Process</strong>Engineers, Advance <strong>Process</strong>Control Engineers, ProjectEngineers & all technicalpersonnel involved with OffshoreOperation, maintenance &Projects.Recent events such as the DeepwaterHorizon underline the need to identifyand assess all hazards related to fixedoffshore facilities and floatingproduction and storage (FPSO) facilities.The associated risks need to beappropriately reduced in order tomaintain the integrity of these facilities,profitable operations and the reputationof the operator. Participants will beintroduced to the concepts of offshoreregulations, internationally adoptedstandards and the latest tools andtechniques for the risk assessment, andmanagement of offshore related safetysystems. They will be able to apply theirnewly acquired knowledge and skills tobetter manage their processes,operational related hazards andassociated risks.

WORKSHOPOBJECTIVIESLed by a globally recognised expert inoffshore related functional safety, thisworkshop will equip participants with themost popular and internationally adoptedmethods and tools for identifying offshorerelated hazards and structuring theprotective systems to provide sufficientrisk reduction. It will cover the functionalhierarchy and requirements of platformshutdown systems including Total PlatformShutdown (TPS), Emergency Shutdown(ESD) levels and topsides Surface <strong>Process</strong>Shutdown (SPS) Systems.There is often confusion andmisconception about what constitutesHIPS or HIPPS as these mean differentthings to different operators. Thisworkshop will look at a standard approachfor determining the requirements for highintegrity protective systems and sometypical generic HIPPS arrangements.Workshop LeaderThe ALARP principles will be used todemonstrate whether sufficient riskreduction can be achieved using bothpreventative and mitigating risk reductionmeasures.The application of Fire & Gas systemshave a very significant role to play inmitigating the ‘after the event’ risk in theoffshore environment. This workshop willlook at the contribution these systemsmake in reducing risk and the differentand, sometimes inconsistent, approachestaken by operators.Operators need to understand andanalyse the hazards and associated riskson their offshore process facilities. Suchhazards can lead to loss of life, damage totheir asset, loss of production andprofitability, damage to the environmentand <strong>com</strong>pany reputation. Participants willbe introduced to the concepts of maininternational standards IEC 61508 and IEC61511 that cover this area of riskassessment and risk reduction.Hazards do not only represent risk interms of safety, but they can also meansignificant incurred losses from productionand equipment damage. Companyreputation can also be severely<strong>com</strong>promised if it is exposed toenvironmental issues which areparticularly sensitive for offshoreoperators, and the assessment ofenvironmental impact will also be covered.The workshop topics cover the conceptsof identifying hazards, hazard analysis andHAZOP. This will be further developedinto the assessment of risk and methodsof risk reduction using instrumentedsystems and other technology. Bothqualitative and quantitative methods forundertaking safety, asset loss andenvironmental risk assessments will bediscussed and applied.Delegates will be taken through therequirements for a <strong>Safety</strong> RequirementsSpecification (SRS) and shown how toundertake appropriate cost effectivedesigns for <strong>Safety</strong> Instrumented Systems(SIS) and <strong>Safety</strong> Instrumented Functions(SIF) and how optimal test andmaintenance strategies for them can beachieved. You will be shown how to takeadvantage of the most popular standardsto achieve capital expenditure savings andongoing operational expenditure savingsfor emergency shutdown and fire and gassystems.Throughout the workshop, emphasis willbe placed on experience and realisticpractical exercises and case studies will beused to <strong>com</strong>pliment the instruction.Clive TimmsBSc., MPhil., CEng., MIETInternational Functional <strong>Safety</strong> ExpertC&C Technical Support Services, StrathayrRhu-Na_Haven Road,Aboyne, AB34 5JB, U.K. | Tel: +44 13398 86618,Email: c.timms@ifb.co.uk, | Web: www.silsupport.<strong>com</strong>Mr. Clive Timms has over 40 years experience in the petrochemicalindustry with offshore and onshore plants experience. He retiredfrom Shell UK Exploration and Production in 2001 where he wasHead of Automation and Control. He is now a Director of C & CTechnical Support Services Limited which specialise in the applicationof and training for the IEC 61508 and IEC 61511 standards. Hechaired the UKOOA working group that produced the UKOOAGuidelines for Instrument-based Protective Systems, as an offshoresector interpretation of IEC 61508. He is a Chartered Engineer with aBSc. and MPhil in Control Engineering; he is a Fellow of the Instituteof Measurement & Control, a Member of the IET and a TÜVFunctional <strong>Safety</strong> Expert. He currently chairs the Institute ofMeasurement and Control <strong>Safety</strong> Panel.Past Head of Automation and Control for Shell UK Exploration and Production *Technical Authority for the Shell Expro Northern Business Unit * Past Chairman of theUKOOA Instrumentation and Control Group * Current Chairman of the Institute ofMeasurement and Control <strong>Safety</strong> Panel * TUV Certified Functional <strong>Safety</strong> ExpertFunctional <strong>Safety</strong> Consultant to:The UK HSE Buncefield Working Group 5 Total * UK Woodside Offshore Petroleum,Australia * ChevronTexaco Houston, USA * Honeywell at MOL Refinery Hungary* Honeywell at Arpechim Refinery Romania * ABS Consulting Kuwait * MillenniumChemicals UK * Maersk Janice Facility Alarm Review * the Talisman MOPUSTOR FPSOprojectPublications Include:A Methodology for Alarm Classification and Prioritisation – IEE: People in Control, June1999. * IEC 61508 is it Pain or Gain? – Measurement & Control, Volume 35, July 2002.* IEC 61508/61511- Pain or Gain – American Institute of Chemical Engineers: <strong>Process</strong><strong>Safety</strong> Progress (Vol. 22 No. 2) – June 2003. * IEC 61511- an aid to COMAH and<strong>Safety</strong> Case Regulations <strong>com</strong>pliance – IEE: IEC 61511 Roll-Out Seminar December2003. * How to Achieve 90% of the Gain without Too Much Pain. – Measurement &Control, Volume 37/1, February 2004. * Determination of <strong>Safety</strong> Integrity Levels TakingInto Account ALARP- Cost Benefit Analysis – IChemE: Hazards XIX, March 2006. *Climbing the AlarmMountain – <strong>Safety</strong> Control Systems Conference, Brisbane, Australia,November 2006. * Achieving ALARP with <strong>Safety</strong> Instrumented Systems – Measurement& Control, Volume 39/10, December 2006. * # Hazards Equal Trips or Alarms or Both– IChemE <strong>Process</strong> <strong>Safety</strong> and Environmental Protection, Volume 87 January 2009. * SISReplacement on Live <strong>Process</strong>es – Measurement & Control Vol 42/06 Juky 2009.

WORKSHOPPROGRAMREQUIREMENTS FOR OFFSHORESAFEGUARDING METHODS ANDSYSTEMS· Design criteria for offshorerelated shutdown levels (TPS,ESD, TPS & EDP)· Subsea flow line protection andSubsurface Isolation Valves(SSIVs)· Pipeline riser valve logic· Platform pipeline crossovers· Production well shutdown andSubsurface <strong>Safety</strong> Valves (SSSVs)· Emergency shutdown systems(ESD)· Surface process shutdownsystems (SPS)· Emergency DepressurisationSystems (EDP)· Fire and Gas Systems (F&G)· <strong>Safety</strong> Instrumented Systems (SIS)· <strong>Safety</strong> Instrumented Functions(SIF)· Designing SIF and SIS· HIPS/HIPPSHAZARDS AND ASSOCIATEDRISKS· Identifying hazards and theprinciples of HAZOP· <strong>Safety</strong> Management Systems· The <strong>Safety</strong> Life Cycle· The principles of ALARP andtolerable risk· Risk reduction layers· Risk mitigationMETHODS FOR RISKASSESSMENT· Qualitative risk assessment· Quantitative risk assessment· Fault Tree Analysis (FTA)· Risk graphs and matrices andcalibration· Independent protection layers· Layers of Protection Analysis(LOPA)· <strong>Safety</strong> Integrity Levels (SIL)· SIL determination by qualitativemethods· SIL determination by quantitativemethodsHARDWARE DESIGNCONSIDERATIONS ANDCALCULATIONS· Integrity specification of a SIF· Selection of appropriate<strong>com</strong>ponents and subsystems forSIF/SIS design· The concept of ‘proven in use’and ‘not proven in use’· Field devices· Initiators (Sensors), logic solversand final elements (Valves) for SIS· Failures types· Failure modes· Systematic failures· Random failures· Failure and reliability· Demand modes· Probability of failure on demand(PFD)· SIF implementation for lowdemand modesIMPORTANCE OF TESTING ANDMAINTENANCE· Importance of testing· Relationship between testing andthe probability of failure· Importance of maintenance· Relationship betweenmaintenance and the probabilityof failure· Fractional dead times· Common cause failure and itsaffect on PFD· Safe Failure Fraction· Hardware fault tolerance· Partial closure testing of valves· Measurement validation and<strong>com</strong>parison· Reliability data types, sources andconversionsNOTE: Practical exercises will be performed throughout the course. Syndicate exercises will be undertaken in groups. All exerciseswill be taken from real life examples.Offshore <strong>Process</strong> <strong>Safety</strong> Workshop1Email: training@parengg.<strong>com</strong>On-line registration: www.parengg.<strong>com</strong>24 Ways to Register3 Fax nomination to: +974 44117045Tel: +974 44117272| Mob: +974 6648 465343 DAYS20 th to 22 nd March 2011DOHA, QATARFUTUREPROGRAMSOn ProjectManagement* Details will be announced shortlyBasic Courses in Project Management1 Introduction to Project Management 17 th to 19 th April 2011 3 days2 Financial Intelligence for Project Managers 20 th to 21 st April 2011 2 days3 Project Contract & Risk Management 24 th to 26 th April 2011 3 days4 Introduction to Project Manager’s Competencies 27 th to 28 th April 2011 2 daysAdvanced Courses in Project Management5 Advanced Project Management 15 th to 17 th May 2011 3 days6 Setting up Project Management Office 18 th to 19 th May 2011 2 days7 Enterprise Project Management Solutions 22 nd to 23 rd May 2011 2 days8 Leadership & Emotional Intelligence for Project Managers 24 th to 26 th May 2011 3 days9Project Management ProfessionalPMP Facilitation Course 5 th to 9 th June 2011 5 days