Cryogenic Controls PDF (CAVMC-0514 - Cash Valve

Cryogenic Controls PDF (CAVMC-0514 - Cash Valve

Cryogenic Controls PDF (CAVMC-0514 - Cash Valve

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Cryogenic</strong> <strong>Controls</strong>/Pressure Reducing <strong>Valve</strong>s/Pressure Build-Up Regulators<br />

<strong>Cryogenic</strong>s – the science of materials at<br />

extremely low temperatures – has become more<br />

and more important to industry. One important<br />

aspect of this field is the liquification of normally<br />

gaseous elements, including the following,<br />

which are widely used throughout industry:<br />

OXYGEN – Used extensively in BOF furnaces<br />

in the steel industry, for metal cutting, as a<br />

rocket fuel and in medicine.<br />

ACETYLENE – Widely used in welding.<br />

NITROGEN – Used in refrigeration systems, for<br />

metal degassing, in aerosol packaging and in<br />

cryogenic surgery.<br />

HYDROGEN – Used as a rocket propellant and<br />

in the production of several metals.<br />

ARGON – Widely used in incandescent lamps<br />

and fluorescent tubes.<br />

HELIUM – Used for arc welding, in the<br />

manufacture of electron tubes and in cryogenic<br />

research.<br />

CARBON DIOXIDE – Used in refrigeration, to<br />

make aerosol tanks and in fire fighting.<br />

Other cryogenic fluids include liquefied natural<br />

gas, fluorine, krypton, neon, methane and<br />

ethane.<br />

Industrial gases were previously stored in large,<br />

bulky, pressurized metal containers, but now<br />

these gases are stored and shipped in their<br />

liquid state in cryogenic containers called<br />

“Dewars” or converters. Dewars are jacketed<br />

storage vessels that safely maintain liquids at<br />

cryogenic temperatures. The main advantage of<br />

cryogenic containers is a substantial saving of<br />

storage space as demonstrated by the following<br />

example: 162.8 standard cubic feet [4.61 cubic<br />

Construction<br />

Brass forged body and spring chamber; bronze trim and<br />

diaphragms; Teflon® seat disc and diaphragm gasket;<br />

stainless steel pressure spring. All parts are commercially<br />

cleaned for cryogenic service.<br />

NOTE: Also available in stainless steel and special<br />

construction for Hi-Purity service. Contact your sales<br />

representative.<br />

Temperature Rating<br />

+150°F to -320°F [339°K to 78°K]<br />

Maximum Initial Pressure<br />

600 psi [42.18 kg/sq cm]<br />

2<br />

meters] of gas at ambient temperature, when<br />

subjected to a pressure of 2,400 psi [168.72<br />

kg/sq cm] in a pressurized container, will have a<br />

measured volume of one cubic foot [0.028 cubic<br />

meter]; however, 696 standard cubic feet [19.1<br />

cubic meters] of the same gas can be stored in<br />

its liquid state at cryogenic temperatures in a<br />

Dewar with the same measured volume of one<br />

cubic foot [0.028 cubic meter]. This means that,<br />

under cryogenic conditions, the Dewar can<br />

accommodate 4.28 times the quantity of a<br />

normally gaseous element as a pressurized gas<br />

cylinder.<br />

<strong>Cryogenic</strong> converters are available in a variety<br />

of sizes and shapes and can be either<br />

stationary or installed on over-the-road transport<br />

trucks. They are generally used for liquids with a<br />

boiling point anywhere from -109.3°F [194.7°K]<br />

for carbon dioxide to -452°F [4.3°K] for helium.<br />

Dewars are supplied with inbuilt controls that<br />

allow the material to be drawn as either liquid or<br />

gas. The schematic located on the back cover<br />

illustrates a typical cryogenic container and<br />

controls. While there are many different versions<br />

of this basic system, the components remain<br />

fairly constant. <strong>Cash</strong> <strong>Valve</strong> manufactures a<br />

variety of controls for cryogenic systems,<br />

including liquid and gas line-pressure build-up<br />

regulators, economizer (heat leak) back<br />

pressure valves, temperature safety valves,<br />

combination valves, shut-off valves and finalline/service-line<br />

regulators. This data sheet<br />

presents a detailed description of <strong>Cash</strong> <strong>Valve</strong>’s<br />

line of cryogenic-service valves.<br />

The Pressure Build-up Circuit<br />

The purpose of the build-up circuit is to maintain<br />

in the converter a pressure approximately 25 psi<br />

[1.76 kg/sq cm] above that required to drive the<br />

liquid to the final vaporizer and to maintain a<br />

pressure differential of approximately 25 psi<br />

[1.76 kg/sq cm] or higher across the service line<br />

regulator. To do this, liquid is drawn into the<br />

pressure build-up coil, where it is warmed by<br />

ambient air and vaporized. The gas then passes<br />

1 the pressure build-up regulator and into the<br />

top of the tank, where it begins to build up<br />

pressure because expansion is limited by the<br />

fixed volume. When this pressure reaches the<br />

set point of the pressure build-up regulator, the<br />

regulator shuts off, stopping vaporization and<br />

pressure build-up. As liquid is forced from the<br />

tank to the final vaporizer, pressure in the tank<br />

begins to drop and the pressure build-up<br />

regulator again begins operating.<br />

The pressure build-up regulator may be located<br />

in the liquid line before the pressure build-up<br />

coil. Since it is now used for liquid rather than<br />

gas service, the regulator may have a smaller<br />

orifice or be a smaller-sized valve. The operation<br />

of a liquid pressure build-up regulator is the<br />

same as that of a gas regulator with the<br />

exception that it regulates the liquid flow before<br />

the pressure build-up coil rather than the gas<br />

flow after the coil. When pressure in the tank<br />

drops, the liquid pressure build-up regulator<br />

opens, allowing liquid to flow through the<br />

pressure build-up coil and vaporize.<br />

<strong>Cash</strong> <strong>Valve</strong> manufactures pressure build-up<br />

regulators for most cryogenic system<br />

applications. The Type A-32 is a small (1/4",<br />

8 mm) pressure build-up valve; the larger<br />

Type B, Type G-60 and Type E-55 can be used<br />

for either liquid or gas. The Type B is available<br />

in sizes from 1/4" to 2" [8 mm to 50 mm], the<br />

G-60 from 1/4" to 11/2" [8 mm toh 40 mm] and the<br />

Type E-55 from 11/4" to 2" [32 mm to 50 mm].<br />

A-32 Pressure Reducing or Pressure Build-Up Service ____________________________<br />

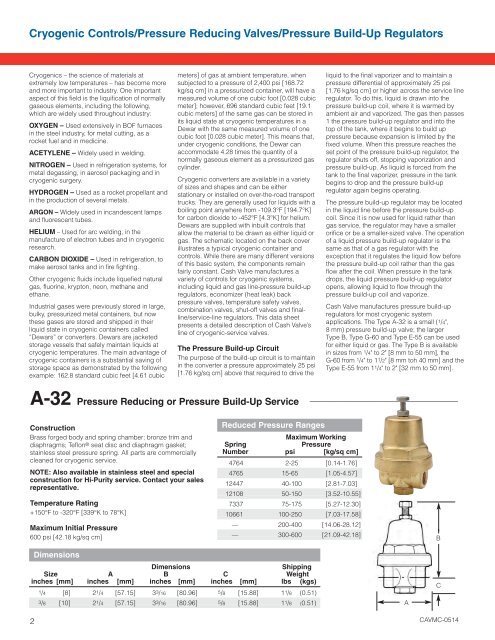

Reduced Pressure Ranges<br />

Maximum Working<br />

Spring Pressure<br />

Number psi [kg/sq cm]<br />

4764 2-25 [0.14-1.76]<br />

4765 15-65 [1.05-4.57]<br />

12447 40-100 [2.81-7.03]<br />

12108 50-150 [3.52-10.55]<br />

7337 75-175 [5.27-12.30]<br />

10661 100-250 [7.03-17.58]<br />

— 200-400 [14.06-28.12]<br />

— 300-600 [21.09-42.18]<br />

Dimensions<br />

Dimensions Shipping<br />

Size A B C Weight<br />

inches [mm] inches [mm] inches [mm] inches [mm] lbs (kgs)<br />

1/4 [8] 21/4 [57.15] 33/16 [80.96] 5/8 [15.88] 11/8 (0.51)<br />

3/8 [10] 21/4 [57.15] 33/16 [80.96] 5/8 [15.88] 11/8 (0.51)<br />

A<br />

B<br />

C<br />

<strong>CAVMC</strong>-<strong>0514</strong>