Hydra HD.pmd - WIKA

Hydra HD.pmd - WIKA

Hydra HD.pmd - WIKA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

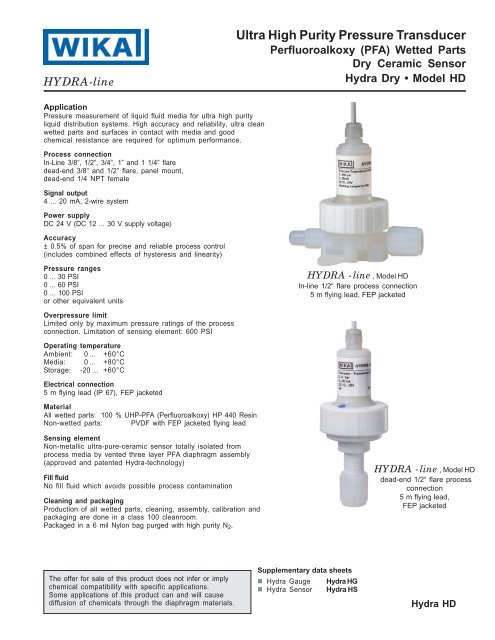

HYDRA-lineUltra High Purity Pressure TransducerPerfluoroalkoxy (PFA) Wetted PartsDry Ceramic Sensor<strong>Hydra</strong> Dry • Model <strong>HD</strong>ApplicationPressure measurement of liquid fluid media for ultra high purityliquid distribution systems. High accuracy and reliability, ultra cleanwetted parts and surfaces in contact with media and goodchemical resistance are required for optimum performance.Process connectionIn-Line 3/8”, 1/2”, 3/4”, 1” and 1 1/4” flaredead-end 3/8” and 1/2” flare, panel mount,dead-end 1/4 NPT femaleSignal output4 ... 20 mA, 2-wire systemPower supplyDC 24 V (DC 12 ... 30 V supply voltage)Accuracy± 0.5% of span for precise and reliable process control(includes combined effects of hysteresis and linearity)Pressure ranges0 ... 30 PSI0 ... 60 PSI0 ... 100 PSIor other equivalent unitsHYDRA - line, Model <strong>HD</strong>In-line 1/2“ flare process connection5 m flying lead, FEP jacketedOverpressure limitLimited only by maximum pressure ratings of the processconnection. Limitation of sensing element: 600 PSIOperating temperatureAmbient: 0 ... +60°CMedia: 0 ... +80°CStorage: -20 ... +60°CElectrical connection5 m flying lead (IP 67), FEP jacketedMaterialAll wetted parts: 100 % UHP-PFA (Perfluoroalkoxy) HP 440 ResinNon-wetted parts: PVDF with FEP jacketed flying leadSensing elementNon-metallic ultra-pure-ceramic sensor totally isolated fromprocess media by vented three layer PFA diaphragm assembly(approved and patented <strong>Hydra</strong>-technology)Fill fluidNo fill fluid which avoids possible process contaminationCleaning and packagingProduction of all wetted parts, cleaning, assembly, calibration andpackaging are done in a class 100 cleanroom.Packaged in a 6 mil Nylon bag purged with high purity N 2 .HYDRA - line, Model <strong>HD</strong>dead-end 1/2“ flare processconnection5 m flying lead,FEP jacketedThe offer for sale of this product does not infer or implychemical compatibility with specific applications.Some applications of this product can and will causediffusion of chemicals through the diaphragm materials.Supplementary data sheets• <strong>Hydra</strong> Gauge <strong>Hydra</strong> HG• <strong>Hydra</strong> Sensor <strong>Hydra</strong> HS<strong>Hydra</strong> <strong>HD</strong>

DimensionsHYDRA-line, In-line flare process connection2386 751.03Process connectionDimensions[mm]H 1 H 2 L L1F B 1 B 2 Ød2in- line 3/8" flare 130 155 118 127 16 40 62 5.5in- line 1/2" flare 130 155 122 133 16 40 62 5.5in- line 3/4" flare 135 160 122 133 19 40 62 5.5in- line 1" flare 160 185 165 179 25 56 78 6.5in- line 1 1/4" flare 160 185 224 238 25 56 78 6.5HYDRA-line, Model <strong>HD</strong>, dead-end process connection2436 465.022436 392.02Dimensions [mm]Process connectionH 1 H 2 SW1 SW2 ØD 2dead-end 3/8" flare 161 ± 2 min. 179 27 15/16 " 64dead-end 1/2" flare 164 ± 2 min. 182 27 15/16 " 64dead-end 1/4 NPT female 117 ± 2 min. 135 27 - 642

Considerations for use:The central PVDF-nut may not be loosend from the housing as this may cause the process fluid to leak destroying themeasuring unit.Once loosened and retightened the fuction is no longer ensured.Wiring details2-wire systemred U B +/S+ (1)flying leadblack 0V/S- (2)Ordering information for pressure system HYDRA-line, Model <strong>HD</strong>FieldNo.Code FeaturesUnitB barP psiA kPa1 ? other Please state as additional textRangeBF 0 bar ... 2.5 bar 0 psi ... 30 psi 0 kPa ... 250 kPaBG 0 bar ... 4 bar 0 psi ... 60 psi 0 kPa ... 400 kPaBH 0 bar ... 6 bar 0 psi ... 100 psi 0 kPa ... 600 kPa2 ?? other Please state as additional text1)Electrical connection3 H 5 m flying leads with free ends (IP 67, FEP jacketed)Digital indicatorZ without2 integrated 4 digit LED, model HI, see data sheet SP 99.234 3 separate for panel mount, 4 digit LED, model HI, see data sheet SP 99.23Process connection06 In-line 3/8 " flare08 In-line 1/2 " flare12 In-line 3/4 " flare16 In-line 1 " flare20 In-line 1 1/4 " flare40 dead-end 3/8 " flare42 dead-end 1/2 " flare5 50 dead-end 1/4 NPT femaleFlare nut77 PFA Only for flare connections, not for NPT75 PVDF Only for flare connections, not for NPT6 ZZ without Only with NPT connectionsAdditional order infoYES NO7 1 Z additional text Please state in clearly understandable text !Order code for Model <strong>HD</strong>1 2 3 4 5 6 7<strong>HD</strong> - H –Additional text:Optional designs on request3

THE MEASURE OFTotal Performance TMSpecifications given in this price list represent the state of engineering at the time of printing.Modifications may take place and the specified materials may change without prior notice<strong>WIKA</strong> Instrument Corporation1000 Wiegand BoulevardLawrenceville, Georgia 30043-5868Tel: 770-513-8200 Fax: 770-338-5118http://www.wika.com e-mail: info@wika.com