ERIKS Sealing Technology - Eriks UK

ERIKS Sealing Technology - Eriks UK

ERIKS Sealing Technology - Eriks UK

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

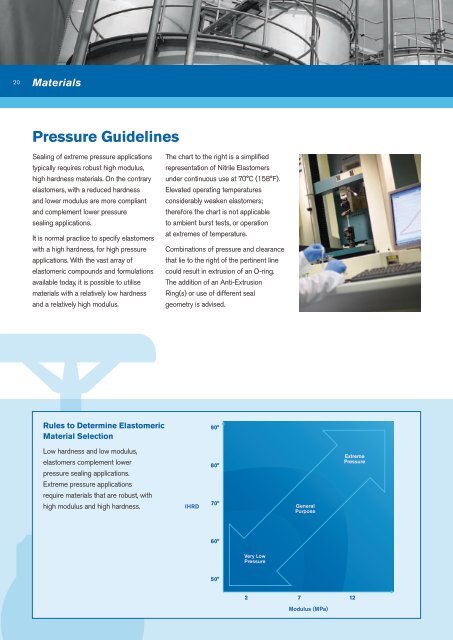

20 Materials21Pressure GuidelinesO-ring Pressure CapabilityO-Ring Pressure Capability<strong>Sealing</strong> of extreme pressure applicationstypically requires robust high modulus,high hardness materials. On the contraryelastomers, with a reduced hardnessand lower modulus are more compliantand complement lower pressuresealing applications.It is normal practice to specify elastomerswith a high hardness, for high pressureapplications. With the vast array ofelastomeric compounds and formulationsavailable today, it is possible to utilisematerials with a relatively low hardnessand a relatively high modulus.The chart to the right is a simplifiedrepresentation of Nitrile Elastomersunder continuous use at 70°C (158°F).Elevated operating temperaturesconsiderably weaken elastomers;therefore the chart is not applicableto ambient burst tests, or operationat extremes of temperature.Combinations of pressure and clearancethat lie to the right of the pertinent linecould result in extrusion of an O-ring.The addition of an Anti-ExtrusionRing(s) or use of different sealgeometry is advised.Differential Pressure (Bar)40035030025020015010050ElastomerHardness70 °IRHD80 °IRHD90 °IRHD00.05 0.1 0.15 0.2 0.25 0.3Radial Extrusion Gap (mm)Contact <strong>ERIKS</strong> for assistance in selecting the correct solution for your high pressure application.Rules to Determine ElastomericMaterial Selection90°Low hardness and low modulus,elastomers complement lowerpressure sealing applications.Extreme pressure applicationsrequire materials that are robust, withhigh modulus and high hardness.IHRD80°70°GeneralPurposeExtremePressure60°Very LowPressure50°2 7 12 17Modulus (MPa)