ERIKS Sealing Technology - Eriks UK

ERIKS Sealing Technology - Eriks UK

ERIKS Sealing Technology - Eriks UK

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

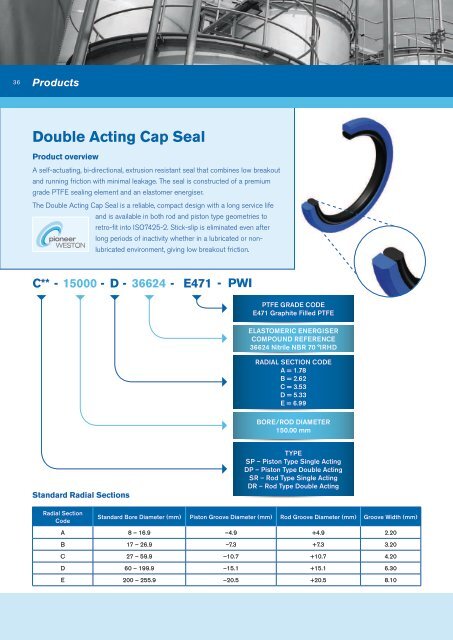

36 Products37Double Acting Cap SealEnergiser MaterialsProduct overviewElastomerCompoundReferenceColourHardness°IRHDTemperatureApplicationA self-actuating, bi-directional, extrusion resistant seal that combines low breakoutand running friction with minimal leakage. The seal is constructed of a premiumgrade PTFE sealing element and an elastomer energiser.The Double Acting Cap Seal is a reliable, compact design with a long service lifeand is available in both rod and piston type geometries toretro-fit into ISO7425-2. Stick-slip is eliminated even afterlong periods of inactivity whether in a lubricated or nonlubricatedenvironment, giving low breakout friction.Nitrile, NBR,Buna NEthylenePropylene,EPDM, EPMSilicone,VMQ36624 Black 7055914 Black 7055914PC Black 70714177 Red 70–35 to +110°C–31 to +230°F–55 to +130°C–67 to +266°F–50 to +150°C–58 to +302°F–55 to +230°C–67 to +446°FStandard compound with good compression-set values and mediumacrylonitrile content for use with hydraulic oils, vegetable oils, animal fats,acetylene, alcohols, water, air, fuels and many other fluids.Standard, sulphur cured EPDM compound with very good compressionsetfor use with solvents, alcohols, ketones, esters, organic and inorganicacids. Not recommended for animal fats, vegetable or mineral oils.High performance peroxide cured EPDM compound with very goodcompression-set, steam, ozone and weathering resistance.General purpose silicone with excellent physical and temperatureresistance up to 220°C. Extremely high and low temperature range foruse in air, oxygen dry heat, ozone, hot water to 150°C, and glycol basedbrake fluids. Silicones are recommended only for static applications.C** - 15000 - D - 36624 - E471 - PWIptfe grade codeE471 Graphite Filled PTFEElASToMERIC energisercompound reference36624 Nitrile NBR 70 °IRHDFluorocarbonFKM,Viton ® A51414 Black 7551414G Green 75Viton ® GF 514141 Black 75–20 to +200°C–4 to +392°F–20 to +200°C–4 to +392°F–10 to +200°C+14 to +392°FGeneral purpose compound with very low compression-setcharacteristics at high temperatures and chemical resistance to oils,fats, fuels. Suitable for vacuum applications.General purpose compound with very low compression-setcharacteristics at high temperatures and chemical resistance to oils,fats, fuels. Suitable for vacuum applications.Original Viton ® GF-Terpolymer with improved steam andtemperature resistance.radial section codeA = 1.78B = 2.62C = 3.53D = 5.33E = 6.99PTFE Gradesbore/rod diameter150.00 mmMaterialReferenceDescription Wear Factor (K) ApplicationStandard Radial SectionsTypeSP – Piston Type Single ActingDP – Piston Type Double ActingSR – Rod Type Single ActingDR – Rod Type Double ActingE400 Virgin Polytetrafluoroethylene (PTFE) 1500 Static, Low Duty Cycles.E431Glass and Molybdenum Disulphidereinforced PTFE15Dynamic/Static, Medium Duty Cycles, Hardened MetalRunning Surfaces.E471 Graphite reinforced PTFE 10 Dynamic, Medium Duty Cycles.Radial SectionCodeStandard Bore Diameter (mm) Piston Groove Diameter (mm) Rod Groove Diameter (mm) Groove Width (mm)A 8 – 16.9 –4.9 +4.9 2.20B 17 – 26.9 –7.3 +7.3 3.20C 27 – 59.9 –10.7 +10.7 4.20D 60 – 199.9 –15.1 +15.1 6.30E 200 – 255.9 –20.5 +20.5 8.10E462 Carbon/Graphite reinforced PTFE 15 Dynamic, Medium Duty Cycles.E491 Ekonol reinforced PTFE 2E282Z Carbon/Graphite/PPS reinforced PTFE 1Dynamic/Static, Medium to High Duty Cycles, Minimum 45 HRcRunning Surface.Dynamic/Static, High Duty Cycles, Hardened MetalRunning Surfaces.