Operational manual - Mercury

Operational manual - Mercury

Operational manual - Mercury

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

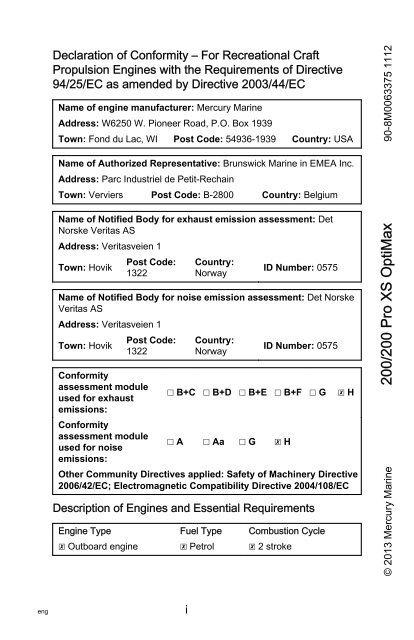

Declaration of Conformity – For Recreational CraftPropulsion Engines with the Requirements of Directive94/25/EC as amended by Directive 2003/44/ECName of engine manufacturer: <strong>Mercury</strong> MarineAddress: W6250 W. Pioneer Road, P.O. Box 1939Town: Fond du Lac, WI Post Code: 54936‐1939 Country: USAName of Authorized Representative: Brunswick Marine in EMEA Inc.Address: Parc Industriel de Petit‐RechainTown: Verviers Post Code: B‐2800 Country: BelgiumName of Notified Body for exhaust emission assessment: DetNorske Veritas ASAddress: Veritasveien 1Town: HovikPost Code:1322Country:NorwayID Number: 0575Name of Notified Body for noise emission assessment: Det NorskeVeritas ASAddress: Veritasveien 1Town: HovikPost Code:1322Conformityassessment moduleused for exhaustemissions:Conformityassessment moduleused for noiseemissions:Country:NorwayID Number: 0575☐ B+C ☐ B+D ☐ B+E ☐ B+F ☐ G ☒ H☐ A ☐ Aa ☐ G ☒ HOther Community Directives applied: Safety of Machinery Directive2006/42/EC; Electromagnetic Compatibility Directive 2004/108/ECDescription of Engines and Essential RequirementsEngine Type Fuel Type Combustion Cycle☒ Outboard engine ☒ Petrol ☒ 2 stroke© 2013 <strong>Mercury</strong> Marine 200/200 Pro XS OptiMax 90-8M0063375 1112eng i

Identification of Engines Covered by This Declaration ofConformityName of engine family1.5L OptiMax 75, 90, 115, 115Pro XS, 125 hp, 80 Jet2.5L OptiMax 135, 150, 150Pro XS, 175 hp3.0L OptiMax 200, 200 Pro XS,225 hpUnique engineidentificationnumber(s) or enginefamily code(s):starting serial numberModule HCertificate0B228000 RCD‐H‐2 Rev 40B228000 RCD‐H‐2 Rev 40B228000 RCD‐H‐2 Rev 4EssentialrequirementsStandardsAnnex 1.B—Exhaust EmissionsB.1 engineidentificationB.2 exhaustemissionrequirementsOthernormativedocument/methodTechnicalfile☐ ☐ ☒☒* ☐ ☐B.3 durability ☐ ☐ ☒B.4 owner's<strong>manual</strong>Annex 1.C—Noise EmissionsC.1 Noiseemission levelsC.2 Owner's<strong>manual</strong>Please specify inmore detail(* = mandatorystandard)* EN ISO8178‐1:1996☒ ☐ ☐ ISO 8665: 2006☒* ☐ ☐ EN ISO 14509☐ ☒ ☐ Owner's <strong>manual</strong>This declaration of conformity is issued under the sole responsibility of themanufacturer. I declare on behalf of the engine manufacturer that the enginesmentioned preceding complies with all applicable essential requirements inthe way specified.ii eng

Name / function:Mark D. Schwabero, President<strong>Mercury</strong> MarineDate and place of issue:September 04, 2012Fond du Lac, Wisconsin, USAWelcomeYou have selected one of the finest outboards available. Itincorporates numerous design features to ensure operating easeand durability.With proper care and maintenance, you will enjoy using thisproduct for many boating seasons. To ensure maximumperformance and carefree use, we ask that you thoroughly readthis <strong>manual</strong>.The Operation, Maintenance and Warranty Manual containsspecific instructions for using and maintaining your product. Wesuggest that this <strong>manual</strong> remain with the product for readyreference whenever you are on the water.Thank you for purchasing one of our products. We sincerelyhope your boating will be pleasant!<strong>Mercury</strong> MarineEPA Emissions RegulationsOutboards sold by <strong>Mercury</strong> Marine in the United States arecertified to the United States Environmental Protection Agencyas conforming to the requirements of the regulations for thecontrol of air pollution from new outboard motors. Thiscertification is contingent on certain adjustments being set tofactory standards. For this reason, the factory procedure forservicing the product must be strictly followed and, whereverpracticable, returned to the original intent of the design.Maintenance, replacement, or repair of the emission controldevices and systems may be performed by any marine enginerepair establishment or individual.eng iii

Engines are labeled with an emission control information decalas permanent evidence of EPA certification.! WARNINGThe engine exhaust from this product contains chemicalsknown to the state of California to cause cancer, birth defectsor other reproductive harm.Warranty MessageThe product you have purchased comes with a limited warrantyfrom <strong>Mercury</strong> Marine. The terms of the warranty are set forth inthe Warranty Information section of this <strong>manual</strong>. The warrantystatement contains a description of what is covered, what is notcovered, the duration of coverage, how to best obtain warrantycoverage, important disclaimers and limitations of damages, andother related information. Please review this information.The description and specifications contained herein were ineffect at the time this <strong>manual</strong> was approved for printing. <strong>Mercury</strong>Marine, whose policy is one of continued improvement, reservesthe right to discontinue models at any time, and to changespecifications, designs, methods, or procedures without noticeand without incurring obligation.<strong>Mercury</strong> Marine, Fond du Lac, Wisconsin U.S.A.Printed in the U.S.A.© 2013, <strong>Mercury</strong> MarineAlpha, Axius, Bravo One, Bravo Two, Bravo Three, Circle M withWaves Logo, K‐planes, Mariner, MerCathode, MerCruiser,<strong>Mercury</strong>, <strong>Mercury</strong> with Waves Logo, <strong>Mercury</strong> Marine, <strong>Mercury</strong>Precision Parts, <strong>Mercury</strong> Propellers, <strong>Mercury</strong> Racing,MotorGuide, OptiMax, Quicksilver, SeaCore, Skyhook,SmartCraft, Sport‐Jet, Verado, VesselView, Zero Effort, Zeus,and #1 On the Water are registered trademarks of BrunswickCorporation. <strong>Mercury</strong> Product Protection is a registered servicemark of Brunswick Corporation.iv eng

<strong>Mercury</strong> Premier Service<strong>Mercury</strong> evaluates the service performance of its dealers andassigns its highest rating of "<strong>Mercury</strong> Premier" to thosedemonstrating an exceptional commitment to service.Earning a <strong>Mercury</strong> Premier Service rating means a dealer:• Achieves a high 12‐month service Customer SatisfactionIndex (CSI) score for warranty service.• Possesses all of the necessary service tools, testequipment, <strong>manual</strong>s, and parts books.• Employs at least one certified or master technician.• Provides timely service for all <strong>Mercury</strong> Marine customers.• Offers extended service hours and mobile service, whenappropriate.• Uses, displays, and stocks an adequate inventory ofgenuine <strong>Mercury</strong> Precision Parts.• Offers a clean, neat shop with well‐organized tools andservice literature.eng v

vi eng

Warranty InformationWarranty Registration United States and Canada....................... 1Transfer of Warranty United States and Canada.........................1Transfer of <strong>Mercury</strong> Product Protection (Extended ServiceCoverage) Plan United States and Canada.................................2Outboard Limited Warranty..........................................................33 Year Limited Warranty Against Corrosion................................ 7Warranty Coverage and Exclusions.......................................... 11U.S. EPA Emissions Limited Warranty...................................... 13Emission Control System Components..................................... 13California Emissions Limited Warranty...................................... 14California Air Resources Board Explanation of Your CaliforniaEmission Control Warranty Statement.......................................18Emission Certification Star Label............................................... 19Warranty Policy—Australia and New Zealand........................... 20eng vii

General InformationBoater's Responsibilities............................................................ 27Before Operating Your Outboard............................................... 27Boat Horsepower Capacity........................................................ 28High‐Speed and High‐Performance Boat Operation................. 28Outboard Remote Control Models ............................................ 29Propeller Selection.....................................................................29Remote Steering Notice.............................................................32Lanyard Stop Switch.................................................................. 33Protecting People in the Water.................................................. 37Passenger Safety Message ‐ Pontoon Boats and Deck Boats................................................................................................... 38Wave and Wake Jumping.......................................................... 39Impact with Underwater Hazards...............................................40Exhaust Emissions.................................................................... 42Selecting Accessories for Your Outboard.................................. 44Safe Boating Recommendations............................................... 44Recording Serial Number.......................................................... 48200/200 Pro XS OptiMax Specifications.................................... 49Component Identification........................................................... 50TransportingTrailering Boat/Outboard .......................................................... 51viii eng

Fuel and OilFuel Recommendations............................................................. 52Oil Recommendation................................................................. 54Fuel Additives............................................................................ 54Fuel Requirements.................................................................... 54Avoiding Fuel Flow Restriction.................................................. 54Low Permeation Fuel Hose Requirement ................................. 54EPA Pressurized Portable Fuel Tank Requirements................. 55Fuel Demand Valve (FDV) Requirement................................... 55<strong>Mercury</strong> Marine's Pressurized Portable Fuel Tank.................... 55Filling Remote Oil Tank............................................................. 57Filling Engine Mounted Oil Reservoir Tank............................... 57Filling Fuel Tank........................................................................ 58Features and ControlsRemote Control Features.......................................................... 59Warning System........................................................................ 60Power Trim and Tilt....................................................................63OperationImportant Information.................................................................68Engine Break‐in......................................................................... 69Engine Break‐in Fuel Mixture.................................................... 70Prestarting Check List................................................................70Operating in Freezing Temperatures......................................... 70Operating in Saltwater or Polluted Water.................................. 71Operating at High Elevations..................................................... 71Effects of Elevation and Weather on Performance.................... 71Setting Trim Angle While Running Engine at Idle Speed.......... 72Operating in Shallow Water....................................................... 72Starting the Engine.................................................................... 73Gear Shifting.............................................................................. 76Stopping the Engine.................................................................. 77eng ix

MaintenancePower Package Care................................................................. 78Submerged Power Package...................................................... 78Replacement Parts for Your Power Package............................ 78EPA Emissions Regulations...................................................... 79Inspection and Maintenance Schedule...................................... 80Flushing the Cooling System (Powerhead)............................... 83Flushing the Cooling System (Lower Unit)................................ 84Top Cowl Removal and Installation........................................... 85Cleaning Care for Top Cowl...................................................... 85Alternator Belt Inspection...........................................................86Fuel System............................................................................... 86Steering Link Rod Fasteners..................................................... 89Fuses ........................................................................................ 91Corrosion Control Anode........................................................... 92Spark Plug Inspection and Replacement...................................92Battery Inspection ..................................................................... 94Charging System Fusible Link................................................... 95Propeller Replacement.............................................................. 95Air Compressor Filter................................................................. 99Lubrication Points.................................................................... 101Checking Power Trim Fluid......................................................104Gearcase Lubrication...............................................................105StorageStorage Preparation.................................................................108Fuel System............................................................................. 108Protecting Internal Engine Components.................................. 110Protecting External Outboard Components............................. 110Gearcase................................................................................. 111Positioning Outboard for Storage............................................ 111Battery Storage........................................................................ 111x eng

TroubleshootingStarter Motor Will Not Crank the Engine..................................112Engine Will Not Start................................................................112Engine Runs Erratically........................................................... 113Performance Loss....................................................................113Warning Horn Activates (With Power Loss).............................113Warning Horn Activates (No Power Loss)............................... 114Battery Will Not Hold Charge................................................... 114Owner Service AssistanceLocal Repair Service................................................................116Service Away from Home........................................................ 116Parts and Accessories Inquiries.............................................. 116Service Assistance.................................................................. 116Ordering Literature...................................................................119Outboard Installation<strong>Mercury</strong> Marine Validated Engine Mounting Hardware........... 121Boat Horsepower Capacity...................................................... 122Start in Gear Protection........................................................... 122Selecting Accessories for Your Outboard................................ 122Fuel System............................................................................. 123Installation Specifications........................................................ 125Lifting the Outboard................................................................. 125Steering Cable ‐ Starboard Side Routed Cable....................... 126Steering Link Rod Fasteners................................................... 127Determining Recommended Outboard Mounting Height......... 130Drilling Outboard Mounting Holes............................................ 131Fastening the Outboard to the Transom.................................. 132Electrical, Hoses, Control Cables, and Front Clamp............... 138Oil Injection Set‐Up.................................................................. 151Trim In Pin............................................................................... 154eng xi

Maintenance LogMaintenance Log..................................................................... 156xii eng

WARRANTY INFORMATIONWarranty Registration United States and CanadaTo be eligible for warranty coverage, the product must beregistered with <strong>Mercury</strong> Marine.At the time of sale, the selling dealer should complete thewarranty registration and immediately submit it to <strong>Mercury</strong>Marine via MercNET, e‐mail, or mail. Upon receipt of thiswarranty registration, <strong>Mercury</strong> Marine will record the registration.A copy of the warranty registration should be provided to you byyour selling dealer.NOTE: Registration lists must be maintained by <strong>Mercury</strong> Marineand any dealer of <strong>Mercury</strong> Marine products sold in the UnitedStates, should a safety recall notification under the FederalSafety Act be required.You may change your registered address at any time, includingat time of warranty claim, by calling <strong>Mercury</strong> Marine or sending aletter or fax with your name, old address, new address, andengine serial number to <strong>Mercury</strong> Marine’s warranty registrationdepartment. Your dealer can also process this change ofinformation.<strong>Mercury</strong> MarineAttn: Warranty Registration DepartmentW6250 W. Pioneer RoadP.O. Box 1939Fond du Lac, WI 54936-1939920-929-5054Fax +1 920 907 6663OUTSIDE UNITED STATES AND CANADAFor products purchased outside the United States and Canada,contact the distributor in your country, or the Marine PowerService Center closest to you.Transfer of Warranty United States and CanadaThe limited warranty is transferable to a subsequent purchaser,but only for the remainder of the unused portion of the limitedwarranty. This will not apply to products used for commercialapplications.eng 1

WARRANTY INFORMATIONTo transfer the warranty to the subsequent owner, send or fax acopy of the bill of sale or purchase agreement, new owner’sname, address, and engine serial number to <strong>Mercury</strong> Marine’swarranty registration department. In the United States andCanada, mail to:<strong>Mercury</strong> MarineAttn: Warranty Registration DepartmentW6250 W. Pioneer RoadP.O. Box 1939Fond du Lac, WI 54936-1939920-929-5054Fax +1 920 907 6663Upon processing the transfer of warranty, <strong>Mercury</strong> Marine willrecord the new owner's information.There is no charge for this service.OUTSIDE THE UNITED STATES AND CANADAFor products purchased outside the United States and Canada,contact the distributor in your country, or the Marine PowerService Center closest to you.Transfer of <strong>Mercury</strong> Product Protection (ExtendedService Coverage) Plan United States and CanadaThe remaining coverage period of the Product Protection Plan istransferable to the subsequent purchaser of the engine withinthirty (30) days from the date of sale. Contracts not transferredwithin thirty (30) days of the subsequent purchase will no longerbe valid and the product will no longer be eligible for coverageunder the terms of the contract.To transfer the plan to the subsequent owner, contact <strong>Mercury</strong>Product Protection or an authorized dealer to receive a Requestfor Transfer form. Submit to <strong>Mercury</strong> Product Protection areceipt/bill of sale, a completed Request of Transfer form, and acheck payable to <strong>Mercury</strong> Marine in the amount of $50.00 (perengine) to cover the transfer fee.Plan coverage is not transferable from one product to anotherproduct or for noneligible applications.The certified preowned engine plans are not transferable.2 eng

WARRANTY INFORMATIONFor help or assistance, contact <strong>Mercury</strong> Product ProtectionDepartment at 1‐888‐427‐5373 from 7:30 a.m. to 4:30 p.m. CST,Monday–Friday or e‐mail mpp_support@mercmarine.com.Outboard Limited WarrantyUNITED STATES, CANADA, EUROPE, MIDDLE EAST,AFRICA, AND THE CONFEDERATION OF INDEPENDENTSTATESWHAT IS COVERED: <strong>Mercury</strong> Marine warrants its new productsto be free of defects in material and workmanship during theperiod described below.DURATION OF COVERAGE: This Limited Warranty providescoverage for three (3) years from the date the product is first soldto a recreational use retail purchaser, or the date on which theproduct is first put into service, whichever occurs first.Commercial users of these products receive warranty coverageof one (1) year from the date of first retail sale, or one (1) yearfrom the date on which the product was first put into service,whichever occurs first. Commercial use is defined as any work oremployment related use of the product, or any use of the productwhich generates income, for any part of the warranty period,even if the product is only occasionally used for such purposes.The repair or replacement of parts, or the performance of serviceunder this warranty, does not extend the life of this warrantybeyond its original expiration date. Unexpired warranty coveragecan be transferred from one recreational use customer to asubsequent recreational use customer upon proper reregistrationof the product. Unexpired warranty coverage cannot betransferred either to or from a commercial use customer.Warranty coverage may be terminated for used repossessedproduct; or product purchased at auction, from a salvage yard, orfrom an insurance company.eng 3

WARRANTY INFORMATIONCONDITIONS THAT MUST BE MET IN ORDER TO OBTAINWARRANTY COVERAGE: Warranty coverage is available onlyto retail customers that purchase from a Dealer authorized by<strong>Mercury</strong> Marine to distribute the product in the country in whichthe sale occurred, and then only after the <strong>Mercury</strong> Marinespecified predelivery inspection process is completed anddocumented. Warranty coverage becomes available upon properregistration of the product by the authorized dealer. Inaccuratewarranty registration information regarding recreational use, orsubsequent change of use from recreational to commercial(unless properly reregistered) may void the warranty at the solediscretion of <strong>Mercury</strong> Marine. Routine maintenance outlined inthe Operation and Maintenance Manual must be timelyperformed in order to maintain warranty coverage. <strong>Mercury</strong>Marine reserves the right to make warranty coverage contingentupon proof of proper maintenance.WHAT MERCURY WILL DO: <strong>Mercury</strong>'s sole and exclusiveobligation under this warranty is limited to, at our option,repairing a defective part, replacing such part or parts with newor <strong>Mercury</strong> Marine certified remanufactured parts, or refundingthe purchase price of the <strong>Mercury</strong> product. <strong>Mercury</strong> reserves theright to improve or modify products from time to time withoutassuming an obligation to modify products previouslymanufactured.4 eng

WARRANTY INFORMATIONHOW TO OBTAIN WARRANTY COVERAGE: The customermust provide <strong>Mercury</strong> with a reasonable opportunity to repair,and reasonable access to the product for warranty service.Warranty claims shall be made by delivering the product forinspection to a <strong>Mercury</strong> dealer authorized to service the product.If purchaser cannot deliver the product to such a dealer, writtennotice must be given to <strong>Mercury</strong>. We will then arrange for theinspection and any covered repair. Purchaser, in that case, shallpay for all related transportation charges and/or travel time. If theservice provided is not covered by this warranty, purchaser shallpay for all related labor and material, and any other expensesassociated with that service. Purchaser shall not, unlessrequested by <strong>Mercury</strong>, ship the product or parts of the productdirectly to <strong>Mercury</strong>. Proof of registered ownership must bepresented to the dealer at the time warranty service is requestedin order to obtain coverage.eng 5

WARRANTY INFORMATIONWHAT IS NOT COVERED: This limited warranty does not coverroutine maintenance items, tune‐ups, adjustments, normal wearand tear, damage caused by abuse, abnormal use, use of apropeller or gear ratio that does not allow the engine to run in itsrecommended wide‐open throttle RPM range (see the Operationand Maintenance Manual), operation of the product in a mannerinconsistent with the recommended operation/duty cycle sectionof the Operation and Maintenance Manual, neglect, accident,submersion, improper installation (proper installationspecifications and techniques are set forth in the installationinstructions for the product), improper service, use of anaccessory or part not manufactured or sold by us, jet pumpimpellers and liners, operation with fuels, oils or lubricants whichare not suitable for use with the product (see the Operation andMaintenance Manual), alteration or removal of parts, waterentering the engine through the fuel intake, air intake or exhaustsystem, or damage to the product from insufficient cooling watercaused by blockage of the cooling system by a foreign body,running the engine out of water, mounting the engine too high onthe transom, or running the boat with the engine trimmed out toofar. Use of the product for racing or other competitive activity, oroperating with a racing type lower unit, at any point, even by aprior owner of the product, voids the warranty.Expenses related to haul‐out, launch, towing, storage, telephone,rental, inconvenience, slip fees, insurance coverage, loanpayments, loss of time, loss of income, or any other type ofincidental or consequential damages are not covered by thiswarranty. Also, expenses associated with the removal and/orreplacement of boat partitions or material caused by boat designfor access to the product are not covered by this warranty.No individual or entity, including <strong>Mercury</strong> Marine authorizeddealers, has been given authority by <strong>Mercury</strong> Marine to makeany affirmation, representation or warranty regarding theproduct, other than those contained in this limited warranty, andif made, shall not be enforceable against <strong>Mercury</strong> Marine.6 eng

WARRANTY INFORMATIONFor additional information regarding events and circumstancescovered by this warranty, and those that are not, see theWarranty Coverage section of the Operation and MaintenanceManual, incorporated by reference into this warranty.DISCLAIMERS AND LIMITATIONS:THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FORA PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. TO THEEXTENT THAT THEY CANNOT BE DISCLAIMED, THE IMPLIEDWARRANTIES ARE LIMITED IN DURATION TO THE LIFE OF THEEXPRESS WARRANTY. INCIDENTAL AND CONSEQUENTIAL DAMAGESARE EXCLUDED FROM COVERAGE UNDER THIS WARRANTY. SOMESTATES/COUNTRIES DO NOT ALLOW FOR THE DISCLAIMERS,LIMITATIONS AND EXCLUSIONS IDENTIFIED ABOVE, AS A RESULT,THEY MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOUSPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER LEGALRIGHTS WHICH VARY FROM STATE TO STATE AND COUNTRY TOCOUNTRY.3 Year Limited Warranty Against CorrosionWHAT IS COVERED: <strong>Mercury</strong> Marine warrants that each new<strong>Mercury</strong>, Mariner, <strong>Mercury</strong> Racing, Sport‐Jet, M 2 Jet Drive,Tracker by <strong>Mercury</strong> Marine Outboard, <strong>Mercury</strong> MerCruiserInboard or Sterndrive Engine (Product) will not be renderedinoperative as a direct result of corrosion for the period of timedescribed below.DURATION OF COVERAGE: This limited corrosion warrantyprovides coverage for three (3) years from either the date theproduct is first sold, or the date on which the product is first putinto service, whichever occurs first. The repair or replacement ofparts, or the performance of service under this warranty, doesnot extend the life of this warranty beyond its original expirationdate. Unexpired warranty coverage can be transferred tosubsequent (noncommercial use) purchaser upon properreregistration of the product.eng 7

WARRANTY INFORMATIONCONDITIONS THAT MUST BE MET IN ORDER TO OBTAINWARRANTY COVERAGE: Warranty coverage is available onlyto retail customers that purchase from a Dealer authorized by<strong>Mercury</strong> Marine to distribute the product in the country in whichthe sale occurred, and then only after the <strong>Mercury</strong> Marinespecified predelivery inspection process is completed anddocumented. Warranty coverage becomes available upon properregistration of the product by the authorized dealer. Corrosionprevention devices specified in the Operation and MaintenanceManual must be in use on the boat, and routine maintenanceoutlined in the Operation and Maintenance Manual must betimely performed (including, without limitation, the replacement ofsacrificial anodes, use of specified lubricants, and touch‐up ofnicks and scratches) in order to maintain warranty coverage.<strong>Mercury</strong> Marine reserves the right to make warranty coveragecontingent upon proof of proper maintenance.WHAT MERCURY WILL DO: <strong>Mercury</strong>'s sole and exclusiveobligation under this warranty is limited to, at our option,repairing a corroded part, replacing such part or parts with newor <strong>Mercury</strong> Marine certified remanufactured parts, or refundingthe purchase price of the <strong>Mercury</strong> product. <strong>Mercury</strong> reserves theright to improve or modify products from time to time withoutassuming an obligation to modify products previouslymanufactured.8 eng

WARRANTY INFORMATIONHOW TO OBTAIN WARRANTY COVERAGE: The customermust provide <strong>Mercury</strong> with a reasonable opportunity to repair,and reasonable access to the product for warranty service.Warranty claims shall be made by delivering the product forinspection to a <strong>Mercury</strong> dealer authorized to service the product.If purchaser cannot deliver the product to such a dealer, writtennotice must be given to <strong>Mercury</strong>. We will then arrange for theinspection and any covered repair. Purchaser, in that case, shallpay for all related transportation charges and/or travel time. If theservice provided is not covered by this warranty, purchaser shallpay for all related labor and material, and any other expensesassociated with that service. Purchaser shall not, unlessrequested by <strong>Mercury</strong>, ship the product or parts of the productdirectly to <strong>Mercury</strong>. Proof of registered ownership must bepresented to the dealer at the time warranty service is requestedin order to obtain coverage.WHAT IS NOT COVERED: This limited warranty does not coverelectrical system corrosion; corrosion resulting from damage,corrosion which causes purely cosmetic damage, abuse, orimproper service; corrosion to accessories, instruments, steeringsystems; corrosion to factory installed jet drive unit; damage dueto marine growth; product sold with less than a one year limitedProduct warranty; replacement parts (parts purchased bycustomer); products used in a commercial application.Commercial use is defined as any work or employment relateduse of the product, or any use of the product which generatesincome, for any part of the warranty period, even if the product isonly occasionally used for such purposes.eng 9

WARRANTY INFORMATIONCorrosion damage caused by stray electrical currents (onshorepower connections, nearby boats, submerged metal) is notcovered by this corrosion warranty and should be protectedagainst by the use of a corrosion protection system, such as the<strong>Mercury</strong> Precision Parts or Quicksilver MerCathode systemand/or Galvanic Isolator. Corrosion damage caused by improperapplication of copper base antifouling paints is also not coveredby this limited warranty. If antifouling protection is required,Tri‐Butyl‐Tin‐Adipate (TBTA) base antifouling paints arerecommended on Outboard and MerCruiser boating applications.In areas where TBTA base paints are prohibited by law, copperbase paints can be used on the hull and transom. Do not applypaint to the outboard or MerCruiser product. In addition, caremust be taken to avoid an electrical interconnection between thewarranted product and the paint. For MerCruiser product, anunpainted gap of at least 38 mm (1.5 in.) should be left aroundthe transom assembly. Refer to the Operation and MaintenanceManual for additional details.For additional information regarding events and circumstancescovered by this warranty, and those that are not, see theWarranty Coverage section of the Operation and MaintenanceManual, incorporated by reference into this warranty.DISCLAIMERS AND LIMITATIONS:THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FORA PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. TO THEEXTENT THAT THEY CANNOT BE DISCLAIMED, THE IMPLIEDWARRANTIES ARE LIMITED IN DURATION TO THE LIFE OF THEEXPRESS WARRANTY. INCIDENTAL AND CONSEQUENTIAL DAMAGESARE EXCLUDED FROM COVERAGE UNDER THIS WARRANTY. SOMESTATES/COUNTRIES DO NOT ALLOW FOR THE DISCLAIMERS,LIMITATIONS AND EXCLUSIONS IDENTIFIED ABOVE, AS A RESULT,THEY MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOUSPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER LEGALRIGHTS WHICH VARY FROM STATE TO STATE AND COUNTRY TOCOUNTRY.10 eng

WARRANTY INFORMATIONWarranty Coverage and ExclusionsThe purpose of this section is to help eliminate some of the morecommon misunderstandings regarding warranty coverage. Thefollowing information explains some of the types of services thatare not covered by warranty. The provisions set forth followinghave been incorporated by reference into the Three Year LimitedWarranty Against Corrosion Failure, the International LimitedOutboard Warranty, and the United States and Canada LimitedOutboard Warranty.Keep in mind that warranty covers repairs that are needed withinthe warranty period because of defects in material andworkmanship. Installation errors, accidents, normal wear, and avariety of other causes that affect the product are not covered.Warranty is limited to defects in material or workmanship, butonly when the consumer sale is made in the country to whichdistribution is authorized by us.Should you have any questions concerning warranty coverage,contact your authorized dealer. They will be pleased to answerany questions that you may have.GENERAL EXCLUSIONS FROM WARRANTY1. Minor adjustments and tune‐ups, including checking,cleaning, or adjusting spark plugs, ignition components,carburetor settings, filters, belts, controls, and checkinglubrication made in connection with normal services.2. Factory installed jet drive units ‐ Specific parts excludedfrom the warranty are: the jet drive impeller and jet driveliner damaged by impact or wear, and water damageddriveshaft bearings as a result of improper maintenance.3. Damage caused by neglect, lack of maintenance, accident,abnormal operation, or improper installation or service.4. Haul‐out, launch, towing charges, removal and/orreplacement of boat partitions or material because of boatdesign for necessary access to the product, all relatedtransportation charges and/or travel time, etc. Reasonableaccess must be provided to the product for warranty service.Customer must deliver product to an authorized dealer.eng 11

WARRANTY INFORMATION5. Additional service work requested by customer other thanthat necessary to satisfy the warranty obligation.6. Labor performed by other than an authorized dealer may becovered only under the following circumstances: whenperformed on emergency basis (providing there are noauthorized dealers in the area who can perform the workrequired or have no facilities to haul‐out, etc., and priorfactory approval has been given to have the work performedat this facility).7. All incidental and/or consequential damages (storagecharges, telephone or rental charges of any type,inconvenience or loss of time or income) are the owner'sresponsibility.8. Use of other than <strong>Mercury</strong> Precision or Quicksilver partswhen making warranty repairs.9. Oils, lubricants, or fluids changed as a matter of normalmaintenance is customer's responsibility unless loss orcontamination of same is caused by product failure thatwould be eligible for warranty consideration.10.Participating in or preparing for racing or other competitiveactivity or operating with a racing type lower unit.11.Engine noise does not necessarily indicate a serious engineproblem. If diagnosis indicates a serious internal enginecondition which could result in a failure, conditionresponsible for noise should be corrected under thewarranty.12.Lower unit and/or propeller damage caused by striking asubmerged object is considered a marine hazard.13.Water entering engine through the fuel intake, air intake, orexhaust system or submersion.14.Failure of any parts caused by lack of cooling water, whichresults from starting motor out of water, foreign materialblocking inlet holes, motor being mounted too high, ortrimmed too far out.15.Use of fuels and lubricants which are not suitable for usewith or on the product. Refer to the Maintenance section.12 eng

WARRANTY INFORMATION16.Our limited warranty does not apply to any damage to ourproducts caused by the installation or use of parts andaccessories which are not manufactured or sold by us.Failures which are not related to the use of those parts oraccessories are covered under warranty if they otherwisemeet the terms of the limited warranty for that product.U.S. EPA Emissions Limited WarrantyConsistent with the obligations created by 40 CFR Part 1045,Subpart B, <strong>Mercury</strong> Marine provides a five year or 175 hours ofengine use, whichever occurs first, to the retail customer, thatthe engine is designed, built, and equipped so as to conform atthe time of sale with applicable regulations under section 213 ofthe Clean Air Act, and that the engine is free from defects inmaterials and workmanship which cause the engine to fail toconform with applicable regulations. This emission‐relatedwarranty covers all the components listed in the EmissionControl System Components.Emission Control System ComponentsThe EPA and California emission‐related warranty covers all thefollowing list of components:COMPONENTS OF THE EMISSIONS CONTROL SYSTEM:1. Fuel metering systema. Carburetor and internal parts (and/or pressure regulatoror fuel injection system)b. Cold start enrichment systemc. Intake valves2. Air induction systema. Intake manifoldb. Turbocharger or supercharger systems (whereapplicable)3. Ignition systema. Spark plugsb. Magneto or electronic ignition systemc. Spark advance/retard systemeng 13

WARRANTY INFORMATIONd. Ignition coil and/or control modulee. Ignition wires4. Lubrication system (4‐Stroke engines excluded)a. Oil pump and internal partsb. Oil injectorsc. Oil meter5. Exhaust systema. Exhaust manifoldb. Exhaust valves6. Miscellaneous items used in above systemsa. Hoses, clamps, fittings, tubing, sealing gaskets ordevices, and mounting hardwareb. Pulleys, belts, and idlersc. Vacuum, temperature, check and time sensitive valvesand switchesd. Electronic controlsThe emission‐related warranty does not cover componentswhose failure would not increase an engine's emissions on anyregulated pollutant.California Emissions Limited WarrantyThe California Air Resources Board has promulgated airemission regulations for outboard engines. The regulations applyto all outboard engines sold to retail consumers in California, andwhich were manufactured for the 2001 model year and later.<strong>Mercury</strong> Marine, in compliance with those regulations, providesthis limited warranty for the emission control systems (see thecomponents listed in the Emission Control SystemComponents), and further warrants that the outboard enginewas designed, built, and equipped to conform with all applicableregulations adopted by the California Air Resources Boardpursuant to its authority in Chapters 1 and 2, Part 5, Division 26of the Health and Safety Code. For information regarding thelimited warranty for the nonemission‐related components of theoutboard, please see the limited warranty statement for youroutboard.14 eng

WARRANTY INFORMATIONWHAT IS COVERED: <strong>Mercury</strong> Marine warrants the componentsof the emissions control systems (see the components listed inthe Emission Control System Components) of its new, 2001model year and later outboards, sold by a California dealer toretail customers residing in California, to be free from defects inmaterial or workmanship, that cause the failure of a warrantedpart to be identical in all material respects to that part asdescribed in the application of <strong>Mercury</strong> Marine for certificationfrom the California Air Resources Board, for the period of time,and under the conditions, identified below. The cost to diagnosea warranty failure is covered under the warranty (if the warrantyclaim is approved). Damage to other engine components causedby the failure of a warranted part will also be repaired underwarranty.DURATION OF COVERAGE: This limited warranty providescoverage for the components of the emissions control systems ofnew, 2001 model year and later outboards, sold to retailcustomers in California for four (4) years from either the date theproduct is first sold, or first put into service, whichever occursfirst, or the accumulation of 250 hours of engine operation (asdetermined by the engine's hour meter, if any). Emission‐relatednormal maintenance items such as spark plugs and filters, thatare on the warranted parts list, are warranted up to their firstrequired replacement interval only. Refer to Emission ControlSystem Components and Maintenance Schedule. The repair orreplacement of parts, or the performance of service under thiswarranty, does not extend the life of this warranty beyond itsoriginal expiration date. Unexpired warranty coverage can betransferred to a subsequent purchaser. (See instructions ontransfer of warranty.)eng 15

WARRANTY INFORMATIONHOW TO OBTAIN WARRANTY COVERAGE: The customermust provide <strong>Mercury</strong> with a reasonable opportunity to repairand reasonable access to the product for warranty service.Warranty claims shall be made by delivering the product forinspection to a <strong>Mercury</strong> dealer authorized to service the product.If purchaser cannot deliver the product to such a dealer, pleasenotify <strong>Mercury</strong> Marine and <strong>Mercury</strong> will then arrange for theinspection and any covered repair. Purchaser, in that case, shallpay for all related transportation charges and/or travel time. If theservice provided is not covered by this warranty, purchaser shallpay for all related labor and material, and any other expensesassociated with that service. Purchaser shall not, unlessrequested by <strong>Mercury</strong>, ship the product or parts of the productdirectly to <strong>Mercury</strong>.WHAT MERCURY WILL DO: <strong>Mercury</strong> Marine's sole andexclusive obligation under this warranty is limited to, at ourexpense and at our option, repairing or replacing defective partswith new or <strong>Mercury</strong> Marine certified remanufactured parts, orrefunding the purchase price of the <strong>Mercury</strong> product. <strong>Mercury</strong>reserves the right to improve or modify products from time totime without assuming an obligation to modify productspreviously manufactured.WHAT IS NOT COVERED: This limited warranty does not coverroutine maintenance items, tune‐ups, adjustments, normal wearand tear, damage caused by abuse, abnormal use, use of apropeller or gear ratio that does not allow the engine to run in itsrecommended wide‐open throttle RPM range (see GeneralInformation ‐ Specifications), operation of the product in amanner inconsistent with the recommended operationprocedures, neglect, accident, submersion, improper installation(proper installation specifications and techniques are set forth inthe installation instructions for the product), improper service, jetpump impellers and liners, operation with fuels, oils, or lubricantswhich are not suitable for use with the product (see Fuel andOil), alteration or removal of parts.16 eng

WARRANTY INFORMATIONExpenses related to haul‐out, launch, towing, storage, telephone,rental, inconvenience, slip fees, insurance coverage, loanpayments, loss of time, loss of income, or any other type ofincidental or consequential damages are not covered by thiswarranty. Also, expenses associated with the removal and/orreplacement of boat partitions or material caused by boat designfor access to the product are not covered by this warranty.Nonwarranty maintenance, replacement, or repair of emissioncontrol devices and systems may be performed by any marineengine repair establishment or individual. The use ofnon‐<strong>Mercury</strong> parts for nonwarranty maintenance or repairs willnot be grounds for disallowing other warranty work. The use ofadd‐on (as defined at section 1900 (b)(1) and (b)(10) of Title 13of the California Code of Regulations) or modified parts notexempted by the California Air Resources Board may begrounds for disallowing a warranty claim, at the discretion of<strong>Mercury</strong> Marine. Failures of warranted parts caused by the useof a nonexempted add‐on or modified part will not be covered.DISCLAIMERS AND LIMITATIONSTHE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FORA PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. TO THEEXTENT THAT THEY CANNOT BE DISCLAIMED, THE IMPLIEDWARRANTIES ARE LIMITED IN DURATION TO THE LIFE OF THEEXPRESS WARRANTY. INCIDENTAL AND CONSEQUENTIAL DAMAGESARE EXCLUDED FROM COVERAGE UNDER THIS WARRANTY. SOMESTATES/COUNTRIES DO NOT ALLOW FOR THE DISCLAIMERS,LIMITATIONS AND EXCLUSIONS IDENTIFIED ABOVE, AS A RESULT,THEY MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOUSPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER LEGALRIGHTS WHICH VARY FROM STATE TO STATE AND COUNTRY TOCOUNTRY.If you have any questions regarding your warranty rights andresponsibilities, you should contact <strong>Mercury</strong> Marine at1‐920‐929‐5040.eng 17

WARRANTY INFORMATIONAs the outboard engine owner, you should, however, be awarethat <strong>Mercury</strong> Marine may deny you warranty coverage if youroutboard engine or a part has failed due to abuse, neglect,improper maintenance, or unapproved modifications.You are responsible for presenting your outboard to a <strong>Mercury</strong>dealer authorized to service the product as soon as a problemexists. The warranty repairs will be completed in a reasonableamount of time, not to exceed 30 days.If you have any questions regarding your warranty rights andresponsibilities, you should contact <strong>Mercury</strong> Marine at1‐920‐929‐5040.Emission Certification Star LabelOutboards are labeled on the cowl with one of the following starlabels.The symbol for a cleaner marine engine means:Cleaner air and water ‐ for a healthier lifestyle and environment.Better fuel economy ‐ burns up to 30–40 percent less gas and oilthan conventional carbureted two‐stroke engines, saving moneyand resources.Longer emission warranty ‐ protects consumer for worry‐freeoperation.One Star ‐ Low Emission22531The One Star label identifies engines that meetthe Air Resources Board's 2001 exhaustemissions standards. Engines meeting thesestandards have 75% lower emissions thanconventional carbureted two‐stroke engines.These engines are equivalent to the U.S. EPA's2006 standards for marine engines.Two Stars ‐ Very Low Emission42537The Two Star label identifies engines that meetthe Air Resources Board's Personal Watercraftand Outboard marine engine 2004 exhaustemissions standards. Engines meeting thesestandards have 20% lower emissions than OneStar ‐ Low Emission engines.eng 19

WARRANTY INFORMATIONThree Stars ‐ Ultra Low Emission42538The Three Star label identifies engines that meetthe Air Resources Board's Personal Watercraftand Outboard marine engine 2008 exhaustemissions standards or the Sterndrive andInboard marine engine 2003‐2008 exhaustemission standards. Engines meeting thesestandards have 65% lower emissions than OneStar ‐ Low Emission engines.Four Stars ‐ Super Ultra Low Emission42539The Four Star label identifies engines that meetthe Air Resources Board's Sterndrive and Inboardmarine engine 2009 exhaust emission standards.Personal Watercraft and Outboard marine enginesmay also comply with these standards. Enginesmeeting these standards have 90% loweremissions than One Star ‐ Low Emission engines.Warranty Policy—Australia and New ZealandMERCURY/MARINER OUTBOARD LIMITED WARRANTY–AUSTRALIA AND NEW ZEALAND POLICYThis limited warranty is given by Marine Power International PtyLtd ACN 003 100 007 of 41–71 Bessemer Drive, DandenongSouth, Victoria 3175 Australia (telephone (61) (3) 9791 5822)e‐mail: merc_info@mercmarine.com.What is Covered<strong>Mercury</strong> Marine warrants its new products to be free of defects inmaterial and workmanship during the period described below.The benefits to the consumer given by the warranty are inaddition to other rights and remedies of the consumer under alaw in relation to the goods or services to which the warrantyrelates.20 eng

WARRANTY INFORMATIONGuarantees Under Australian Consumer LawOur goods come with guarantees that cannot be excluded underthe Australian Consumer Law. You are entitled to a replacementor refund for a major failure and compensation for any otherreasonably foreseeable loss or damage. You are also entitled tohave the goods repaired or replaced if the goods fail to be ofacceptable quality and the failure does not amount to a majorfailure.Warranty Period for Recreational UseThis Limited Warranty provides coverage for three (3) years fromthe date the product is first sold to a recreational use retailpurchaser, or the date on which the product is first put intoservice, whichever occurs first. Unexpired warranty coveragecan be transferred to a subsequent recreational use customerupon proper registration of the product.Warranty Period for Commercial UseCommercial users of these products receive warranty coverageunder this Limited Warranty of one (1) year from the date of firstretail sale, or one (1) year from the date on which the productwas first put into service, whichever occurs first. Commercial useis defined as any work or employment related use of the product,or any use of the product which generates income, for any partof the warranty period, even if the product is only occasionallyused for such purposes. Unexpired warranty coverage cannot betransferred either to or from a commercial use customer.eng 21

WARRANTY INFORMATIONConditions That Must Be Met to Obtain Warranty CoverageWarranty coverage under this Limited Warranty is available onlyto retail customers that purchase from a Dealer authorized by<strong>Mercury</strong> Marine to distribute the product in the country in whichthe sale occurred, and then only after the <strong>Mercury</strong> Marinespecified predelivery inspection process is completed anddocumented. Warranty coverage becomes available upon properregistration of the product by the authorized dealer. Inaccuratewarranty registration information regarding recreational use, orsubsequent change of use from recreational to commercial(unless properly registered) may void the warranty at the solediscretion of <strong>Mercury</strong> Marine. Routine maintenance outlined inthe Operation and Maintenance Manual must be timelyperformed in order to maintain warranty coverage. <strong>Mercury</strong>Marine reserves the right to make warranty coverage contingentupon proof of proper maintenance.What <strong>Mercury</strong> Will Do<strong>Mercury</strong> Marine's sole and exclusive obligation under thisLimited Warranty is limited to, at our option, repairing a defectivepart, replacing such part or parts with new or <strong>Mercury</strong> Marinecertified remanufactured parts, or refunding the purchase price ofthe <strong>Mercury</strong> Marine product. <strong>Mercury</strong> Marine reserves the rightto improve or modify products from time to time withoutassuming an obligation to modify products previouslymanufactured.22 eng

WARRANTY INFORMATIONHow to Obtain Warranty Coverage Under This Limited WarrantyThe customer must provide <strong>Mercury</strong> Marine with a reasonableopportunity to repair and reasonable access to the product forwarranty service. Warranty claims shall be made by deliveringthe product for inspection to a <strong>Mercury</strong> Marine dealer authorizedto service the product. A list of dealers and their contact details isavailable at www.mercurymarine.com.au. If the purchaser cannotdeliver the product to such a dealer, written notice must be givento <strong>Mercury</strong> Marine at the address shown above. <strong>Mercury</strong> Marinewill then arrange for the inspection and any covered repair. ThisLimited Warranty will not cover the purchaser for all relatedtransportation charges and travel time. If the service provided isnot covered by this limited warranty, the purchaser shall pay forall related labor and material and any other expenses associatedwith that service, provided that a consumer will not be obligatedto pay where the service has been carried out to remedy a failureof an acceptable quality guarantee which is binding on <strong>Mercury</strong>Marine under the Australian Consumer Law. The purchaser shallnot, unless requested by <strong>Mercury</strong> Marine, ship the product orparts of the product directly to <strong>Mercury</strong> Marine. Proof ofregistered ownership must be presented to the dealer at the timewarranty service is requested in order to obtain coverage underthis Limited Warranty.eng 23

What is Not CoveredWARRANTY INFORMATIONThis limited warranty does not cover routine maintenance items,tune‐ups, adjustments, normal wear and tear, damage causedby abuse, abnormal use, use of a propeller or gear ratio thatdoes not allow the engine to run in its recommended wide‐openthrottle RPM range (see the Operation and MaintenanceManual), operation of the product in a manner inconsistent withthe recommended operation/duty cycle section of the Operationand Maintenance Manual, neglect, accident, submersion,improper installation (proper installation specifications andtechniques are set forth in the installation instructions for theproduct), improper service, use of an accessory or part notmanufactured or sold by us, jet pump impellers and liners,operation with fuels, oils or lubricants which are not suitable foruse with the product (see the Operation and MaintenanceManual), alteration or removal of parts, water entering the enginethrough the fuel intake, air intake or exhaust system, or damageto the product from insufficient cooling water caused by blockageof the cooling system by a foreign body, running the engine outof water, mounting the engine too high on the transom, orrunning the boat with the engine trimmed out too far. Use of theproduct for racing or other competitive activity, or operating witha racing type lower unit, at any point, even by a prior owner ofthe product, voids the warranty.Expenses related to haul‐out, launch, towing, storage, telephone,rental, inconvenience, slip fees, insurance coverage, loanpayments, loss of time, loss of income, or any other type ofincidental or consequential damages are not covered by thisLimited Warranty. Also, expenses associated with the removaland/or replacement of boat partitions or material caused by boatdesign for access to the product are not covered by thiswarranty.24 eng

WARRANTY INFORMATIONNo individual or entity, including <strong>Mercury</strong> Marine authorizeddealers, has been given authority by <strong>Mercury</strong> Marine to makeany affirmation, representation or warranty regarding theproduct, other than those contained in this limited warranty, andif made, shall not be enforceable against <strong>Mercury</strong> Marine. Foradditional information regarding events and circumstancescovered by this warranty, and those that are not, see theWarranty Coverage section of the Operation and MaintenanceManual, incorporated by reference into this warranty.Expense of Claiming This Limited WarrantyThis Limited Warranty does not cover any expenses you mayincur claiming the warranty.DISCLAIMERS AND LIMITATIONS:EXCEPT FOR APPLICABLE GUARANTEES AND OTHER RIGHTS ANDREMEDIES THAT A CONSUMER MAY HAVE UNDER THE AUSTRALIANCONSUMER LAW OR OTHER LAW IN RELATION TO WHICH THEPRODUCTS RELATE, THE IMPLIED WARRANTIES OFMERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AREEXPRESSLY DISCLAIMED. TO THE EXTENT THAT THEY CANNOT BEDISCLAIMED, THE IMPLIED WARRANTIES ARE LIMITED IN DURATIONTO THE LIFE OF THE EXPRESS WARRANTY. INCIDENTAL ANDCONSEQUENTIAL DAMAGES ARE EXCLUDED FROM COVERAGEUNDER THIS LIMITED WARRANTY.TRANSFER OF WARRANTY—AUSTRALIA AND NEWZEALAND POLICYThe limited warranty is transferable to a subsequent purchaser,but only for the remainder of the unused portion of the limitedwarranty. This will not apply to products used for commercialapplications.To transfer the warranty to the subsequent owner, send or fax acopy of the Bill of Sale or Purchase Agreement, new owner’sname, address, and hull identification number (HIN) to <strong>Mercury</strong>Marine’s Warranty Registration Department. In Australia andNew Zealand, mail to:eng 25

<strong>Mercury</strong> MarineWARRANTY INFORMATIONAttn: Warranty Registration DepartmentBrunswick Asia Pacific GroupPrivate Bag 1420Dandenong South, Victoria 3164AustraliaUpon processing the transfer of warranty, <strong>Mercury</strong> Marine willsend registration verification to the new owner of the product bymail. There is no charge for this service.You may change your address at any time, including at the timeof the warranty claim, by calling <strong>Mercury</strong> Marine or sending aletter or fax with your name, old address, new address, and hullidentification number (HIN) to <strong>Mercury</strong> Marine’s WarrantyRegistration Department.26 eng

GENERAL INFORMATIONBoater's ResponsibilitiesThe operator (driver) is responsible for the correct and safeoperation of the boat and the safety of its occupants and generalpublic. It is strongly recommended that each operator read andunderstand this entire <strong>manual</strong> before operating the outboard.Be sure that at least one additional person onboard is instructedin the basics of starting and operating the outboard and boathandling in case the driver is unable to operate the boat.Before Operating Your OutboardRead this <strong>manual</strong> carefully. Learn how to operate your outboardproperly. If you have any questions, contact your dealer.Safety and operating information that is practiced, along withusing good common sense, can help prevent personal injury andproduct damage.This <strong>manual</strong> as well as safety labels posted on the outboard usethe following safety alerts to draw your attention to special safetyinstructions that should be followed.! DANGERIndicates a hazardous situation which, if not avoided, will resultin death or serious injury.! WARNINGIndicates a hazardous situation which, if not avoided, couldresult in death or serious injury.! CAUTIONIndicates a hazardous situation which, if not avoided, couldresult in minor or moderate injury.NOTICEIndicates a situation which, if not avoided, could result inengine or major component failure.eng 27

GENERAL INFORMATIONBoat Horsepower Capacity! WARNINGExceeding the boat's maximum horsepower rating can causeserious injury or death. Overpowering the boat can affect boatcontrol and flotation characteristics or break the transom. Donot install an engine that exceeds the boat's maximum powerrating.Do not overpower or overload your boat. Most boats will carry arequired capacity plate indicating the maximum acceptablepower and load as determined by the manufacturer followingcertain federal guidelines. If in doubt, contact your dealer or theboat manufacturer.U.S. COAST GUARD CAPACITYMAXIMUM HORSEPOWER XXXMAXIMUM PERSONCAPACITY (POUNDS)MAXIMUM WEIGHTCAPACITYXXXXXX26777High‐Speed and High‐Performance Boat OperationIf your outboard is to be used on a high‐speed orhigh‐performance boat with which you are unfamiliar, werecommend that you never operate it at its high speed capabilitywithout first requesting an initial orientation and familiarizationdemonstration ride with your dealer or an operator experiencedwith your boat/outboard combination. For additional information,obtain a copy of our Hi‐Performance Boat Operation bookletfrom your dealer, distributor, or <strong>Mercury</strong> Marine.28 eng

GENERAL INFORMATIONOutboard Remote Control ModelsThe remote control connected to your outboard must beequipped with a start in neutral only protection device. Thisprevents the engine from starting when the shift is actuated inany position other than neutral.! WARNINGStarting the engine with the drive in gear can cause seriousinjury or death. Never operate a boat that does not have aneutral‐safety‐protection device.N26838Propeller SelectionThe propeller on your outboard is one of the most importantcomponents in the propulsion system. An improper propellerchoice can significantly affect the performance of your boat andcould result in damage to the outboard engine.When choosing a propeller, a full selection of aluminum andstainless steel propellers specifically designed for your outboardare available through <strong>Mercury</strong> Marine. To view the entire productoffering and find the correct propeller that is best suited for yourapplication, visit www.mercmarinepropellers.com or see yourlocal authorized <strong>Mercury</strong> dealer.SELECTING THE CORRECT PROPELLERAn accurate tachometer for measuring engine speed is importantin choosing the correct propeller.eng 29

GENERAL INFORMATIONChoose a propeller for your boating application that will allow theengine to operate within the specified full throttle operatingrange. When operating the boat at full throttle under normal loadconditions, the engine RPM should be in the upper half of therecommended full throttle RPM range. Refer to Specifications.If engine RPM is above that range, select a propeller ofincreased pitch in order to reduce engine RPM. If engine RPM isbelow the recommended range, select a propeller of reducedpitch to increase engine RPM.IMPORTANT: To ensure proper fit, and performance, <strong>Mercury</strong>Marine recommends the use of <strong>Mercury</strong> or Quicksilver brandedpropellers and mounting hardware.Propellers are designated by the diameter, pitch, number ofblades, and material. The diameter and pitch are stamped (cast)into the side or the end of the propeller hub. The first numberrepresents the diameter of the propeller and the second numberrepresents the pitch. For example, 14x19 represents a propellerwith a 14 inch diameter and 19 inches of pitch.ab22669a - Diameterb - Pitch ‐ Travel during one revolutionThe following are some propeller basics that will help youdetermine the correct propeller for your boating application.30 eng

GENERAL INFORMATIONDiameter ‐ The diameter is the distance across the imaginarycircle that is made when the propeller rotates. The correctdiameter for each propeller has been predetermined for thedesign of your outboard. However, when more than onediameter is available for the same pitch, use a larger diameter forheavy boat applications and a smaller diameter for lighterapplications.Pitch ‐ The pitch is the theoretical distance, in inches, that apropeller travels forward during one revolution. Pitch can bethought of similar to gears in a car. The lower the gear, the fasterthe car will accelerate, but with lower overall top speed.Likewise, a lower pitch propeller will accelerate quickly, buttop‐end speed will be reduced. The higher the propeller pitch thefaster the boat will usually go; though typically slowingacceleration.Determining the correct pitch size ‐ First, check the full throttleRPM under normal load condition. If the full throttle RPM iswithin the recommended range, select a replacement or upgradepropeller with the same pitch as the current propeller.• Adding 1 inch of pitch will reduce the full throttle RPM by150 to 200• Subtracting 1 inch of pitch will increase full throttle RPM by150 to 200• Upgrading from a 3‐blade propeller to a 4‐blade propellerwill generally decrease full throttle RPM by 50 to 100IMPORTANT: Avoid damage to the engine. Never use apropeller which allows the engine to exceed the recommendedfull throttle RPM range when under normal full throttle operation.eng 31

PROPELLER MATERIALGENERAL INFORMATIONMost propellers manufactured by <strong>Mercury</strong> Marine are made fromeither aluminum or stainless steel. Aluminum is suitable forgeneral purpose use and is standard equipment on many newboats. Stainless steel is over five times more durable thanaluminum and typically provides performance gains inacceleration and top end speed due to design efficiencies.Stainless steel propellers also come in a larger variety of sizesand styles that allow you to dial in the ultimate performance foryour boat.3 BLADE VS. 4 BLADEAvailable in many sizes of both aluminum and stainless, 3 and4‐blade propellers have unique performance characteristics. Ingeneral, 3‐blade propellers offer good all around performanceand higher top speed than 4‐blade propellers. However, 4‐bladepropellers are usually faster to plane and more efficient atcruising speeds, but lack the top end speed of a 3‐bladepropeller.Remote Steering NoticeThe steering link rod that connects the steering cable to theengine must be fastened utilizing self‐locking nuts. Theseself‐locking nuts must never be replaced with common nuts(nonlocking) as they will work loose and vibrate off, freeing thelink rod to disengage.32 eng

GENERAL INFORMATION! WARNINGImproper fasteners or improper installation procedures canresult in loosening or disengagement of the steering link rod.This can cause a sudden, unexpected loss of boat control,resulting in serious injury or death due to occupants beingthrown within or out of the boat. Always use requiredcomponents and follow instructions and torque procedures.a - Self‐locking nutsaa27740Lanyard Stop SwitchThe purpose of a lanyard stop switch is to turn off the enginewhen the operator moves far enough away from the operator'sposition (as in accidental ejection from the operator's position) toactivate the switch. Tiller handle outboards and some remotecontrol units are equipped with a lanyard stop switch. A lanyardstop switch can be installed as an accessory ‐ generally on thedashboard or side adjacent to the operator's position.eng 33

GENERAL INFORMATIONThe lanyard is a cord usually 122–152 cm (4–5 feet) in lengthwhen stretched out, with an element on one end made to beinserted into the switch and a snap on the other end for attachingto the operator. The lanyard is coiled to make its at‐rest conditionas short as possible to minimize the likelihood of lanyardentanglement with nearby objects. Its stretched‐out length ismade to minimize the likelihood of accidental activation shouldthe operator choose to move around in an area close to thenormal operator's position. If it is desired to have a shorterlanyard, wrap the lanyard around the operator's wrist or leg, ortie a knot in the lanyard.ab21629a - Lanyard cordb - Lanyard stop switchRead the following Safety Information before proceeding.34 eng

GENERAL INFORMATIONImportant Safety Information: The purpose of a lanyard stopswitch is to stop the engine when the operator moves far enoughaway from the operator's position to activate the switch. Thiswould occur if the operator accidentally falls overboard or moveswithin the boat a sufficient distance from the operator's position.Falling overboard and accidental ejections are more likely tooccur in certain types of boats such as low sided inflatables,bass boats, high performance boats, and light, sensitive handlingfishing boats operated by a hand tiller. Falling overboard andaccidental ejections are also likely to occur as a result of pooroperating practices such as sitting on the back of the seat orgunwale at planing speeds, standing at planing speeds, sittingon elevated fishing boat decks, operating at planing speeds inshallow or obstacle infested waters, releasing your grip on asteering wheel or tiller handle that is pulling in one direction,drinking alcohol or consuming drugs, or daring high speed boatmaneuvers.While activation of the lanyard stop switch will stop the engineimmediately, a boat will continue to coast for some distancedepending upon the velocity and degree of any turn at shutdown. However, the boat will not complete a full circle. While theboat is coasting, it can cause injury to anyone in the boat's pathas seriously as the boat would when under power.We strongly recommend that other occupants be instructed onproper starting and operating procedures should they berequired to operate the engine in an emergency (if the operatoris accidentally ejected).! WARNINGIf the operator falls out of the boat, stop the engine immediatelyto reduce the possibility of serious injury or death from beingstruck by the boat. Always properly connect the operator to thestop switch using a lanyard.eng 35

GENERAL INFORMATION! WARNINGAvoid serious injury or death from deceleration forces resultingfrom accidental or unintended stop switch activation. The boatoperator should never leave the operator's station without firstdisconnecting the stop switch lanyard from the operator.Accidental or unintended activation of the switch during normaloperation is also a possibility. This could cause any, or all, of thefollowing potentially hazardous situations:• Occupants could be thrown forward due to unexpected lossof forward motion ‐ a particular concern for passengers inthe front of the boat who could be ejected over the bow andpossibly struck by the gearcase or propeller.• Loss of power and directional control in heavy seas, strongcurrent, or high winds.• Loss of control when docking.KEEP THE LANYARD STOP SWITCH AND LANYARDCORD IN GOOD OPERATING CONDITIONBefore each use, check to ensure the lanyard stop switch worksproperly. Start the engine and stop it by pulling the lanyard cord.If the engine does not stop, have the switch repaired beforeoperating the boat.Before each use, visually inspect the lanyard cord to ensure it isin good working condition and that there are no breaks, cuts, orwear to the cord. Check that the clips on the ends of the cord arein good condition. Replace any damaged or worn lanyard cords.36 eng

GENERAL INFORMATIONProtecting People in the WaterWHILE YOU ARE CRUISINGIt is very difficult for a person standing or floating in the water totake quick action to avoid a boat heading in his/her direction,even at slow speed.21604Always slow down and exercise extreme caution any time youare boating in an area where there might be people in the water.Whenever a boat is moving (coasting) and the outboard gearshift is in neutral position, there is sufficient force by the water onthe propeller to cause the propeller to rotate. This neutralpropeller rotation can cause serious injury.WHILE THE BOAT IS STATIONARY! WARNINGA spinning propeller, a moving boat, or any solid deviceattached to the boat can cause serious injury or death toswimmers. Stop the engine immediately whenever anyone inthe water is near your boat.Shift the outboard into neutral and shut off the engine beforeallowing people to swim or be in the water near your boat.eng 37

GENERAL INFORMATIONPassenger Safety Message ‐ Pontoon Boats andDeck BoatsWhenever the boat is in motion, observe the location of allpassengers. Do not allow any passengers to stand or use seatsother than those designated for traveling faster than idle speed.A sudden reduction in boat speed, such as plunging into a largewave or wake, a sudden throttle reduction, or a sharp change ofboat direction, could throw them over the front of the boat.Falling over the front of the boat between the two pontoons willposition them to be run over by the outboard.BOATS HAVING AN OPEN FRONT DECKNo one should ever be on the deck in front of the fence while theboat is in motion. Keep all passengers behind the front fence orenclosure.Persons on the front deck could easily be thrown overboard orpersons dangling their feet over the front edge could get theirlegs caught by a wave and pulled into the water.26782! WARNINGSitting or standing in an area of the boat not designed forpassengers at speeds above idle can cause serious injury ordeath. Stay back from the front end of deck boats or raisedplatforms and remain seated while the boat is in motion.38 eng

GENERAL INFORMATIONBOATS WITH FRONT MOUNTED, RAISED PEDESTALFISHING SEATSElevated fishing seats are not intended for use when the boat istraveling faster than idle or trolling speed. Sit only in seatsdesignated for traveling at faster speeds.Any unexpected, sudden reduction in boat speed could result inthe elevated passenger falling over the front of the boat.26783Wave and Wake JumpingOperating recreational boats over waves and wake is a naturalpart of boating. However, when this activity is done with sufficientspeed to force the boat hull partially or completely out of thewater, certain hazards arise, particularly when the boat entersthe water.26784The primary concern is the boat changing direction while in themidst of the jump. In such case, the landing may cause the boatto veer violently in a new direction. Such a sharp change indirection can cause occupants to be thrown out of their seats, orout of the boat.eng 39

GENERAL INFORMATION! WARNINGWave or wake jumping can cause serious injury or death fromoccupants being thrown within or out of the boat. Avoid waveor wake jumping whenever possible.There is another less common hazardous result from allowingyour boat to launch off a wave or wake. If the bow of your boatpitches down far enough while airborne, upon water contact itmay penetrate under the water surface and submarine for aninstant. This will bring the boat to a nearly instantaneous stopand can send the occupants flying forward. The boat may alsosteer sharply to one side.Impact with Underwater HazardsReduce speed and proceed with caution whenever you drive aboat in shallow water areas, or in areas where you suspectunderwater obstacles may exist which could be struck by theoutboard or the boat bottom. The most important thing you cando to help reduce injury or impact damage from striking a floatingor underwater object is to control the boat speed. Under theseconditions, boat speed should be kept to a minimum planingspeed of 24 to 40 km/h (15 to 25 mph).26785Striking a floating or underwater object could result in an infinitenumber of situations. Some of these situations could result in thefollowing:• Part of the outboard or the entire outboard could break looseand fly into the boat.40 eng

GENERAL INFORMATION• The boat could move suddenly in a new direction. Such asharp change in direction can cause occupants to be thrownout of their seats or out of the boat.• A rapid reduction in speed. This will cause occupants to bethrown forward, or even out of the boat.• Impact damage to the outboard and/or boat.Keep in mind, the most important thing you can do to helpreduce injury or impact damage during an impact is control theboat speed. Boat speed should be kept to a minimum planingspeed when driving in waters known to have underwaterobstacles.After striking a submerged object, stop the engine as soon aspossible and inspect it for any broken or loose parts. If damageis present or suspected, the outboard should be taken to anauthorized dealer for a thorough inspection and necessaryrepair.The boat should also be checked for any hull fractures, transomfractures, or water leaks.Operating a damaged outboard could cause additional damageto other parts of the outboard, or could affect control of the boat.If continued running is necessary, do so at greatly reducedspeeds.! WARNINGOperating a boat or engine with impact damage can result inproduct damage, serious injury, or death. If the vesselexperiences any form of impact, have an authorized <strong>Mercury</strong>Marine dealer inspect and repair the vessel or power package.eng 41

Exhaust EmissionsGENERAL INFORMATIONBE ALERT TO CARBON MONOXIDE POISONINGCarbon monoxide (CO) is a deadly gas that is present in theexhaust fumes of all internal combustion engines, including theengines that propel boats, and the generators that power boataccessories. By itself, CO is odorless, colorless, and tasteless,but if you can smell or taste engine exhaust, you are inhalingCO.Early symptoms of carbon monoxide poisoning, which are similarto the symptoms of seasickness and intoxication, includeheadache, dizziness, drowsiness, and nausea.! WARNINGInhaling engine exhaust gases can result in carbon monoxidepoisoning, which can lead to unconsciousness, brain damage,or death. Avoid exposure to carbon monoxide.Stay clear from exhaust areas when engine is running. Keepthe boat well‐ventilated while at rest or underway.STAY CLEAR OF EXHAUST AREAS41127Engine exhaust gases contain harmful carbon monoxide. Avoidareas of concentrated engine exhaust gases. When engines arerunning, keep swimmers away from the boat, and do not sit, lie,or stand on swim platforms or boarding ladders. While underway,do not allow passengers to be positioned immediately behind theboat (platform dragging, teak/body surfing). This dangerouspractice not only places a person in an area of high engineexhaust concentration, but also subjects them to the possibility ofinjury from the boat propeller.42 eng

GENERAL INFORMATIONGOOD VENTILATIONVentilate the passenger area, open side curtains or forwardhatches to remove fumes.Example of desired air flow through the boat:21622POOR VENTILATIONUnder certain running and/or wind conditions, permanentlyenclosed or canvas enclosed cabins or cockpits with insufficientventilation may draw in carbon monoxide. Install one or morecarbon monoxide detectors in your boat.Although the occurrence is rare, on a very calm day, swimmersand passengers in an open area of a stationary boat thatcontains, or is near, a running engine may be exposed to ahazardous level of carbon monoxide.1. Examples of poor ventilation while the boat is stationary:ab21626a - Operating the engine when the boat is moored in aconfined spaceb - Mooring close to another boat that has its engineoperatingeng 43