MTT13 CAT773(F)

MTT13 CAT773(F)

MTT13 CAT773(F)

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

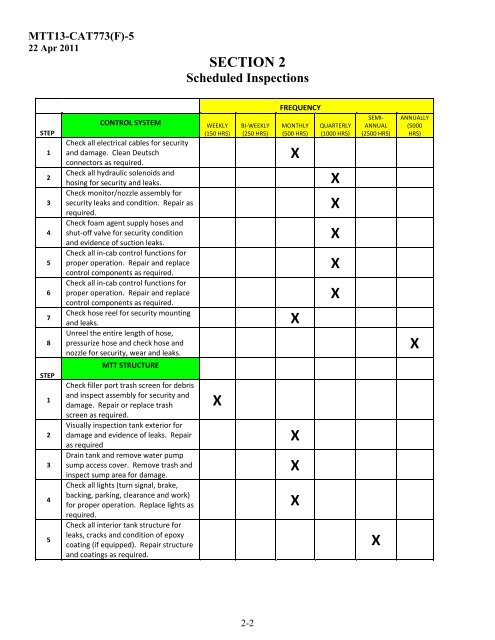

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011SECTION 2Scheduled InspectionsSTEP12345678STEP12345CONTROL SYSTEMCheck all electrical cables for securityand damage. Clean Deutschconnectors as required.Check all hydraulic solenoids andhosing for security and leaks.Check monitor/nozzle assembly forsecurity leaks and condition. Repair asrequired.Check foam agent supply hoses andshut-off valve for security conditionand evidence of suction leaks.Check all in-cab control functions forproper operation. Repair and replacecontrol components as required.Check all in-cab control functions forproper operation. Repair and replacecontrol components as required.Check hose reel for security mountingand leaks.Unreel the entire length of hose,pressurize hose and check hose andnozzle for security, wear and leaks.MTT STRUCTURECheck filler port trash screen for debrisand inspect assembly for security anddamage. Repair or replace trashscreen as required.Visually inspection tank exterior fordamage and evidence of leaks. Repairas requiredDrain tank and remove water pumpsump access cover. Remove trash andinspect sump area for damage.Check all lights (turn signal, brake,backing, parking, clearance and work)for proper operation. Replace lights asrequired.Check all interior tank structure forleaks, cracks and condition of epoxycoating (if equipped). Repair structureand coatings as required.WEEKLY(150 HRS)XBI-WEEKLY(250 HRS)FREQUENCYMONTHLY(500 HRS)XXXXXQUARTERLY(1000 HRS)XXXXXSEMI-ANNUAL(2500 HRS)XANNUALLY(5000HRS)X2-2