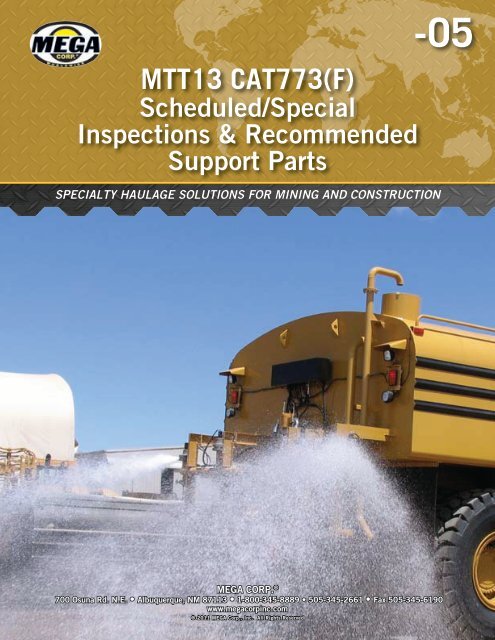

MTT13 CAT773(F)

MTT13 CAT773(F)

MTT13 CAT773(F)

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SECTION 1Definitions and Abbreviations<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011High Pressure Motor (11)This safety label is located on the hydraulicmotor.Hydraulic motor and supply lines contain oilunder high pressure. Improper removal andrepair procedures could cause severe injury.To remove or repair, instructions in theMaintenance Manual must be followed.ABBREVIATIONSBFV – Butterfly ValveCCW – Counter ClockwiseCW - ClockwiseFT - FeetFPM – Feet Per MinuteGPM – Gallons Per MinuteIN/SQ FT – Inches per Square FeetKM-H – Kilometers HourKg – kilogramsl - litersLT – Leftm - metersMPH – Miles Per HourMTT – Mega Truck Tankpsi - pounds square inchRPM – Revolutions Per MinuteRT – RightSQ FT – Square FeetVDC – Volts Direct CurrentConfined Space (12)This safety label is located near water tankaccess and fill ports.Do not enter confined spaces withoutfollowing established site specificprocedures. Failure to follow proper safetyprocedures will result in serious injury ordeath.1-5

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011SECTION 2Scheduled InspectionsContentsDescription ………………….…….……... 2-1Sprayheads ……………………………….. 2-1Control System …………………………… 2-2MTT Structure ……………..……………... 2-2Water Pump System .......…………............. 2-3DESCRIPTIONThis section establishes scheduled maintenance inspections of the installed MTT at the designatedfrequencies. Performing these inspections will identify potential system discrepancies and allowpreventative maintenance to be performed before a component or system is rendered totallyinoperative.**NOTE: Vehicles operated in extremely low quality water environments may require more frequentinspections.STEP123456SPRAYHEADSCheck spray head for damage andclean deflector ring and spray headopening.Check hydraulic lines for security,damage and leaks.Check spray head drop-in assembly forleaks with spray head switch OFF andwater pump ON. Replace drop-inassembly as required.Check spray head base plate and upperhousing mount bolts for security.Check spray head adjustable deflectorring for damage and correctadjustment. Apply dry-film lubricantto the deflector inner ring.Check spray head base plate forevidence of leaks. Replace base plateO-ring as required.WEEKLY(150 HRS)XXBI-WEEKLY(250 HRS)FREQUENCYMONTHLY(500 HRS)XXXQUARTERLY(1000 HRS)SEMI-ANNUAL(2500 HRS)ANNUALLY(5000 HRS)X2-1

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011SECTION 2Scheduled InspectionsSTEP12345678STEP12345CONTROL SYSTEMCheck all electrical cables for securityand damage. Clean Deutschconnectors as required.Check all hydraulic solenoids andhosing for security and leaks.Check monitor/nozzle assembly forsecurity leaks and condition. Repair asrequired.Check foam agent supply hoses andshut-off valve for security conditionand evidence of suction leaks.Check all in-cab control functions forproper operation. Repair and replacecontrol components as required.Check all in-cab control functions forproper operation. Repair and replacecontrol components as required.Check hose reel for security mountingand leaks.Unreel the entire length of hose,pressurize hose and check hose andnozzle for security, wear and leaks.MTT STRUCTURECheck filler port trash screen for debrisand inspect assembly for security anddamage. Repair or replace trashscreen as required.Visually inspection tank exterior fordamage and evidence of leaks. Repairas requiredDrain tank and remove water pumpsump access cover. Remove trash andinspect sump area for damage.Check all lights (turn signal, brake,backing, parking, clearance and work)for proper operation. Replace lights asrequired.Check all interior tank structure forleaks, cracks and condition of epoxycoating (if equipped). Repair structureand coatings as required.WEEKLY(150 HRS)XBI-WEEKLY(250 HRS)FREQUENCYMONTHLY(500 HRS)XXXXXQUARTERLY(1000 HRS)XXXXXSEMI-ANNUAL(2500 HRS)XANNUALLY(5000HRS)X2-2

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011SECTION 2Scheduled Inspections2-4(Blank)

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 201113. Turn monitor ON.14. Turn dump bar ON.15. Turn drain ON.16. Turn pump OFF.SECTION 3Special Inspections2. Inspect tank interior to ensure it is clean, ifthe tank is coated, ensure coating integrity,clean or repair as required.3. Install sump cover with new gasket.4. Ensure water separator filter drain is closedif equipped.Engaging/disengaging the water pumpabove LOW IDLE may result in waterpump component damage and reducedservice life.17. Turn system OFF.18. If equipped with a pneumatic spray system,drain water separator filter inside solenoidcontrol box.19. If unit is equipped with a suction loadingstation, ensure volute case petcock isOPEN.20. If unit is equipped with front spray bar,ensure spray bar drain is OPEN and wateris not left in hose.21. If unit is equipped with a hose reel, unrollhose, adjust discharge nozzle to OPEN, turnhose reel gate valve(s) ON, allow water todrain from hose and rewind.22. Check to ensure all water has drained fromtank.To restore unit to service from drainedstorage;1. Lubricate water pump bearings asinstructed in -2 manual. Inject 2 oz. ofgrease in each water pump shaft bearinggrease fitting and 4 to 5 injections of greaseto lantern ring grease fitting.5. Remove and clean hydraulic solenoidcontrol box filter before operating machine.6. Start engine.7. Turn system ON.8. Turn pump ON.Engaging/disengaging the water pumpabove LOW IDLE may result in waterpump component damage and reducedservice life.9. Ensure all sprayhead controls are OFF.10. Turn dump bar OFF.11. Turn drain OFF.12. Turn monitor OFF.13. Turn pump OFF.Engaging/disengaging the water pumpabove LOW IDLE may result in waterpump component damage and reducedservice life.14. Turn system OFF.15. Turn engine OFF.16. Close all drain valves and petcocks3-2

SECTION 4Recommended Support Parts<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011Description ………………….…….…... 4-1Spray Head Parts Group ……….…..….. 4-1Control System Parts Group .……......... 4-2Water Pump Parts Group ………….….. 4-2Hydraulic Drive Motor Parts Group …. 4-3Monitor Parts Group ……………..…... 4-3Miscellaneous Parts Group ……..…..... 4-3DESCRIPTIONThis section contains a listing of recommended support parts that should be available in the supplywarehouse. The tables are categorized by specific sub system of the MTT. DO NOT FORGET that allMTTs are not configured the same and there are several variations of water pumps, hydraulic drivemotors, monitors and BFVs. Ensure MTT serial numbers and actual component part numbers arechecked before ordering any parts. Once parts are issued from warehouse stock ensure depletedquantities are replenished to keep the recommended support parts package at 100%.Several support parts are designated as a “quick change assembly” and should be used to minimizerepair time of an operational MTT. Broken assemblies can be repaired by maintenance and laterreturned to the supply warehouse as a serviceable part.SPRAY HEAD PARTS GROUPPART DESCRIPTION PART NO. QTY1. Spray Head Drop-in Assembly 300409 62. Spray Head Diaphragm 300208 183. Guide Disk, Lower 300209 24. Guide Disk, Upper 300210 25. Stem Bolt 300211 26. O-Ring, Stem Bolt 300215 47. Stem Nut 300214 28. Bell Washer 300212 29. Spray Head Spring 300213 610. Cap Screw, SS, Housing 355335 1611. Washer, Lock, SS, Housing 355337 1612. Washer, Flat, SS, Housing 355336 1613. Spray Head Deflector Ring 300216 614. Spray Head Deflector Ring Knob 302912 615. O-Ring, Base 354502 1616. Washer, Flat (Base Plate Mount) 355295 817. Bolt (Base Plate Mount) 355294 818. Hydraulic Spray System **MTT Serial No. Specific Parta. Hydraulic Spray Head Assy. (QCA) 025610 2b. Cylinder, Hydraulic 304744 2c. Nut, Hex 1/2 x 20 350044 44-1

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011SECTION 4Recommended Support PartsB. CONTROL SYSTEM PARTS GROUPPART DESCRIPTION PART NO. QTY1. Joystick, Universal **MTT Serial No. Specific Part 303041 12. Timer, Intermittent **MTT Serial No. Specific Part 304751 13. Switch, SPST, Green Lens (Cab Control) 305019 14. Switch, SPST, White Lens (Cab Control) 305020 15. Switch, DPDT, No Lens (Cab Control) 305021 26. Sensor, Water Level ** MTT Serial No. Specific Part 303822 17. Hydraulic Spray System ** MTT Serial No. Specific Parta. Solenoid Valve, Hydraulic (Solenoid Box) 305156 2b. Coil, 24 VDC, (Solenoid Box) 304859 2c. Filter Element (Solenoid Box) 305276 1WATER PUMP PARTS GROUPPART DESCRIPTION PART NO. QTY1. M-4 ** MTT Serial No. Specific Part (QCA) 304991 12. Ring Packing, Shaft Seal 305114 33. Shaft Kit 305095 14. Seal, Grease 304960 15. Ring, Snap 305103 16. Ring, Thrust 305104 17. Key, Impeller 305106 28. Coupling 305102 19. Screw, Set 305107 210. Seal, O-ring, Volute 305111 111. Wear Ring, Frame 305091 112. Wear Ring, Volute 305092 113. Washer, Impeller 305093 114. Bolt, Impeller 305109 115. Washer, Lock, Impeller 305110 116. Packing Gland, Set 305098 117. Slinger 305100 118. Stud, Packing Gland 305105 219. Nut, Packing Gland 350026 420. Ring, Lantern 305112 14-2

SECTION 4Recommended Support Parts<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011WATER PUMP DRIVE MOTOR PARTS GROUPPART DESCRIPTION PART NO. QTY1. Motor, Hydraulic (M75 30-7) ** MTT Serial No. Specific Part 302080 12. Seal Kit, (M75) 300944 13. Flow Control Valve 300161 1MONITOR SUPPORT PARTS GROUPPART DESCRIPTION PART NO. QTY1. Joint Rebuild Kit 305141 12. Electric Monitor ** MTT Serial No. Specific Parta. Motor, Electric 304618 13. Hydraulic Monitor ** MTT Serial No. Specific Parta. Motor, Hydraulic 304656 1b. Solenoid Valve (Monitor Control Valve Assembly) 304858 1c. Solenoid Coil (Monitor Control Valve Assembly) 304859 2MISCELLANEOUS PARTS GROUPPART DESCRIPTION PART NO. QTY1. Valve, Butterfly, 3” 300030 12. Valve, Gate, 1.5” (Spray Bar) 300106 13. Valve, 3/4" Ball (Spray Bar) 300627 24. Seal, Coupling, 4” Dresser 300820 25. O-Ring, #24 (Split Flange) 354816 204-3

<strong>MTT13</strong>-<strong>CAT773</strong>(F)-522 Apr 2011SECTION 4Recommended Support PartsNOTES4-4