Optimize Powder Processing - Chemical Processing

Optimize Powder Processing - Chemical Processing

Optimize Powder Processing - Chemical Processing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

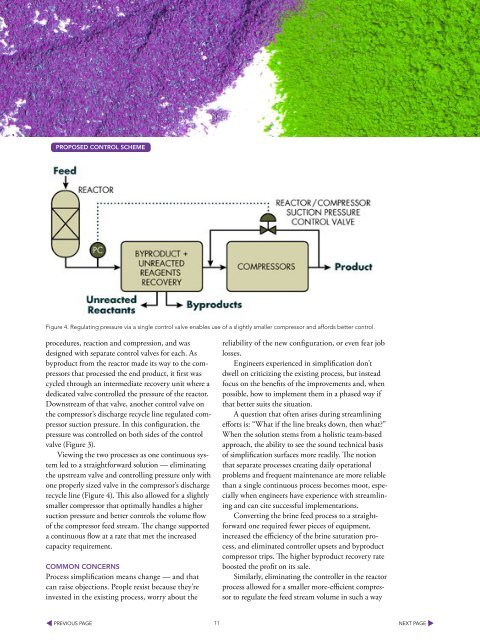

PROPOSED CONTROL SCHEMEFigure 4. Regulating pressure via a single control valve enables use of a slightly smaller compressor and affords better control.procedures, reaction and compression, and wasdesigned with separate control valves for each. Asbyproduct from the reactor made its way to the compressorsthat processed the end product, it first wascycled through an intermediate recovery unit where adedicated valve controlled the pressure of the reactor.Downstream of that valve, another control valve onthe compressor’s discharge recycle line regulated compressorsuction pressure. In this configuration, thepressure was controlled on both sides of the controlvalve (Figure 3).Viewing the two processes as one continuous systemled to a straightforward solution — eliminatingthe upstream valve and controlling pressure only withone properly sized valve in the compressor’s dischargerecycle line (Figure 4). This also allowed for a slightlysmaller compressor that optimally handles a highersuction pressure and better controls the volume flowof the compressor feed stream. The change supporteda continuous flow at a rate that met the increasedcapacity requirement.COMMON CONCERNSProcess simplification means change — and thatcan raise objections. People resist because they’reinvested in the existing process, worry about thereliability of the new configuration, or even fear joblosses.Engineers experienced in simplification don’tdwell on criticizing the existing process, but insteadfocus on the benefits of the improvements and, whenpossible, how to implement them in a phased way ifthat better suits the situation.A question that often arises during streamliningefforts is: “What if the line breaks down, then what?”When the solution stems from a holistic team-basedapproach, the ability to see the sound technical basisof simplification surfaces more readily. The notionthat separate processes creating daily operationalproblems and frequent maintenance are more reliablethan a single continuous process becomes moot, especiallywhen engineers have experience with streamliningand can cite successful implementations.Converting the brine feed process to a straightforwardone required fewer pieces of equipment,increased the efficiency of the brine saturation process,and eliminated controller upsets and byproductcompressor trips. The higher byproduct recovery rateboosted the profit on its sale.Similarly, eliminating the controller in the reactorprocess allowed for a smaller more-efficient compressorto regulate the feed stream volume in such a way11