You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

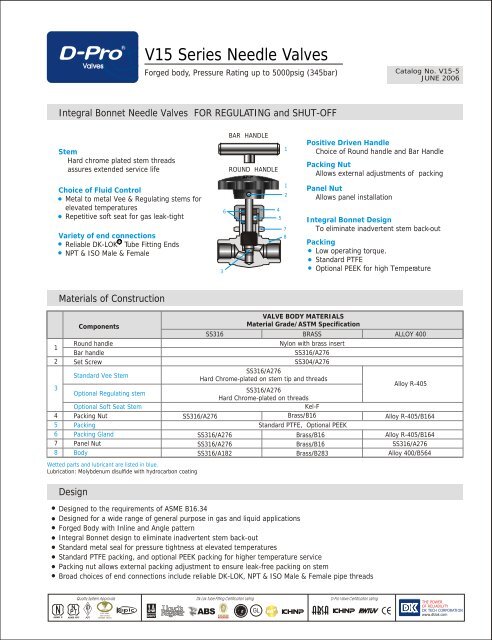

<strong>V15</strong> <strong>Series</strong> <strong>Needle</strong> <strong>Valves</strong>Forged body, Pressure Rating up to 5000psig (345bar)Catalog No. <strong>V15</strong>-5JUNE 2006Integral Bonnet <strong>Needle</strong> <strong>Valves</strong> FOR REGULATING and SHUT-OFFStemHard chrome plated stem threadsassures extended service lifeBAR HANDLEROUND HANDLE1Positive Driven HandleChoice of Round handle and Bar HandlePacking NutAllows external adjustments of packingChoice of Fluid ControlMetal to metal Vee & Regulating stems forelevated temperaturesRepetitive soft seat for gas leak-tightVariety of end connectionsReliable DK-LOK Tube Fitting EndsNPT & ISO Male & Female36124578Panel NutAllows panel installationIntegral Bonnet DesignTo eliminate inadvertent stem back-outPackingLow operating torque.Standard PTFEOptional PEEK for high TemperatureMaterials of Construction12345678ComponentsRound handleBar handleSet ScrewStandard Vee StemOptional Regulating stemOptional Soft Seat StemPacking NutPackingPacking GlandPanel NutBodyWetted parts and lubricant are listed in blue.Lubrication: Molybdenum disulfide with hydrocarbon coatingVALVE BODY MATERIALSMaterial Grade/ASTM SpecificationSS316 BRASS ALLOY 400Nylon with brass insertSS316/A276SS304/A276SS316/A276Hard Chrome-plated on stem tip and threadsAlloy R-405SS316/A276Hard Chrome-plated on threadsKel-FSS316/A276 Brass/B16 Alloy R-405/B164Standard PTFE, Optional PEEKSS316/A276SS316/A276SS316/A182Brass/B16Brass/B16Brass/B283Alloy R-405/B164SS316/A276Alloy 400/B564DesignDesigned to the requirements of ASME B16.34Designed for a wide range of general purpose in gas and liquid applicationsForged Body with Inline and Angle patternIntegral Bonnet design to eliminate inadvertent stem back-outStandard metal seal for pressure tightness at elevated temperaturesStandard PTFE packing, and optional PEEK packing for higher temperature servicePacking nut allows external packing adjustment to ensure leak-free packing on stemBroad choices of end connections include reliable DK-LOK, NPT & ISO Male & Female pipe threadsTHE POWEROF RELIABILITYDK TECH CORPORATIONwww.dklok.com

<strong>Needle</strong> <strong>Valves</strong><strong>V15</strong> <strong>Series</strong>Operationo oPressure rating up to 5000psig (345bar) @100 F (38 C)o o o oTemperature rating up to 450 F (232 C) with standard PTFE packing; up to 600 F (315 C) with optional PEEK packingPanel mounting without packing disruptionStandard SS316 and Brass material valve constructionDK-LOK Gap gauge allows easy inspection for sufficient tube pull-up before a system is pressurized<strong>Valves</strong> for Sour Gas Service meeting the requirements of NACE MR0175 are availableFactory TestEvery valve is tested with the nitrogen @1000psig (68bar) for leakage at the seat to a maximum allowable leak rate of0.1 SCCM. The packing is tested for no detectable leakage.Panel MountingHow to mount on panel.Panel NutDisassemblyPanel hole drill and thickness mm( inch)Valve<strong>Series</strong><strong>V15</strong>A<strong>V15</strong>B<strong>V15</strong>C<strong>V15</strong>DPanelHole Drill13.5 ( 0.53)13.5 ( 0.53)20.0 ( 0.78)26.2 ( 1.03)Panel ThicknessMin.3.17( 0.12)Max.6.35( 0.25)1. Loosen the handle set screw using an allen key and remove the handleHandle Set Screw Allen KeyValve <strong>Series</strong><strong>V15</strong>A & <strong>V15</strong>B<strong>V15</strong>C<strong>V15</strong>DAllen KeyRound Handle Bar HandleHex.2.5mmHex. 4.0mmHex.3.0mmHex. 5.0mm2. Remove the packing nut & panel nut and set aside for later use.3. Place the valve bonnet in the panel hole.Reassembly4. Tighten the panel nut onto the valve bonnet.Keep the panel nut always on the external portion of the panel.5. Finger tighten the packing nut onto the valve body.6. Place the handle on the stem. Align the set screw with the groove on theside of the stem. Tighten the set screw.7. Fully close the valve and retract the stem two or three turns before torquethe packing nut to the torque value below.Valve <strong>Series</strong><strong>V15</strong>A, <strong>V15</strong>B<strong>V15</strong>C<strong>V15</strong>Dlbf.ft5.210.625.1Torquekgf.cm71146347Choice of Stem TipVee Stem Regulating Stem Soft seatMetal to metal Vee stem for pressuretightness at elevated temperature.Regulating stem for flow rate controlKEL-F soft seat for repetitive shut-off on gas.Round Handle is recommended for soft seat valve.Note: Soft seat packing adjustment may be required during service to compensate the physical compression of soft seat after repeated shut-off.2C2001,2004, 2005. Dk Tech Corporation. All Right Reserved.

<strong>Needle</strong> <strong>Valves</strong><strong>V15</strong> <strong>Series</strong>Ordering Information and Table of DimensionsInline PatternHAngle PatternAOPENH 1AOPENDDL1L2BAR HANDLEBValve BasicOrdering Number<strong>V15</strong>A<strong>V15</strong>B<strong>V15</strong>C<strong>V15</strong>DF-2N-M-2N-MD-2N2T-D-2T-D-3M-F-2N-M-2N-M-4N-MD-4N4T-D-6M-D-4T-D-8M-F-4N-F-4R-MF-4N-MD-4N6T-M-6N-MD-6N6T-MD-6N8T-D-10M-D-6T-D-12M-D-8T-F-6N-F-6R-F-8N-F-8R-M-8N-MF-8N-D-8T-D-12T- 3/4 in. Dk-LokAll dimensions shown are for reference only and are subject to change. Dimensions with DK-LOK nuts are in finger-tight position.Patterns: To order angle pattern, use -A as a suffix to the valve ordering number. Example : <strong>V15</strong>A-F-2N-ATechnical DataLEnd ConnectionsInletOutlet1/8 in. Female NPT1/8 in. Male NPT1/8 in. Male NPT 1/8" Dk-Lok1/8 in. Dk-Lok3mm Dk-Lok1/8 in. Female NPT1/8 in. Male NPT1/4 in. Male NPT1/4 in. Male NPT 1/4" Dk-Lok6mm Dk-Lok1/4 in. Dk-Lok8mm Dk-Lok1/4 in. Female NPT1/4 in. Female ISO Tapered1/4 in. Male NPT1/4 in. Male NPT3/8 in. Male NPT3/8 in. Male NPT3/8 in. Male NPT10mm Dk-Lok3/8 in. Dk-Lok12mm Dk-Lok1/4" Female NPT3/8" Dk-Lok3/8" Dk-Lok1/2" Dk-Lok1/2 in. Dk-Lok3/8 in. Female NPT3/8 in. Female ISO Tapered1/2 in. Female NPT1/2 in. Female ISO Tapered1/2 in. Male NPT1/2 in. Male NPT 1/2" Female NPT1/2 in. Dk-LokOrificeASME Material Group TABLE 2-2.2 N/A TABLE 2-3.4Material NameASME CLASS RatingSS3162080BrassN/AAlloy 4001500Temperature @ pressure psig bar psig bar psig Baro o100 F (38 C)500034530002073000206o o200 F (93 C)429329623531622640181-65 (-54 ) tooo300 F (148 C)387726720591422470170oo350 F (176 C)371925614711012430167oo400 F (204 C)3562246392272390164oo450 F (232 C)3437237--2380163Note : Pressure rating of valve is sometimes limited to the working pressure of pipe ends and the tubing connected.Refer to DK-LOK Tube Fitting catalog for the details of working pressures in various tubing sizes, materials and wall thickness.2.0( .08)4.3( .17)6.4( .25)9.5( .375)Cv0.090.370.731.80EL2Unit : mm ( inch)DimensionsA B L L1 L2 E D H H1Working pressureThe class rating and rated working pressure are the way that ASME standards simpllify the design process. The pressure rating is governed by the allowable stress ofdifferent material group, class rating, and service temperature.60( 2.36)60( 2.36)71( 2.80)99( 3.90)21( .83)26(1.02)21( .83)25( .98)29( 1.14)30( 1.18)28( 1.10)29( 1.14)33( 1.30)36(1.42)38( 1.50)49(1.93)42( 1.65)47( 1.85)52( 2.05)42( 1.65)50( 1.97)54( 2.13)57.6( 2.27)59.2( 2.33)56( 2.20)61.2( 2.41)58( 2.28)62.2( 2.45)65( 2.56)66( 2.60)72( 2.83)76( 2.99)97( 3.82)21(.83)25( .98)28.8( 1.13)28( 1.10)29( 1.14)33.2( 1.31)36( 1.42)38( 1.50)21( .83)26( 1.02)21( .83)20( .79)26( 1.02)25( .98)28.8( 1.13)29.6( 1.16)48.5( 1.91)28( 1.10)33.2( 1.31)29( 1.14)33.2( 1.31)36( 1.42)33.2( 1.31)36( 1.42)38( 1.50)9.5( .37)9.5( .37)13( .51)19( .75)11( .43)11( .43)13.5( .53)19( .75)36( 1.42)36( 1.42)50( 1.97)66( 2.06)32( 1.26)45( 1.77)64( 2.52)76( 3.00)3

Temperature and Pressure Rating with standard PTFE and Optional PEEK packingValve MaterialSS316BrassAlloy 400<strong>Needle</strong> <strong>Valves</strong>StemMetal to metal(Vee & Regulating)Soft Seat(Kel-F)Metal to metal(Vee & Regulating)Soft Seat(Kel-F)Metal to metal(Vee & Regulating)Soft Seat(Kel-F)Temperature RatingF ( C)-65 to 450(-54 to 232)-65 to 200(-54 to 93)-65 to 400(-54 to 204)-65 to 200(-54 to 93)-65 to 450(-54 to 232)-65 to 200(-54 to 93)with PTFE packingPressure Rating@100 (38 )5000 psig(345 bar)3000 psig(207 bar)3000 psig(207 bar)Temperature RatingF( C)-65 to 600(-54 to 315)-65 to 200(-54 to 93 )-65 to 400(-54 to 204)-65 to 200(-54 to 93)-65 to 500(-54 to 260)-65 to 200(-54 to 93)<strong>V15</strong> <strong>Series</strong>with PEEK packingPressure Rating@100 (38 )3130 psig(215 bar)3000 psig(207 bar)2370 psig(162 bar)Flow Curves<strong>V15</strong>CFor <strong>V15</strong>A, 15B & 15C<strong>V15</strong>C0.8For <strong>V15</strong>D2.00.7<strong>V15</strong>D0.61.50.5<strong>V15</strong>B<strong>V15</strong>B0.4 Cv<strong>V15</strong>D1.0Cv0.30.2Vee stem and Soft seatRegulating stem0.5<strong>V15</strong>A<strong>V15</strong>A0.19 8 7 6 5 4 3 2 1 0 5 4 3 2 1 0Turns Open of Valve HandleTurns Open of Valve HandleHo w to orderSelect applicable Valve Pattern, Stem Tip, Handle and Body material from designators listed below.<strong>V15</strong>B-F-2N<strong>V15</strong>B-F-2N-PK-A -R-BH-S-SValve PatternStem PackingDesignatorStem DesignatorHandle DesignatorBody MaterialDesignatorNil : Inline patternA : Angle patternNil : Standard PTFEPK : PEEKNil : Standard Vee stem tipR : Regulating tipK : Kel-F Soft seatNil : Nylon Round HandleBH : Bar HandleS : SS316B : BrassM : Alloy 400Handle for Soft SeatRound Handle is recommended for soft seat valve to prevent the soft seat from damage.We reserve the right to change specifications stated in this catalog for our continuing program of improvement.Safe Valve SelectionThe selection of a valve for any application or system design must be considered to ensure safe performance.Valve function, valve rating, material compatibility,proper installation, operation and maintenance remain the sole responsibillty of the system designer and the user. Dk Tech accepts no liability for any improperselection, installation, operation or maintenance.THE POWEROF RELIABILITYDK TECH CORPORATIONwww.dklok.comDK TECH TrademarksMailing Address826, Naesam-Ri, Juchon-Myeon, Gimhae-City,Gyeong Nam, Korea 621-841DK TECH contact informationTel. (82) 55-338-0114Fax. (82) 55-338-6745E-mail: sales@dklok.comFor International customersTel. (82) 55-338-0031/2Fax. (82) 55-338-6746E-mail: dklok@dklok.com