OSB Oil/Water Separator Catalog - ZEKS Compressed Air Solutions

OSB Oil/Water Separator Catalog - ZEKS Compressed Air Solutions

OSB Oil/Water Separator Catalog - ZEKS Compressed Air Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

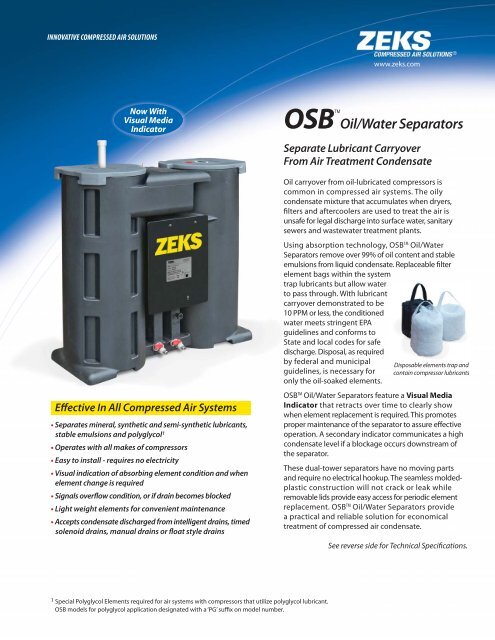

INNOVATIVE COMPRESSED AIR SOLUTIONSwww.zeks.comNow WithVisual MediaIndicator<strong>OSB</strong>TM<strong>Oil</strong>/<strong>Water</strong> <strong>Separator</strong>sSeparate Lubricant CarryoverFrom <strong>Air</strong> Treatment CondensateEffective In All <strong>Compressed</strong> <strong>Air</strong> Systems• Separates mineral, synthetic and semi-synthetic lubricants,stable emulsions and polyglycol 1• Operates with all makes of compressors• Easy to install - requires no electricity• Visual indication of absorbing element condition and whenelement change is required• Signals overflow condition, or if drain becomes blocked• Light weight elements for convenient maintenance• Accepts condensate discharged from intelligent drains, timedsolenoid drains, manual drains or float style drains<strong>Oil</strong> carryover from oil-lubricated compressors iscommon in compressed air systems. The oilycondensate mixture that accumulates when dryers,filters and aftercoolers are used to treat the air isunsafe for legal discharge into surface water, sanitarysewers and wastewater treatment plants.Using absorption technology, <strong>OSB</strong> TM <strong>Oil</strong>/<strong>Water</strong><strong>Separator</strong>s remove over 99% of oil content and stableemulsions from liquid condensate. Replaceable filterelement bags within the systemtrap lubricants but allow waterto pass through. With lubricantcarryover demonstrated to be10 PPM or less, the conditionedwater meets stringent EPAguidelines and conforms toState and local codes for safedischarge. Disposal, as requiredby federal and municipalguidelines, is necessary foronly the oil-soaked elements.Disposable elements trap andcontain compressor lubricants<strong>OSB</strong> TM <strong>Oil</strong>/<strong>Water</strong> <strong>Separator</strong>s feature a Visual MediaIndicator that retracts over time to clearly showwhen element replacement is required. This promotesproper maintenance of the separator to assure effectiveoperation. A secondary indicator communicates a highcondensate level if a blockage occurs downstream ofthe separator.These dual-tower separators have no moving partsand require no electrical hookup. The seamless moldedplasticconstruction will not crack or leak whileremovable lids provide easy access for periodic elementreplacement. <strong>OSB</strong> TM <strong>Oil</strong>/<strong>Water</strong> <strong>Separator</strong>s providea practical and reliable solution for economicaltreatment of compressed air condensate.See reverse side for Technical Specifications.1 Special Polyglycol Elements required for air systems with compressors that utilize polyglycol lubricant.<strong>OSB</strong> models for polyglycol application designated with a ‘PG’ suffix on model number.

<strong>OSB</strong> TM <strong>Oil</strong>/<strong>Water</strong> <strong>Separator</strong>s<strong>OSB</strong>1250<strong>OSB</strong>1250PG<strong>OSB</strong>750<strong>OSB</strong>750PG<strong>OSB</strong>350<strong>OSB</strong>350PG<strong>OSB</strong>175<strong>OSB</strong>175PGTechnical SpecificationsAIR COMPRESSOR CONNECTION SIZE ELEMENT DIMENSIONS SHIPPINGMODEL CAPACITY APPLICATION INLETS (Qty.) OUTLET TYPE WIDTH DEPTH HEIGHT WEIGHT (lbs.)<strong>OSB</strong>175 Up to 175 scfm Mineral, Synthetic, 1/2” (2) 1” Absorption (TWR 1) 23.O” 7.5” 24.0” 23Semi-Synthetic <strong>Oil</strong>s, Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>175PG Up to 175 scfm Polyglycol 1/2” (2) 1” Absorption (TWR 1) 23.0” 7.5” 24.0” 23Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>350 175 to 350 scfm Mineral, Synthetic, 1/2” (2) 1” Absorption (TWR 1) 25.6” 9.5” 29.5” 42Semi-Synthetic <strong>Oil</strong>s, Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>350PG 175 to 350 scfm Polyglycol 1/2” (2) 1” Absorption (TWR 1) 25.6” 9.5” 29.5” 42Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>750 350 to 750 scfm Mineral, Synthetic, 1/2” (2) 1” Absorption (TWR 1) 30.7” 12.0” 35.4” 71Semi-Synthetic <strong>Oil</strong>s, Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>750PG 350 to 750 scfm Polyglycol 1/2” (2) 1” Absorption (TWR 1) 30.7” 12.0” 35.4” 71Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>1250 750 to 1250 scfm Mineral, Synthetic, 1/2” (2) 1” Absorption (TWR 1) 38.2” 15.0” 35.4” 106Semi-Synthetic <strong>Oil</strong>s, Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong>1250PG 750 to 1250 scfm Polyglycol 1/2” (2) 1” Absorption (TWR 1) 38.2” 15.0” 35.4” 106Absorption (TWR 2)Carbon Finishing (TWR 2)<strong>OSB</strong> TM model selection is based on total air compressor capacity andlubricant type. Refer to the Technical Specifications chart to choosethe model that meets or exceeds the total volume (SCFM) of thecompressed air system.For installations up to 2500 SCFM, <strong>ZEKS</strong> recommends the use of two <strong>OSB</strong>1250 units.Specifications, illustrative materials and descriptions contained herein were as accurate as known at the time this publication wasapproved for printing. The company reserves the right to change specifications, discontinue models, equipment or design withoutnotice and without incurring obligation. The information set out in this brochure is for preliminary information only and is not intendedto constitute any representation or warranty by <strong>ZEKS</strong> to potential customers or to form the basis of a contract with any customer.© 2013 <strong>ZEKS</strong> <strong>Compressed</strong> <strong>Air</strong> <strong>Solutions</strong> <strong>OSB</strong> 03131302 Goshen ParkwayWest Chester, PA 19380Phone: 610-692-9100 800-888-2323Fax: 610-692-9192Web: www.zeks.com