Vehicle Handling with Tire Tread Separation - Transportation Safety

Vehicle Handling with Tire Tread Separation - Transportation Safety

Vehicle Handling with Tire Tread Separation - Transportation Safety

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

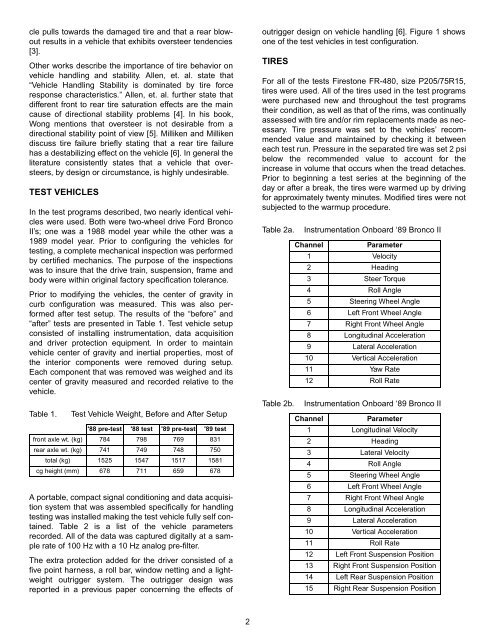

cle pulls towards the damaged tire and that a rear blowoutresults in a vehicle that exhibits oversteer tendencies[3].Other works describe the importance of tire behavior onvehicle handling and stability. Allen, et. al. state that“<strong>Vehicle</strong> <strong>Handling</strong> Stability is dominated by tire forceresponse characteristics.” Allen, et. al. further state thatdifferent front to rear tire saturation effects are the maincause of directional stability problems [4]. In his book,Wong mentions that oversteer is not desirable from adirectional stability point of view [5]. Milliken and Millikendiscuss tire failure briefly stating that a rear tire failurehas a destabilizing effect on the vehicle [6]. In general theliterature consistently states that a vehicle that oversteers,by design or circumstance, is highly undesirable.TEST VEHICLESIn the test programs described, two nearly identical vehicleswere used. Both were two-wheel drive Ford BroncoII’s; one was a 1988 model year while the other was a1989 model year. Prior to configuring the vehicles fortesting, a complete mechanical inspection was performedby certified mechanics. The purpose of the inspectionswas to insure that the drive train, suspension, frame andbody were <strong>with</strong>in original factory specification tolerance.Prior to modifying the vehicles, the center of gravity incurb configuration was measured. This was also performedafter test setup. The results of the “before” and“after” tests are presented in Table 1. Test vehicle setupconsisted of installing instrumentation, data acquisitionand driver protection equipment. In order to maintainvehicle center of gravity and inertial properties, most ofthe interior components were removed during setup.Each component that was removed was weighed and itscenter of gravity measured and recorded relative to thevehicle.Table 1.Test <strong>Vehicle</strong> Weight, Before and After Setup'88 pre-test '88 test '89 pre-test '89 testfront axle wt. (kg) 784 798 769 831rear axle wt. (kg) 741 749 748 750total (kg) 1525 1547 1517 1581cg height (mm) 678 711 659 678A portable, compact signal conditioning and data acquisitionsystem that was assembled specifically for handlingtesting was installed making the test vehicle fully self contained.Table 2 is a list of the vehicle parametersrecorded. All of the data was captured digitally at a samplerate of 100 Hz <strong>with</strong> a 10 Hz analog pre-filter.The extra protection added for the driver consisted of afive point harness, a roll bar, window netting and a lightweightoutrigger system. The outrigger design wasreported in a previous paper concerning the effects ofoutrigger design on vehicle handling [6]. Figure 1 showsone of the test vehicles in test configuration.TIRESFor all of the tests Firestone FR-480, size P205/75R15,tires were used. All of the tires used in the test programswere purchased new and throughout the test programstheir condition, as well as that of the rims, was continuallyassessed <strong>with</strong> tire and/or rim replacements made as necessary.<strong>Tire</strong> pressure was set to the vehicles’ recommendedvalue and maintained by checking it betweeneach test run. Pressure in the separated tire was set 2 psibelow the recommended value to account for theincrease in volume that occurs when the tread detaches.Prior to beginning a test series at the beginning of theday or after a break, the tires were warmed up by drivingfor approximately twenty minutes. Modified tires were notsubjected to the warmup procedure.Table 2a.Table 2b.Instrumentation Onboard ‘89 Bronco IIChannelParameter1 Velocity2 Heading3 Steer Torque4 Roll Angle5 Steering Wheel Angle6 Left Front Wheel Angle7 Right Front Wheel Angle8 Longitudinal Acceleration9 Lateral Acceleration10 Vertical Acceleration11 Yaw Rate12 Roll RateInstrumentation Onboard ‘89 Bronco IIChannelParameter1 Longitudinal Velocity2 Heading3 Lateral Velocity4 Roll Angle5 Steering Wheel Angle6 Left Front Wheel Angle7 Right Front Wheel Angle8 Longitudinal Acceleration9 Lateral Acceleration10 Vertical Acceleration11 Roll Rate12 Left Front Suspension Position13 Right Front Suspension Position14 Left Rear Suspension Position15 Right Rear Suspension Position2