Download - James H. Heal Co., Ltd

Download - James H. Heal Co., Ltd

Download - James H. Heal Co., Ltd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

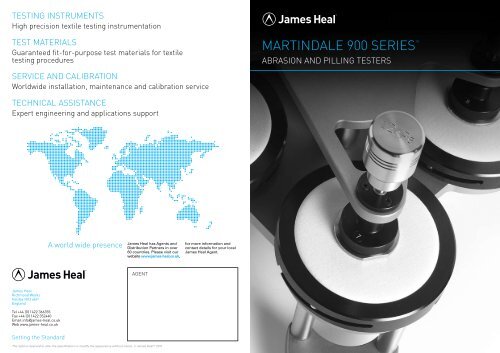

TESTING INSTRUMENTSHigh precision textile testing instrumentationTEST MATERIALSGuaranteed fit-for-purpose test materials for textiletesting proceduresTMMARTINDALE 900 SERIESABRASION AND PILLING TESTERSSERVICE AND CALIBRATIONWorldwide installation, maintenance and calibration serviceTECHNICAL ASSISTANCEExpert engineering and applications supportA world wide presence<strong>James</strong> <strong>Heal</strong> has Agents andDistribution Partners in over60 countries. Please visit ourwebsite www.james-heal.co.uk,for more information andcontact details for your local<strong>James</strong> <strong>Heal</strong> Agent.AGENT<strong>James</strong> <strong>Heal</strong>Richmond WorksHalifax HX3 6EPEnglandTel +44 (0) 1422 366355Fax +44 (0) 1422 352440Email info@james-heal.co.ukWeb www.james-heal.co.ukSetting the StandardThe right is reserved to alter the specification or modify the appearance without notice. © <strong>James</strong> <strong>Heal</strong> TM 2011

MARTINDALE 900 SERIES TMULTIMATE FOR FLEXIBILITY AND EASE OF USEWHAT WE DOAT JAMES HEAL, WE ARE DEDICATEDTO DESIGNING AND DEVELOPING HIGHPRECISION TESTING INSTRUMENTS ANDTEST MATERIALS FOR PHYSICALAND COLOUR FASTNESS TESTING -SERVING THE TEXTILES AND NONWOVENSINDUSTRIES SINCE 1872. OUR WORLDWIDESERVICE AND CALIBRATION DIVISIONAND EXPERT TECHNICAL ASSISTANCECOMPLEMENT OUR PRODUCT RANGE,ADDING REAL VALUE TO YOUR LABORATORYTESTING ACTIVITIES.Setting the StandardWe are committed to formingclose relationships, andhave established numerouspartnerships within thetextile industry, from tradeand standards organisations,to test houses, customersand distribution partners.With a heritage spanningsome 139 years, we haveevolved and grown througha culture of continuousimprovement, resulting in athorough understanding ofthe applications, operatingconditions and requirementsof customers worldwide –from independent testinglaboratories and testhouses, to fabric suppliers,manufacturers and retailers.Using knowledge andexpertise, we consistentlyset the industry standardthrough product innovationand technology, withcustomer and user needs,present and future,driving our technologicaladvancements.Customers can be assuredthat with <strong>James</strong> <strong>Heal</strong>, youwill always receive thehighest levels of productquality and customerservice. We have Agents andDistribution partners all overthe globe, ensuring locallyavailable product whenever,and wherever you need it.Above LeftAbove RightMain Picture- Mini-Martindale2 stations- Midi-Martindale5 stations- Maxi-Martindale9 stations12

MARTINDALE 900 SERIES TMULTIMATE FOR FLEXIBILITY AND EASE OF USEThe 900 SeriesOur innovative productdesign team has set a newstandard with the nextgeneration Martindale 900Series. Flexible, the seriesincludes three models, fullypopulated with nine, five ortwo stations. Each combinethe best in style, quality,affordability and functionality– introducing users to thenext level in abrasion andpilling testing.- Finger grips foreasy removal oftop plate- Easy access toevery singlestation fromthe front ofthe machine- Emergency stop- Precisionengineeredtop platemanufacturedfrom aircraft gradehard anodisedaluminium- User-friendlycontrol panelPictured- Maxi-Martindale9 stations3 4

MARTINDALE 900 SERIES TMULTIMATE FOR FLEXIBILITY AND EASE OF USETEST MATERIALS FORYOUR MARTINDALEIn laboratory testing, yourinstrumentation is extremelyimportant - but valid testresults are only obtainedif all process variables arereduced to an acceptableminimum. You shoulduse controlled conditions,and accurate, regularlyserviced and calibratedinstruments operated bywell-trained technicians.Equally important are thetest materials that you useand renew during testing;these must provide accurateresults to reassure you thatthe product will conformconsistently to the specifiedstandard.For your Martindale, you mayneed Abrasive Cloth, Feltand Foam. If you invest inthe best instrument, it makessense to use the best testmaterials as well.We understand the criticalrelationship betweeninstrument and testmaterials. We manufactureboth, and are able toguarantee that our testmaterials are fully compliantwith the relevant standards.We have our own in-housetest materials laboratory,which is constantly checkingthe quality and compliance ofthe products which we sell.Our test materials areavailable with the supply ofnew instruments and fromconveniently situated localstockists, when they run out.Key features:<strong>Co</strong>mpliant with:EN ISO 12947EN ISO 12945 - 2- Versatile and intuitive user interface- Audible control with sound promptsto assist the user- Easy change between Abrasion, Pillingand Straight Line motions- Easy access to every station from thefront – without having to remove thetop plate- Stylish and ergonomic design- Lighter weight materials- Low power consumption- Real value for moneyASTM D4966 (Abrasion)ASTM D4970 (Pilling)JIS L 1096ISO 17704EN 13520EN 14605EN 14325EN 943What isavailable foryour MartindaleApplicationsStandards andTest Methods- Worldwide Service,Maintenance and Support- UKAS Calibration- 18 Months’ Warranty- Martindale Test Materials- Fabric Abrasion- Fabric Pilling- Glove Abrasion- Sock Abrasion- Leather (Ball Plate)- <strong>Co</strong>llar and Cuff Abrasion- The 900 Series complieswith all known national andinternational Martindalestandards and test methodsfor Fabric Abrasion, Pillingand Sock Testing- The Maxi-Martindale andMidi-Martindale are approvedby Marks & SpencerISO 5470 - 2SN 198529 and SN 198525IS 12673M&S P17, P18 and P19Next 18 and 26MAINTAINING YOURMARTINDALEIn the field of textile testing,there is nothing moreimportant than standards.When a <strong>James</strong> <strong>Heal</strong>instrument reaches yourlab, you can be assuredthat it will operate to thesestandards.The ongoing maintenanceof your machine is just asimportant – that’s why weoffer <strong>James</strong> <strong>Heal</strong> Serviceand Calibration as part ofour continuous commitmentto you. Including a serviceand calibration contractfollowing the purchase ofyour instrument gives youaccess to our unrivalledteam of industry expertsand engineers to ensurethat you get the most outof your investment. Notonly that, our service teamprovide you with peace ofmind that should a problemoccur, you have us to rely onfor technical assistance andsupport.We can fully support youby offering maintenanceand calibration at anylocation across the world.This is complemented byan additional fully equippedService and Calibration Teamlocated in Hong Kong andChina.Service andCalibrationTechnicalAssistance- Installation and <strong>Co</strong>mmissioning- Servicing, Repairs and Spares- Calibration and Maintenance- Experienced and accredited InstrumentTechnicians- UKAS & ISO 17025 Calibration Standards- Rapid Response – Reduced Downtime- Applications Support- Engineering Support- In-depth Laboratory Testing and Analysis- Knowledge Centre - access to our expertadvice in all aspects of physical and colourfastness testing- Training: at <strong>James</strong> <strong>Heal</strong>, on your premises,or (in some cases) on-lineEN 13770EN 388and many others5 6

MARTINDALE 900 SERIES TMTOOLBOXMARTINDALE 900 SERIES TMTOOLBOXFabric Abrasion- Applications:Flat woven, knitted and nonwoven fabricsLeather Abrasion (Ball Plate)- Applications:Leather surfaces (particularly upholstery for cars)- Typical Standards:EN ISO 12947-1 and ASTM D4966- Typical Standards:VDA 230-211, ISO 17076-2 and IUP 48-2- Tooling Required:Abrasion Station Kit 794-516- Tooling Required:Ball Plate Station Kit 794-410Fabric Pilling- Applications:Woven and knitted fabricsEdge Abrasion (Line <strong>Co</strong>ntact)- Applications:Shirt collars and cuffs, rucksack straps and similar articles- Typical Standards:EN ISO 12945-2- Typical Standards:Under development- Tooling Required:Pilling Station Kit 794-517- Tooling Required:Line <strong>Co</strong>ntact Station Kit 794-411Sock Abrasion- Applications:Knitted footwear (socks, tights and hosiery)- Typical Standards:EN 13770 - Method 1- Tooling Required:Sock Abrasion Station Kit 794-518Scratch Resistance- Applications:Laminate floor coverings, high pressure laminates,high gloss or painted surfaces or components- Typical Standards:Please enquire- Tooling Required:Please enquire7 8Tooling Required: Reference is made to the principal tooling only – many tests/methods require additional accessories and test materials.

TECHNICAL DATAREADY TO PLACE AN ORDER?ORDERING IS MADE EASY WITH THIS SELECTOR TABLE:ScopeNo. of specimensExposed area of test specimenAbrasion Pilling Sock AbrasionWoven, knitted & certainnonwoven fabrics2, 5 or 96.45cm 2Woven & knitted fabrics(staple spun yarns)2, 5 or 964.5cm 2All fibre compositions& all end uses2, 5 or 93.14cm 2USER KEY3 Our Recommendationl Your ChoiceINSTRUMENTSMaxi-Martindale (9 stations) 902-932 l l l l l l l lMidi-Martindale (5 stations)ORDER CODE902-931FabricAbrasionISO12947FabricAbrasionASTMD4966FabricPillingISO12945-2STANDARD / METHODFabricPillingASTMD4970SockAbrasionEN 13770GloveAbrasionEN 388Leather(Ball Plate)ISO17076-2Line<strong>Co</strong>ntactl l l l l l l lWorking pressure ontest specimen9 kPa (apparel)12 kPa (upholstery)2.5 cN/cm 2 (knitteds)6.5 cN/cm 2 (wovens)23.86 kPaMini-Martindale (2 stations)TOOLING902-933l l l l l l l lRotational speed47.5 +/- 2.5rpm47.5 +/- 2.5rpm47.5 +/- 2.5rpmAbrasion Station Kit794-516✓ ✓ ✓ ✓ ✓Total stroke of drive units60.5 +/- 0.5mm24.0 +/- 0.5mm60.5 +/- 0.5mmPilling Station Kit794-517✓Parallelism of top plate toabrading tables< 0.05mm< 0.05mm< 0.05mmSpecimen Mounting Mandrel (one per instrument)Sock Abrasion Station Kit525-256794-518✓✓Parallelism of sample holdersto abrading tables< 0.05mm< 0.05mm< 0.05mmBlock Spanner Adaptor525-311✓12 kPa Weight (one per Sock Abrasion Station Kit)526-041✓Ball Plate Station kit794-410✓Line <strong>Co</strong>ntact Station Kit794-411✓INSTALLATION DATAINSTRUMENT CALIBRATIONUKAS Certificate of Calibration for Martindale202-409✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓SPECIMEN PREPARATIONSample Cutter (38mm diameter)902-222✓ ✓ ✓ ✓ ✓ ✓ ✓Sample Cutter (140mm diameter)902-221✓ ✓ ✓ ✓ ✓ ✓SPECIMEN ASSESSMENTEMPA Woven and Knitted Photographic Standards766-451✓ASTM D3512 Pilling Photographic Standards766-450✓IWS Pilling Photographic Standards for Woven Fabrics SM50766-459✓IWS Pilling Photographic Standards for Knitted Fabrics SM54766-460✓ISO Grey Scale for assessing Change in <strong>Co</strong>lour766-200✓AATCC Gray Scale for <strong>Co</strong>lor Change766-512✓TEST MATERIALSPack (5m) Abrasive Cloth701-202✓ ✓ ✓ ✓ ✓MINI-MARTINDALE MIDI-MARTINDALE MAXI-MARTINDALERoll (50m) Abrasive Cloth701-203✓ ✓ ✓ ✓ ✓Physical DataDepth Height Width Weight610mm 320mm 520mm 48kgPhysical DataDepth Height Width Weight670mm 320mm 700mm 59kgPhysical DataDepth Height Width Weight670mm 320mm 890mm 80kgPack (100) Pre-cut Discs of Abrasive Cloth (140mm diameter)Pack (20) Woven Felt Pads (140mm diameter)Pack (20) Woven Felt Pads (90mm diameter)Pack (20) Nonwoven Felt Pads (140mm diameter)701-207714-612714-611714-602✓ ✓ ✓ ✓✓ ✓ ✓✓✓✓Electrical requirements:Electrical requirements:Electrical requirements:Pack (20) Nonwoven Felt Pads (90mm diameter)714-601Single Phase 85-264V AC 50/60 HzSingle Phase 85-264V AC 50/60 HzSingle Phase 85-264V AC 50/60 HzPack (2000) Pre-cut Discs of Foam (38mm diameter)786-256✓ ✓ ✓ ✓9 10This list is not exhaustive. More specialised accessories and test materials are available for less common standards or test methods.Please enquire for further information. You can contact us at: support@james-heal.co.uk