advanced boiler technology-warga boiler

advanced boiler technology-warga boiler

advanced boiler technology-warga boiler

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WARGA BOILERADVANCED FIRE TUBE BOILERDESIGN

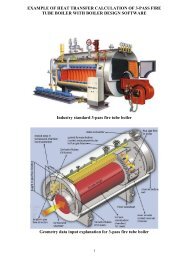

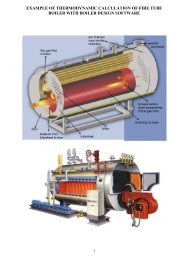

Scotch Marine <strong>boiler</strong> downsides•Too Too numerous tubes & too manypasses•Tubesheet Tubesheet cracking•Efficiency Efficiency degradation at part load•Large Large amount of refractory liningbeing a heat sink

Scotch Marine <strong>boiler</strong> downsidesToo numerous tubes in up to 4 passes

Scotch Marine <strong>boiler</strong> downsidesLarge amount of refractory lining at frontand rear

Scotch Marine <strong>boiler</strong> downsidesEfficiency degradation at part loadlosses (up to 15%)<strong>boiler</strong>efficiency(also calledinput/outputefficiency)measured bydirectmethodinstant efficiency (alsocalled combustionefficiency) measured byindirect methodseasonalinput/outputefficiency50100110<strong>boiler</strong> load [%]

Main areas of improvents of ScotchMarine <strong>boiler</strong> design•Tube Tube & passes number reduction•Elimination of refractory lining

Ways to improve Scotch Marine<strong>boiler</strong> design•Exact Exact heat transfer calculation•Introduction of cooled door•Common Common platform

WARGA BOILER• Up to 70% less tubes• Up to 100% intensified heat transfer (2.5sq.ft./HP<strong>boiler</strong>)• Only 2 passes in reverse flue design• No o refractory lining• Cooled door design meeting all criteria applicable alsoon steam s<strong>boiler</strong>s• No o efficiency degradation at part load (efficiencyincreases at part load - unique in industry)• Absence of tubesheet cracking• Common platform• Retrofit of installed Scotch Marine <strong>boiler</strong>s possible

WARGA BOILER IN USATucson Medical Center

WARGA BOILER IN USATucson Medical Center•33 high pressure 400HP steam <strong>boiler</strong>s installed in1999•Design Design and claims proven with data log•Return Return on investment in 2 years•20.5% 20.5% reduced fuel usage for same amount of steamgenerated at unchanged fuel-toto-steam efficiency(!)•No No downsides observed•No No trace of tubesheet chacks after 10 years ofoperation (on previous two 600HP <strong>boiler</strong>s tubesreplaced 2 times in 20 year operation, furnacerewelded in first year)

WARGA BOILER IN USASide view

WARGA BOILER IN USASide view

WARGA BOILER IN USAJust 75 2.5” tubes in 400HP <strong>boiler</strong>

WARGA BOILER IN USACooled door with burner orifice

WARGA BOILER IN USARear view

US BOILER RETROFIT MARKETSIZE