Doctor blades - Unger - Messer und Ersatzteile für die Druck

Doctor blades - Unger - Messer und Ersatzteile für die Druck

Doctor blades - Unger - Messer und Ersatzteile für die Druck

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

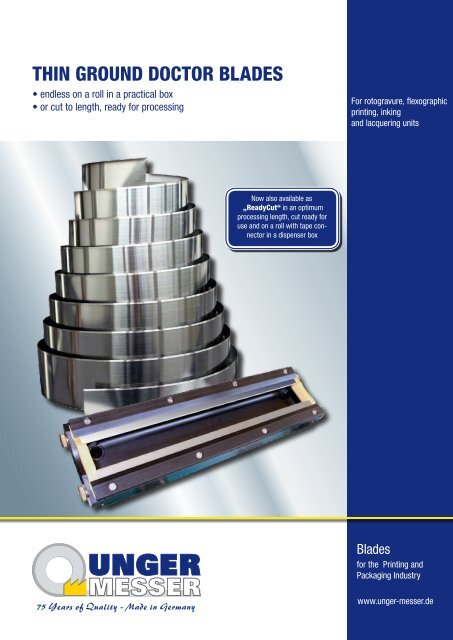

Thin gro<strong>und</strong> docTor <strong>blades</strong><br />

• endless on a roll in a practical box<br />

• or cut to length, ready for processing<br />

75 Years of Quality - Made in Germany<br />

Now also available as<br />

„readycut“ in an optimum<br />

processing length, cut ready for<br />

use and on a roll with tape connector<br />

in a dispenser box<br />

For rotogravure, flexographic<br />

printing, inking<br />

and lacquering units<br />

Blades<br />

for the Printing and<br />

Packaging Industry<br />

www.unger-messer.de

Quality<br />

Precision<br />

Expertise<br />

The highest quality and precision can be taken for granted in<br />

the production of <strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong>. It starts<br />

with selecting high-quality raw materials and continues in the<br />

production process. The <strong>blades</strong> are manufactured on state-ofthe-art<br />

CNC controlled systems which ensure consistent quality<br />

by a complex measuring process<br />

Only high-purity, cold-rolled doctor blade steels with a proven<br />

level of quality are used for <strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong>.<br />

A special, gentle grinding process (cooler grinding) ensures<br />

consistent quality without altering the raw material.<br />

After the grinding process, the doctor blade steel (lamella) is<br />

gently polished using a new method. The finished doctor blade<br />

is then rolled into environmentally friendly packages using a<br />

fully automated process and entirely without the edges touching,<br />

or it is cut to ready-to-use fixed lengths.<br />

<strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong> offer a consistently high<br />

production quality, and the best material quality; this guarantees<br />

high service lives and optimum results when used.<br />

<strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong> are characterised by exact<br />

straightness and precise evenness.<br />

<strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong> have an exceptionally uniform<br />

material structure without inhomogeneities and harmful<br />

inclusions.<br />

<strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong> guarantee high wear resistance,<br />

extreme tensile strength and hardness.

In the „ReadyCut“ design, <strong>Unger</strong> thin gro<strong>und</strong> doctor <strong>blades</strong><br />

in different grades are cut precisely to the desired length and<br />

supplied endless on a roll in a practical dispenser box with<br />

easy to release tape connectors.<br />

<strong>Unger</strong> thin gro<strong>und</strong> doctor<br />

<strong>blades</strong> in „ReadyCut“<br />

design are available with<br />

and without polished<br />

section and in different<br />

versions with<br />

- straight edges<br />

- edges ro<strong>und</strong>ed off on<br />

one side<br />

or<br />

- edges ro<strong>und</strong>ed off on<br />

both sides.<br />

The advantages of the „ReadyCut“ design are obvious:<br />

ReadyCut thin gro<strong>und</strong> doctor <strong>blades</strong> in a precise fixed<br />

length can be used immediately and are ready for processing.<br />

No extra work is required when changing over.<br />

ReadyCut thin gro<strong>und</strong> doctor <strong>blades</strong> create no waste and<br />

facilitate easy and quick doctor blade change over without<br />

damaging the lamella.<br />

ReadyCut thin gro<strong>und</strong> doctor <strong>blades</strong> minimise the risk of<br />

injury generated from cutting and prevent unnecessary downtimes.<br />

Innovation<br />

Optimisation

Areas of use<br />

Possible<br />

dimensions<br />

closing doctor blade<br />

working doctor blade<br />

cylinder<br />

contact zone width<br />

Bruno <strong>Unger</strong> GmbH & Co KG<br />

Hellerwaldstraße 1<br />

D-56154 Boppard<br />

Tel.: (0 67 42) 89 83-0<br />

Telefax: (0 67 42) 89 83-50<br />

Internet: www.unger-messer.de<br />

E-Mail: webmaster@unger-messer.de<br />

lamella width<br />

lamella<br />

thickness<br />

doctor blade width<br />

supporting doctor blade<br />

doctor blade<br />

thickness<br />

contact zone angle<br />

Flexographic printing Rotogravure, coatings<br />

Dimensions (please always state when placing an order !)<br />

<strong>Doctor</strong> blade thickness: 0.15 - 0.30 mm<br />

<strong>Doctor</strong> blade width: 10.00 - 80.00 mm<br />

Lamella thickness: 0.05-0.15 mm<br />

Lamella width: 0.80 - 2.50 mm<br />

Contact zone angle: optional<br />

<strong>Doctor</strong> blade length: optional as endless rolled stock,<br />

or as ReadyCut cut precisely to<br />

length<br />

Thin gro<strong>und</strong> doctor <strong>blades</strong> are also available<br />

on request in coated grades !