Euromate SCS central filter system the number one solution in large ...

Euromate SCS central filter system the number one solution in large ...

Euromate SCS central filter system the number one solution in large ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

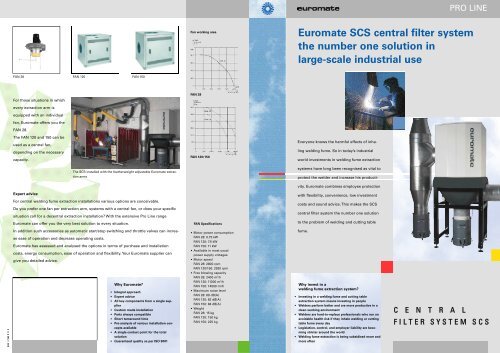

PRO LINEFan work<strong>in</strong>g area<strong>Euromate</strong> <strong>SCS</strong> <strong>central</strong> <strong>filter</strong> <strong>system</strong><strong>the</strong> <strong>number</strong> <strong>one</strong> <strong>solution</strong> <strong>in</strong><strong>large</strong>-scale <strong>in</strong>dustrial useFAN 28 FAN 120FAN 150For those situations <strong>in</strong> whichFAN 28every extraction arm isequipped with an <strong>in</strong>dividualfan, <strong>Euromate</strong> offers you <strong>the</strong>FAN 28.The FAN 120 and 150 can beused as a <strong>central</strong> fan,depend<strong>in</strong>g on <strong>the</strong> necessarycapacity.FAN 120/150Every<strong>one</strong> knows <strong>the</strong> harmful effects of <strong>in</strong>hal<strong>in</strong>gweld<strong>in</strong>g fume. So <strong>in</strong> today’s <strong>in</strong>dustrialworld <strong>in</strong>vestments <strong>in</strong> weld<strong>in</strong>g fume extractionThe <strong>SCS</strong> <strong>in</strong>stalled with <strong>the</strong> fea<strong>the</strong>rweight adjustable <strong>Euromate</strong> extractionarms<strong>system</strong>s have long been recognised as vital toprotect <strong>the</strong> welder and <strong>in</strong>crease his productivity.<strong>Euromate</strong> comb<strong>in</strong>es employee protectionExpert advicewith flexibility, convenience, low <strong>in</strong>vestmentFor <strong>central</strong> weld<strong>in</strong>g fume extraction <strong>in</strong>stallations various options are conceivable.Do you prefer <strong>one</strong> fan per extraction arm, <strong>system</strong>s with a <strong>central</strong> fan, or does your specificsituation call for a de<strong>central</strong> extraction <strong>in</strong>stallation? With <strong>the</strong> extensive Pro L<strong>in</strong>e rangecosts and sound advice. This makes <strong>the</strong> <strong>SCS</strong><strong>central</strong> <strong>filter</strong> <strong>system</strong> <strong>the</strong> <strong>number</strong> <strong>one</strong> <strong>solution</strong><strong>Euromate</strong> can offer you <strong>the</strong> very best <strong>solution</strong> to every situation.FAN Specificationsto <strong>the</strong> problem of weld<strong>in</strong>g and cutt<strong>in</strong>g tableIn addition such accessories as automatic start/stop switch<strong>in</strong>g and throttle valves can <strong>in</strong>creaseease of operation and decrease operat<strong>in</strong>g costs.<strong>Euromate</strong> has assessed and analysed <strong>the</strong> options <strong>in</strong> terms of purchase and <strong>in</strong>stallationcosts, energy consumption, ease of operation and flexibility.Your <strong>Euromate</strong> supplier cangive you detailed advice.Why <strong>Euromate</strong>?• Integral approach• Expert advice• All key comp<strong>one</strong>nts from a s<strong>in</strong>gle supplier• Custom made <strong>in</strong>stallation• Parts always compatible• Short turnaround time• Pre-analysis of various <strong>in</strong>stallation conceptsavailable• A s<strong>in</strong>gle contact po<strong>in</strong>t for <strong>the</strong> total<strong>solution</strong>• Guaranteed quality as per ISO 9001• Motor power consumptionFAN 28: 0.75 kWFAN 120: 7.5 kWFAN 150: 11 kW• Available <strong>in</strong> most usualpower supply voltages• Motor speedFAN 28: 2800 rpmFAN 120/150: 2920 rpm• Free blow<strong>in</strong>g capacityFAN 28: 2400 m 3 /hFAN 120: 11000 m 3 /hFAN 150: 14500 m 3 /h• Maximum noise levelFAN 28: 69 dB(A)FAN 120: 82 dB(A)FAN 150: 84 dB(A)• WeightFAN 28: 15 kgFAN 120: 150 kgFAN 150: 225 kgfume.Why <strong>in</strong>vest <strong>in</strong> aweld<strong>in</strong>g fume extraction <strong>system</strong>?• Invest<strong>in</strong>g <strong>in</strong> a weld<strong>in</strong>g fume and cutt<strong>in</strong>g tableextraction <strong>system</strong> means <strong>in</strong>vest<strong>in</strong>g <strong>in</strong> people• Welders perform better and are more productive <strong>in</strong> aclean work<strong>in</strong>g environment• Welders are hard-to-replace professionals who run anavoidable health risk if <strong>the</strong>y <strong>in</strong>hale weld<strong>in</strong>g or cutt<strong>in</strong>gtable fume every day• Legislation, control, and employer liability are becom<strong>in</strong>gstricter around <strong>the</strong> world• Weld<strong>in</strong>g fume extraction is be<strong>in</strong>g subsidised more andmore oftenC E N T R A LF I L T E R S Y S T E M S C S

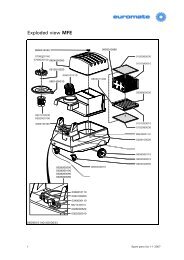

CENTRAL FILTER SYSTEM <strong>SCS</strong><strong>SCS</strong><strong>Euromate</strong> <strong>SCS</strong> <strong>central</strong> <strong>filter</strong> <strong>system</strong>A feature of <strong>the</strong> <strong>SCS</strong> <strong>central</strong> self-clean<strong>in</strong>g <strong>filter</strong><strong>system</strong> is a <strong>filter</strong> surface of 150 m 2 .This givesModular constructionIf a greater capacity is required, several <strong>SCS</strong> <strong>system</strong>scan be easily l<strong>in</strong>ked due to <strong>the</strong> modular constructionmethod.Dimensions <strong>SCS</strong>it a clear advantage over compet<strong>in</strong>g <strong>system</strong>s.Long <strong>filter</strong> lifeThe <strong>Euromate</strong> <strong>central</strong> <strong>filter</strong> <strong>system</strong> works accord<strong>in</strong>g toIn addition <strong>the</strong> <strong>SCS</strong> is equipped with <strong>the</strong> uni-a 3-step <strong>filter</strong> concept. The external pre-separator removessparks and <strong>large</strong> dust particles. In addition <strong>the</strong> <strong>SCS</strong>que RoboCleanPlus ® clean<strong>in</strong>g <strong>system</strong> forultra-effective clean<strong>in</strong>g. The <strong>filter</strong> is cleanedWeld<strong>in</strong>g robots and <strong>in</strong>dustrial ventilation,important areas of application of <strong>the</strong> <strong>SCS</strong>(Luyt, Krommenie; Holland)<strong>filter</strong> hous<strong>in</strong>g construction adds an extra step to <strong>the</strong>clean<strong>in</strong>g process. Its shape lets it act as a cycl<strong>one</strong>,reduc<strong>in</strong>g <strong>the</strong> dust load on <strong>the</strong> <strong>filter</strong> cartridge. The 3-step<strong>filter</strong><strong>in</strong>g <strong>system</strong>, <strong>the</strong> <strong>large</strong> <strong>filter</strong> surface, and <strong>the</strong>with powerful thrusts of compressed air, seg-RoboCleanPlus ® <strong>system</strong> all contribute to a longer lifespan for <strong>the</strong> <strong>filter</strong>.The unique RoboCleanPlus ® clean<strong>in</strong>g <strong>system</strong> forultra-effective clean<strong>in</strong>gment by segment, with <strong>the</strong> residue be<strong>in</strong>gcaught <strong>in</strong> a high capacity dust conta<strong>in</strong>er onEasy to <strong>in</strong>stallFor optimal <strong>in</strong>stallation flexibility, <strong>the</strong> <strong>SCS</strong> is deliveredwith various air <strong>in</strong>let and outlet options. Comb<strong>in</strong>edwheels.with <strong>the</strong> compact design of <strong>the</strong> <strong>SCS</strong> this allows <strong>the</strong> unitto adapt flawlessly to every workplace situation.Major characteristics of <strong>the</strong> <strong>SCS</strong>• Standard <strong>filter</strong> surface 150 m 2• RoboCleanPlus ® clean<strong>in</strong>g <strong>system</strong>• 3-step separation• High degree of pre-assembly• Multiple air <strong>in</strong>take options• Compact constructionMajor advantages of <strong>the</strong> <strong>SCS</strong>• Long <strong>filter</strong> life• Low energy consumption• Constant high exhaust capacity• Ease of <strong>in</strong>stallation• Flexibility• Requires m<strong>in</strong>imal floor surfaceThe <strong>SCS</strong> can be used to remove dry weld<strong>in</strong>gfume dur<strong>in</strong>g <strong>the</strong> follow<strong>in</strong>g weld<strong>in</strong>g and cutt<strong>in</strong>gprocesses:• MIG/MAG massive thread (GMAW)• MIG/MAG filled thread (FCAW)• Electrode weld<strong>in</strong>g (MMA or SMAW)• TIG (GTAW)• Alum<strong>in</strong>o-<strong>the</strong>rmic weld<strong>in</strong>g• Autogenous weld<strong>in</strong>g• Autogenous cutt<strong>in</strong>g• Plasma arc cutt<strong>in</strong>g• Steel and sta<strong>in</strong>less steel gr<strong>in</strong>d<strong>in</strong>g (not alum<strong>in</strong>ium ormagnesium)This clean<strong>in</strong>g method gives <strong>the</strong> <strong>SCS</strong> a constanthigh exhaust capacity, a low level ofenergy consumption, and a longer <strong>filter</strong> lifespan.The RoboCleanPlus ® clean<strong>in</strong>g <strong>system</strong> is standardoutfitted with a timer, a pressure sensorand <strong>in</strong>tegrated software, offer<strong>in</strong>g you <strong>the</strong> follow<strong>in</strong>gthree options as standard features:• fully automatic clean<strong>in</strong>g• clean<strong>in</strong>g via programmable time switch• immediate manual clean<strong>in</strong>gThe <strong>SCS</strong> plus a plasma cutt<strong>in</strong>g table(Kühme, Bochum; Germany)The flexibility of <strong>in</strong>dividual fans makes <strong>the</strong>m <strong>the</strong><strong>solution</strong> of choice(Hovuma, Reuver; Holland)The <strong>SCS</strong> with a <strong>central</strong> fanThe <strong>SCS</strong> – just like all <strong>the</strong> o<strong>the</strong>r <strong>Euromate</strong> products – ischaracterised by a high degree of pre-assembly,mak<strong>in</strong>g it easy to <strong>in</strong>stall.The uses of <strong>the</strong> <strong>SCS</strong>The <strong>SCS</strong> <strong>filter</strong> <strong>system</strong> is excellent for <strong>large</strong>-scale <strong>in</strong>dustrialuse, be<strong>in</strong>g developed especially for remov<strong>in</strong>g and<strong>filter</strong><strong>in</strong>g harmful substances and vapours releaseddur<strong>in</strong>g weld<strong>in</strong>g, cutt<strong>in</strong>g, and gr<strong>in</strong>d<strong>in</strong>g processes <strong>in</strong> <strong>the</strong>metal <strong>in</strong>dustry.Integral approachA <strong>central</strong> <strong>filter</strong> <strong>system</strong> al<strong>one</strong> is not <strong>the</strong> complete answerto your weld<strong>in</strong>g fume problem. The <strong>SCS</strong> is part of<strong>Euromate</strong>’s Pro L<strong>in</strong>e range. This range offers all <strong>the</strong> keycomp<strong>one</strong>nts such as extraction arms, fans etc. requiredfor a total <strong>solution</strong>, completely tuned to your specificoperat<strong>in</strong>g situation.Data on <strong>the</strong> <strong>SCS</strong>• Can be supplied for all <strong>the</strong> usualpower supply voltages and frequencies• Cartridge <strong>filter</strong> with SurfacePlus ®treatment• Filter surface area: 150 m 2• Filter efficiency: up to 99.8%• RoboCleanPlus ® automatic<strong>filter</strong> clean<strong>in</strong>g <strong>in</strong>clusive of controlbox• Compressed air connection:4-5 bar• Compressed air consumption:max. 150 NL/m<strong>in</strong>• Maximal capacity: 4500 to9000 m 3 /h (depend<strong>in</strong>g on <strong>the</strong>application)• To be <strong>in</strong>stalled with apre-separator for sparks and<strong>large</strong> dust particles• Inlet/outlet open<strong>in</strong>g: Ø 400 mm• Filter residue conta<strong>in</strong>er:100 liters• Weight: 250 kg• Dimensions: 1200 mm L x1200 mm W x 2900 mm H (exclusiveof pre-separator)• Transport height: 2200 mm• Air <strong>in</strong>let position: 8 options• Air outlet position: 2 options• Pre-separator dimensions:750 mm L x 600 mm W x2500 mm H• Inlet pre-separator: Ø 630 mm;outlet pre-separator: Ø 400 mm