Bayer Bayer - Backed By Bayer

Bayer Bayer - Backed By Bayer

Bayer Bayer - Backed By Bayer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

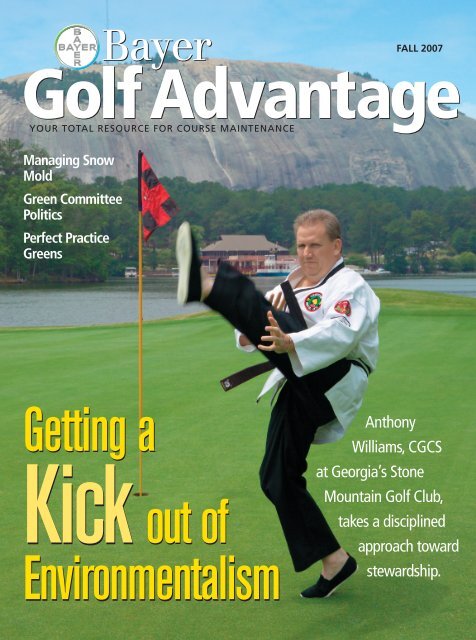

<strong>Bayer</strong>FALL 2007Golf AdvantageYOUR TOTAL RESOURCE FOR COURSE MAINTENANCEManaging SnowMoldGreen CommitteePoliticsPerfect PracticeGreensGetting aKick out ofEnvironmentalismAnthonyWilliams, CGCSat Georgia’s StoneMountain Golf Club,takes a disciplinedapproach towardstewardship.

CONTENTSFALL 2007Features8 Purple Cow Winner Stands Outin Field of ExpertsAnthony Williams, CGCS at Georgia’s Stone Mountain GolfClub, wins with his environmental stewardship.BY CURT HARLER11 Accessibility:Finding Common GroundCourses can be made accessible to disabled players withoutimpacting turf or the speed of play.BY JENNIFER PAIRE13 Sail Ho Back AfloatFormer Navy golf course gets $3.3 million renovation.BY BARBARA MCCABE18 Working with the GreenCommitteeLessons learned and shared.BY ANTHONY PIOPPI 24 Practice Makes PerfectPractice greens need the same attention as the greenson the course.118BY MARK LESLIE26 A Steelworker’s GetawayFormer company recreational facility now thrives asa private club.BY DEBBIE CLAYTON28 Knowing WhatSuperintendents ExpectFormer superintendent turned distributor knows what hiscustomers want.28BY CURT HARLER2 Golf Advantage Fall 2007

<strong>Bayer</strong>Golf AdvantageGolf Advantage is published byBAYER ENVIRONMENTAL SCIENCEP.O. Box 120142 T.W. Alexander Dr.Research Triangle Park, NC 27709www.<strong>Backed</strong>by<strong>Bayer</strong>.com3030 Pests I Love to Hate:Gray Snow MoldDon’t let gray snow mold take hold on your course.BY NED TISSERAT AND TAMLA BLUNT32 Ronstar Flo Herbicide —Flexible, Easy ApplicationA new flowable formulation makes it even easier to apply Ronstar ® .BY DR. DON MYERS AND LAURENCE MUDGE34 Conditioning is KeyMyrtlewood Golf Club uses conditioning to keep turf in shapeduring peak playing periods.BY NANCY HOLBERTEditorial StaffCurt Harler Editor 440-238-4556curt@curtharler.comSusan Porter Executive EditorJamie Gooch Managing EditorKristen Morabito Graphic DesignerDebbie Clayton Contributing EditorNancy Holbert Contributing EditorMark Leslie Contributing EditorBarbara McCabe Contributing EditorJerry Mix Contributing EditorJennifer Paire Contributing EditorNed Tisserat Contributing EditorAnthony Pioppi Contributing EditorDon Myers Contributing EditorCirculation QuestionsAntoinette Sanchez-Perkins Audience Development Managerasanchez-perkins@questex.com 216-706-3750PRODUCED IN PARTNERSHIP WITH:Questex Landscape Group600 Superior Ave. East, Suite 1100Cleveland, OH 44114800-669-1668www.landscapegroup.com<strong>Bayer</strong> Environmental Science StaffNeil Cleveland Director, Chipco Professional Productsneil.cleveland@bayercropscience.com 919-549-2548Scott Welge Director of Marketingscott.welge@bayercropscience.com 919-549-2105Rich Burns National Account Manager 919-549-2563rich.burns@bayercropscience.comMike Ruizzo National Account Manager 919-549-2559michael.ruizzo@bayercropscience.comDepartments4 Chip ShotLove your job or leave it.6 Far & WideIndustry news and trends.16 OutlooksBrian Tepper wants you to meet Gordon Vosti.20 Talk BackWe asked several assistants who had experience with SeashorePaspalum to talk about the emerging Southern grass.37 On The RoadNew <strong>Bayer</strong> managers, scholarship winners and Dylox ® insecticideformulation news.ON THE COVER: PHOTO BY BOB MAYNARDMike Daly Business Manager, Fungicides/Golf Market Leadmichael.daly@bayercropscience.com 919-549-2550Ben Cicora Business Manager, Herbicides 919-549-2558ben.cicora@bayercropscience.comBryan Gooch Business Manager, Imidacloprid 919-549-2555bryan.gooch@bayercropscience.comJason Kuhlemeier Business Manager, Fipronil and Classic Insecticidesjason.kuhlemeier@bayercropscience.com 919-549-2743Jim Fetter Northern Regional Manager 614-307-5705jim.fetter@bayercropscience.comBrian Tepper Western Regional Manager 619-307-1328brian.tepper@bayercropscience.comEric Kalasz Southern Regional Manager 919-491-4361eric.kalasz@bayercropscience.comAdvisory BoardLoren Breedlove, Kansas City Country ClubBland Cooper CGCS, The Sulstone GroupDarren J. Davis, Olde Florida Golf ClubDon Ferreri, Seven Bridges Golf ClubDean Graves CGCS, Chevy Chase ClubScott Niven CGCS, The Stanwich ClubSteve Pearson CGCS, The Falls Country ClubMatt S. Peltier CGCS, Spring Hill Country ClubFrank Wong, University of California/RiversideStephen W. Wood CGCS, El Conquistador Country ClubFred Yelverton, North Carolina State UniversityFor information on <strong>Bayer</strong> products and programs,visit www.<strong>Backed</strong>by<strong>Bayer</strong>.com Copyright 2007, <strong>Bayer</strong> Environmental Sciencewww.<strong>Backed</strong>by<strong>Bayer</strong>.com Golf Advantage 3

CHIP SHOTMIKE DALY / BUSINESS MANAGERLove it or Leave ItIf you don’t have apassion for what youare doing on a dailybasis, it’s a good indicationthat youshould reconsideryour livelihood.Many folks grow up believing that work is something theyhave to do, not something they'd actually enjoy getting outof bed in the morning to do. Then there are those of youwho work on golf courses.According to recent surveys conducted by Golfdom magazine, golf coursesuperintendents are happier than most with their work. In 2005, 61 percent of400 golf superintendents polled said they like their jobs on most days, while 21percent of them stated they were “ecstatic” about their jobs. With an 82 percentoverall approval rating, I'd say being a golf course superintendent must bea pretty decent occupation.This high level of satisfaction may come as a surprise when you considerthe odds stacked against you in this profession. You are ultimately responsiblefor providing near-perfect turfgrass, while having almost no control of thethings that can ruin your best intentions.Being a golf course superintendent is like being a farmer — you are at themercy of the weather in producing the end-result: in your case, beautiful,playable turfgrass. If that's not hard enough, you interact with people all daylong, worry about meeting a budget, and struggle with employee retention, irrigationmalfunctions and equipment problems … not to mention, weeklygolfing events!But the many superintendents I’ve talked to through the years say nothingcan beat working on a course all day long, enjoying the peaceful, gorgeous surroundings.They love the all-involving nature of the job and the satisfaction ofproducing what amounts to a work of art on a regular basis. Working nine tofive is an alien concept to a golf course superintendent. It's more like whateverit takes to get the job done.Here at <strong>Bayer</strong> we can relate to the all-encompassing nature of your job. Weenjoy the day-to-day process of identifying what is important to you and creatingnew solutions for some of your worst pest problems. Our job is making sureyour job is a little less stressful, at least from disease, insect and weed issues.If you don't have a passion for what you are doing on a daily basis, it’s agood indication that you should reconsider your livelihood. Life’s too short tosit around hating your job. The most recent Golfdom survey — conducted inlate 2006 — confirmed again that superintendents are happy in their work: avast majority of the 600 superintendents polled said they would do it all againif given the choice.Tell Us What You Think!Superintendents can win one of five $100 American Express gift cardsas a thank you for responding to <strong>Bayer</strong> Golf Advantage’s 5-minute surveyonline at www.questex.com/bgasurvey.Respond by Dec. 1 to be eligible to win. Winners will be drawn at random.Respond today!Mike DalyGolf Industry Manager<strong>Bayer</strong> Environmental Science919-549-2550michael.daly@bayercropscience.com4 Golf Advantage Fall 2007

FAR & WIDEINDUSTRY NEWSRain Sensors Pay Backin About a YearRain sensing shutoff devicesfor irrigation systems havethe potential to save significantamounts of water,says the researcher who created thefirst draft of testing protocols forrain sensors for the industry. Theyare cheap, too.University of Florida researcherMichael Dukes spoke to more than60 attendees at the Smart Water ApplicationTechnologies (SWAT) rainsensor meeting in Gainesville, Fla.,earlier this year. The payback insavings from installing an effectiverain sensing shutoff device is generallyless than a year because the devicesare relatively inexpensive,Dukes says.Weather-based controllers, knownas smart controllers, schedule irrigationbased on detailed informationabout site conditions.Rain sensors are the second productcategory taken on by the IrrigationAssociation’s SWAT program, whichfacilitates third-party testing of productswith water-saving potential andpromotes the use of proven water-savingtechnology.The GreenGolfer ChallengeDozens of golf courses have announcedtheir support of AudubonInternational’s Green Golfer Challenge.Audubon International isinviting golfers and superintendentsin the U.S. and Canada to take partin the Challenge by pledging to becomean Audubon Green Golfer. <strong>By</strong>doing so, they take steps to supportenvironmental stewardship whileplaying the game.Pledges from participating golfcourses will be collected andcounted by Audubon Internationalwith ongoing totals posted online.Prizes will be awarded to courseswith the most golfers signed up.Revolver Herbicide Label Revisions GrantedSeveral revisionsto theRevolver®herbicidelabel have been approvedby the EPA,announced <strong>Bayer</strong>Environmental Science,a business divisionof <strong>Bayer</strong> Crop-Science LP. Theyinclude the addition ofbuffalograss, as well as additionalwarm-season turf cultivarstolerant to use of the postemergent herbicide.For use as a spot treatment, Revolver may now be appliedat rates from 0.5 to 2 fluid oz. per gallon of water, dependingon the weed and stage of growth. In addition, Revolvermay now be applied to bermudagrass up to one weekprior to overseeding with perennial ryegrass and up to oneday prior to overseeding with Poa trivialis.“Additional warm-season turf varieties tolerant to Revolverwere added to the label, including Champion, MiniVerdi, seeded Princess and seeded Riviera varieties and thezoysiagrass varieties Emerald and seeded Champion,“ saidDon Myers, herbicide product development manager for<strong>Bayer</strong>. “For best results, treatments should occur when theaverage daily temperature is above 70 degrees F to controlmature weeds.”Other changes include: increased rates for control of volunteer ryegrass, tallfescue and other cool season grasses from 0.2 – 0.6 to 0.1 –0.8 ounces product per 1,000 sq. ft. application to sprigged bermudagrass may be made nosooner than two weeks after sprigging. application to seeded zoysiagrass may be made up toone week prior to seeding.For further information about new uses for Revolver,visit www.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com and view the revised productlabel.www.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 5

FAR & WIDECrow donates $100,000 ToEnvironmental InstituteTom Crow, founder of Cobra Golfand former Australia Amateur golfchampion, contributed $100,000 toThe Environmental Institute forGolf, the philanthropic organizationof the GCSAA.Crow won club championships atKingston Heath, Royal Melbourneand Royal Sydney. He also won the1952 Victorian Close Championship,the 1956 Victorian Amateur Championshipand the 1957 Victorian Championof Champions, setting a courserecord of 63 on Royal Melbourne’sWest Course. In 1973, Crow and hisfamily moved to the United States,and with $60,000 he founded CobraGolf Inc., dedicated to bringing thebest in equipment at an affordableprice to golfers at all experience levels.Endorsed by the likes of Normanand Hale Irwin, Cobra’s selling pricemore than two decades later was$750 million, highlighting a phenomenalfinancial success story thathas had a vital impact on the game.Crow developed the legendary“Baffler," a utility wood that begana race by nearly all other golf companiesto recreate. He initiated theGovernment Seizes Counterfeit Sprayersthree-wedge system, created thefirst extra-length driver and reintroducedgraphite shafts to the marketfor lighter-weight clubs. Crow’s contributionson behalf of the gamecontinue today and include his rolein bringing the life story of famousgolfer Bobby Jones to movie screensin “Bobby Jones — Stroke of Genius.”He was awarded the 2003Ernie Sabayrac Award by the PGA ofAmerica for “life contribution tothe golf industry."Crow has also committed to anotherthree-year term on The Institute’sAdvisory Council.“Tom Crow has been a friend toThe Institute for many years,” saysGreg Norman, who heads the Institute.“His unwavering support, innovativeideas as well as his time and financialcontributions have helpedshape its strategic direction.”“I have been very fortunate tohave been around the great gameof golf my entire life," Crow says. “Iwanted to continue my commitmentto The Institute because of the importantrole environmental stewardshipplays with golf."American manufacturers scored a victoryin the war against trademark infringementwhen federal agents recentlyseized counterfeit Solo sprayers thatwere being exhibited at a show by Zhe-Jiang Shixia Sprayer Co., Ltd. of ZhejiangProvince, China.The U.S. Department of HomelandSecurity Immigration and CustomEnforcement got involved after Zhe-Jiang Shixia refused to remove theknockoff of a Solo Model 425 professionalbackpack sprayer from its exhibit.Three agents, including SupervisorySpecial Agent Michael J. Cestare,seized the sprayers being sold underthe SeeSa brand.The incident is the latest in a long listof trademark infractions involving Zhe-Jiang Shixia, according to Solo’s president,David Longfield. “We are very aggressivein the protection of our patentsand trademarks, and have had repeatedcommunications and confrontation withZheJiang Shixia over the last severalyears,” he adds.What’s on CourseOwners’ MindsThe nation’s largest golfcourse ownership groupsare in deal-making moodswith their sights set ongetting even bigger in theyear to come, according toa survey conducted at the2007 Multi-Course OwnersLeadership Retreat hosted by the NationalGolf Course Owners Association.They also see their own employees as thekey to attracting golfers to their courses,and feel it’s mostly the responsibility oflocal facilities to grow the game.The companies surveyed own or operateseven or more courses in the U.S. andworldwide.The largest number of attendees (44percent) said they planned to increasetheir golf course holdings in the next 12months through acquisition. That numberwas up from 29 percent a year ago.Seventeen percent said they planned tosell courses in the next year, and 25 percentsaid their plans included acquisitionand disposition.A highly engaging and well-trainedstaff is the most effective tool in motivatinggolfers to choose one facility over another,according to 43 percent of the respondents.A “value-added” experience,which might include a free golf carrental, range balls or a restaurant credit,was the top choice of 25 percent of theowners and operators, while only 10 percentsaid discounting green fees is thebest way to attract customers.When it comes to adding newgolfers and increasing participationrates among existing golfers, most (40percent) think that’s the shared responsibilityof golf courses at the local levelwith support from national governingbodies such as the PGA of America, theUSGA or the PGA Tour.The owners said they intend to increasemarketing to women (73 percent) morethan any other group in the next year.6 Golf Advantage Fall 2007

More Fungicide FolliesDispelling myths about diseasemanagement in golf course turfTwo more widely believed myths about disease managementappear below. The realities may surprise you.Myth #3: Contact fungicides are necessary for curativedisease control.When turf managers encounter a disease breakout, theirfirst reaction is to reach for a quick solution. Many believethis quick solution is a contact fungicide. Often,they can see active mycelium on the plant and they believea contact fungicide will kill it. However, when a diseaseis active, it resides within the plant. Contact fungicidesstay on the outside of the plant, protecting theplant from infection.It is true that most contact fungicides will stop thegrowth of mycelium and cause its collapse. But a contactfungicide will not stop disease already within infectedplants. An effective systemic fungicide is needed to “cure”infected plants. It will also stop the growth of the myceliumon the outside of the plant.A good solution for most turf disease problems is to usea fungicide with both contact and systemic properties. Alternatively,turf managers can simply combine a contactwith a systemic fungicide, which has become a commonlyaccepted practice.It’s a Fact:Win a free iPod! Do you have a fungicide tip ormyth to share with other superintendents? Ifso, send your idea to <strong>Bayer</strong> Golf Advantage, c\oDebbie Clayton, 200 S. Broad Street, Philadelphia,PA 19102 or via e-mail:dclayton@tierneyagency.com.If your idea is turned into an illustration forthe magazine, we’ll send you an iPod in appreciation.Myth #4: Fairy ring symptoms always includemushrooms and ringsStereotypical fairy ring symptoms consist of a ring ofmushrooms and a green ring of lush growing turf. However,fairy ring symptoms are as diverse as the 60 or so fungithat can cause this disease. Not all of these signs or symptomsinvolve mushrooms and rings.For example, fairy ring symptoms might be localized dryspots in the shape of a ring or many partial rings. You might seemushrooms alone or green rings by themselves. Other symptomsmight include wilting in a circular pattern or coalescingrings — sometimes in the shape of a Mickey Mouse head!The reason for these diverse symptoms is that fairy ringfungi do not attack the turf; they inhabit the soil, growing onorganic matter. Many of the surface symptoms on the turf aredue to the pathogen modifying the soil, releasing nitrogen, toxinsor a byproduct which can lead to hydrophobic areas of soil.These symptoms often can be prevented with proactivetreatments of preventive fungicides on greens that have a historyof fairy ring. Curative fungicide applications are not as reliableand will not control localized dry spot.Alternatively, not allring-like symptoms are fairy ring. There are other diseases thatcan cause fairy ringlikesymptoms.ILLUSTRATIONS BY MATT EVERITTwww.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 7

PURPLE COWIMAGE: TELLING YOUR STORYAnthony Williams, CGCS atGeorgia’s Stone MountainGolf Club, is also a 5th DanBlack Belt. He shows his respectfor the environmentby helping others be goodstewards of the land.Purple CowWinner Stands OutIn Field of Green ExpertsRespect for the land“I grew up in a small agriculture-based townand was in the FFA (Future Farmers of America)in Oxford, Ga.,” Williams says. “Youlearned the land is your living, the goldengoose. Nature is the foundation. Everythingbuilds from being a good environmentalsteward. My dad and granddad taught methat, if you take care of the land, it will takecare of you.”Williams says the best place to start gettinggreen on a golf course is with a water program.“Havea master plan,”he advises.“I suggestbasing continuing education goals foryourself and your key staff on water.” Thenext steps are to have good water testing programsto determine the quality of water onthe course and to conduct a pesticide screeningto resolve any runoff issues.After that, work up an integrated pestmanagement program. “IPM is not abouteliminating chemicals. IPM is about choosingthe right chemical, at the right time, at theright rate,” Williams says. “You’ll save moneyand help the environment.”But, he adds, any environmental programhas to be a long-term activity. “Don’t give upon your water plan or forget your diagnosticsteps on your IPM,” he encourages.“My guysat Stone Mountain have embraced IPM as achallenge.”One IPM key is to teach people betterscouting techniques. His staff grew from twoto six licensed applicators last year. Three applicators(including him) are licensed in multiplecategories. “That’s a big benefit for meright now and a big benefit for them in theirfuture careers,” Williams notes.changed at that kind of meeting,” Williamssays. He recalls a gentleman from Spain whoalso runs a Robert Trent Jones Senior course.“We had a lot in common: similar design,similar grasses and similar challenges,” he recalls.“Superintendents are a brotherhood.”Williams’ background doesn’t hurt hiscause. He completed the GCSAA EnvironmentalManagement Program last year,number 39 to do so. Before that, he earned a2005 Environmental Leaders in Golf(ELGA) Award in the National Resort Category,and a 2006 award in the National PublicCategory, taking Overall winner as well.He is the first superintendent to win backto-backNational ELGA awards, a feat longconsidered impossible.Golf backgroundWilliams’ first job was at PineIsle Golf Club,Lake Lanier Islands, Ga., originally a Stouffer’s,then a Renaissance (Marriott) Resort.He spent 20 years there learning the business.At PineIsle he started an intensive environmentalmanagement program, getting involvedwith Audubon and becoming theAudubon Steward for Georgia. He and hisstaff completed the Audubon Program for theresort, making it a Certified Audubon CooperativeSanctuary (ACSP).At the same time,Williams started competingin the “Environmental Leaders in GolfAwards” program. At PineIsle he earned aChapter Award with his first entry. After leavingPineIsle,he transferred to Stone Mountain.From his very first supervisor’s meeting atStone Mountain, Williams stressed the impor-IPM is not abouteliminatingchemicals. IPM isabout choosingthe right chemical,at the righttime, at the rightrate to protectyour ‘environomic’assets.— Anthony Williams<strong>By</strong> Curt HarlerWhen Anthony Williams,CGCS at Stone MountainGolf Club, Stone Mountain,Ga., wins his greenjacket, it will not be for breaking par at theMasters. It will be for communicating environmentaland other green ideas to superintendentsat Stone Mountain and otherMarriott golf resorts around the country.Matthew Park, assistant superintendentof grounds at Stone Mountain, and HeadEquipment Technician Jim Stuart nominatedWilliams for the <strong>Bayer</strong> Golf AdvantagePurple Cow award this fall. In nominatinghim for the Purple Cow award, Park said:“The leadership team of Stone MountainGolf maintenance believes we have in ourpresence a legendary creature. He stands outso much that he has indeed made himself abit of an oddity among the rest.”Given to superintendents who see theirrole in a different way, the Purple Cowawards those who find innovative methodsto communicate the importance of theirtheir profession to others, whether in thegolf industry or the general public.PHOTO BY: BOB MAYNARDWorking with othersWilliams is one of Marriott Golf’s “go-to”guys for all things environmental because ofhis willingness to share what he knows.“He goes above and beyond to stress theimportance of environmental managementto his staff, his colleagues, Marriott Golf,everyone,” says Park.Williams has conducted numerous environmentaltours for superintendents from asfar away as Russia, England and Japan. Somewere featured in “Stewardship News,” the officialnewsletter of Audubon International.“An amazing number of ideas are ex-The PURPLE COW<strong>Bayer</strong> is proud to present the Purple Cow Award to superintendentswho find innovative and successful ways to communicate the importanceof their practices and theirprofession to golfers and thepublic. In each issue of <strong>Bayer</strong>Golf Advantage, we will pay tributeto one of these leaders by featuringthem in an article and awarding them50,000 Accolades points.DO YOU KNOW A PURPLE COW?TO NOMINATE DISTINGUISHED LEADERSCONTACT US via curt@curtharler.com or at 440/238-4556.8 Golf Advantage Fall 2007www.<strong>Backed</strong>by<strong>Bayer</strong>.com Golf Advantage 9

PURPLE COWAnthony Williams, second(human) from the left,and the grounds departmentat Stone Mountainhave earned numerouskudos for their environmentalstewardship.The StoneMountaingroundsdepartmentfinished lastyear $47,000under budget.tance of sound environmental management.He made it clear to his staff that he intended toimplement strong environmental managementprograms. Williams got off to a quickstart when he became one of the first superintendentsin Georgia to draft written best-managementpractices for a water conservation planand file it with state officials. This programhelped Stone Mountain become a CertifiedAudubon Cooperative Sanctuary — thetwelfth in Georgia and number 598 worldwide.Get the word outWilliams is among the first to tell people it doesnot cost a lot — other than some time spentplanning — to be a successful, environmentallyconscious course. The Stone Mountaingrounds department finished last year $47,000under budget and established a new groundsbenchmark in leadership by scoring a 90 percenton the 2006 Marriott Associate OpinionSurvey ... the highest in the company.All of this would be superb if it were justcommunicated to staff at Stone Mountain.But Williams generated 58 grounds-relatedpress items, earning him the 2006 MarriottGolf Crystal Achievement Award for PublicRelations Excellence. In 2005, Williams wasthe first grounds manager in company historyto win this award.Don’t mess with himIf you don’t agree with Williams’ environmentalstand, it might be best not to mentionit to his face. Last year, he reached a personalmilestone by passing the masters test in TenshiGoJu Karate, earning promotion to 5thDan Black Belt.“Martial arts teach you discipline, organizationand deep commitment,” saysWilliams, who runs a karate school (dojo) inhis home.“When others give up, you have tocontinue. We practice five lifelong virtues.They are faith, protocol, perseverance, serviceand vision.”Actually, martial arts helped him get intogolf. He earned college tuition at AbrahamBaldwin Agricultural College by teachingkarate.His son Luke, who grew up on a golfcourse, followed his dad’s footsteps and nowworks as a martial arts teacher.Williams says there is a special spot inheaven for his wife of 22 years, Phyllis, andother superintendents’wives:“Their support,willingness to hold dinner, and put up withmillions of things earns them a special placeup there,” he says.He also tips his hat to Buck Workman andprevious Purple Cow winners Wade Thomasand Mark Esoda as GGCSA leaders who haveshowed him the way.“Life is about choices,” Williams says.“Good choices usually produce good results.Sometimes, life throws you a curve. It’s howyou handle it that counts.” 10 Golf Advantage Fall 2007

BUSINESSACCESSIBILITYAccessibility:Finding Common Ground<strong>By</strong> Jennifer PaireAward-winning golfer and motivatorDennis Walters saysmaking golf courses accessibleto disabled players boils downto common sense.“As far as access to tee boxes, they have toget something up there to mow it, so chancesare there’s a convenient way for someoneplaying in a single rider car to have access toa tee,” says Walters, who makes 90 to 100 appearancesat golf courses across the countryas The Dennis Walters Golf Show.A paraplegic for 30 years, Walters’ dreamwas the PGA Tour when the golf cart he wasriding in flipped, leaving him paralyzedfrom the waist down. He learned to play golfagain and shares his golf technique and personalencouragement at courses everywhereand at PGA Tour, Senior PGA Tour, LPGAand Nike Tour events.Accessible accommodationsGolf course accessibility has been in the spotlightfor years, highlighted most recently byan increasing number of programs to encouragedisabled golfers to play and a federalreview requested by the GCSAA and theNGCOA to determine whether courses arerequired to have single rider cars on hand.But, the ADA is not only about whethercourses have the cars. The American DisabilitiesAct requires golf courses to providegoods and services to people with disabilitieson an equal basis with the rest of the generalpublic. Private courses that allow any sort ofpublic play are also required to accommodateplayers with disabilities.“An accommodation means lots of differentthings,” says Carrie Riordan, GCSAA directorof information and public policy. “Itcould be how the pro shop is organized. Dothey have a TTY system for making reservationsfor someone who can’t hear or speak?While organizations,including the GCSAA,have worked for more than 15 years to developaccessibility guidelines for golf courses, there isstill some confusion among superintendents asto what it means for their course specifically.Riordansays it all boils down to communicationand knowing the player.Feeling the fearThe fears of superintendents are fueled bymisconceptions, says Sam Samuelson, CGCSat Haggin Oaks Golf Complex in Sacramento,Calif., one of several municipal coursesthat have pioneered accessibility.PGA Pro Ron Tristanowith golfer Don Johnstonof Brecksville, Ohio, atThe Edwin Shaw ChallengeGolf Course andDriving Range at AkronGeneral Medical Center.www.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 11

The award-winningDennis Walters of theDennis Walters GolfShow, makes about 100appearances a year atgolf courses across thecountry sharing his golfingtechniques and personalstory.“I am not afraid of these things,” Samuelsonsays of single rider cars. The city owns fiveof them that circulate between the city’scourses as needed. “I took it upon myself totake (a cart) out and learn how to use one …I drove it on greens and in bunkers and experiencedwhat it is like and became quite interestedin it. They are great devices. They doless damage than triplex greens mowers.”Samuelson encourages superintendentsto embrace what is happening federally,whether a course currently has regular disabledplayers or not.“Within five years (single rider cars) will bemandated,” he says.“Why not be proactive?”Addressing another prevalent perception,Samuelson says having a disability does notnecessarily slow golfers down any more thanthose who are able-bodied.Boomers Can Benefitfrom ADA RequirementsAll courses are governed by the Americans with Disabilities Act (ADA), butnot all have disabled players or the terrain to encourage them. But, thatdoesn’t mean accessibility won’t have fringe benefits to other players.The Walker Course at Clemson University in Clemson, S.C., was built as anaccessible course 11 years ago, but Don Garrett, CGCS, says players are mainlyuniversity students, faculty and seniors.The course doesn’t get many disabled players at all, but when Garrett hasseen players in assisted devices play, “I am amazed,” he says.“We are a very hilly terrain. It’s just certain design elements at the tees andgreens that make it accessible. To me a lot of those elements will make it moreaccessible especially for seniors who don’t fall into handicap categories.”Whether disabled or older, both golfing markets represent revenue opportunitiesfor courses. A survey conducted by the Paralyzed Veterans of Americaindicated that 21 percent of its members would play golf if it were accessible.There are 78 million Americans born between 1946 and 1964 – that’s one infour Americans. Their numbers will decrease 17 percent between now and2025. About 11 percent report that their physical condition prevents them fromplaying golf at least sometimes. Another 24 percent fear their infirmities willprevent them from playing in the future.“There is the fear that it will slow up play,”he says. “I have found the people in adaptivecarts are more attentive to golf etiquette andplay than anyone else. Many times they arefaster and they take much better care of thecourse as far as fixing divots and ball marks.”Many superintendents also fear the loss ofcontrol over their greens and whether theycan protect them from cart usage.“In the winter months and our rainy season,you will have days that you don’t allowcarts, and we will make exceptions,” Samuelsonsays. “I’ll meet the golfers on the first teeand talk to them and explain about the wetareas. They are very cooperative and attentiveto what needs to be done.”Education and involvement are key to betterunderstanding what golfers need and whata course needs. Haggin Oaks has programsfor stroke survivors, amputees and childrenwith Down’s Syndrome, to name a few.“You get involved in these programs andyou see people who have played or want toplay and give them the ability to strike a balland the expression on their faces is fabulous.If you can’t enjoy that, there’s somethingwrong. It’s a tremendous feeling,” he says.The origins of accessibilityThe Edwin Shaw Challenge Golf Course andDriving Range at Akron General MedicalCenter in Akron, Ohio, was the first golf facilityin the nation built for individuals withdisabilities. Among its features: Wheelchairaccessiblepaths, handrails on the tees, andslopes with inclines of 8 percent or less.PGA Pro Ron Tristano says the purpose ofthe program is to work with the golfers ontheir particular goals, whether that is hittingthe ball 25 yards or 200 yards. And, if the goalis to get back on a course for regular play, Tristanoworks with them until he believes theyare ready for it.“The superintendent’s first alliance is to hismembership and I know a lot of people arenot aware of how capable people are with disabilities,”Tristano says. “They can play oncourses and can play at a reasonable pacewithout doing any significant damage.“We think we are growing the game,” Tristanosays. “We hope we will open everyone’seyes to the necessity of giving people a chance.It’s a learning process for everyone.” 12 Golf Advantage Fall 2007

COURSE PROFILERENOVATIONThe 5th hole offers views ofhistoric Liberty Station, SanDiego International Airportand downtown San Diego.Sail Ho Back AfloatFormer Navy golf course gets $3.3 million renovation<strong>By</strong> Barbara McCabeWhen the Navy vacated the historicNaval Training Center(NTC) in San Diego in 1997,it left behind the old Sail HoGolf Course, a nine-hole executive track usedby the thousands of sailors who trained there.Originally opened in 1925, the 17-acre facility,whichsits on the northern end of the formermilitary base in the city’s Point Lomaneighborhood, played an important role inSan Diego’s golf history. Sam Snead was headpro there during his time in the Navy and all ofSan Diego’s golf greats, including Billy Casper,Jack Renner and Craig Stadler competed there.Sail Ho was also the birthplace of San Diego’sJunior Golf Program and both Gene Littlerand Phil Mickelson played junior tournamentson this course.Through the efforts of San Diego’s RedevelopmentAgency and its partner The CorkyMcMillin Companies, the former NTC,which occupies 361 acres of waterfront propertyon the northern shore of San Diego Bay,is being transformed into a new urban villageknown as Liberty Station. As part of the $850million makeover, the Sail Ho Golf Course,which deteriorated after the Navy abandonedit, was given a badly needed facelift.Extreme makeoverThe $3.3 million renovation, crafted by SanDiego golf course architect Cary Bickler, whoplayed on the course as a child, features redesignedfairways, greens and practice facilities.The facility lies within the NTC HistoricDistrict, the portion of the site that includesthe original barracks and offices. Because ofthis, the Spanish Revival-style architecture ofthe building that housed the former lockerrooms, showers and pro shop had to be preserved.The building — with its characteristicarches and open-air courtyard — was restoredand converted into a new clubhousefeaturing a bar and grill, outdoor patio, modernpro shop and administrative offices. Anotherhistoric structure, the 10,000-gallonwater tank that sits in the middle of the golfcourse, was also restored.“The old course was in pretty bad shape,”says golf course superintendent Ralph Lackovic.It closed for renovation in August 2004.When Lackovic became superintendent inMarch 2006, he had six months to ready thecourse for its opening on October 1.“They were just starting the irrigation systemwhen I arrived,”he says.“The last week ofMarch, we started the sod on the green surrounds,tees and bunker surrounds. Aroundthe second week in May, when the GN1The No. 9 tee and fairwaybefore and after constructionillustrate howmuch renovation wasneeded.www.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 13

PhoenicianBillbugsIdentifiedWhen Sail Ho SuperintendentRalph Lackovic spottedtiny white grubs beneathhis bermudagrasssod, he brought in turfgrassconsultant Wendy Gelernterof PACE Turfgrass ResearchInstitute in San Diego. Gelernteridentified the grubsas Phoenician billbug larvae.“About 10 percent ofthe courses in Southern Californiahave them,” she says.“They're very common onwarm-season turf, includingbermudagrass, kikuyugrassand paspalum. They don'tbother the bentgrass orother cool-season grasses.”Unlike most beetle grubs,which feed on the roots ofthe plant, billbug grubs feedinside the stem.Phoenician billbug larvaeare less than 1/4 in. long.Damage may not becomenoticeable until the end oftheir life cycle. The symptoms— small, straw-coloredpatches on the turf — looka lot like dollar spot.To control the infestation,Lackovic appliedMerit ® 0.5 G insecticide tothe entire tee at the full labeledrate. “Merit is a goodproduct for these grubs,”says Gelernter. “It's better touse it preventively, butwe've seen control of thelarvae curatively as well.”bermudagrass sod was established, fertilizedand rooted in, they came in and hydrospriggedthe fairways and the rough. Thelast Dominant Plus bentgrass green was finishedseeding on April 15. It was crunch timetoward the end, but we opened on time.”The power of oneFormerly an assistant superintendent at SanVicente Golf Club in rural Ramona, Calif.,Lackovic cultivated the tender young turf single-handedlythroughout the spring.“The sodded areas had to be mowed almostright away,” he says.“I had to walk mowthe greens with a light walker mower. I washere for a couple of months by myself. It wasmid-May before I hired somebody to help mewith the mowing.”During his first few months on the job,Lackovic operated without a steady powersource.“A few years after the Navy left, the citydisconnected the water and electricity,”he explains.“As the project came on line, we wereprovided with water, but only temporarypower was available and it wasn’t set up tobring power to the irrigation system. Right atgrow-in, when it’s most important to havepower, I didn’t have any.” With help from aportable generator, Lackovic was able to getthe irrigation system running. “Eventually,power was supplied to the building and I wasable to hook up the irrigation control systemand the computer.”The trouble with billbugsA few months after the course opened, Lackovicwas forced to resod a 500-ft. section oftee No. 3, which sits in a shaded area of thecourse.“The bermudagrass just doesn’t seemto want to thrive there,” says Lackovic. In December,Lackovic found Phoenician billbuglarvae on that tee.Anticipating that he might have a problemwith black turfgrass ataenius, a known pest inthe area, he purchased Merit® 0.5 G insecticideas a preventive measure. Since Merit isalso labeled for the control of billbug larvae,Lackovic applied the insecticide curatively tothe troubled tee at the full labeled rate of 80lbs. per acre. When Lackovic examined thesection of the course where he obtained thereplacement sod — an outer rough area thathad been hydrosprigged — he found moreSail Ho Superintendent Ralph Lackovicon the No. 3 tee where he foundPhoenician billbug larvae.billbug larvae. A few days later, he found twoadult billbugs on the No. 8 green. “I mighthave to hit all my tees with Merit this year toget rid of these billbug larvae,” he says.The first winter was one of the coldest inSan Diego weather history. It brought frostto the course almost every day, and Poaannua “kept popping up everywhere”throughout the dormant bermudagrass. “Idoubt we’re ever going to overseed here,”says Lackovic. “The winters are very shorthere and the bermudagrass will green upagain in a couple of months.” In the meantime,Lackovic keeps the Poa annua undercontrol with a postemergent treatment ofRevolver® herbicide.A dream come trueMaintaining the high-profile course is adream come true for Lackovic, who hasworked at a number of golf coursesthroughout San Diego County over the last17 years.Lackovic credits his wife, Bette, and herobsession for golf, with steering him back tothe golf course maintenance industry after along hiatus. When playing golf with Bette atTecalote Canyon Golf Course in San Diego’srugged Tecalote Canyon Natural Park, Lackovichad an epiphany. “I had worked on themaintenance crews of a couple of golf coursesback in New York and I remembered howmuch I liked being on a golf course.”After finishingtheir game, Lackovic walked over to themaintenance department and applied for ajob. “It was a week before spring aerificationfor greens, so they took me right on,” helaughs.“That was 1990 and I have been in thegolf course business ever since.” 14 Golf Advantage Fall 2007

OUTLOOKSREGION BY REGIONAKWest isthe Best!<strong>By</strong> Brian TepperWestern Regional Manager - Golf619-307-1328Brian.tepper@bayercropscience.comThe West is the best place tobe in the golf industry!Maybe I’m a little biased,but our territory coverssuch a diversity of geography andterrain that it makes life extremelyinteresting. We have mountains,desert, ocean, prairie and plains allrepresented within one region.As you are aware, <strong>Bayer</strong> has anextremely experienced group ofsales reps throughout the country,and they are exceptionally capablein the Western Region. JimmyJohnson covers the central andnorthern Midwestern states; GaryBrooks handles Texas, Oklahoma,Colorado and New Mexico; DanJim FetterCAORWAHINVIDAZUTMTWYNMWESTERNREGIONCOEric KalaszNDSDNETXKSOKMNIAMOARLAWIILMSINTNALMIKYBrian TepperOHGADumler covers the mountain statesand the Northwest, while StephenKimball, George Raymond andGordon Vosti handle California,Nevada and Arizona. This grouphas a combination of 80+ years ofexperience.Speaking of Gordon Vosti —there’s a guy who always goes theextra mile. Continue reading tofind out what Gordon is doing tohelp the industry — another exampleof the <strong>Backed</strong> by <strong>Bayer</strong>philosophy.WVSOUTHERNREGIONNORTHERNREGIONFLPAVAMDNYMEVTNHMACTRINJDEDCOther regional managers include:Jim Fetter, Northern golf salesregion, 614-307-5705;jim.fetter@bayercropscience.comEric Kalasz, Southern golf salesregion, 619-307-1328;eric.kalasz@bayercropscience.comSCNCMeetGordonVosti<strong>Bayer</strong> rep is one of CalPoly’s big supporters<strong>By</strong> Chris HarrisonSome people have trouble leavingcollege behind. GordonVosti fits that description,though his reason for hangingaround isn’t the lure of fraternitylife or an addiction to taking notes, buta sincere desire to help his chosen profession— the turf industry.Vosti graduated from CaliforniaPolytechnic State University with abachelor’s degree in crop science in1970. He left the San Luis Obispo areato take his first job as a sales rep forUnion Carbide Ag Products in theSouthwest and Rocky Mountain states.“My education at Cal Poly gave mea great background in production agriculture,”he says. “Whether you'regrowing lettuce or turf, the same basicprinciples apply. The school has ateaching philosophy of ‘learn by doing.’We had a lot of hands-on experience inall our classes.” His favorites were entomology,plant pathology, and weed sciences.“They are the foundation ofwhere I am today,” he adds.Vosti’s job history is a roadmap ofthe mergers in the agricultural and turfchemical companies over the years.While his job did not change — he's alwaysbeen a sales rep — his employersdid. In addition to Union Carbide, hevariously reported to Rhone PoulencAg Chemicals, Aventis Crop Scienceand now <strong>Bayer</strong> Environmental Science.College re-immersionAfter moving back to the San LuisObispo area in 1988 to cover centralCalifornia, Vosti became re-immersedin campus life. He served formany years on Cal Poly’s Crop ScienceDepartment and EnvironmentalHorticulture Science DepartmentAdvisory Council, starting in 1995.In addition, he chaired the groupfrom October 1998 until February2002 when Crop Science and EnvironmentalHorticulture merged.“Since I had background in productionhorticulture with my major,and was now working in the turf andornamental field, I had some goodcredentials from an industry perspectiveto help the joining of thesetwo departments,” he recalls.In 2003 Cal Poly named VostiAgriculturalist of the Year, an honorfrom the faculty and staff at theschool who do the selecting.Level-headednessCurrently, Vosti covers Los AngelesCounty and Central California as partof the <strong>Bayer</strong> Environmental Sciencegolf sales team and is respected by hiscolleagues for his in-depth and variedknowledge of the golf industry.“He is the most level-headed,even-tempered professional that Ihave ever worked with,” says his regionalmanager, Brian Tepper. “Heconstantly looks to learn new issuesin the market and seeks solutions.He is a hands-on sales rep who isnot afraid to get down and dirty.”<strong>Bayer</strong> honored Vosti in 2006 withthe prestigious “Green Jacket” awardat the company’s annual meeting.He was honored for excellence inachievement and creating a positiveimage for the industry in his localcommunity.“Gordon is the legend of theWest!” Tepper continues. “He hasseen it all and worked through all theups, downs and the middle.”Gordon Vosti, inred, and Joe Elias,superintendent atKings Country Club,Hanford, Calif., chatat the Central CaliforniaGCSA meetingin May.Gordon Vosti is a long-time supporterof California PolytechnicState University in San Luis Obispo.Member of the boardsAmong the associations on whoseboards Vosti serves are the CaliforniaAg Pest Control Advisor (CAPCA),the California Association of NurserymenPlant Protection Issues and ActionCommittee, and the CypressRidge Golf Course Audubon AdvisoryCommittee. He also was involved indeveloping the fungicide strategy forthe <strong>Bayer</strong> Western Region, includingthe Merit® Arbor market andChipco® Signature positioning.Vosti earned his pest control licensefrom the Department of PesticideRegulation in 1971, and is licensedin all seven categories.“Thisallows me to give chemical recommendationswhere needed,” he says.“IPM recommendations have been inplace a long time and are widely usedin golf turf as well as other markets.”Though he denies being a goodgolfer, Vosti does enjoy industrytournaments, especially thosethrough the local GCSA CentralCoast Chapter. “Let's just say I am ahigh handicapper,” he says. When notsearching for lost balls, he likes toocean kayak at a spot close to home.“What I like best about my job, byfar, is the interaction with people,”Gordon says. “This business is stillone where people buy from people.We have some great tools to use inmarketing our products, but withouta good relationship and trust youwon't have much success.” 16 Golf Advantage Fall 2007www.<strong>Backed</strong>by<strong>Bayer</strong>.com Golf Advantage 17

COMMUNICATIONCOLLABORATIONWorking withthe Green CommitteeLessons learned and shared<strong>By</strong> Anthony Pioppi“It is your courseand you can dowhat you wantand I’ll abide byyour decision.”– Keith AngillyIt was the late 1990s and I was on thegrounds crews of one of the most prestigiousclubs in Connecticut. The superintendentwas enlightening me tothe ways of green committees and how theelection of a new green chairman coulddrastically alter the way he did his job.I didn’t really understand his quandary,so he gave an example: Two weeks before anoutgoing green chairman was going to stepdown he stopped into the superintendent’soffice to commend him on his job and to tellhim the bunkers were in the best conditionhe had ever seen. The next day the incominggreen chairman called the superintendentto say the first priority when he tookover would be to fix the bunkers, which hecouldn’t stand.Turns out the departing chairman was agood player and the incoming couldn’t get agolf ball out of a bunker short of tossing itonto the green.The realities of dealing with green committeescan be harsh, and nightmare storiesabound of green chairmen wanting nothingmore than to put their imprint on a course viasuch methods as tree planting or bunker removal.Overbearing or meddling green committeescan make the job of superintendentdownright unbearable.Playing politicsPat Sisk, now the superintendent at MilwaukeeCountry Club, recalls his experienceat an upstate New York course that will remainnameless. He describes the generaltone of the club as “politically charged,”where members liked employees better ifthey were confrontational and willing to getinvolved in full-blown screaming matches,of which he had many. There, Sisk recalls,the one green chairman who came aboardafter a mutiny in which the entire greencommittee was sacked, envisioned his taskas being to “make it like Winged Foot,”whatever that meant.At Milwaukee, a 1929 C.H. Alison-H.S.Colt design, Sisk has had the opposite experience.There, stability is the rule thanks tothe fact the same green chairman has beenin place for 18 years and there is no greencommittee. Sisk reports directly to his greenchairman and should the members have anyconcerns they are encouraged to discuss itwith the chairman. That hardly means Siskis isolated from members. He takes every opportunityto meet them, often spendingbusy golf mornings on the first tee.“I make myself visible and take every opportunityto educate our members about ourprograms.” he says, adding that establishing apersonal relationship adds to job security.“It’svery easy to fire an invisible guy.”After a number of redesign miscues theclub now has a master plan developed by RenaissanceGolf. The plan must be followed tomaintain the integrity of the design.At Cedar Ridge Country Club in BrokenArrow, Okla., Superintendent Mike Wootenhas had few problems with committees duringhis entire 21-year tenure. The greencommittee and board of directors are dominatedby long-time members of the 1969Joe Finger design. Green chairmen spend a18 Golf Advantage Fall 2007

Green Chairman Speaks:1916 Version<strong>By</strong> Anthony PioppiIt was September, 1916 and Henry B. Sargent was writing the presidentof The Misquamicut Club, James H. Pendleton, to outline what he sawwere his duties as incoming green chairman. American golf was in its infancythen. But by reading Sargent’s words, it is obvious those in his positionwere already overstepping their bounds.“I certainly want to know what responsibilities I am to assume,and whatever they are I will try to carry them unobtrusively and effectively,” hewrote.“I have a fundamental feeling there should be a definite plan made for thegolf course, not too elaborate, but sufficient, for we must consider that thecourse is generally played by medium to poor players, and that it should be anagreeable and enticing course, rather than a difficult and repellent course. Wemay here and there have a hole that is somewhat ideal from a good golfer’sstandpoint, but we must not make it so difficult as to hold up play on a crowdedcourse during the height of the season.“I state this here so that you may realize that I have no intention of suggestingmaking the course into a ‘cranky’ one, but that the course should be planned(as it probably already has been) and then each year add a little something in accordancewith the plan, to show progressive improvement within the means atour disposal, or within the appropriation.”There is no record of how the tenure of Sargent unfolded at Misquamicut, butreading his words it is hard to imagine he was not an unqualified success.There are waysto placate greenchairmen andcommitteeswithout sellingone’s soul.minimum of four years in the position andare only elevated after long stints on thegreen committee. Some of the current membershave been on since the early 1970s. Thegeneral manager and director of golf are alsoon the green committee.“It’s probably as an ideal situation as youcan get,” Wooten says.He’s quite aware of what his reality mightbe. One superintendent friend, he says, is requiredto give daily email updates to hisgreen chairman on every job performed onthe course from syringing of greens to fertilizationrates.There are ways to placate green chairmenand committees without selling one’s soul.Reality checkKeith Angilly is superintendent of Mill RiverCountry Club in Stratford, Conn., and presidentof the Connecticut Association of GolfCourse Superintendents. He says the key todealing with and surviving green committeesand green chairmen is for superintendents toremember their role.“My way of looking at it is it’s their golfcourse and we work at their golf course.We’re stewards. We don’t own the golfcourse,” Angilly says. “We call them ‘ourgreens’ and ‘our fairways’ but they’re not.They’re the members’.”When Angilly took over at Mill Rivermembers were used to playing over the winterwhen warm days occurred, using cartsthat invariably damaged turf. When Angillywas approached by the green chairman andasked to offer his opinion of the situation hereplied,“My suggestion would be to not havecarts or play during the winter, but it is yourcourse and you can do what you want andI’ll abide by your decision.”Mill River is no longer open during thewinter.Angilly adds that the superintendentsand green committees must remember whoshould benefit from any agronomic decisions.“They’re not supposed to set the golfcourse up the way they want it, but the waythe majority of members want it,” he says. www.<strong>Backed</strong>by<strong>Bayer</strong>.com Golf Advantage 19

TALK BACKQUESTION OF THE MONTHWe asked several superintendents who had experience with SeashorePaspalum to talk about the emerging Southern grass. Here's what they said:John ButtsThe Oaks ClubOsprey, Fla.Chris JohnsonMay RiverBluffton, S.C.Scott HammThe Colony Golfand Bay ClubBonita Springs, Fla.Bob VolpeTwin EaglesNaples, Fla.“It's got its growingpains, but it is easier“Figuring fertilityrequirements“Keep the sprigs wet.If they dry, they die. If“I love it. We're inthe learning stage,than bermudagrass. Itwill not shoot tillers, so itis easier to maintainwas something I had towork out on my own.Last year I was at 6 lbs.you think they are toowet, put some morewater on them.”but it is prettier in thewinter than bermudagrass.In November, iton the collars and cartpaths.”nitrogen and that istoo much. Thisis just glowing.When people comeyear, we're looking at 2down (from up North)or 3 lbs. nitrogen. Butthey want to seethe product we producegreen. It lookswhen it's doing goodmakes us look betteroverseeded in thewinter.”than what we are.”20 Golf Advantage Fall 2007

MANAGEMENTPRACTICE GREENSPracticeMakesPerfectPractice greens need the same attention as the greens on the course.<strong>By</strong> Mark LesliePhil Landry uses“cups” that arethe same diameteras regulationcups but can beplaced anywhereon top of thepractice green,held in place byan 8-inch pin.At Desert Highlands in Scottsdale,Ariz., the four practicegreens are so challenging theyserve as one of the venues forthe annual member-guest championship.At Vanderbilt Legends Club in Brentwood,Tenn., five practice greens are bentgrass andone is Champion Bermudagrass because thegolf teams compete on both turfgrasses.At Belgrade Lakes (Maine) Golf Club thepractice green gives a 360-degree view that isto die for, so visiting golfers are certain to leavea calling card: Poa annua from other coursesall over the green.At Double Eagle Golf Club in Galena,Ohio, one practice green fills the circle infront of the clubhouse while a second sits bythe practice range and a third is by the 1st tee.Wherever practice greens are on the golfcourse and whether they are in cool- or warmseasonregions, or the Transition Zone, theconsensus among superintendents is this:There should be no transition between themand the putting greens on the golf course.Maintenance program“We have incorporated our putting courseinto the same maintenance program as wehave on the golf course,” says D. Philip (Phil)Shoemaker Jr., head superintendent at DesertHighlands, a gated community’s centerpiecewhose four separate practice greens total60,000 sq. ft. “We use the same aerification,same fertility, water, topdressing, everything.If the greens on the course get double-cut, orrolled, so do the practice greens.”Traverse City (Michigan) Golf & CountryClub Superintendent Steve Hammon agrees.“We walk-mow the practice green just like theother greens. Water and fertilizer, everythingis the same.”Veteran turfgrass consultant Terry Buchenof Williamsburg, Va., suggests mowing thepractice green first, so that golfers can practiceon it while the regulation greens are being cut.Joe Kennedy Jr., CGCS, twists this idea everso slightly because of the Vanderbilt golf teamsthat use Vanderbilt Legends Club. Kennedytreats his practice greens “exactly the same” asthose on the golf course except at times whena team is going to travel to compete on a golfcourse with faster or slower green speed.“Then, we make that adjustment,”he says.Built to lastAccording to Buchen, who consults on courseconstruction projects around the world, practicegreens should be “built the same, as wellas maintained the same.“If there is a 30-inch collar on the regulation18 greens, there should be a 30-inch collaron the practice green. Likewise, if there isan intermediate cut of rough on the regulation18 greens.”Golf course architect Ray Hearn says he encounterssituations where golf facilities want toscrimp on construction of the practice greens.“I’ve had some suggest not having subsurfacedrainage, or using 6 inches of greens mix insteadof 12 or 15 inches. But it makes no sensebecause we want consistency in the putting experienceand that’s impossible to get if the24 Golf Advantage Fall 2007

greens are fundamentally built differently.”Duplication appears to be one rule ofpractice-green design as well, but it’s a ruleunder attack on some fronts.“The practice green should reflect theputting experience on the golf course,” saysHearn from his Holland, Mich., offices. “But,so often the practice green is the diametric oppositeto those on the golf course. Some aretremendously undulating and when you getout on the golf course the greens are dead flat.”The greatest violators are most often privateclubs where members demand practicegreens with three-to-six-percent slopes “forthe experience” whereas their course’s greensmost likely have one-to-three-percent slopes,”Hearn adds.Not only should green speed and firmnessbe the same,Buchen adds,“The practice greensshould show every feature. If there are shelvesor false tongue on the regulation greens, thepractice green should have them, too.”At Desert Highlands, the practice puttinggreens, nine holes out and nine holes back designedby Jack Nicklaus, are a tour de forcethat at least tweak the “standard” and drawsome golfers to the facility just to play them.Shoemaker doesn’t disappoint.Shoemaker says no windmills or dinosaursclog the way, and golfers don’t losethe ball at the 18th hole. But his crew can adddifficulty by tucking pins and moving the“teeing area”on each of the 18 holes that windthrough his four putting greens, ranging insize from 8,000 to 23,000 sq. ft.Size mattersSome architects are now including a smallpractice green by the 1st tee so golfers canwarm up putting while waiting for their teetime. But the regular practice greens shouldnormally be much larger, on the order of aquarter to even half acre, says Buchen.“The vast majority of practice greensaround the country are built too small,”Hearn says.“Getting two foursomes on themis about it. That’s OK, but God forbid if youget three foursomes on it.“I see a lot of clubs where the actual practicegreen is 4,000 to 5,000 sq. ft., and that’s notright.If you have the room, make it double thesize of your normal greens at a minimum.“As a golfer, when you’re warming up on apractice green,you have a few guys around you.You like to have your own zone — a personal‘bubble’ that helps you concentrate more.”The larger green also allows superintendentsto both use more practice cups andavoid wear. Buchen suggests changing holelocations two to three times a week.Movable cupsPhil Landry, head superintendent at BelgradeLakes, a high-end public course uses“cups” that ease that chore and avoid wearand tear. They are the same diameter as regulationcups but can be placed anywhere ontop of the practice green, held in place by an8-inch pin. That allows Landry’s 8,000-sq.-ft.green to be mowed easily and the “cups”to bemoved every day.In the meantime, he maintains one “real”cup for golfers who insist on it. That one, hesays, gets moved the standard two or threetimes a week.Belgrade Lakes General Manager KyleEvans estimates the moveable “cups” savethousands of dollars a year just in manpower.Meanwhile, one suggestion that all superintendentsmight be able to implement: aspike cleaner at the bag drop-off.Northern golf courses, in particular, encounterPoa annua problems on their practicegreens.“Golfers apparently carry it on their spikesfrom the last course they played on, and itends up with us,” says Landry. That meanshand-picking of weeds for the crew. Belgrade Lakes Golf Clubhead superintendent PhilLandry demonstrates theease of “setting a cup”when it is as simple aspushing it into theground. Behind him is anothermoveable “cup” aswell as a permanent pinplacement. Retired OPGACommissioner Deane Beamancalled the club oneday after playing BelgradeLakes and askedhow to obtain the “cups.”Like most people, he hadnever seen them before.— Photo by Mark Lesliewww.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 25

MANAGEMENTSITE CHALLENGESA Steelworker’s Getaway<strong>By</strong> Debbie ClaytonJohn Denholm, superintendentat Maryland’sSparrow Point, says thecourse’s fairway drainageissues can contribute todisease pressure.What started as a recreationalfacility for executives atBethlehem Steel Company’sBaltimore, Md., facility duringthe steel industry’s heyday has enduredas a solid private golf club near the heart ofthe city. Sparrows Point Country Club, designedby William Gordon and built in 1952,was purchased by the members in 1985, duringthe steel industry’s downward spiral.“They used to call the Bethlehem Steel executivesthe White Hats and we still have a coregroup of those retired guys who play everyTuesday and Thursday throughout the year,”says John Denholm, golf course superintendentsince 1999.“They are mostly in their 70sand 80s but they love their golf and play everyweek that we don’t have snow cover.”Situated on a tree-lined, relatively flatproperty, the Sparrows Point course encompasses285 acres and 27 holes of golf. Thereare 18 bentgrass fairways and nine ryegrassfairways, but all the greens are a bentgrass/Poaannua mix and tees are mostly ryegrass.Roughs are a blend of various grasses, includingcommon bermudagrass, despite thenorthern locale.“Each hole is basically similar. Greens areon the small side — 3,000 to 3,500 sq. ft. —with a bunker on the left and a bunker on theright,” adds Denholm, who was superintendentof the West Course at the BaltimoreCountry Club before coming to SparrowsPoint. “It’s actually a very difficult course toplay because of all the trees. You just have tohit them straight or you’re in trouble.”Denholm should know: he tries to play thecourse at least once a week. “I’m a firm believerin seeing the golf course from thegolfers’ perspective,” he says.Since there are very few elevation changesin the course, drainage can be a problem. Thecourse still has the original push-up greens,which have been heavily modified with sandover the years. While the course has no internaldrainage, there is decent surface drainageon greens. But fairways are a different story.Fairway drainage problems“We have a lot of little pockets that hold wateron fairways,”he explains.“My crew often goesout and squeegees puddles out of the fairwaysso we don’t lose turf, especially in the summertime,when the excess moisture contributesto disease issues.”Dollar spot, brown patch and anthracnoseare all problems at Sparrows Point. Last year,Denholm tried new Tartan® fungicide on hisbentgrass fairways. He applied the product onMay 23 at the rate of 2 oz. per 1,000 sq. ft. andreceived excellent disease control for 28 days.“That application was mostly for dollarspot, since it was a bit early for brown patchat that point,” he explains. “But I used Tartanagain during the heat of the summer asa preventive measure. I applied it on August3 on those same bentgrass fairways and got14 days of control at the 2 oz. rate. It’s a greatproduct!”26 Golf Advantage Fall 2007

Denholm attributes a lot of his success inkeeping fairways healthy to his fertility program.“Lastyear, I put down a total of 4 lbs. ofnitrogen on the bentgrass fairways,”Denholmexplains. “We apply it on average once amonth from May through November. I use agranular product in May, a liquid formulationin July and August, and return to using agranular again in October and November.”His greens fertility program revolves arounda liquid formulation he’s used for the past twoyears. “I really believe it’s key to maintaininghigh quality turf on the greens,” he adds.Controlling anthracnoseAnthracnose is particularly a problem on hisPoa annua greens, but Denholm has gotten itunder control during the past few years witha combination of fertility, cultural practicesand regular applications of Chipco® Signaturefungicide. He tank mixes the productwith a variety of other fungicides throughoutthe season.Anthracnose pressure is so intenseon greens that he stays on a seven- or eightdayspraying program during June, July andAugust.“<strong>By</strong> applying Signature every two weeksduring the spring and summer, we keep theturf healthy enough to withstand diseasestresses,”says Denholm.“I can’t put my fingeron what it does for the plant, but Signatureimproves turf quality.”Chipco Signature contains StressGardformulation technology, also found in Tartanfungicide. Signature positively affectsplant physiology, helping the turf plant moreeffectively manage the stresses of golf courseconditions. Plants treated with Signature developgreater root mass and energy reservesunder heat stress.Denholm’s cultural practices includerolling greens at least twice a week. “It keepsour greens truer when we roll,” he explains.“<strong>By</strong> regular rolling, we can keep our height upand still have fast greens. We currently mowat .135 inch. The higher we keep the height,the more it helps with disease management,particularly anthracnose.”Stressing cultural practicesThough he previously aerified the entirecourse twice a year, Denholm recently purchaseda new Toro aerifier and plans to domore solid tine aerification. His goal is todeep-tine aerify greens at least once a monththis year. But he limits topdressing on greensto the spring and fall months because of theintense anthracnose pressure.“The abrasiveness of working the sand intothe surface creates wounds in the turf,”he continues.“Thiscontributes to stress levels duringperiods of high heat. So if I do topdress duringsummer months, it’s a very light application.”During the season, Denholm’s crew swellsto 28 or 30, but shrinks back to 10 duringwinter months. In the past few years, his crewhas renovated all 27 bunkers and rebuilt severaltee boxes.“Our biggest problem is all the trees atthis location,” he adds. “They create light issuesand root competition and lead todrainage problems, particularly since we aresuch a flat property.”One good thing about the flatness of theSparrows Point property: it’s easier forgolfers to walk the entire course. “Surprisingly,about 50 percent of our members walkthe course,” says Denholm. In fact, it’s difficultto keep track of how many rounds areplayed each year because many of the roughly600 golfing members simply walk to thefirst tee and play. “We record more than40,000 rounds of golf per year,” he adds.In addition to golfing, Sparrows PointCountry Club has swimming, tennis courtsand a boat pier, which not many Baltimorearea golf clubs can boast. “We’re on a rivercalled Bear Creek and it feeds right into theChesapeake Bay,”says Denholm.“You can geton a boat here and be in the Bay within 15minutes. You can also go right into the BaltimoreInner Harbor.”From a steelworker’s haven to a noteworthyprivate club, Sparrows Point has maintainedits reputation as a first-rate golf coursefor the past 50 years. Regularly rolling Sparrows Point’s greensallows the course to have taller grass whilemaintaing fast green speeds.Learning theRopesJohn Denholm was in theright place at the right timewhen he was named assistantgolf course superintendentof Rosemont CountryClub in Fairlawn, Ohio, atthe age of 19. He startedworking on the coursewhen he was 16, and continuedthrough the summerwhile he attended the Universityof Akron, as a civilengineering student.“I figured out that engineeringjust wasn’t my bag,so I dropped out of schoolto work fulltime at the golfcourse,” he relates. “Then Iwent back to college andgot a degree in turfgrassmanagement at The OhioState University’s AgriculturalTechnical Institute(ATI) in Wooster.”He graduated from ATI’stwo-year program in 1993and took a job as superintendentof the West Courseat Baltimore Country Club.Six years later he becamesuperintendent at SparrowsPoint.www.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 27

PROFILEDISTRIBUTORKnowing WhatSuperintendents ExpectFormer superintendent knows what his customers want.<strong>By</strong> Curt HarlerDave Krupp, president of PrecisionTurf & Chemical Inc., Greenfield,Minn., knows what superintendentsexpect from a supplier. Beforeswitching to the business side, Krupp wasa superintendent. He worked at the old EdenvaleGolf Course in Eden Prairie, Minn., thena public facility. It is now the private BentCreek Golf Club.“Having been a superintendent is anadvantage when it comes to understandingand identifying their problems and needs,”Krupp says. “Besides being able to communicatein terms superintendents can relateto, I can observe and ask questions regardingconditions on the course.”Krupp sees the course with a superintendent’seye.“When I am touring a golf course, if somethingdoesn’t look quite right, I can point outthat situation or condition,” he says. “I am aproblem solver. If I can identify a problemand find a solution, I’ve done my job.”That attitude runs all through the company,from taking phone orders to arranging deliveriesor handling inventory control.“Part of selling the products we handleincludes efficient and timely delivery,”Krupp says. “It includes someone who cananswer questions regarding billing or invoicing,or product pricing, delivery or performance.There’s no passing the buck.From left: Dave Kruppjoins his sales staff ChrisHoff and Brad Smith inthe Precision office.28 Golf Advantage Fall 2007

“Our No. 1 goal is to offer superb customerservice. We offer free delivery, usuallywithin 24 hours, and free consultations.”Precision plans to grow steadily by hiring the right people for itscustomer-focused distribution business.Delegation benefitsKrupp’s wife, Jean, is co-owner of the business.Dave calls himself “president and headsalesman” at Precision. It wasn’t always thatway, though. Krupp shares a lesson thatwould befit any new superintendent or aspiringbusiness owner.“Back when I first started Precision, aswith most small businesses, I felt the ownerwas the ‘everything guy,’ which includesbeing head salesman. As the company grewand more demands were placed on me, it becameobvious there are not enough hours inthe day to get everything done,” Krupp says.“Although I still have a very significant clientlist that I call on, it would be impossible forme to provide the expertise and service ourclients have come to expect.”Today, Precision has three solid salesmen,all who had hands-on experience ongolf courses before transitioning to sales.“The three of us have been working as ateam for several years,” Krupp says. “Wekeep in constant communication with informationon developments we comeacross in the field. With that information,we can give our clients the best adviceavailable.”Precision works with most of the bignames in the business, including <strong>Bayer</strong> EnvironmentalScience, Grigg Brothers, EC Grow,Harrells (Polyon), Lebanon Turf, Spyker,Becker Underwood and Kalo.<strong>Bayer</strong> was the first major supplier to signa contract with Precision, an agreement todistribute its products in Minnesota and surroundingareas.“They have been partners with us for 15years,” Krupp says.“<strong>Bayer</strong> has always stepped up to the platewhen there has been an issue regardingproduct performance or product condition,”Krupp says. “That is why we are proud to beassociated with the company. They stand behindtheir products. It’s what they call ‘The<strong>Bayer</strong> Advantage.’”“We have a good relationship with Dave,”agrees Jimmy Johnson, <strong>Bayer</strong> golf field salesrep in the Midwest. “Precision is a customerfocusedcompany that is a very strong supporterof branded product.”Use proven productReliance on brand names is one way Precisionensures superintendents get quality productfrom top companies.“Use proven products manufactured by acompany that stands behind them,” Kruppadvises. Many stories are told about productsthat do not perform to expectations.“Usually this results in loss of turf, lossof confidence by the membership or patrons,and sometimes the loss of a job,” hesays. “Why a superintendent would puthimself and the golf course in that positionis beyond me.“If you use products from the manufacturerthat developed the molecule of the activeingredient, it stands to reason that themanufacturer has the most knowledge of thatmolecule and how to formulate it to get themost out of it. They stand behind the productwith confidence,” Krupp says.There are plenty of other challenges towrestle with. Krupp works hard to keep hisinfrastructure of computers, printers, phonesand trucks updated.“We always try to be more efficient with allthe processes of the business, offering more tothe customer by providing value-added services,”he says.“Expanding the business is notjust providing bodies out in the field makingsales calls, but rather having the right personin the field building relationships with clients.“Precision has goals of growing but ourgrowth will be with the right people,” heconcludes.“We are always looking for goodpeople.” “I look at myselfas a problemsolver. If I canidentify a problemand find asolution to thatproblem, I’vedone my job.”– Dave Kruppwww.<strong>Backed</strong><strong>By</strong><strong>Bayer</strong>.com Golf Advantage 29

SOLUTIONSPESTS WE LOVE TO HATEThe BIG ChillDon’t let gray snow mold take hold on your course.<strong>By</strong> Ned Tisseratand Tamla BluntThere is a misconceptionthatsnow compactioncausedby snowmobilesand skiers increasessnowmold severity.Typhula snow molds, also calledgray or speckled snow mold, are alltoo familiar to superintendentswho manage golf courses in areaswith long winters and heavy snowfall. Thesediseases develop under permanent snowcover and result in circular, straw-coloredpatches of damaged turf in spring. Whitefungal mycelium may be apparent on thematted, dead leaves as the snow recedes.Small, light tan to brown, spherical massesof fungal mycelium called sclerotia are embeddedin the mycelium or leaves.Damage is related to the species of snowmold pathogen present, the turfgrass speciesaffected, and the duration of snow cover.Differing management practicesThere are two primary species of Typhulacausing snow mold, and their distributionand frequency in a location is governed inpart by the length of snow cover. Typhulaishikariensis causes a disease called speckledsnow mold and tends to be more prevalent inareas with very long periods of snow cover(e.g. Canada, the northern Great Lakes regionand the Rocky Mountain region).Typhula incarnata causes an almost identicaldisease called gray snow mold and is morecommon where snow duration is shorter. Becausesymptoms of the two diseases are so similarthey are often lumped together and referredto as “gray snow mold” or “Typhula blight.”Nevertheless, subtle differences between thesediseases may influence management strategies.All turfgrasses can be damaged to someextent by gray snow mold, but injury isoften more severe on perennial ryegrass,bentgrasses and annual bluegrass.A recent study in Wisconsin indicated differencesin susceptibility among creeping, velvetand colonial bentgrasses, with velvet bentgrassthe most susceptible. Furthermore,variety differences within species were noted.This suggests that bentgrass cultivars with increasedsnow mold resistance can be identified.Growth of Typhula is favored by temperaturesnear freezing. Thus, long periods of snowcover that maintain temperatures at the soil surfacejust above freezing are ideal for fungalgrowth.In a recent study we found that the temperatureat the snow/turf interface remained ata stable 32-33 degree F from late Novemberthrough February in Breckenridge, Colo. Theseconditions allow for snow mold growth whileinhibiting other antagonistic microbes.We also found that snow mold symptomsbecame apparent approximately 60 days afterpermanent snow cover and intensified significantlyover the next 30 to 40 days. Thus, snowcover exceeding 60 days increases severity.Preventive fungicidesThe most consistent means of managinggray snow mold is the use of preventivefungicide applications. These applicationsare usually made as close to permanent snowcover as possible. This helps prevent prematurefungicide degradation or dilution/dissipationfrom mowing or irrigation and maximizesthe chemical concentration in or onleaves through the winter.Some superintendents apply a pre-snowmold fungicide approximately two to fourweeks before the final fungicide application inthe fall. This application is thought to sup-30 Golf Advantage Fall 2007